Patents

Literature

77results about How to "Realize position control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On-line quenching production technique for high toughness thick steel plate

InactiveCN101215624AShort production cycleLow costFurnace typesHeat treatment furnacesSteel platesQuenching

A press quenching manufacturing technique process of high strength and ductility thick steel plate belongs to low alloying steel manufacturing technique field, which comprises heating up steel billet to 1100 DEG C to 1250 DEG C, rolling steel plate through two stages of austenite recrystallization zone and non recrystallization zone with 860 DEG C to 950 DEG C of final rolling temperature, realizing steel plate press quenching through adopting two cooling ways of aerial fog and water-curtain with 25-45 DEG C / s of average cooling speed in cooling region, stopping the quenching when temperature reduced to 150 DEG C to 300 DEG C, and drawing the steel plate after quenched under high temperature. The invention overcomes the weaknesses of long productive cycle of current modified treatment method, high cost and unfavorable stability of high strength and ductility steel plate property which is manufactured by TMCP technique, and can manufacture 20mm-50mm high strength and high ductility steel plate with stable property. And the invention has the advantages of short production line and low energy consumption, which can be extensively applied to manufacture steel plate which is needed in the industries of metallurgy, petrifaction, hydroelectricity and marine and the like.

Owner:SHANDONG IRON & STEEL CO LTD

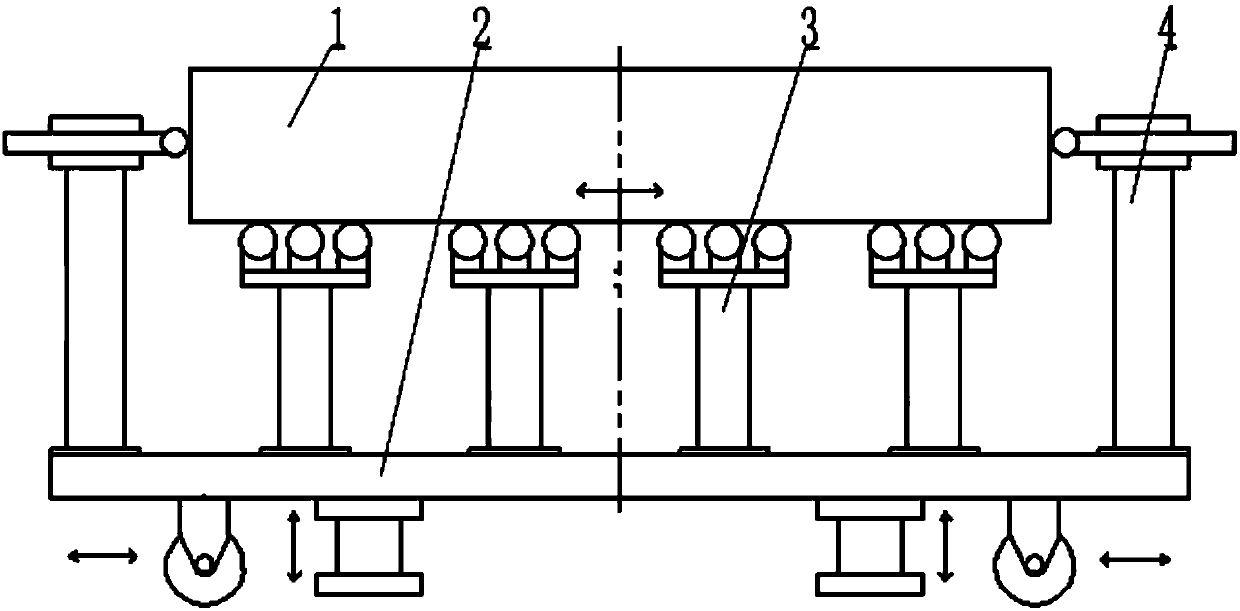

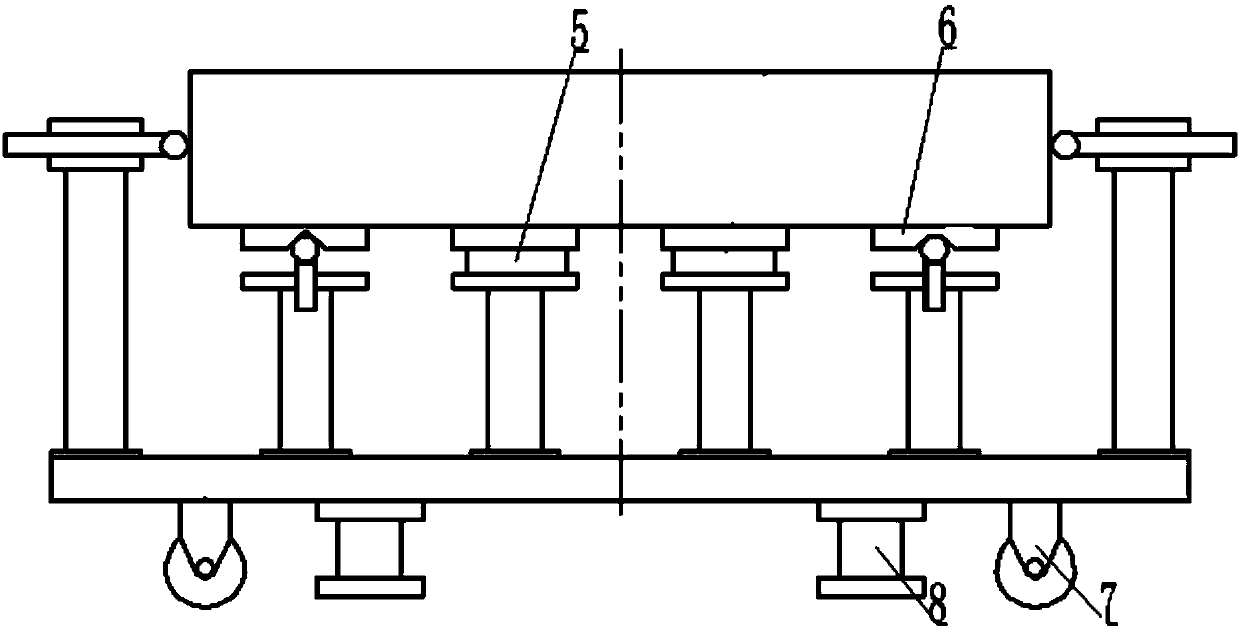

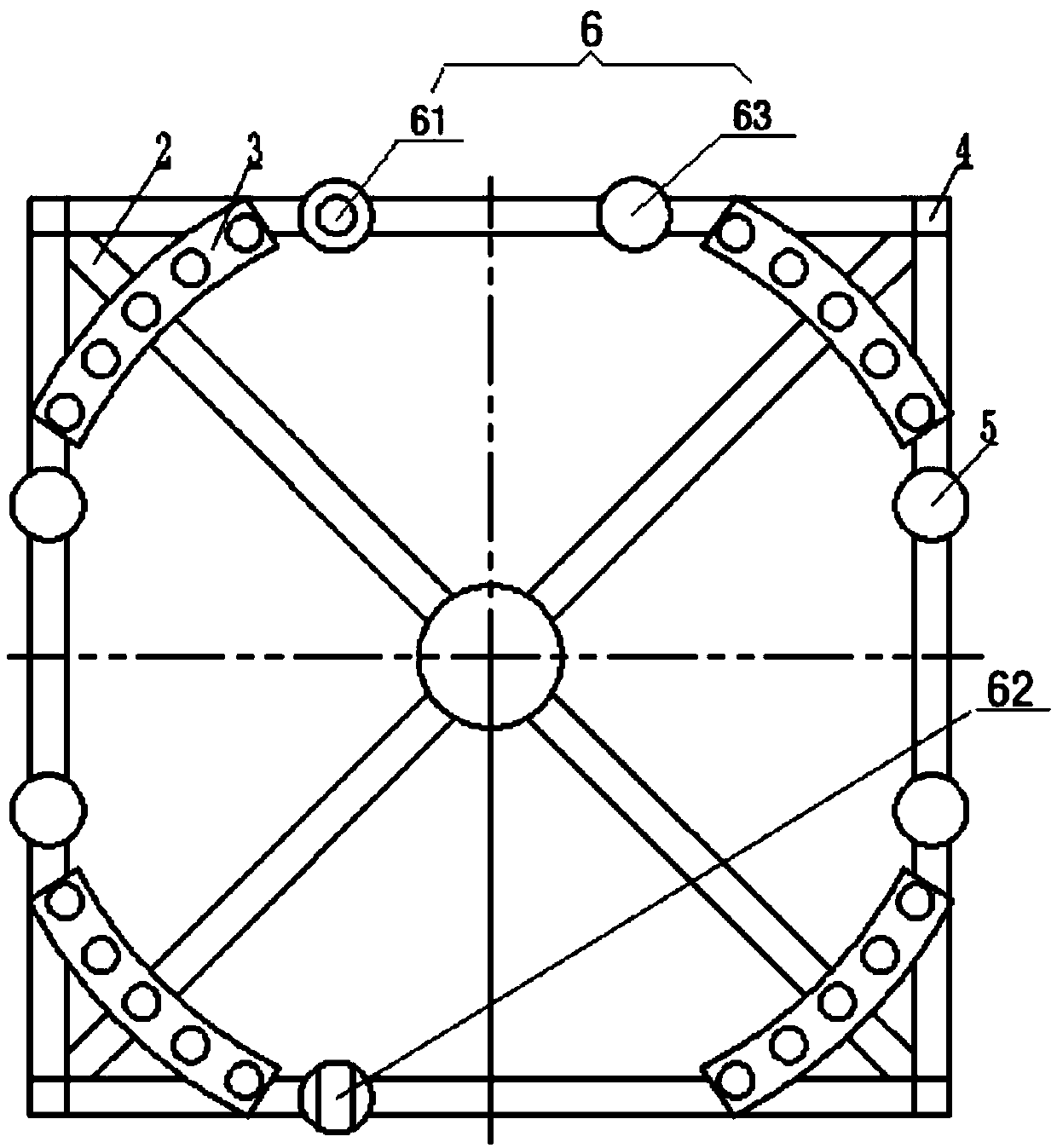

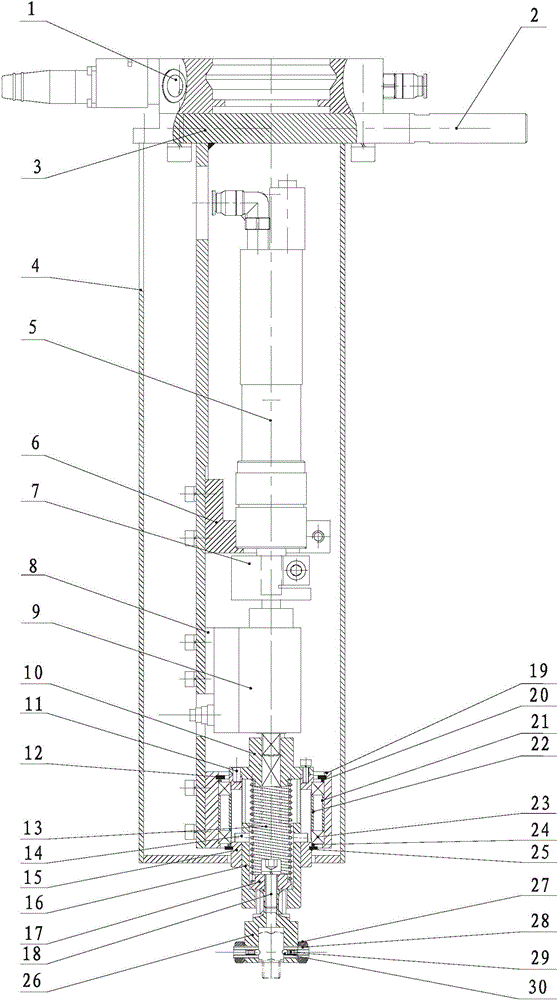

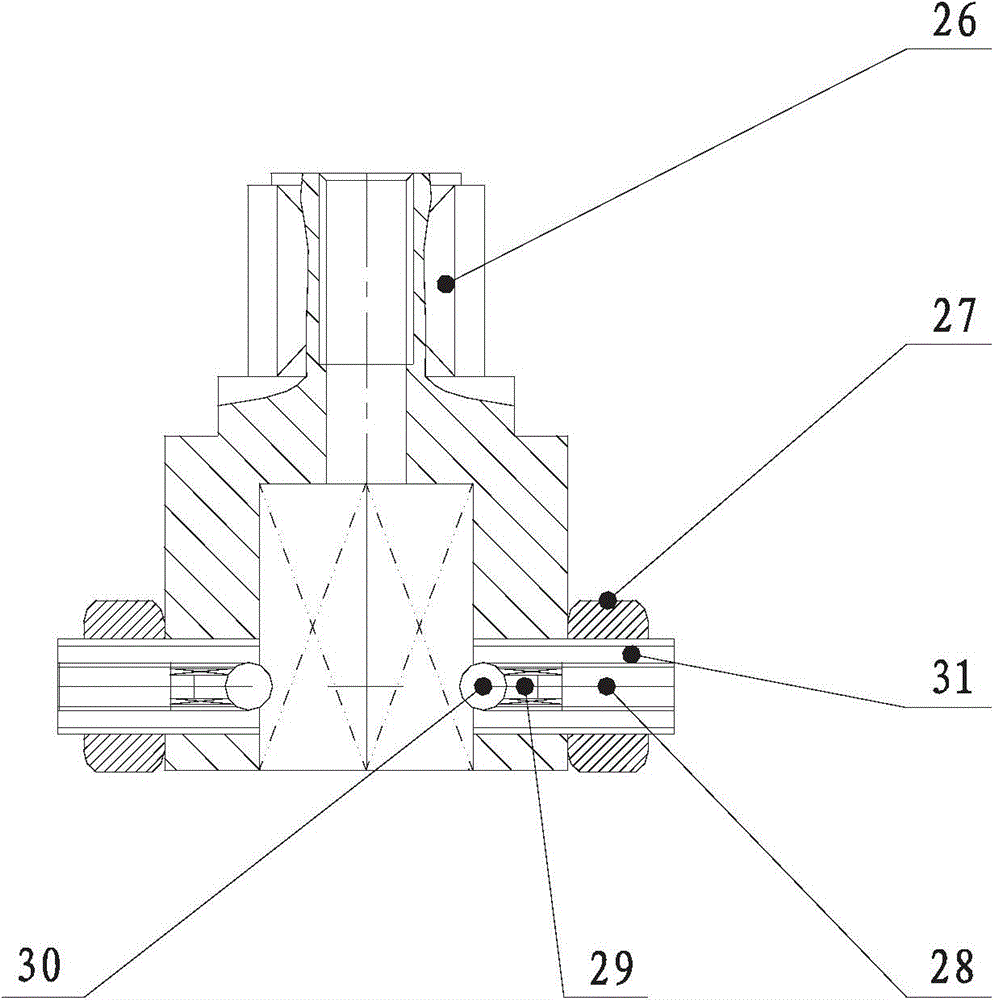

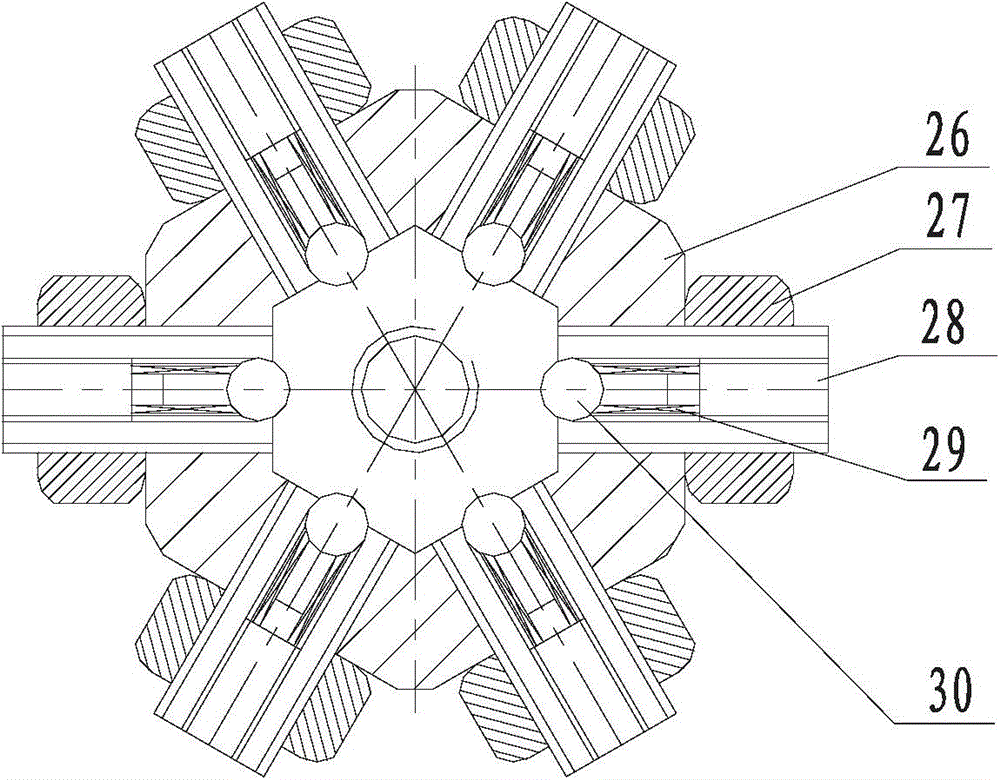

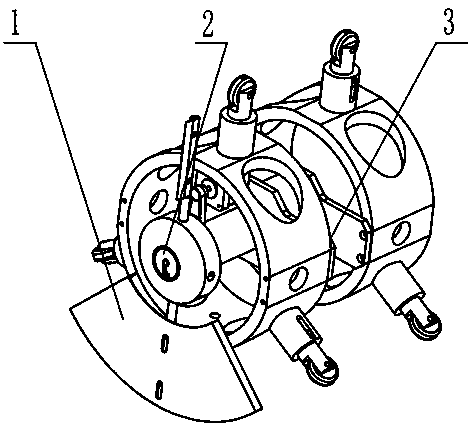

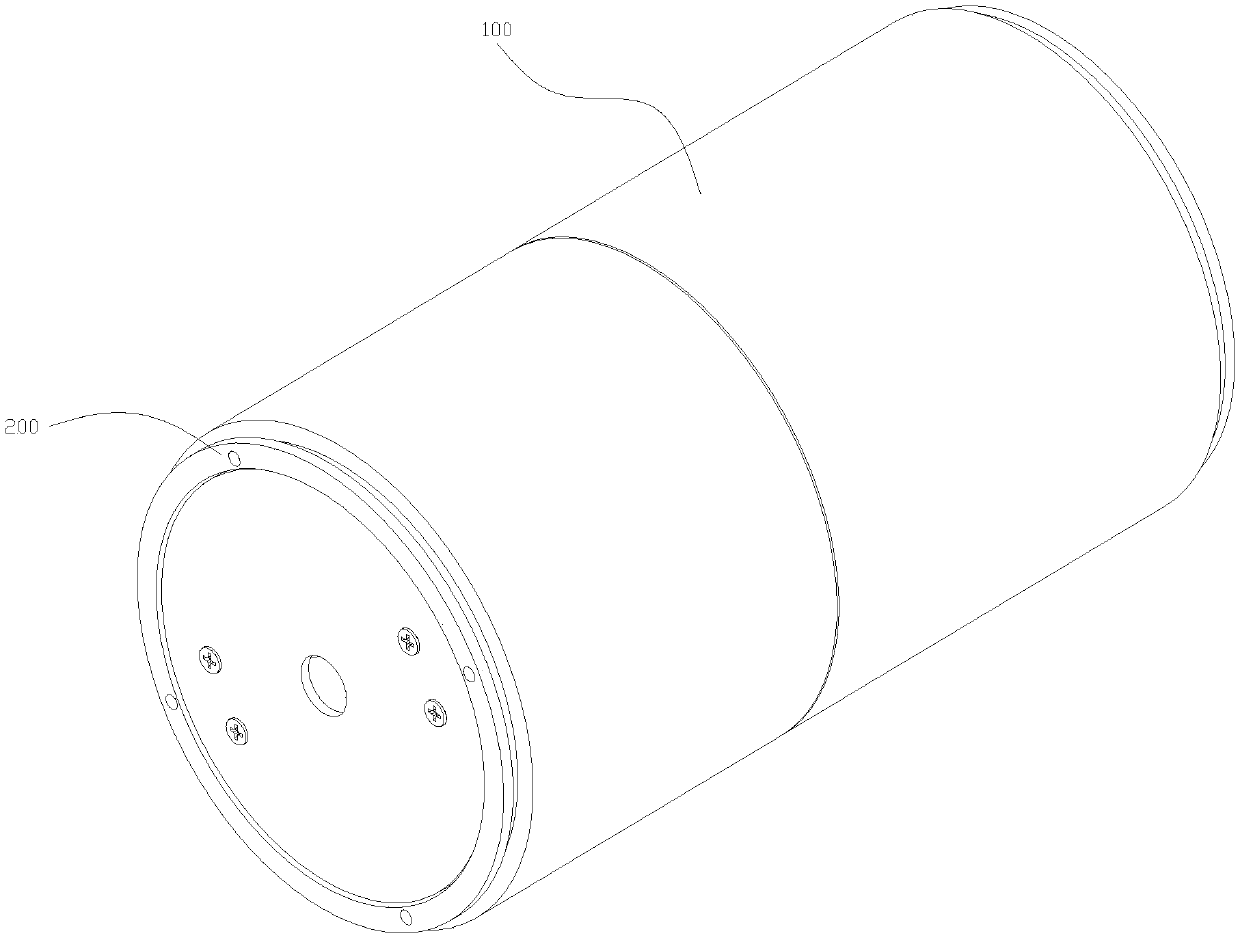

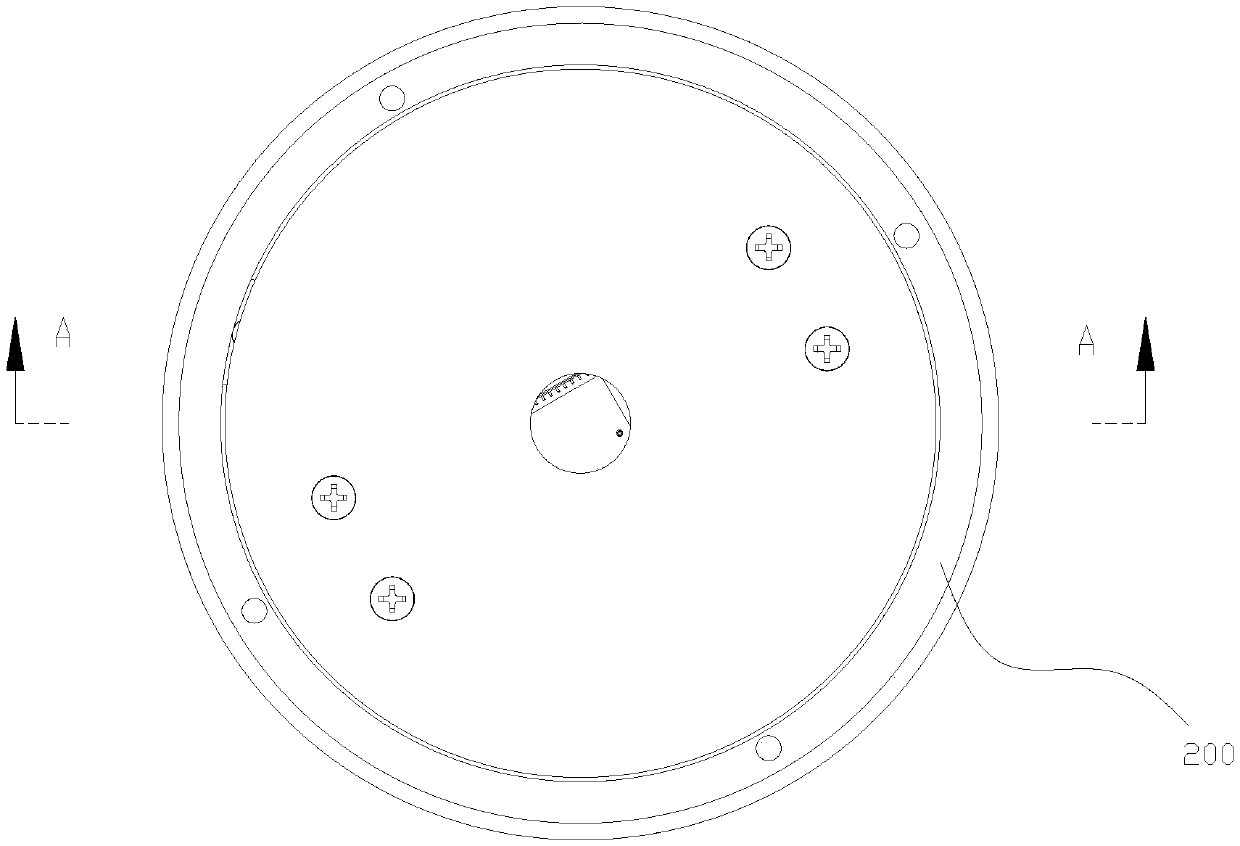

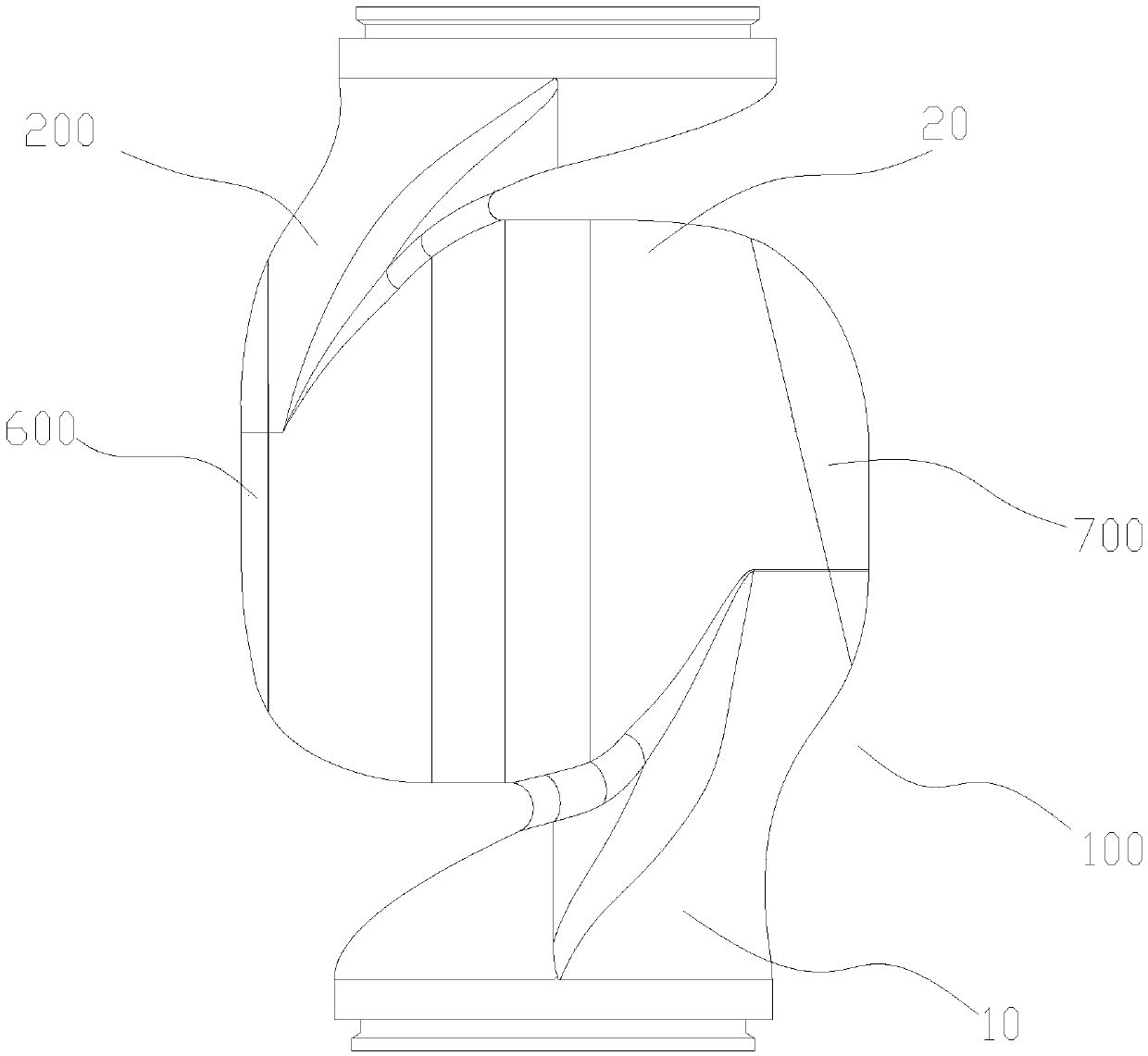

High-precision adjustment device for large-aperture main mirror cell

ActiveCN109683277AAvoid destructionRelease translational degrees of freedomMountingsEngineeringOptical instrument

