Novel medicinal material crushing and drying machine

A technology for crushing dryers and medicinal materials, applied in grain processing and other directions, can solve the problems of ineffective efficacy of medicinal materials, uneven crushing of medicinal materials, time-consuming and labor-intensive, etc., and achieves the effect of facilitating the work of medicine feeding, improving the utilization rate of medicinal materials, and facilitating collection and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

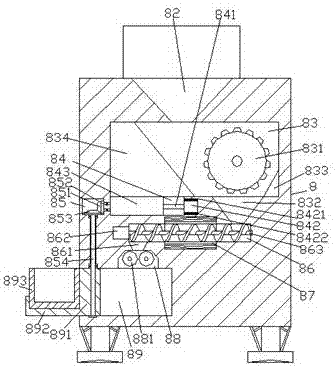

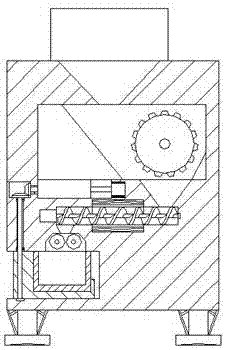

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a new type of medicinal material crushing and drying machine of the present invention includes a fuselage 8, and a conical groove 82 is arranged in the top surface of the fuselage 8, and the bottom of the conical groove 82 is connected with a first left and right extended arrangement. The crushing chamber 83, the extension of the right side of the first crushing chamber 83 is provided with a first crushing device 831, the left side of the first crushing chamber 83 is slid and connected to the inclined plane block 834, and the first crushing device 834 at the bottom of the inclined plane block 834 A crushing chamber 83 inner bottom wall is provided with a guide groove 84, and the guide groove 84 is provided with a left and right extended spiral rod 841, and the right tail of the spiral rod 841 is connected with the first motor 842, The screw thread on the screw rod 841 is connected with a guide block 843,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com