Processing equipment for fireproof layer of fireproof plate

A technology for processing equipment and fireproof layers, which is applied in the field of fireproof layer processing equipment for fireproof boards, can solve problems such as uncontrollable rolling, reduced gravity requirements of pressure rollers, and inability to move, so as to achieve the effect of avoiding wrinkles and reducing gravity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

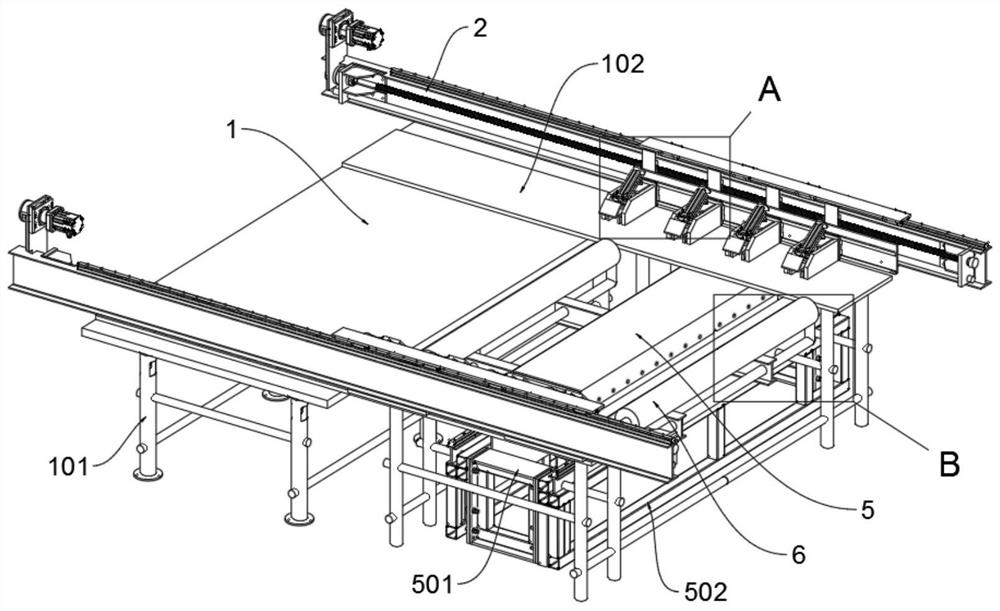

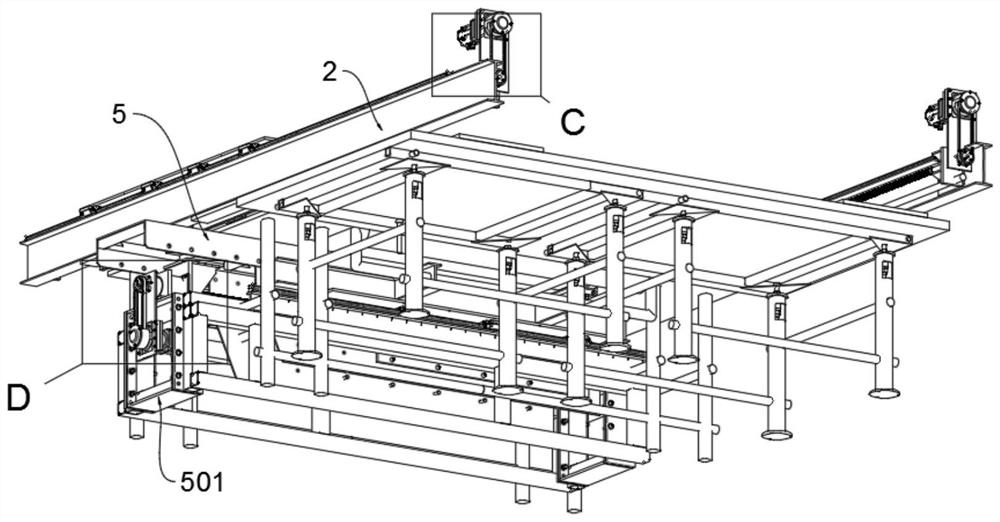

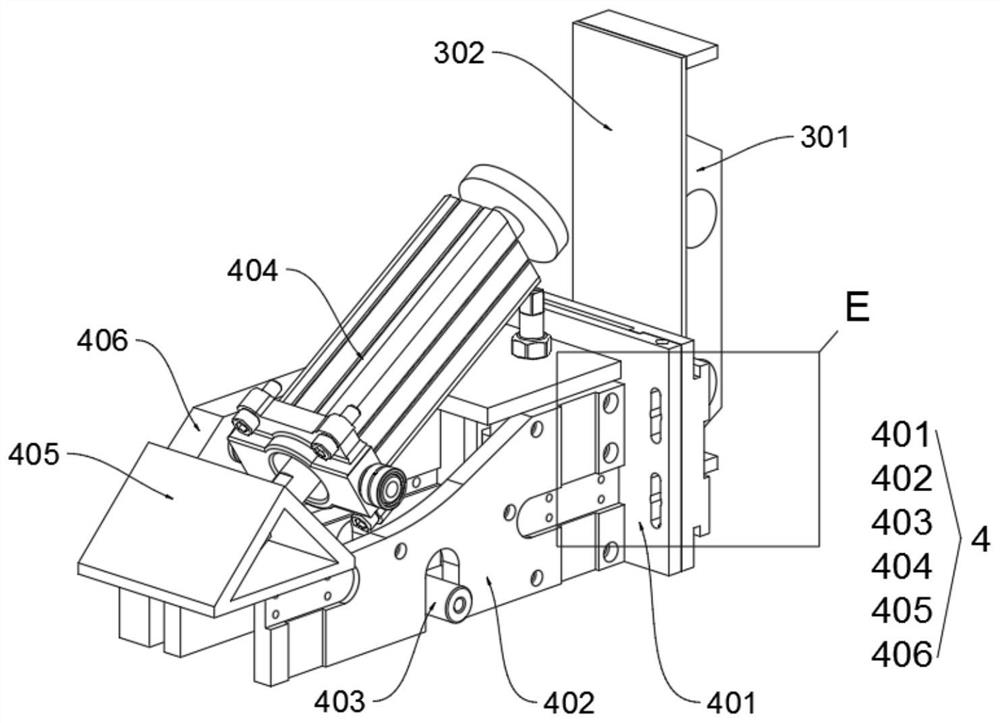

[0034] Example 1: Please refer to Figure 1 to Figure 10 :

[0035] The present invention proposes a fire-proof layer processing equipment for fire-proof boards, comprising: a main platform body 1; There are two groups, and the opposite sides of the two sets of fixed brackets 2 are movably connected to the connecting piece 3; the inner side of the connecting piece 3 is movable and connected to the pressing device 4; the pressing device 4 is electrically connected to the external control circuit of the main table body 1. Link to each other; the top surface of one group on the right side of the round bar support 101 is fixedly connected to the extension table 5; the bottom of the extension table 5 is fixedly connected to the square tube support 502; the inside of the square tube support 502 is equipped with a connecting frame 504; The shaft 601 is movably connected with the pressure roller 6 .

[0036] In addition, according to the embodiments of the present invention, as atta...

Embodiment 2

[0044] On the basis of Embodiment 1, the split structure of the pressing device 4 can be replaced with an integrated structure, so that the area for pressing the kraft paper is larger, thereby avoiding wrinkles at the pressurized position. After the top surface, the kraft paper is pressurized and moved to the left, and the kraft paper is stretched in the front and rear direction while conveying.

[0045] The specific use and function of this embodiment: In the present invention, when the first turning machine 202 circuit is activated, the upper threaded rod 203 is driven to rotate through the belt, and the connecting part 3 is driven to move through the thread engagement so that the top of the connecting part 3 is inside the slideway 201 Sliding, using the slideway 201 can make the connecting piece 3 not rotate with the threaded rod 203 on the screw when moving, so as to ensure translation;

[0046] After the pressurizer 404 starts to work, it applies downward pressure to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com