The invention belongs to the technical field of optical instruments, and provides a high-precision adjustment device for a large-aperture main mirror cell. The high-precision adjustment device comprises a main frame assembly, the upper portion of the main frame assembly is provided with a lifting assembly and an adjusting assembly, an advance ball is arranged on the lifting assembly, and the advance ball is connected with the main mirror cell. The lifting assembly is used for bearing the main mirror cell, the adjusting assembly is provided with an adjusting screw, one end of the adjusting screw is connected with the main mirror cell, the adjusting screw is arranged in the radial direction of the main mirror cell, and the adjusting assembly is used for translation adjustment of the main mirror cell. The high-precision adjustment device can adjust the main mirror cell at multiple degrees of freedom at a high precision.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

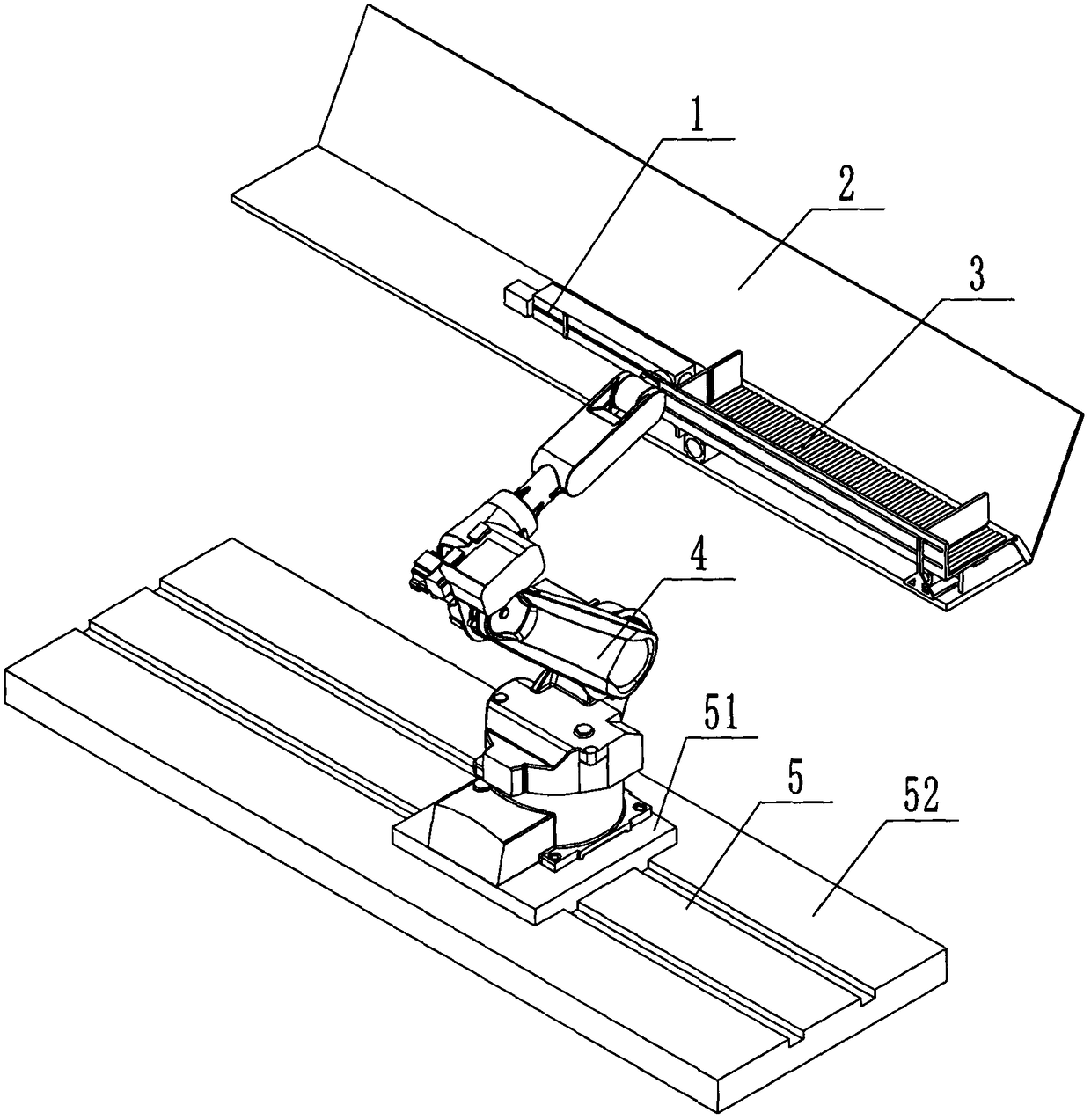

Mechanical arm pose control method based on gesture recognition

ActiveCN107856014ALarge working spaceThe calculation result is accurateProgramme-controlled manipulatorAfter treatmentBluetooth

The invention discloses a mechanical arm pose control method based on gesture recognition. The post of an arm can be obtained through an intelligent wrist belt, and the angle of each joint angle on aworking mechanical arm is solved based on the pose through positive inverse kinematics. The method comprises the specific steps that the wrist belt is wirelessly connected with a PC terminal through Bluetooth, and electromyographic signals collected by an intelligent wrist belt module are transmitted to a remote client; the remote client receives the signals and transmits the signals to a data processing module, the signals are filtered and denoised in the data processing module, and gestures are classified after treatment; after denoising in the data processing module, positive inverse kinematics is used for solving the joint angle; the joint angles of arms of an operator are obtained through two intelligent wrist belts; the signals of the joint angles and operation instruction signals can be transmitted to an intelligent wrist belt module through the remote client; gesture action signals are sent to a simulated mechanical arm in a simulation module; and the simulated arm sends signals to the working mechanical arm, and the mechanical arm executes commands.

Owner:ZHEJIANG UNIV OF TECH

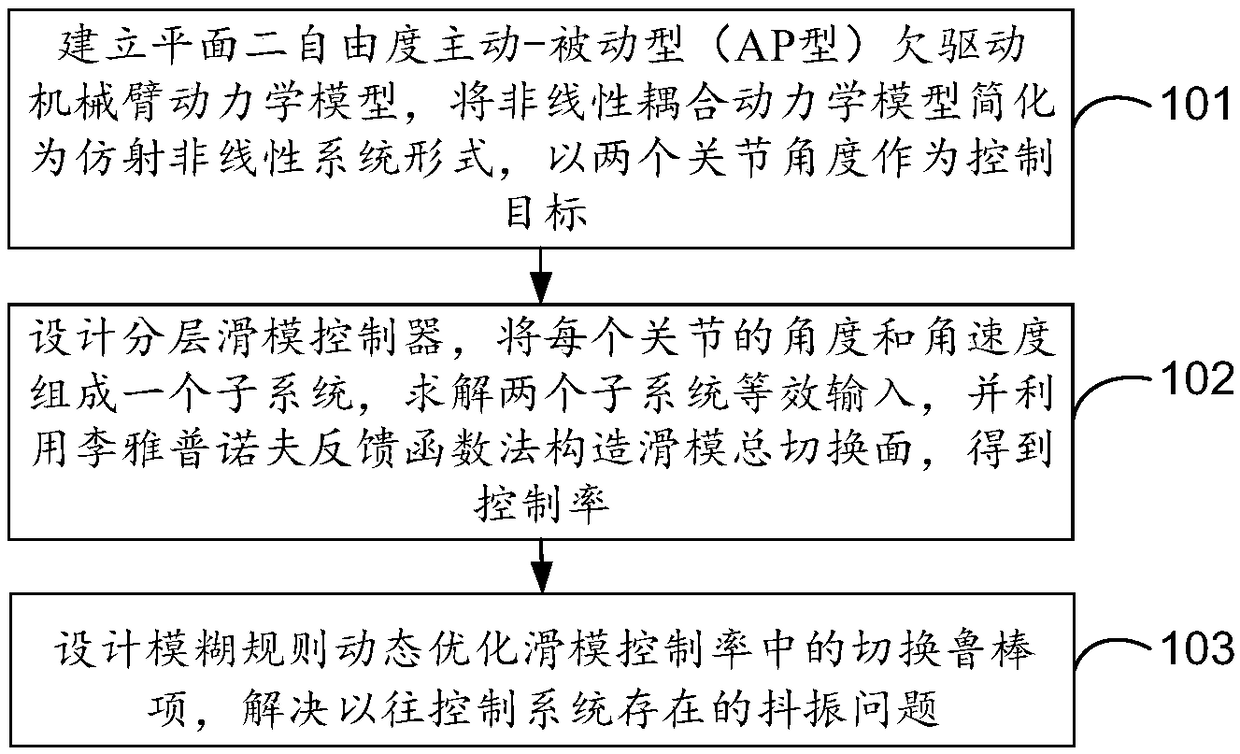

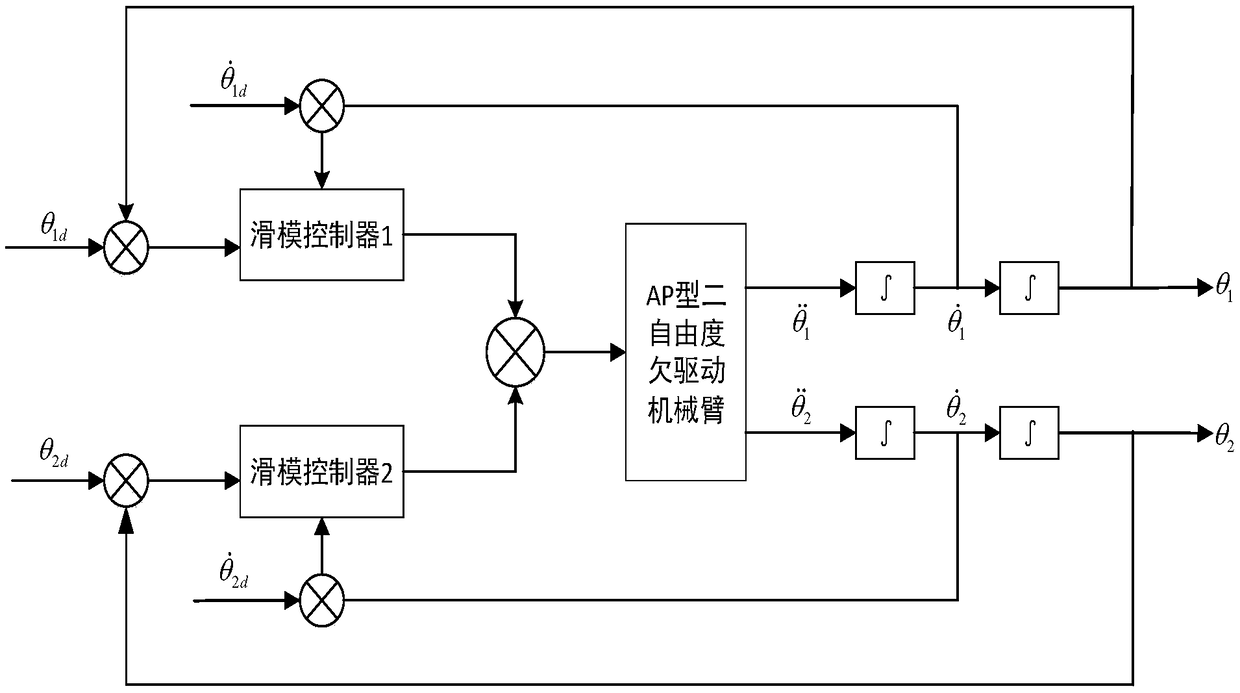

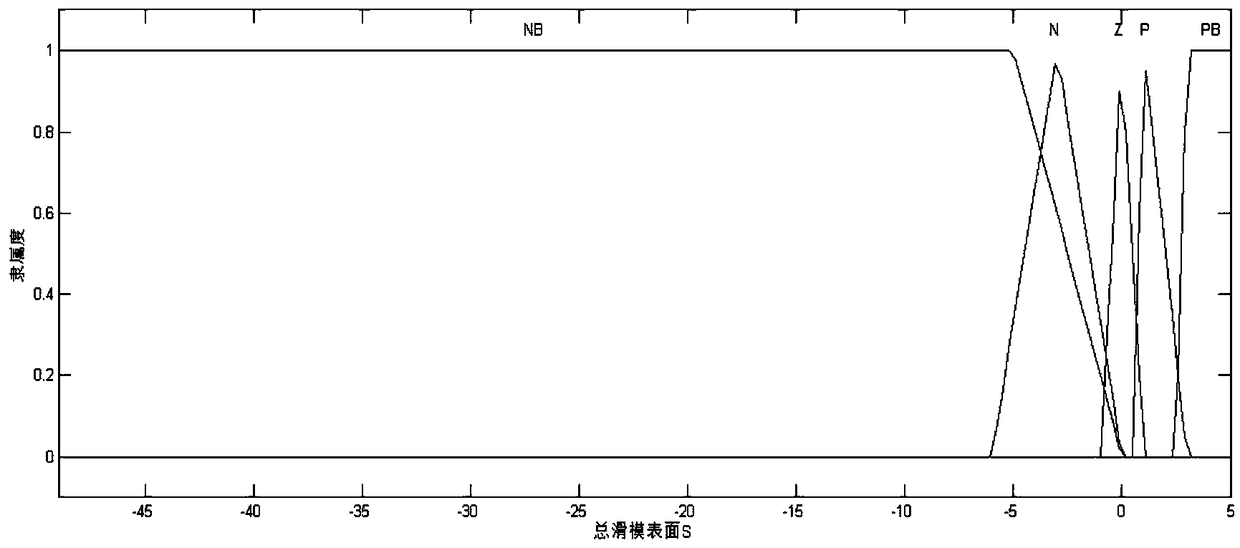

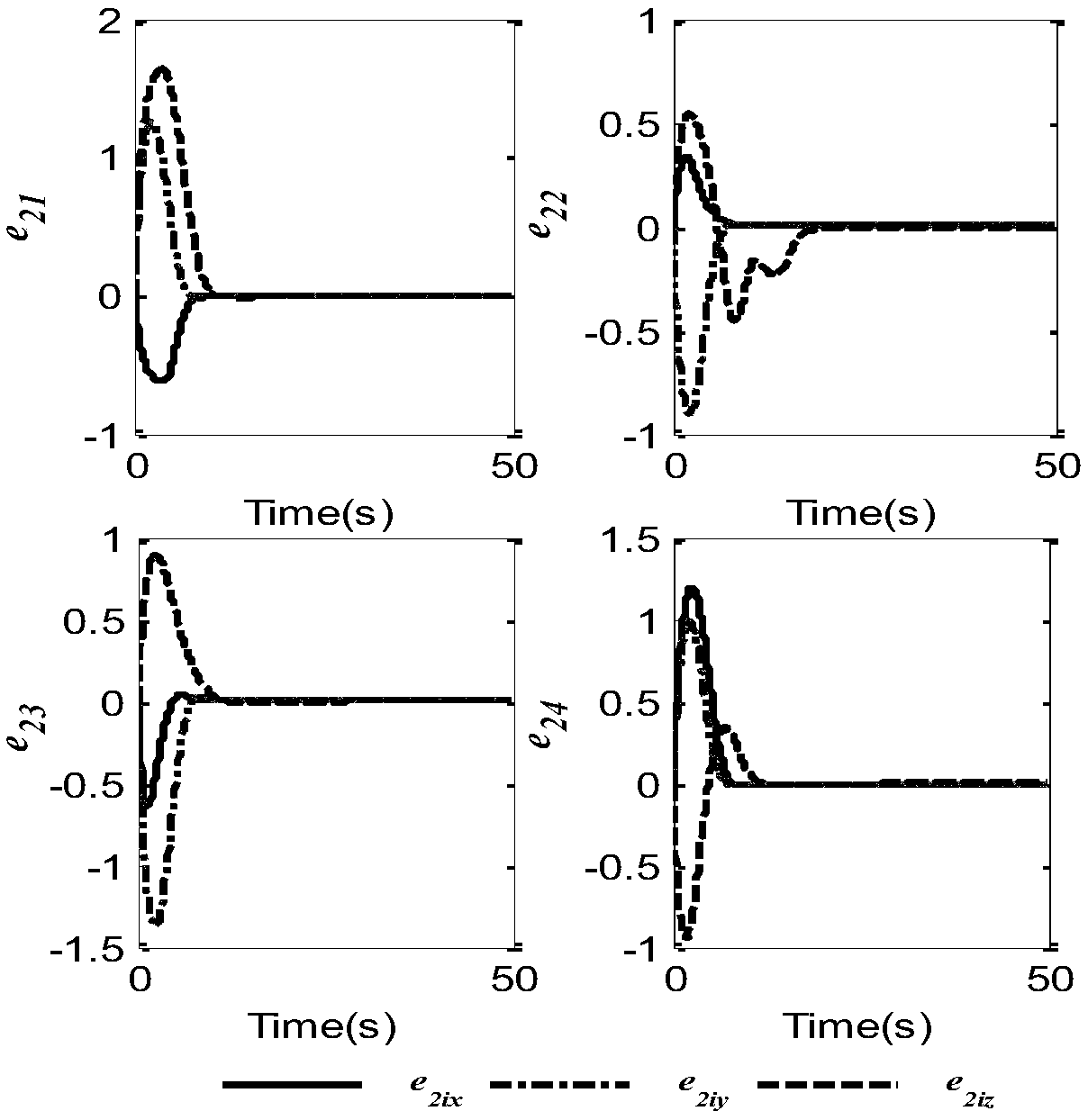

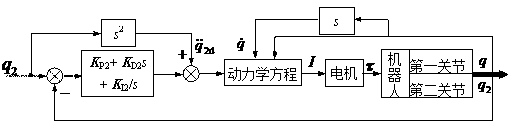

Underactuated mechanical arm layering sliding mode control method based on fuzzy optimization

ActiveCN108972560ARealize position controlShorten the steady state timeProgramme-controlled manipulatorFuzzy ruleControl system

The embodiment of the invention discloses an underactuated mechanical arm layering sliding mode control method based on fuzzy optimization. The method comprises the steps that a plane two-freedom-degree active-passive (AP) underactuated mechanical arm dynamical model is set up, a nonlinear coupling dynamical model is simplified into an affine nonlinear system, and two joint angles are adopted as control targets; then, layering sliding mode controllers are designed, a subsystem is formed by the angle and the angular speed of each joint, the equivalent input of the two subsystems is solved, a sliding mode main switching surface is constructed through a Lyapunov feedback function, and the control rate is obtained; and finally, a fuzzy rule is designed to dynamically optimizing the switching robust item in the sliding mode control rate, and the buffeting problem existing in a previous control system is solved. Compared with other plane two-freedom-degree AP mechanical arm control methods,by means of the technical scheme, the steady-state time of the control process can be reduced, and the control precision can be improved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

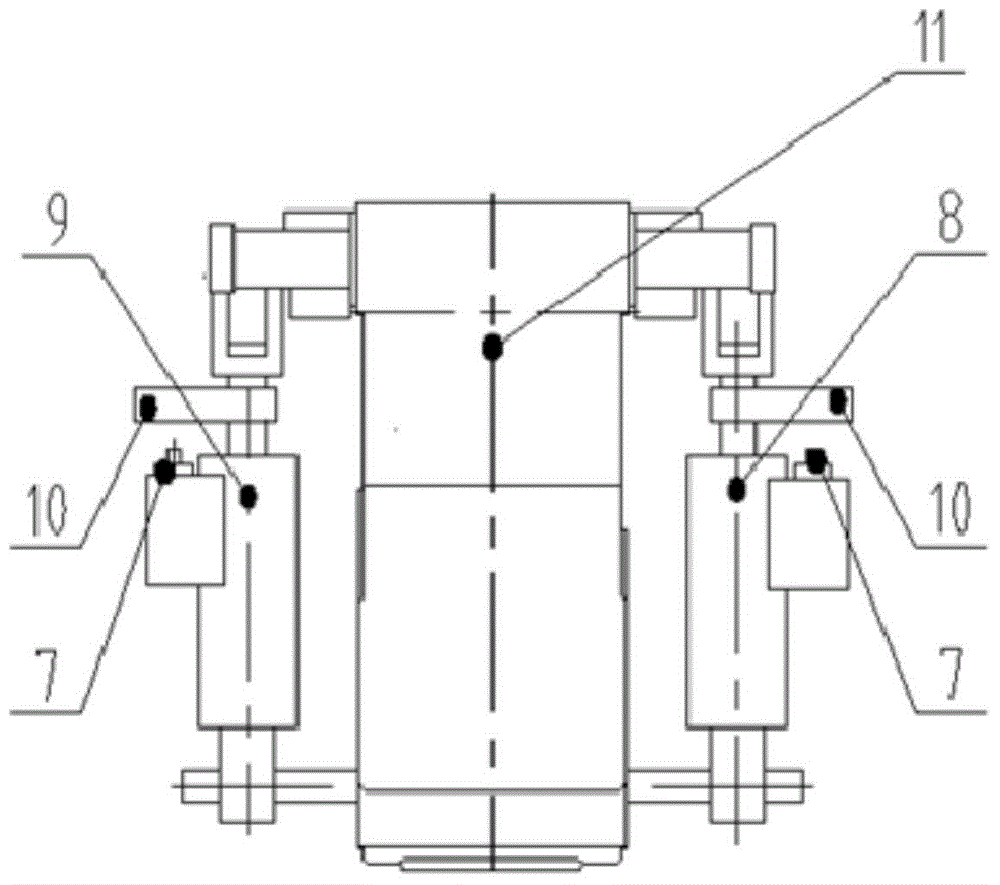

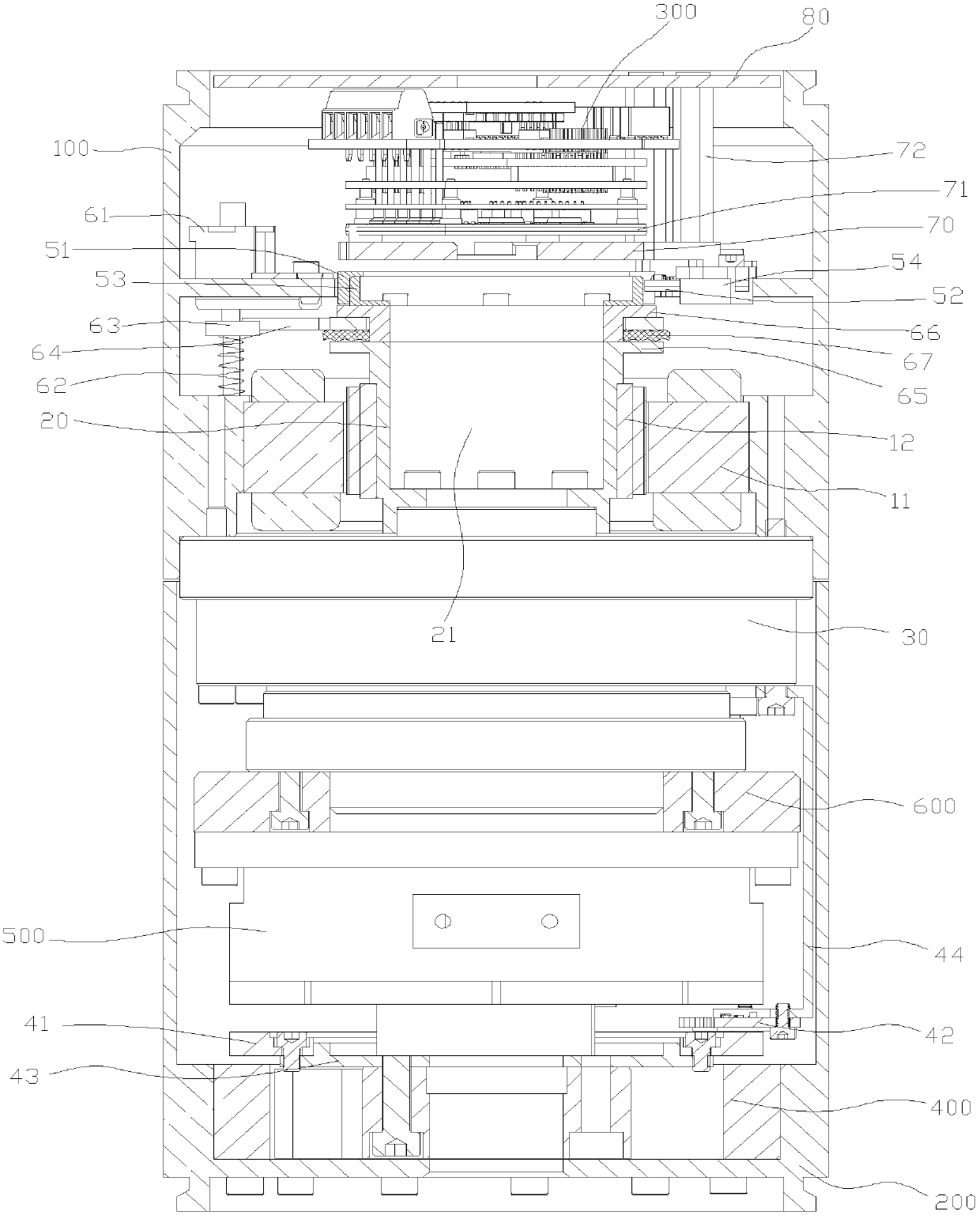

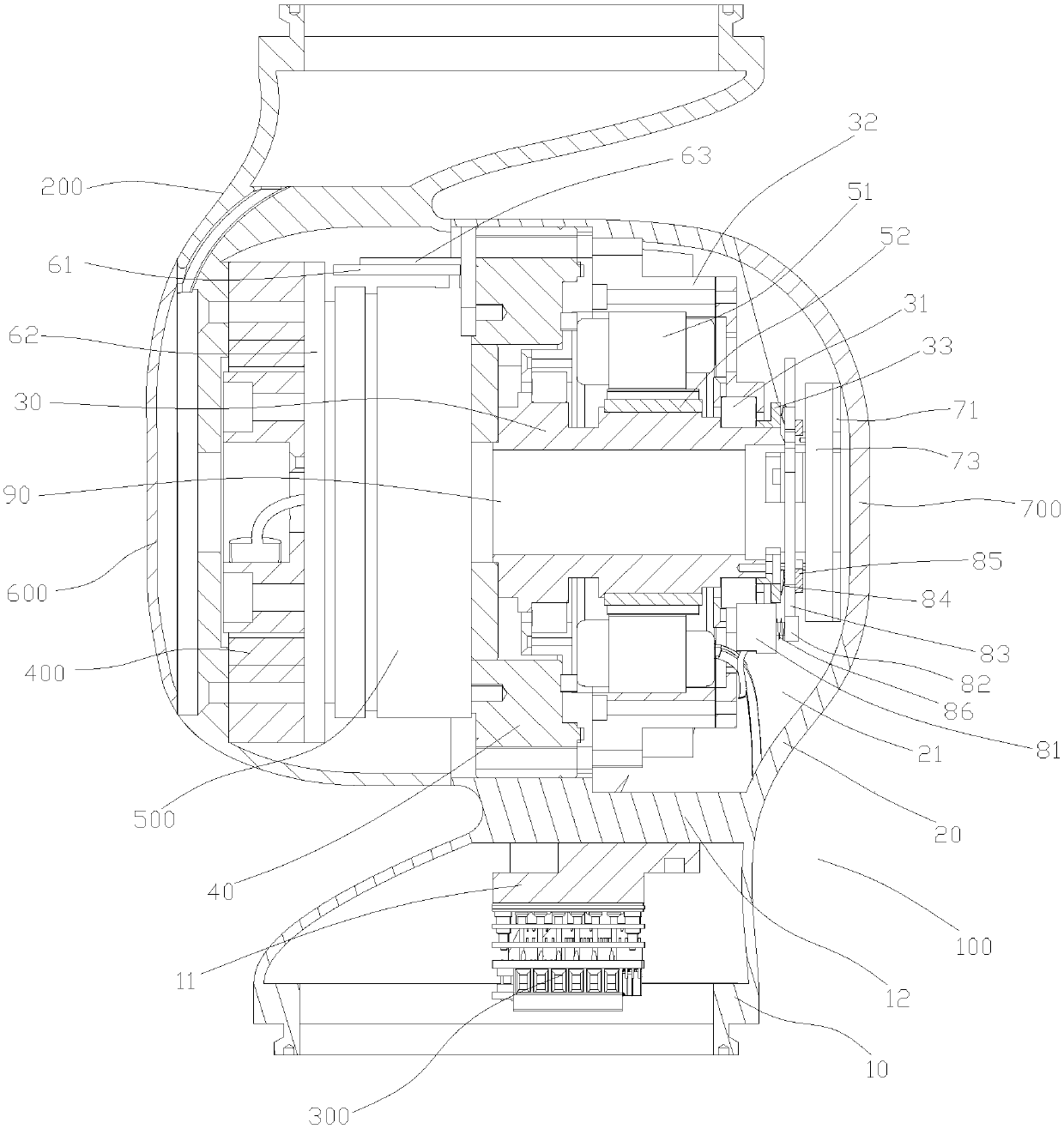

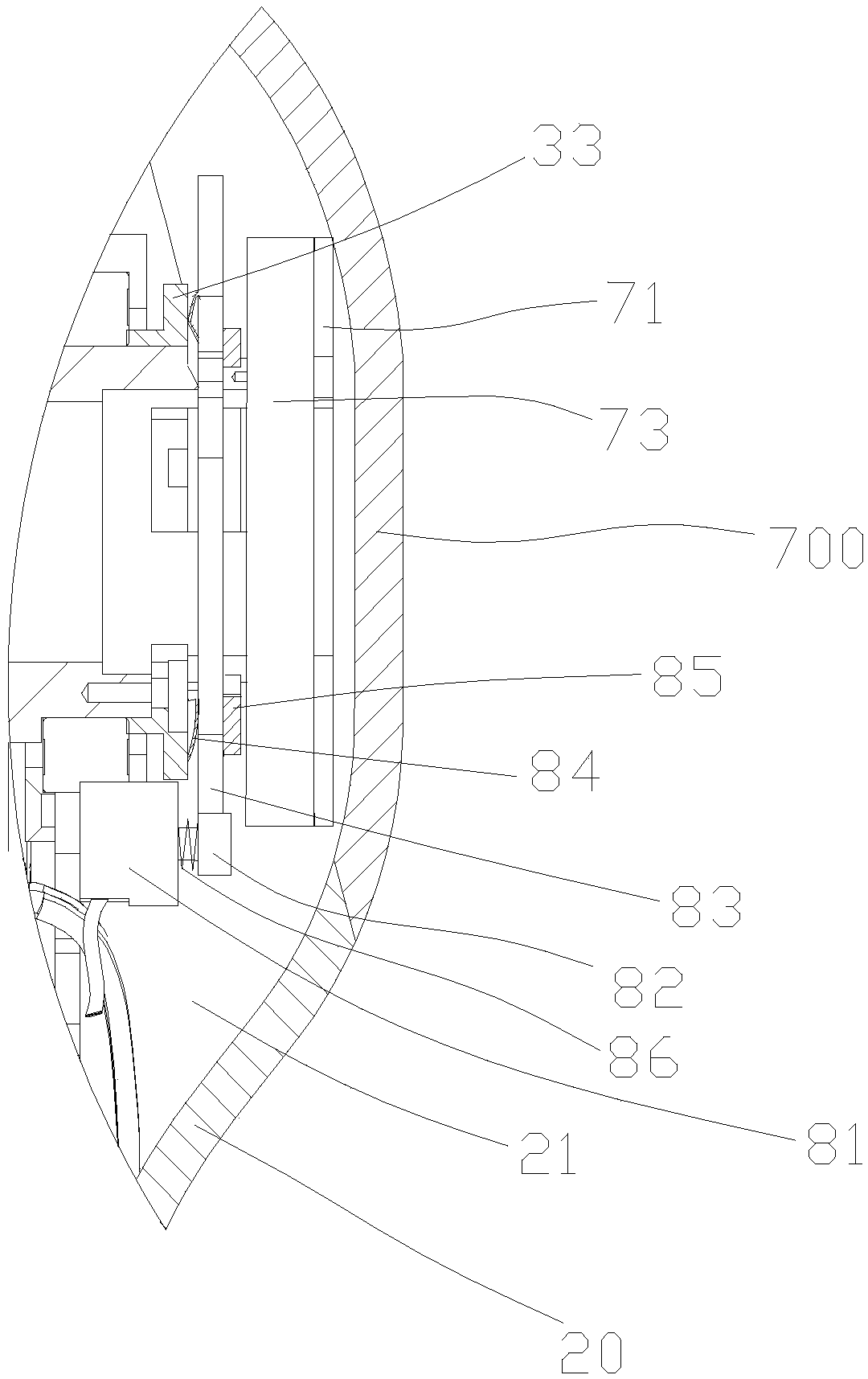

Axial bolt tightening device

InactiveCN104668947AIncrease productivityReduce labor intensityMetal working apparatusMechanical engineeringEngineering

The invention belongs to the technical field of automatic assembly, and particularly relates to an axial bolt tightening device. The axial bolt tightening device comprises a base, an outer cover, a supporting frame, a driving device, a transmission device, a rotation supporting device and a tightening assembly, wherein the outer cover is connected with the base, the supporting frame, the driving device, the transmission device and the rotation supporting device are arranged in the outer cover, the supporting frame is connected with the base, the driving device and the rotation supporting device are installed on the supporting frame, and are in transmission connection through the transmission device, and the rotation supporting device penetrates through the outer cover to be connected with the tightening assembly. The axial bolt tightening device is particularly suitable for continuous automatic assembly and disassembly of axial bolts in a narrow space, and the production efficiency is improved on the basis that the product percent of pass is guaranteed.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

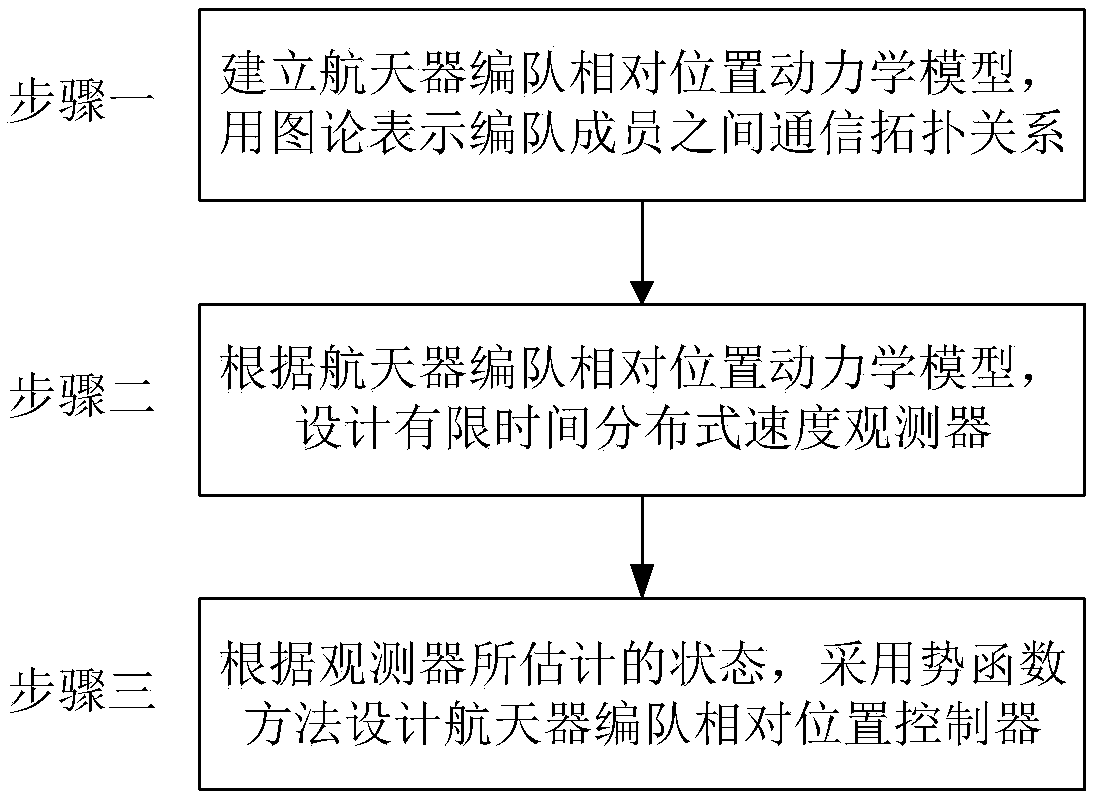

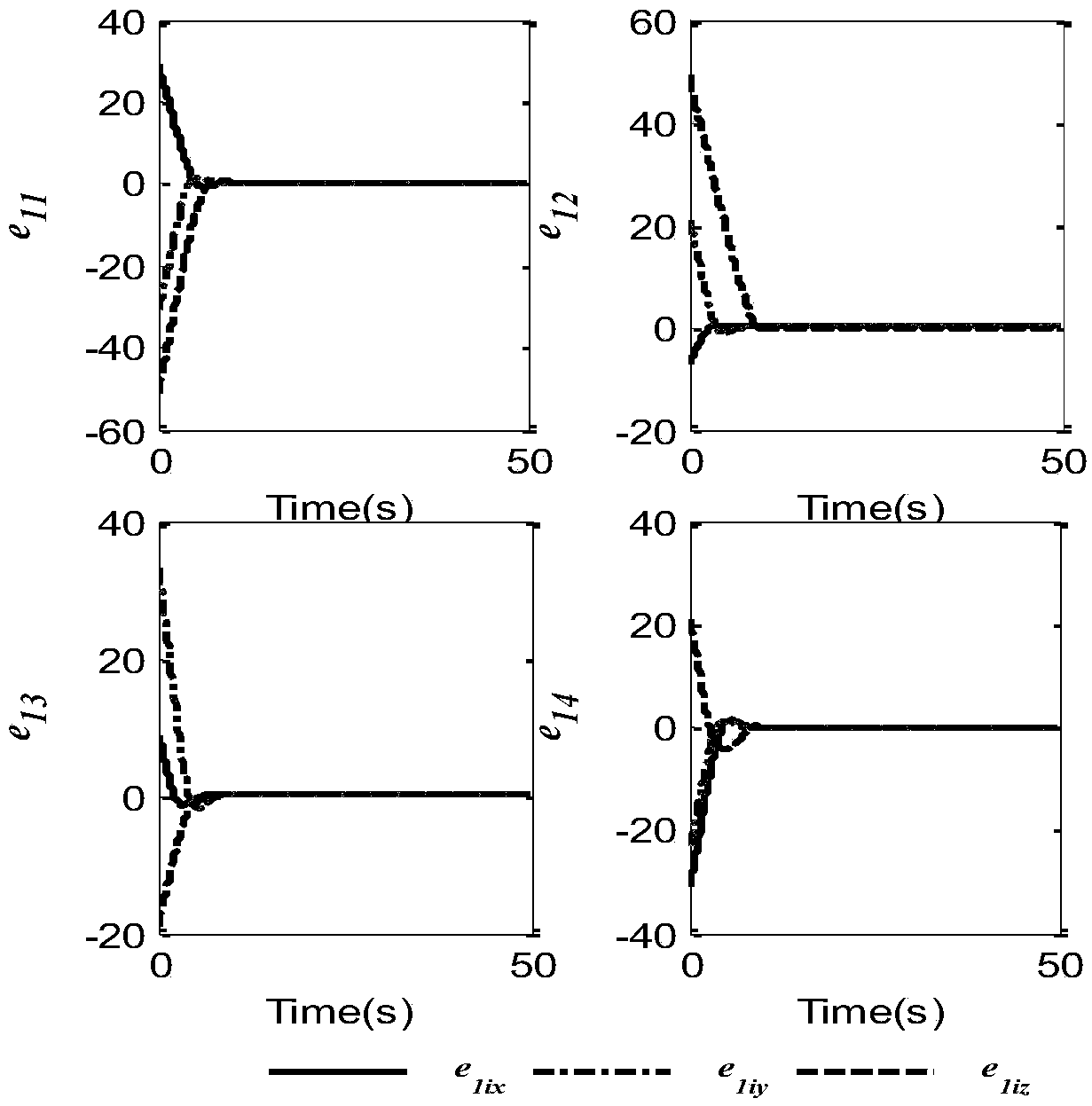

Spacecraft relative position control method based on finite-time distributed type speed observer

ActiveCN109683628APrecise estimate of speed informationRealize position controlPosition/course control in three dimensionsDynamic modelsMathematical Graph

The invention provides a spacecraft formation relative position control method based on a finite-time distributed type speed observer, and belongs to the field of spacecraft formation relative position control. Firstly, according to a spacecraft relative position dynamics model, the graph theory is used for representing the communication topological relationship between formation members; secondly, the finite-time distributed type speed observer is designed; finally, based on velocity observation information, a potential function method is adopted, and the control method which can make the spacecraft formation members reach their desired positions while avoiding collisions during flight is designed. The method achieves the finite-time estimation of the spacecraft speed, a controller can beindependently designed, and the method is suitable for the relative position control of spacecrafts with missing velocity information. The finite-time distributed type velocity observer is adapted totimely and accurately provide velocity estimation information, the relative position of the spacecraft is ensured to reach expected value, and meanwhile the occurrence of collision is avoided.

Owner:HARBIN ENG UNIV

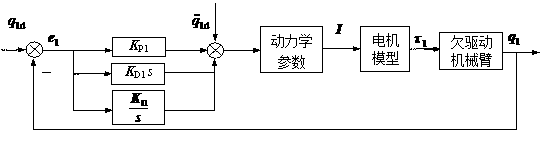

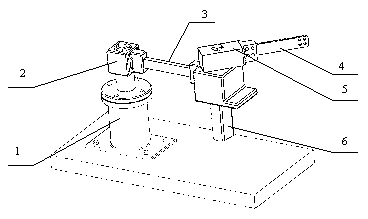

Location control method of 2R underactuated planar mechanical arm based on subdivision control

InactiveCN103128737ASmooth motionThe control object is universalProgramme-controlled manipulatorUnderactuated robotsResearch Object

The invention discloses a location control method of a 2R underactuated planar mechanical arm based on subdivision control. The location control method of the 2R underactuated planar mechanical arm based on subdivision control comprises the following steps: establishing an underactuated planar mechanical arm mechanics module with a driving first joint and a driven second joint, and considering Coulomb friction force and viscous friction force of joints in the module. To an underactuated robot, the friction of the driving joint can be directly compensated by a motor, but the driven joint can not be compensated, and the friction force of the driven joint is utilized. By adopting a time scale method and a proportion integration differentiation (PID) control method, the location control method of the 2R underactuated planar mechanical arm based on subdivision periodically starts joint space and location control to the 2R underactuated planar mechanical arm, and further achieves positioning control to the tail end of the robot. A research objective of the location control method is an underactuation system which includes entirely free joints, and so that the location control method of the 2R underactuated planar mechanical arm based on subdivision control has the advantages of being simplified in a mechanical device and pervasive in the control objective. The location control method of the 2R underactuated planar mechanical arm based on subdivision control utilizes a simple and feasible control method to realize the location control of the 2R underactuated planar mechanical arm, avoids to adopt complex and profound nonlinear control methods, and achieves the purposes of being distinct in train of thought, simple to programming and easy to achieve.

Owner:SHANGHAI PAXING INFORMATION TECH

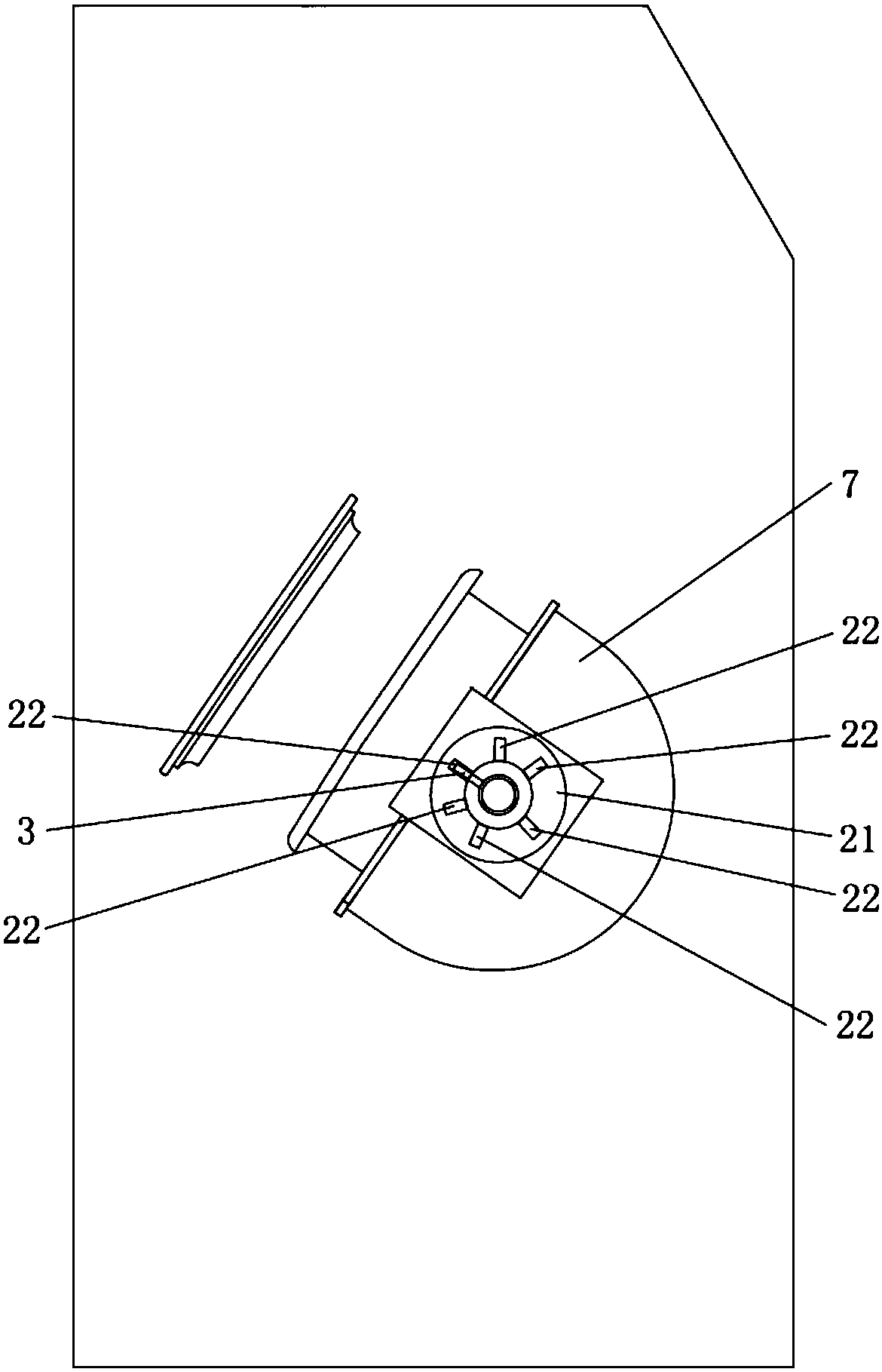

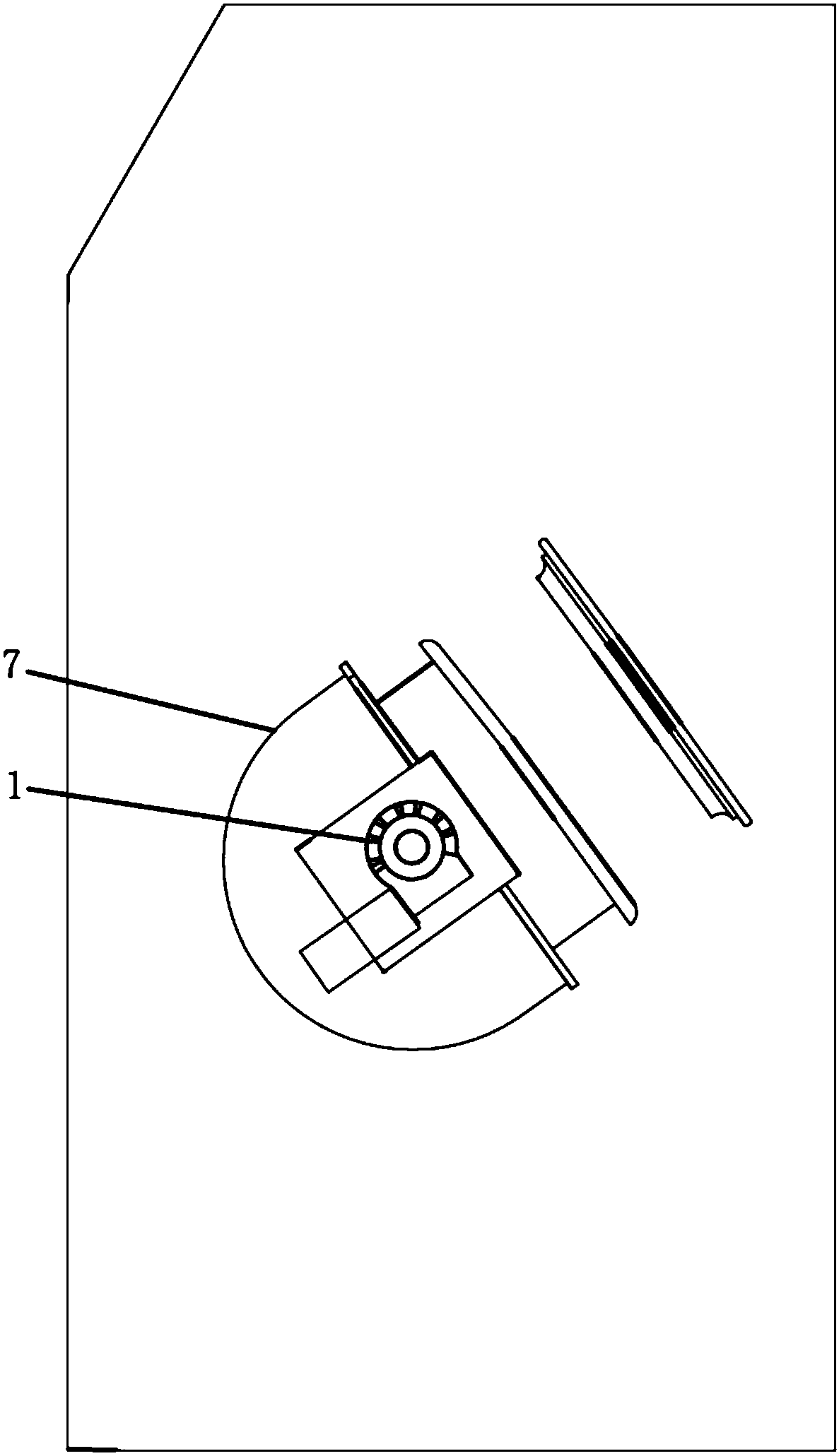

Cooking pot control device for cooking machine and cooking machine

InactiveCN107844079ARealize position controlHigh degree of automationProgramme controlComputer controlElectricityProcess engineering

The invention relates to the technical field of kitchen appliances, and discloses a cooking pot control device for a cooking machine and a cooking machine. The cooking pot control device for the cooking machine includes a driving device, a sensor device, a baffle, a controller and a rotary shaft of a cooking pot and for connection with the cooking machine. The rotary shaft is connected on an output shaft of the driving device. The baffle is provided with a first through hole passing through the left and right surfaces thereof. The first through hole is connected with the rotary shaft. The driving device is electrically connected with the controller. The sensor device includes a sensor mounting seat and a plurality of sensors corresponding respectively to a plurality of stations of the cooking machine. The rotary shaft is rotatably connected on the sensor mounting seat, and the sensors are electrically connected with the controller. The baffle is provided with protruding portions thereon. The sensors are provided with recessed portions. When the cooking pot of the cooking machine is rotated to the corresponding station, the protruding portions rotate into the corresponding recessedportions, and the controller controls the output shaft of the driving device to stop rotating. According to the invention, the automation degree of the position control of the cooking pot of the cooking machine and the positioning accuracy are increased.

Owner:SHENZHEN ADVANCED TECH CO LTD

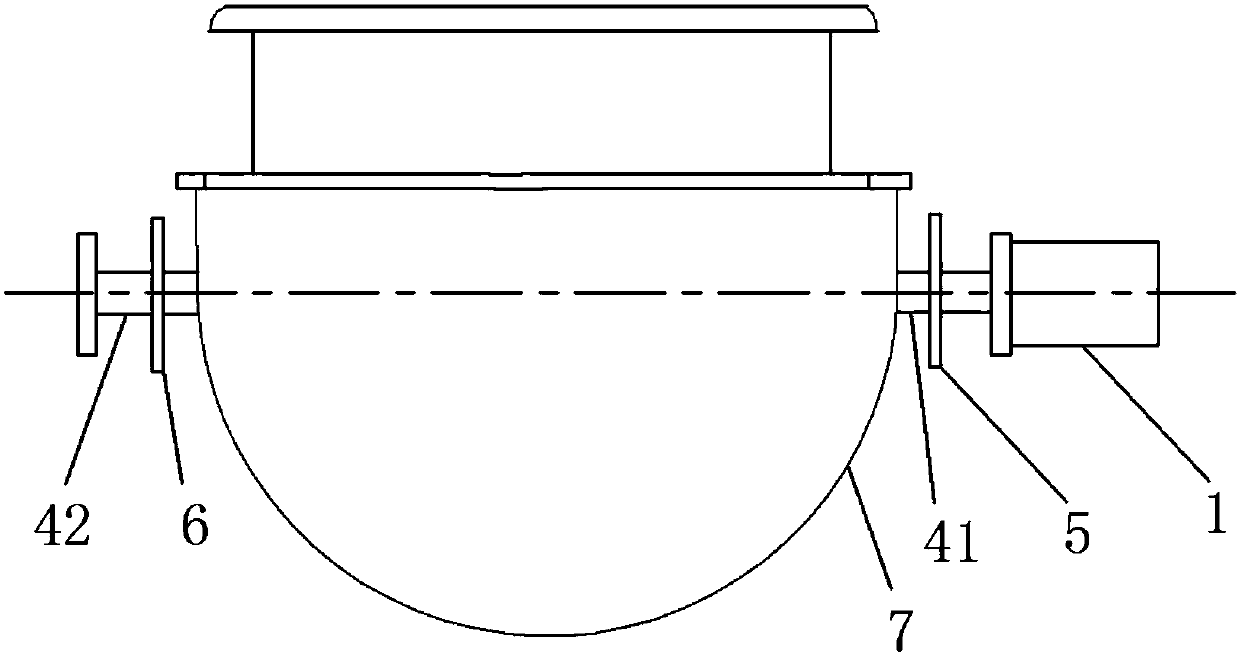

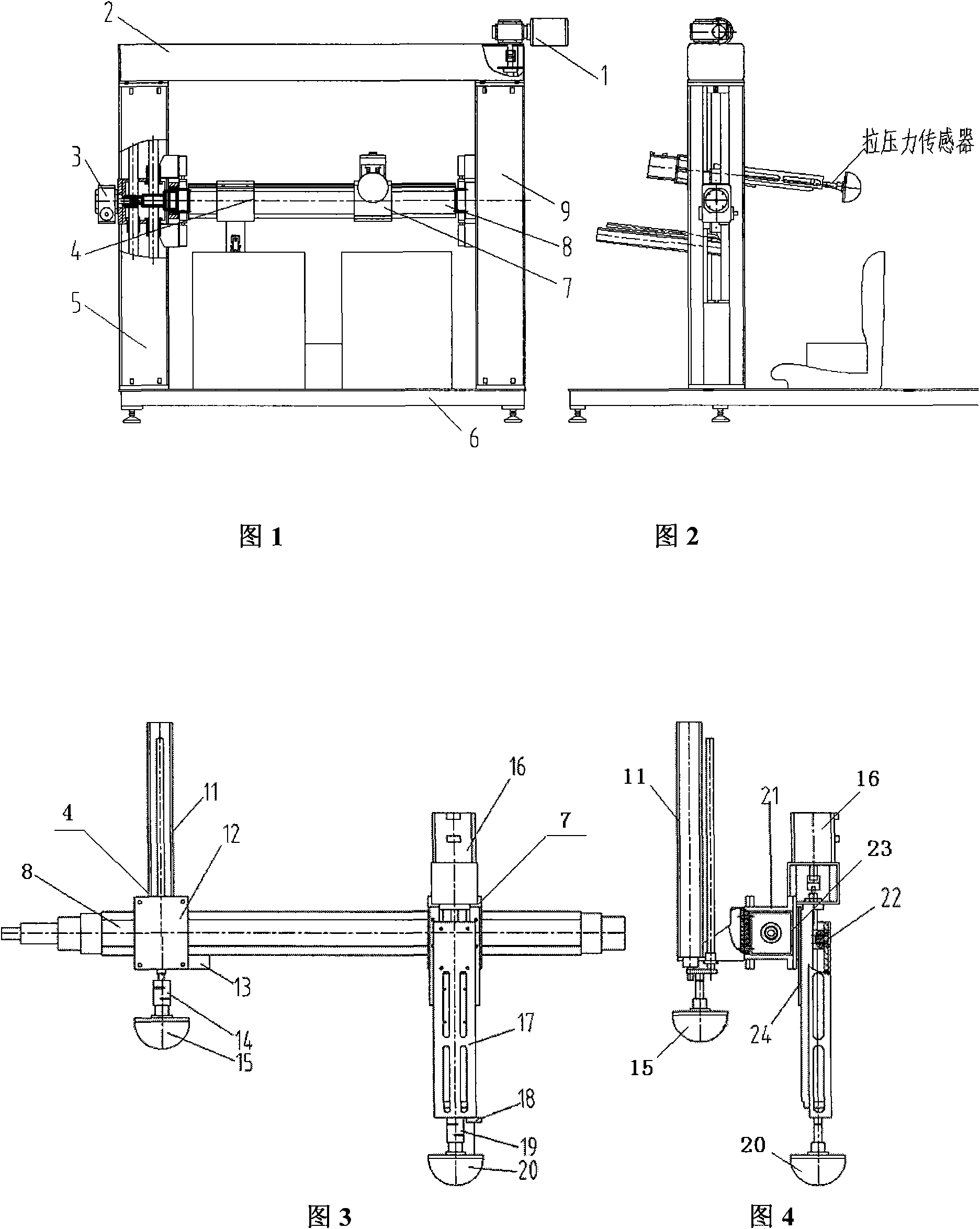

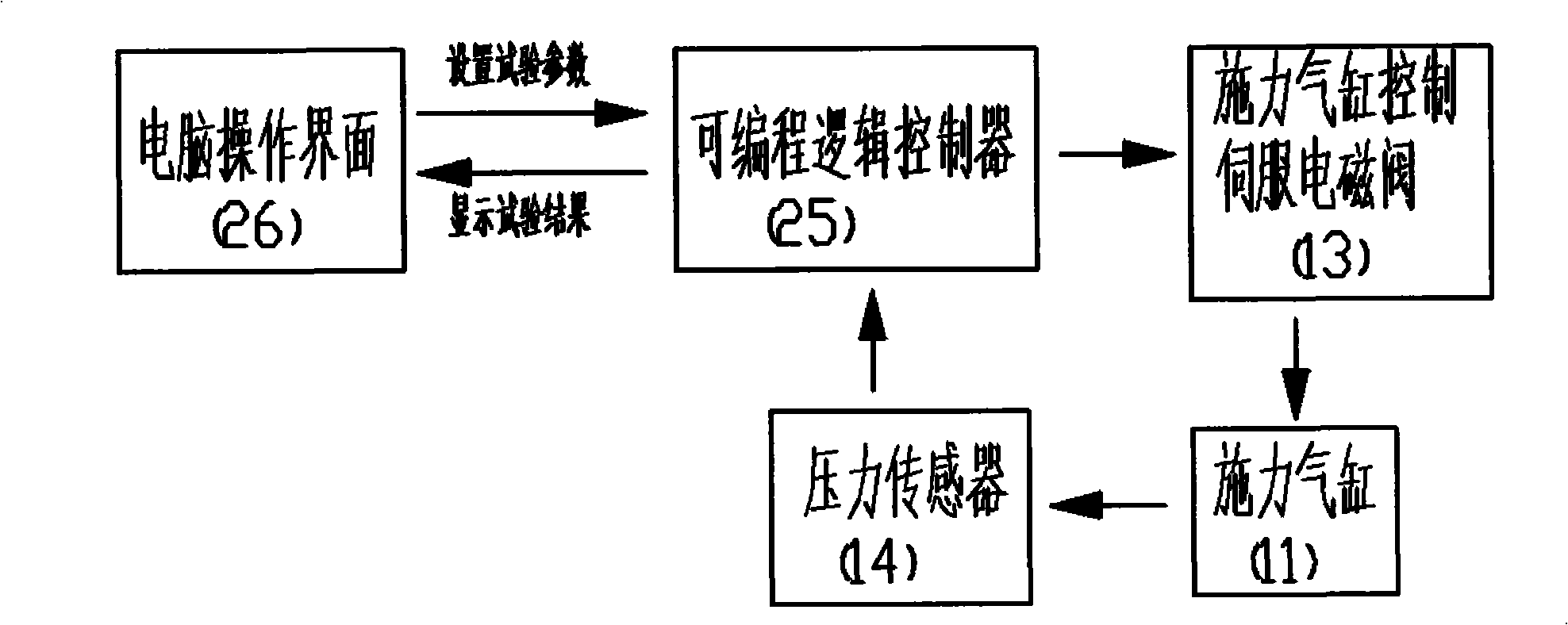

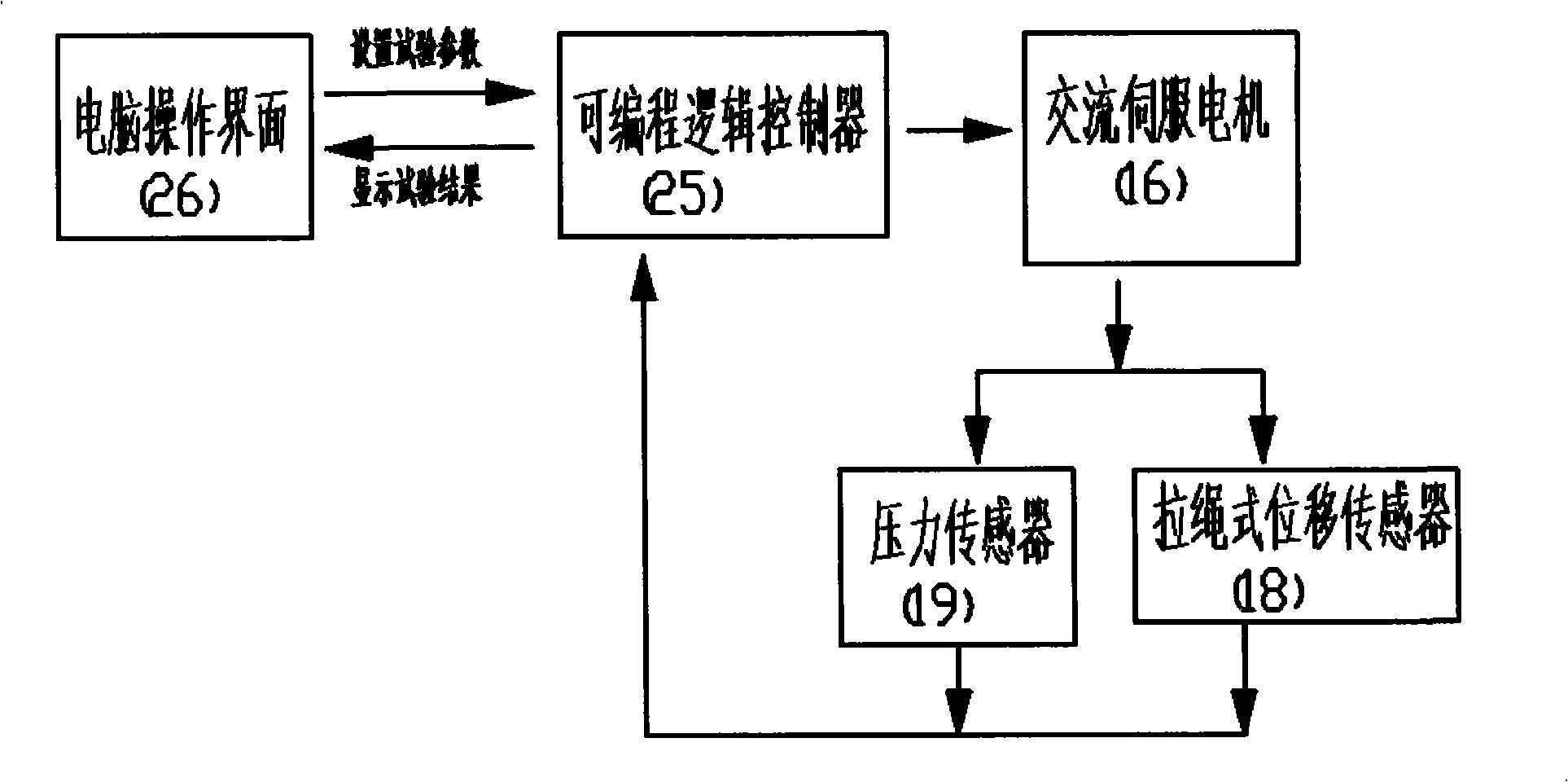

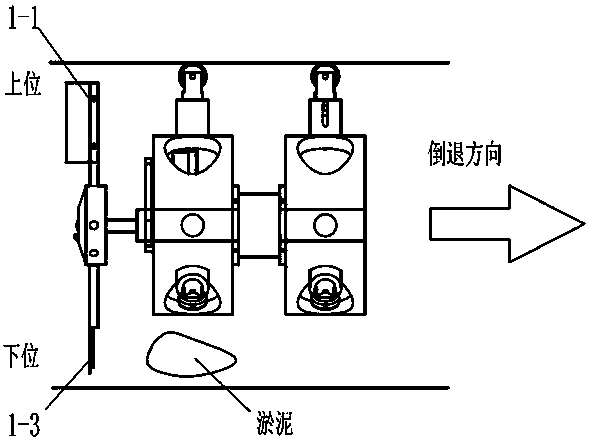

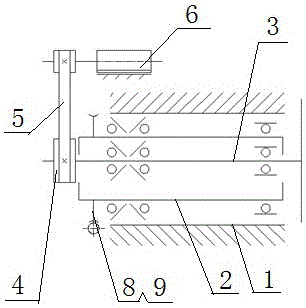

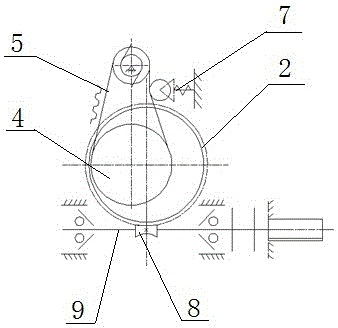

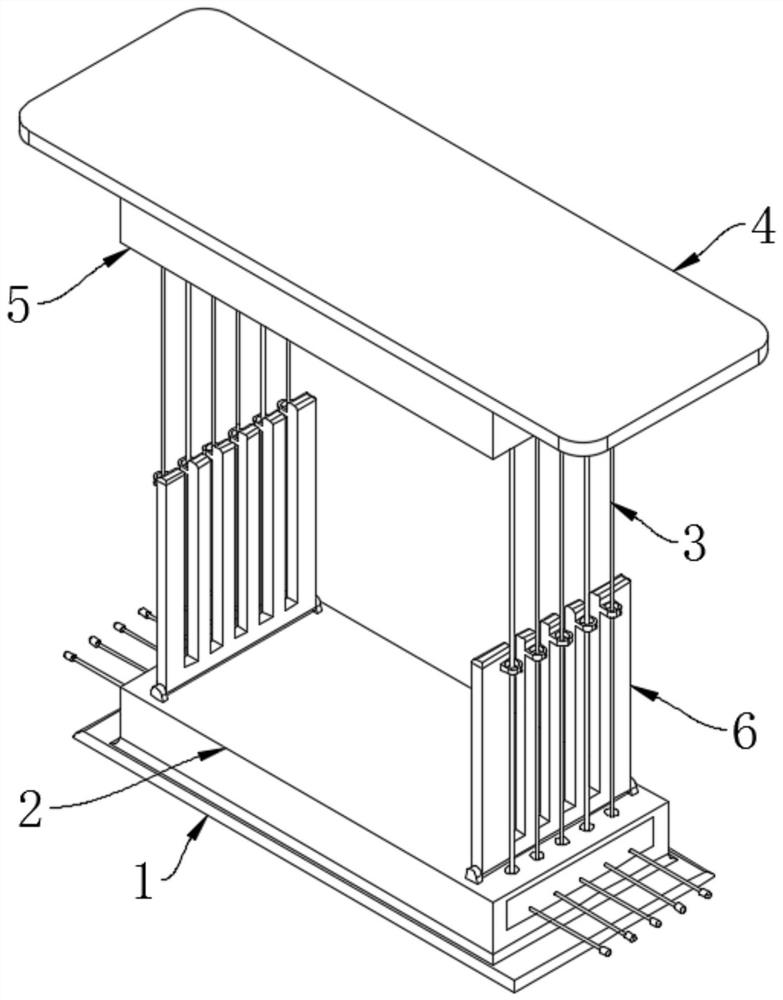

Torque loading tester and controlling system thereof

InactiveCN101526435ARealize position controlFor precise controlStructural/machines measurementProgramme control in sequence/logic controllersClosed loopStatic strength

The invention relates to a novel multifunctional torque loading tester and a controlling system thereof. The tester comprises a bottom board, a left upright post and a right upright post vertically fixed on the bottom board, and an upper cross beam fixed on top ends of the left upright post and the right upright post. Both ends of a middle crossbeam respectively support a left screw and a right screw in the left upright post and the right upright post. An electric motor fixed on the upper cross beam is used for driving the middle cross beam to upwardly and downwardly move through a transmission mechanism of upward and downward movement. One end of the middle cross beam is provided with a hand wheel driving the middle cross beam to rotate in the range from 0 to 180 DEG by a turbine-worm rotating and transmitting mechanism. The middle cross beam is provided with an air cylinder loader and a servomotor loader. The controlling system of the tester is as follows: the air cylinder loader is connected with a pneumatic servo closed-loop controlling system, and the servomotor loader is connected with servomotor closed-loop controlling system. The invention can realize position control, speed control and torque control on the detected product, and the accurate control and detection of the position-change amount and the static strength of the detected product required by the standard, can be conveniently operated on a control panel and a computer, and can realize the detection of a plurality of items.

Owner:SHANGHAI UNIV +1

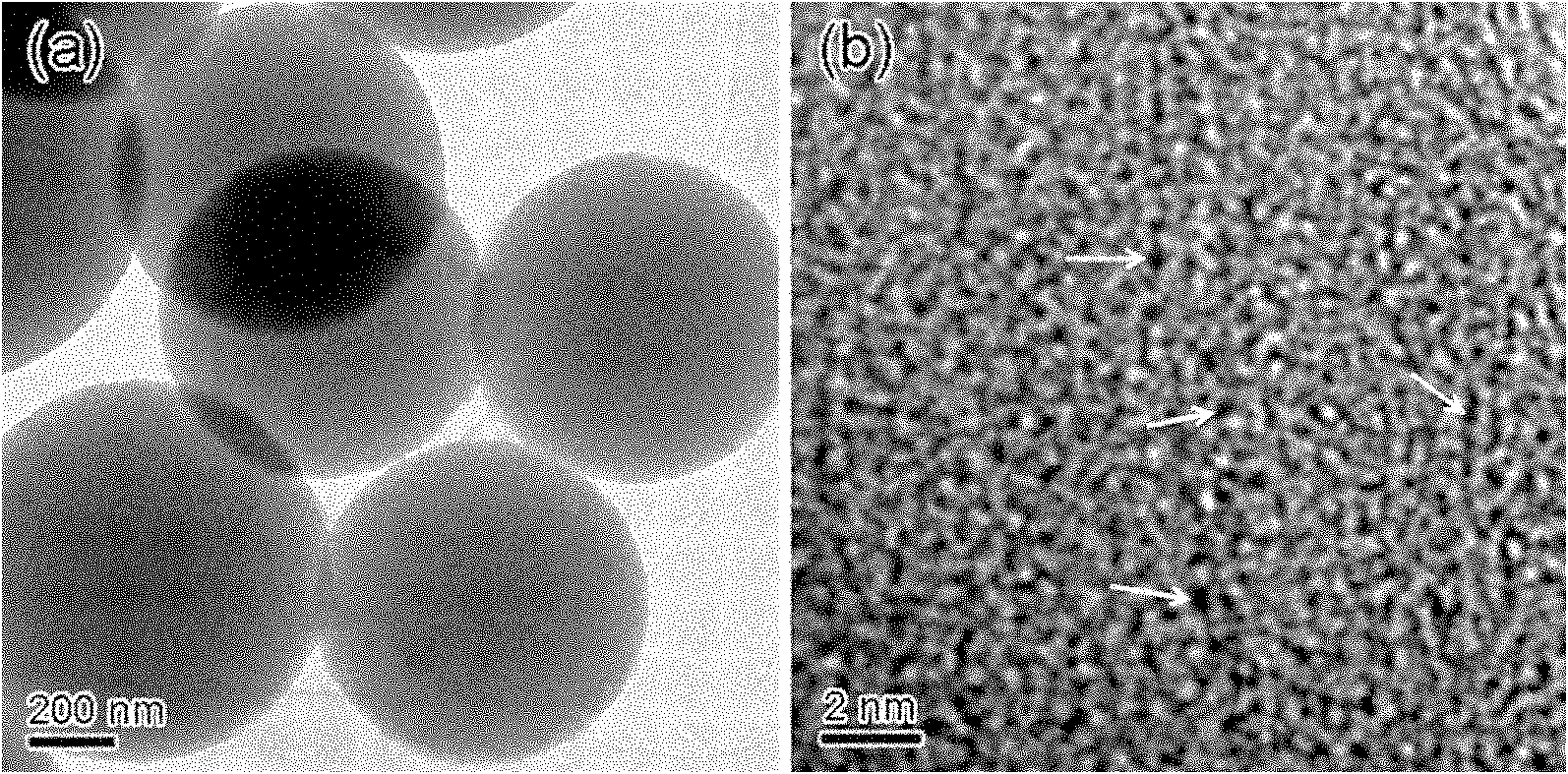

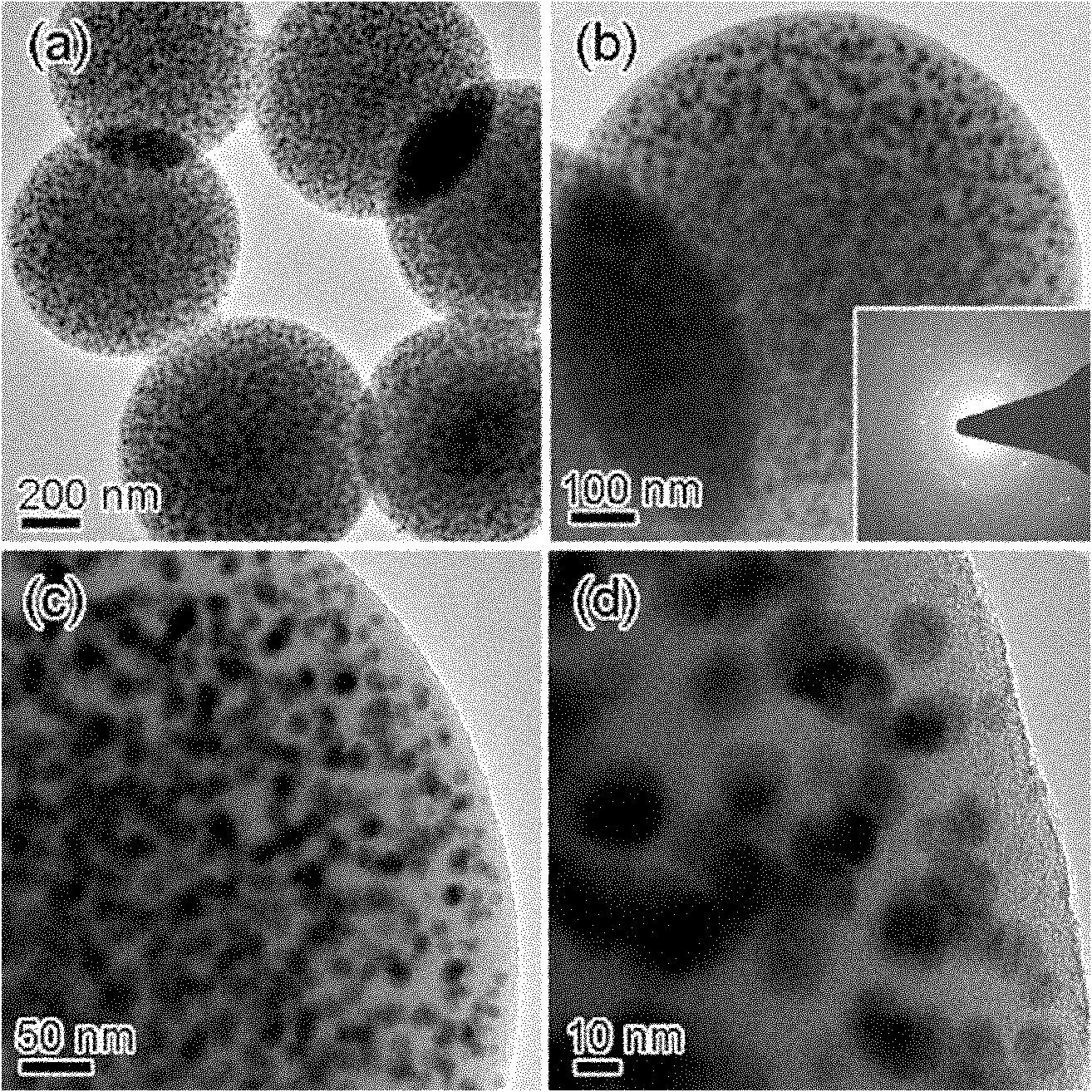

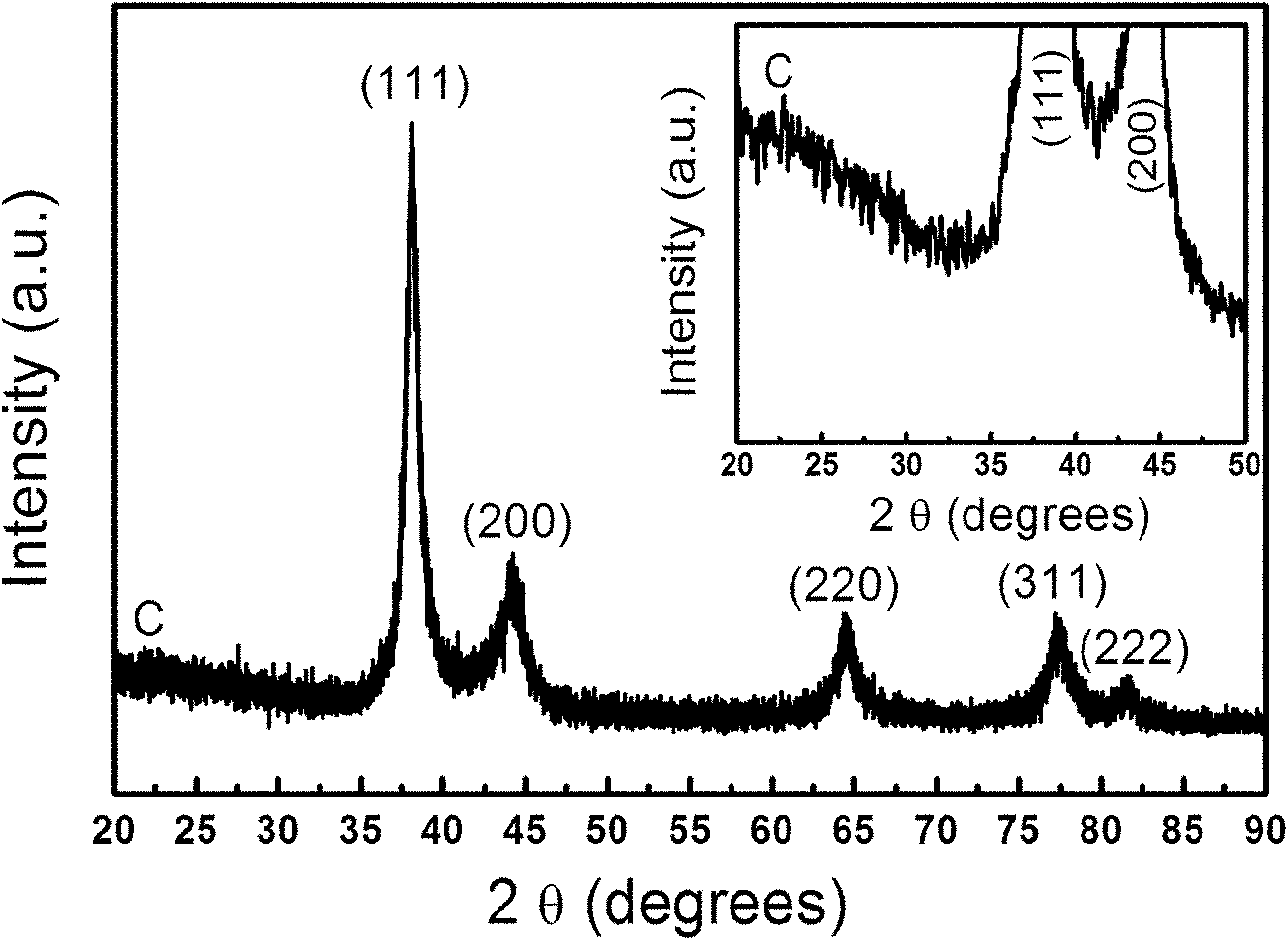

Silver nanoparticle filled microporous carbon spheres, preparation method thereof and use thereof as catalyst

InactiveCN101934376AGood monodispersityEvenly distributedOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsMicrowavePore diameter

The invention relates to a method for preparing silver nanoparticle filled microporous carbon spheres, which can realize uniform nanoparticle filling of the microporous carbon spheres. The invention also provides the silver nanoparticle filled microporous carbon spheres and use thereof as a catalyst. The preparation method comprises the following steps of: adding 0.2 to 0.3g of microporous carbonspheres into 20 to 100ml of 0.2 to 2.5mM ammonical silver solution for soaking; adding a reducing agent into the soaked microporous carbon sphere suspension; and heating by using microwaves for 2 to 10 minutes to reduce ammonical silver ions to obtain the silver nanoparticle filled microporous carbon spheres. The silver nanoparticle filled microporous carbon spheres can be used as a catalyst. The obtained silver nanoparticle filled microporous carbon spheres have the submicron-scale diameter and the pore diameter of less than 2nm; and the filled silver in a form of monodispersed spherical nanoparticles is uniformly dispersed in the microporous carbon spheres, has the controllable diameter in a range of 2 to 50nm, and accounts for 10 to 56 weight percent of silver nanoparticle filled microporous carbon spheres.

Owner:NANJING UNIV

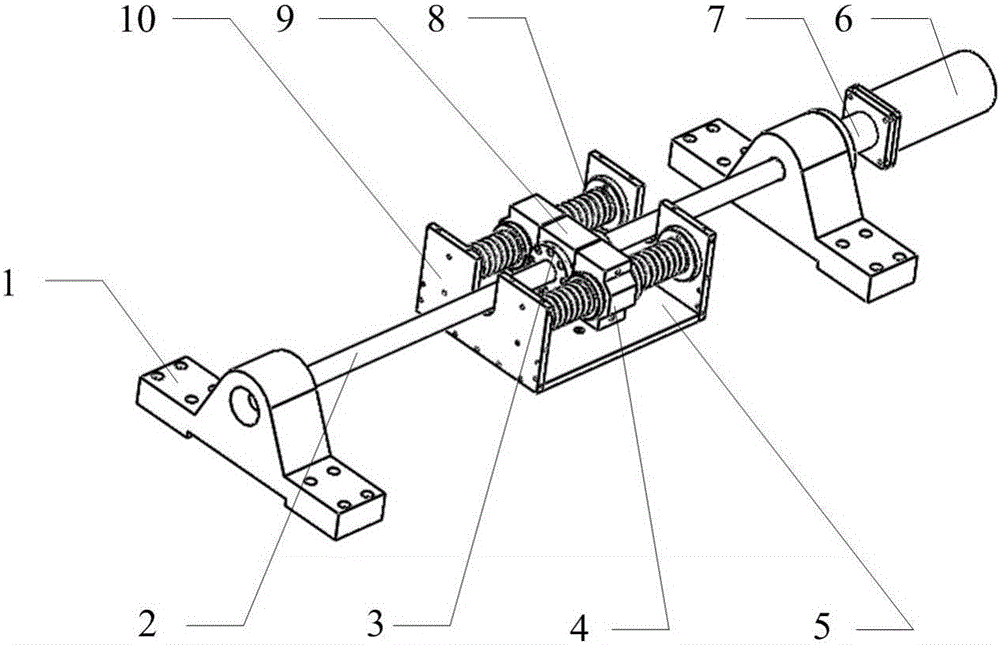

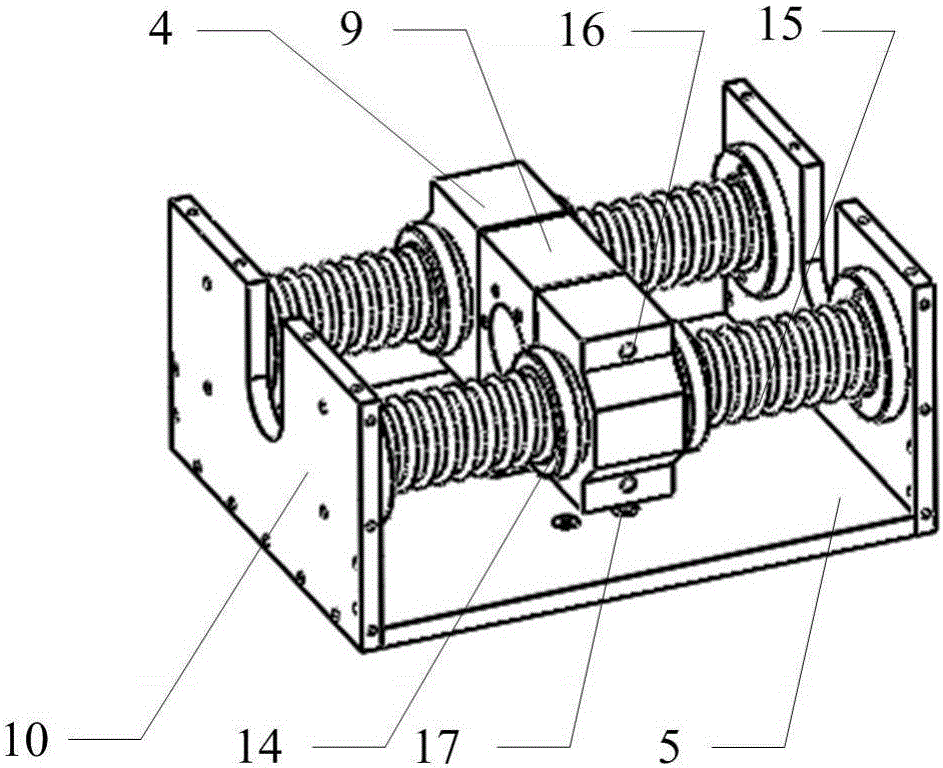

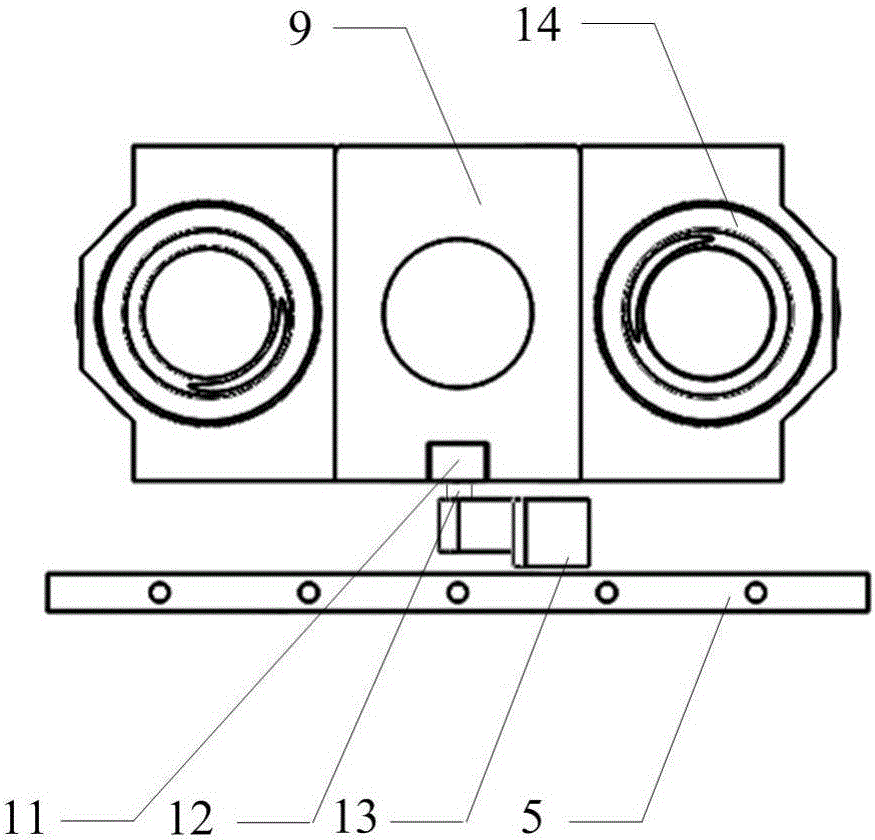

Force/position controllable flexible driver

ActiveCN106181995AAvoid "suffocation" phenomenonInternal force reliefProgramme-controlled manipulatorOptical axisEngineering

Provided is a force / position controllable flexible driver. Polished shafts on the two sides of a sliding bearing of a drive device are each sleeved with springs of a flexible detection device. The other end of a grating ruler of the flexible detection device is connected with a power output plate of a drive output device. A lead screw of the drive device is arranged in a groove in a baffle of the drive output device. The other end of the spring is embedded in the groove in the inner wall of the baffle of the corresponding drive output device. On the basis that a redundant drive parallel-connection mechanism has no internal force motion, both position control and force control over the redundant drive parallel-connection mechanism can be achieved, and accordingly the force / position controllable flexible driver is widely applied to different working places.

Owner:YANSHAN UNIV

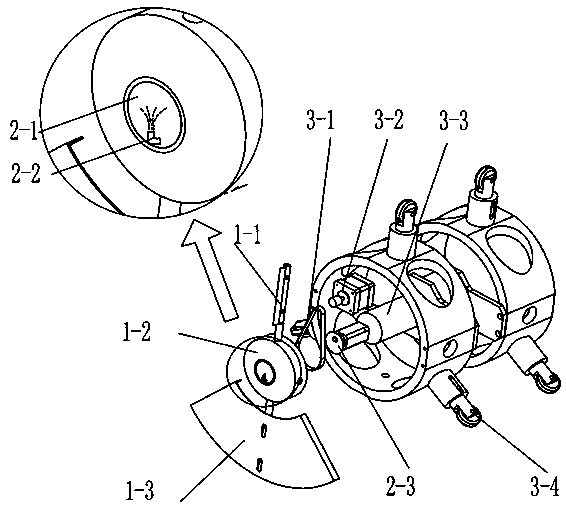

Automatic pipeline robot patrolling and dredging device and method

ActiveCN108266594ARealize position controlImprove cleaning efficiencyPigs/molesMotor driveFree rotation

The invention discloses an automatic pipeline robot patrolling and dredging device. The automatic pipeline robot patrolling and dredging device comprises a dredging unit, a video unit and a patrollingdrive unit. The dredging unit is arranged at the front end of the patrolling drive unit. The video unit is fixed in the dredging unit. The video unit and the patrolling drive unit are coaxially arranged. A sludge scraping cutter set and a sludge retreating cutter set are connected to a hollow disc frame. The hollow disc frame is connected to the patrolling drive unit and can freely rotate aroundthe axis of the patrolling drive unit. A transposition driver is fixed to the patrolling drive unit, a synchronous belt wheel is fixed to the hollow disc frame, and a synchronous belt is arranged between the transposition driver and the synchronous belt wheel. Through vision detection of a camera and the action that a stepping motor drives the sludge scraping cutter set and the sludge retreating cutter set to coordinate and cooperate, one stepping motor can control the positions of the sludge scraping cutter set and the sludge retreating cutter set, and the pipeline cleaning efficiency and thepipeline cleaning accuracy are improved; and patrolling, sludge scraping and sludge retreating functions are integrated, and pertinence and adaptability to the pipeline environment are improved.

Owner:CHINA UNIV OF MINING & TECH

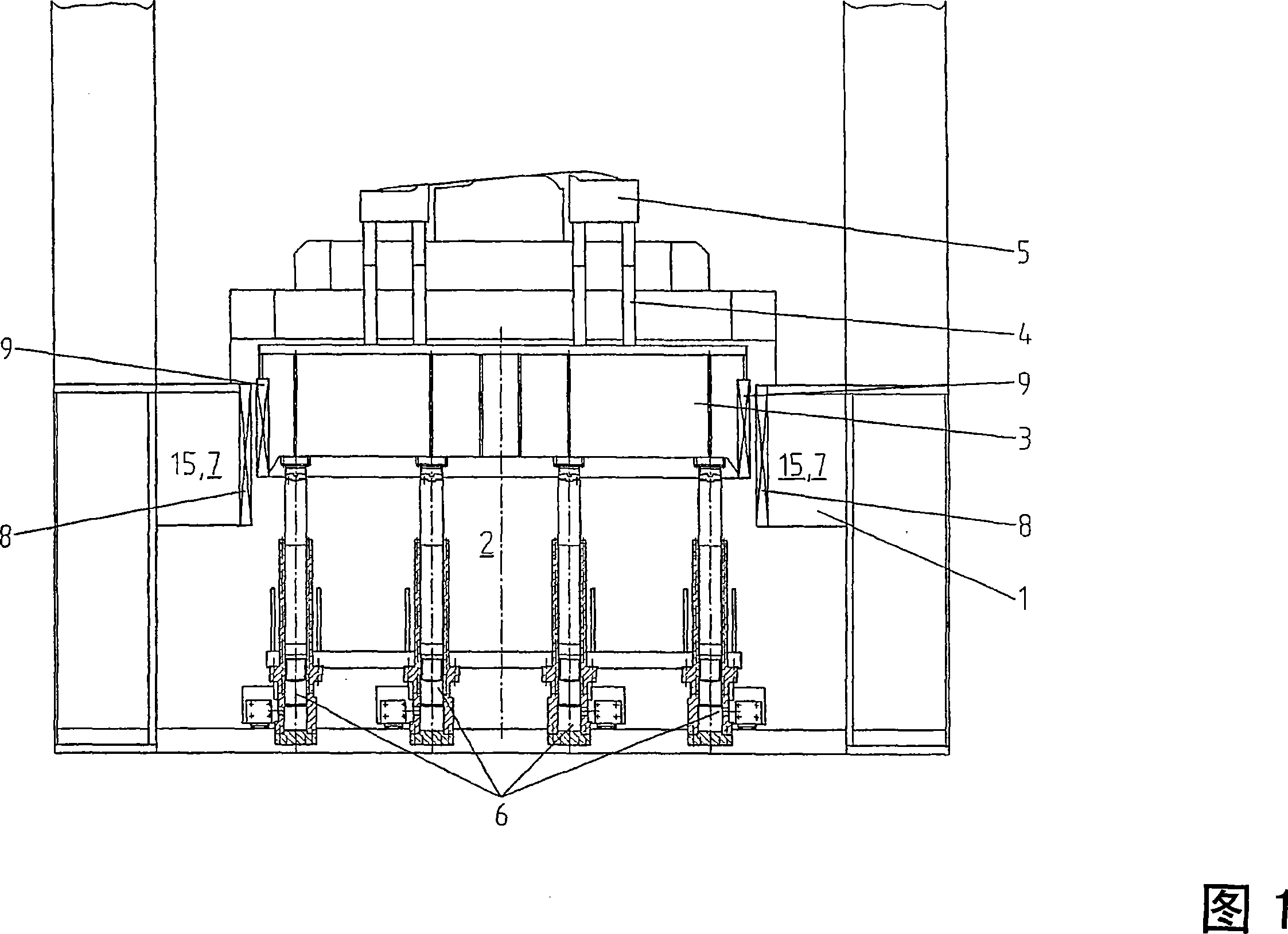

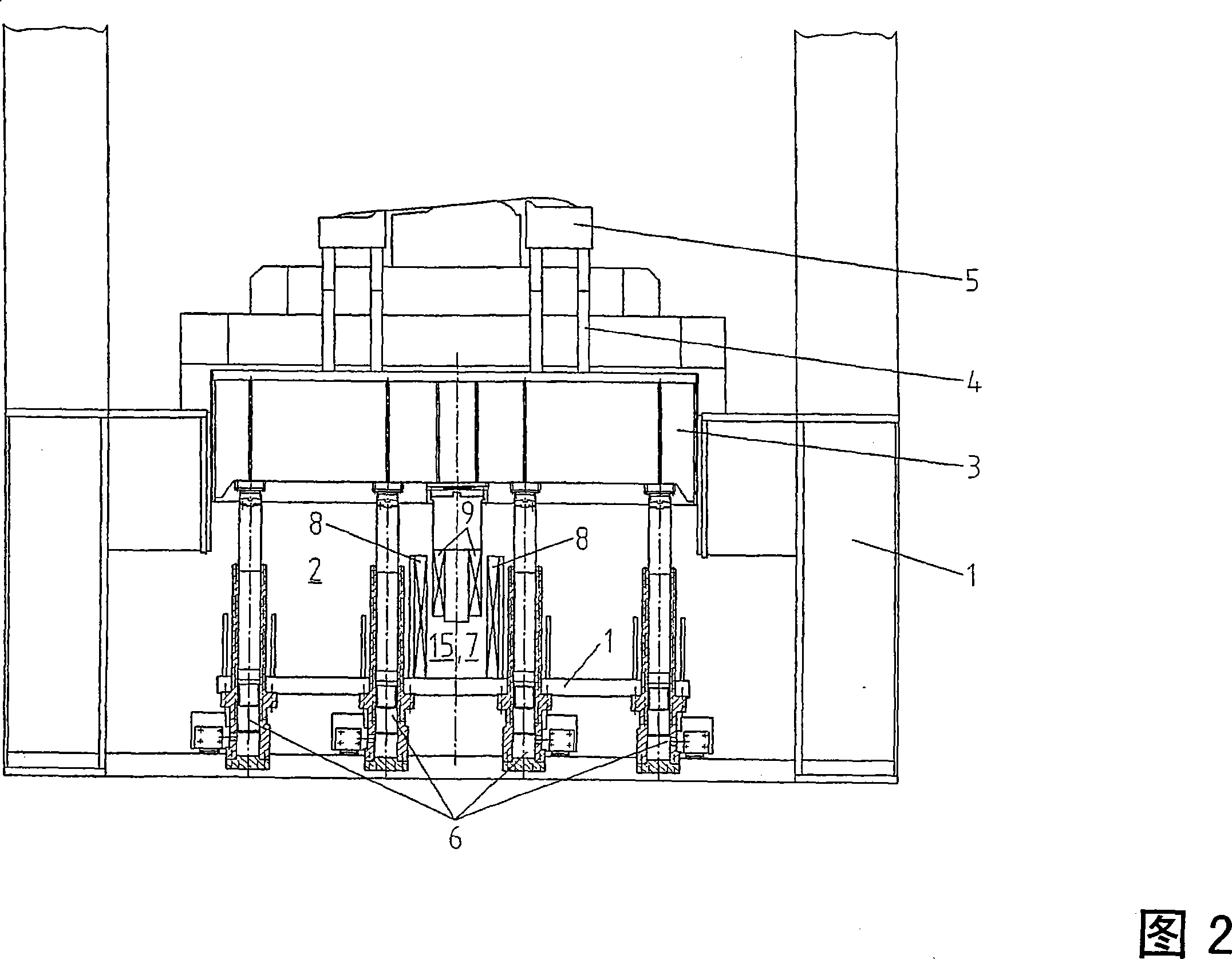

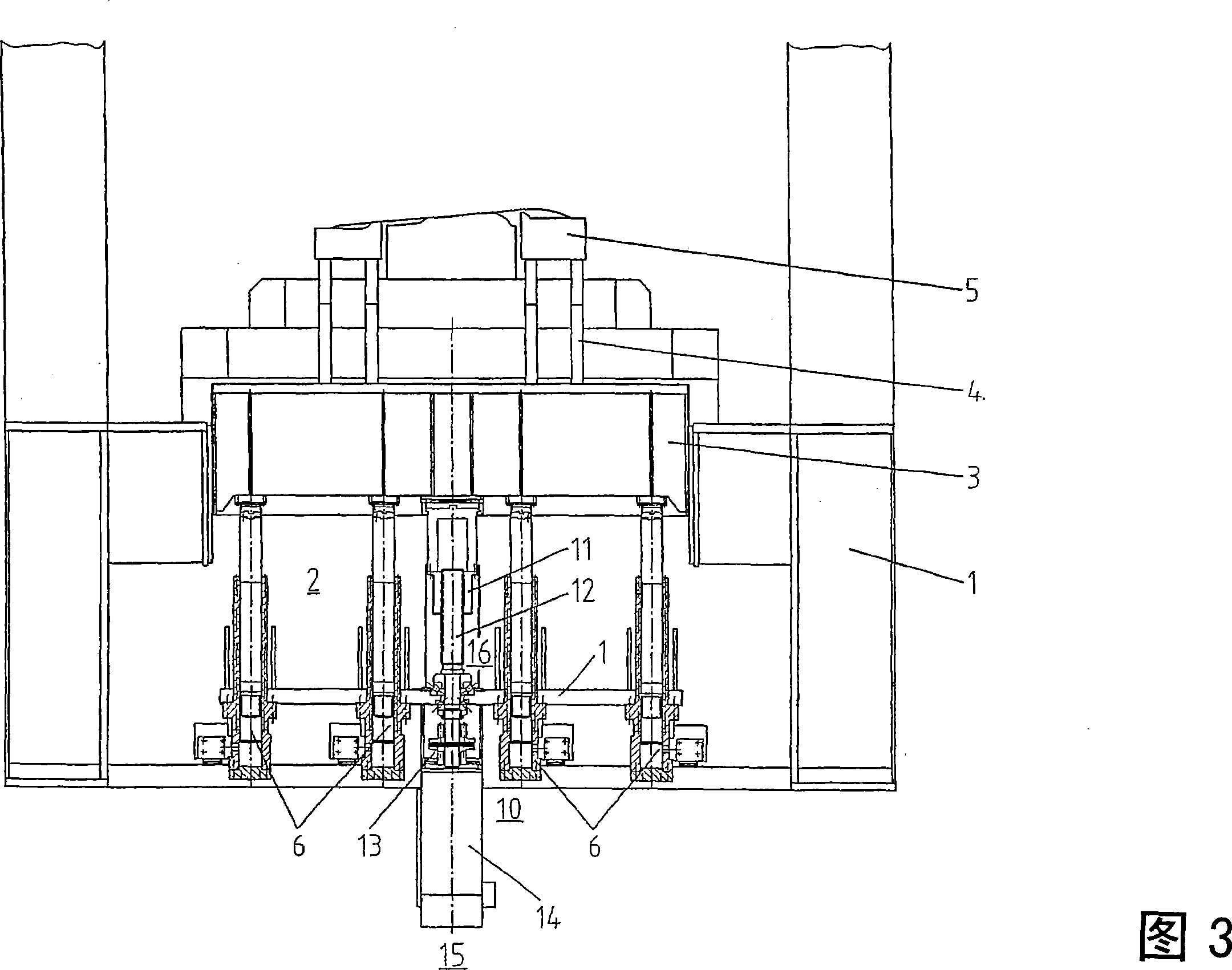

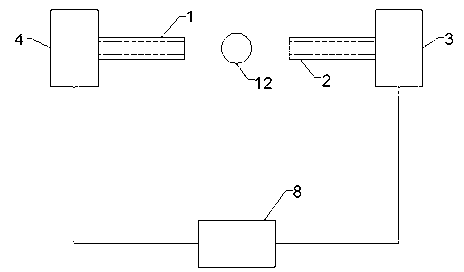

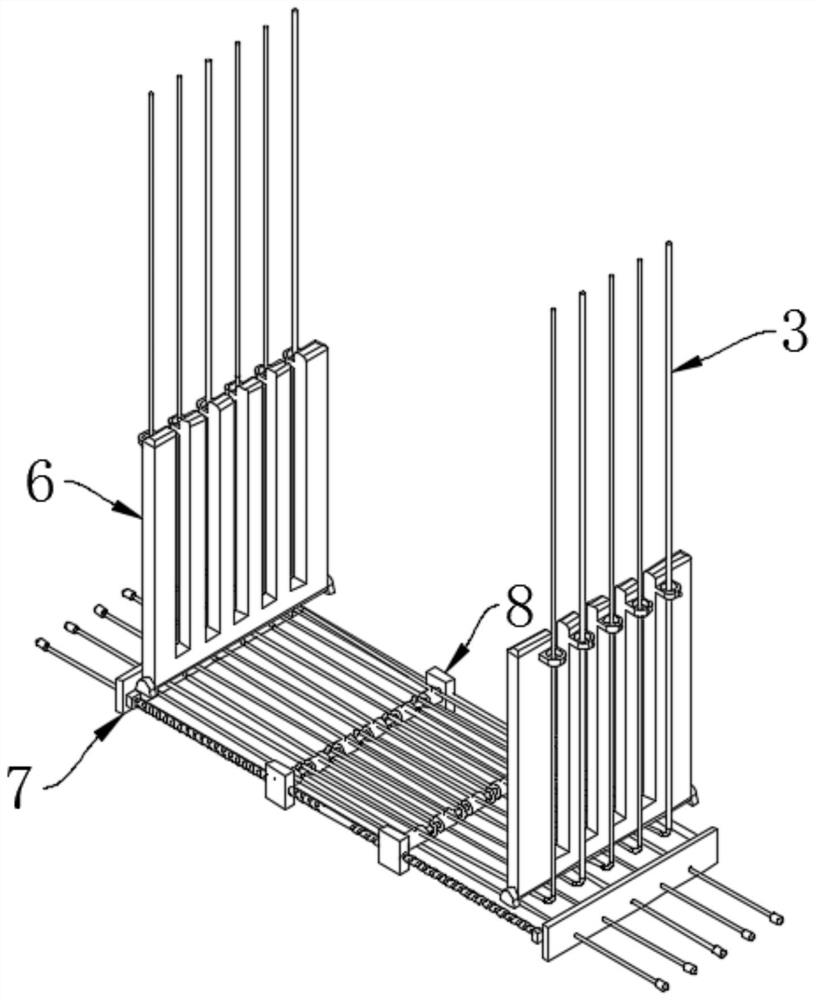

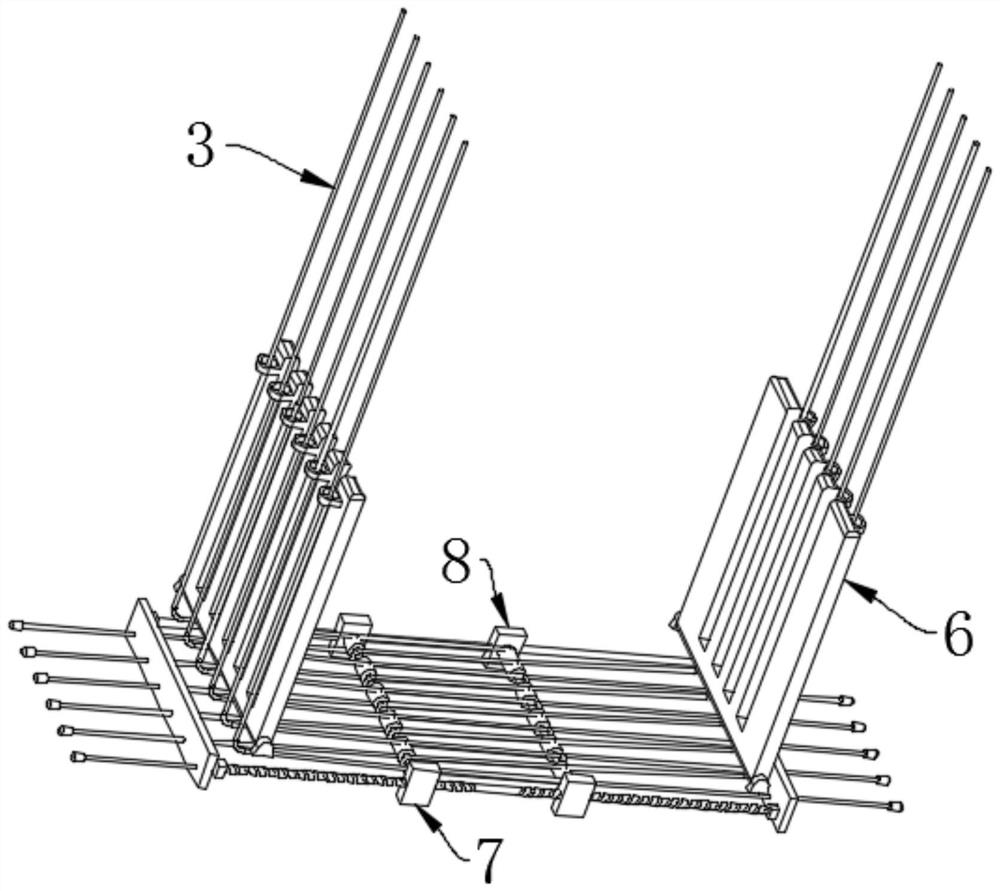

Hybrid drawing cushion facility

The invention relates to a hybrid drawing cushion facility which comprises a combination of fluid cylinders (6) and one or more electric drives (7, 15) acting upon the pressure box (3). The fluid cylinders (6) perform the force function on a high level and the electric drives (7, 15) perform the path function, such as pre-acceleration and run-up, and the force function on a low level when the fluid cylinders (6) are deactivated.

Owner:MASCHFAB MULLER WEINGARTEN AG

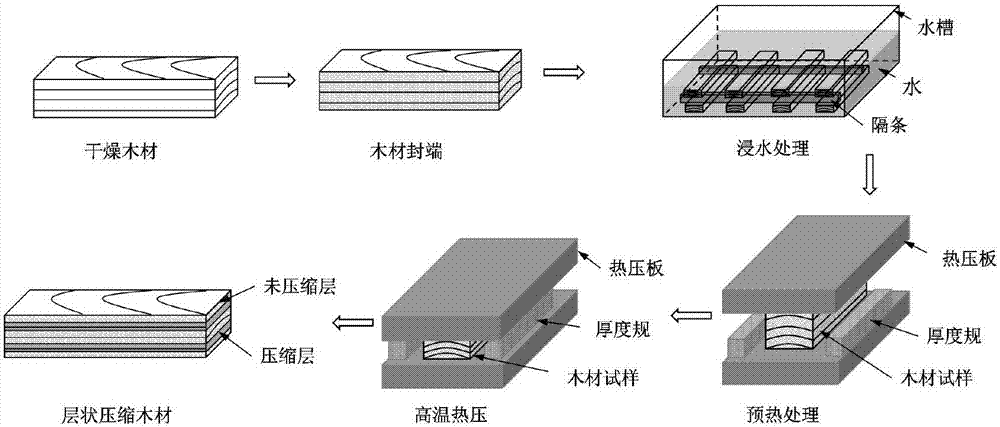

Continuous production method for laminated compression wood

InactiveCN107414981AEnables selective directional densificationImprove performance pricePlywood pressesLaminationEconomic benefitsPulp and paper industry

The invention discloses a continuous production method for laminated compression wood. The method comprises the following specific steps that 1, log is sawn into wood, and then the wood is dried, wherein the moisture content of the dried wood is lower than 20%; 2, the wood is immersed into water to be soaked, and the soaked wood is taken out and placed; 3, the wood is laid out on a hot pressing plate of a hot pressing machine, and the hot pressing machine is rapidly closed to conduct pre-heating treatment on the wood; 4, after pre-heating treatment is conducted, compression treatment of the hot pressing machine is started, wherein the compression speed ranges from 0.05 mm / s to 5 mm / s; and 5, pressure maintaining treatment is conducted, cooling treatment is conducted after pressure maintaining treatment is conducted, and then the laminated compression wood is obtained, wherein the pressure maintaining time is longer than 1 min. According to the continuous production method for the laminated compression wood, the product performance of the laminated compression wood is greatly improved, industrialized production of a laminated compression technology is achieved, and the production efficiency and economic benefit of the compression wood are significantly improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

On-line quenching production technique for high toughness thick steel plate

InactiveCN101215624BRealize different cooling speed controlImproved uneven coolingFurnace typesHeat treatment furnacesProduction lineSheet steel

A press quenching manufacturing technique process of high strength and ductility thick steel plate belongs to low alloying steel manufacturing technique field, which comprises heating up steel billet to 1100 DEG C to 1250 DEG C, rolling steel plate through two stages of austenite recrystallization zone and non recrystallization zone with 860 DEG C to 950 DEG C of final rolling temperature, realizing steel plate press quenching through adopting two cooling ways of aerial fog and water-curtain with 25-45 DEG C / s of average cooling speed in cooling region, stopping the quenching when temperaturereduced to 150 DEG C to 300 DEG C, and drawing the steel plate after quenched under high temperature. The invention overcomes the weaknesses of long productive cycle of current modified treatment method, high cost and unfavorable stability of high strength and ductility steel plate property which is manufactured by TMCP technique, and can manufacture 20mm-50mm high strength and high ductility steel plate with stable property. And the invention has the advantages of short production line and low energy consumption, which can be extensively applied to manufacture steel plate which is needed in the industries of metallurgy, petrifaction, hydroelectricity and marine and the like.

Owner:SHANDONG IRON & STEEL CO LTD

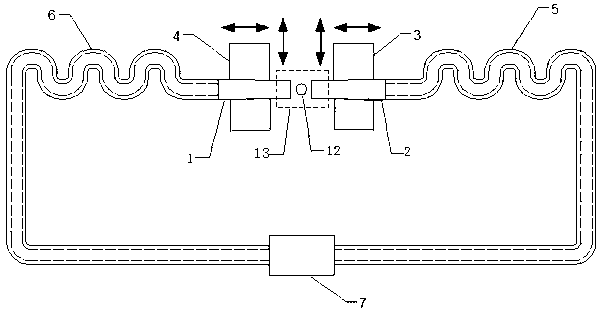

Single-cell clamping method and single-cell position regulating device

InactiveCN103131664ARealize position controlRealize the clamping effectBioreactor/fermenter combinationsBiological substance pretreatmentsFluid viscosityControl cell

The invention provides a single-cell clamping method and a single-cell position regulating device. The method is that in the regulating operation process of cells, fluid pressure and fluid viscosity force between clamping tubes are used for clamping the cells, the cells are wrapped and clamped to move in a non-contacting mode through the movement of the clamping tubes, and so that the position regulation of the cells is achieved. The device comprises two cell clamping tubes, two soft micro tubes, a control unit and a micropump unit which supplies the needed flow to the cell clamping tubes. Each cell clamping tube is connected with the micropump unit through the soft micro tubes, and the two cell clamping tubes are installed on the control unit and are distributed on two sides of the cells. The single-cell clamping method and the single-cell position regulating device can be suitable for the cells with different shapes and different sizes, the three-dimensional position regulation of the cells is achieved, mechanical damage to the cells can be avoided, and the single-cell clamping method and the single-cell position regulating device are beneficial to improving the success rate of cell experiment operation.

Owner:SOUTH CHINA UNIV OF TECH

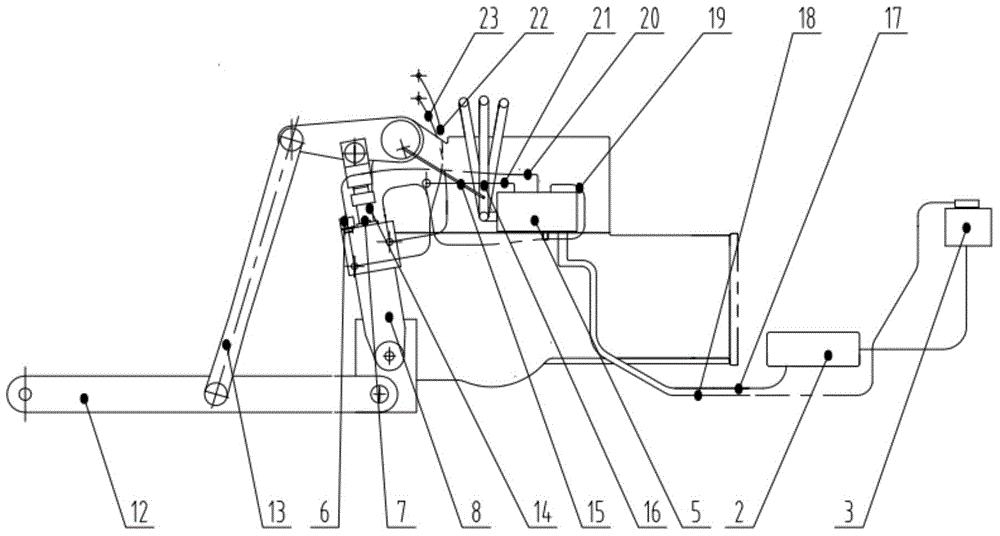

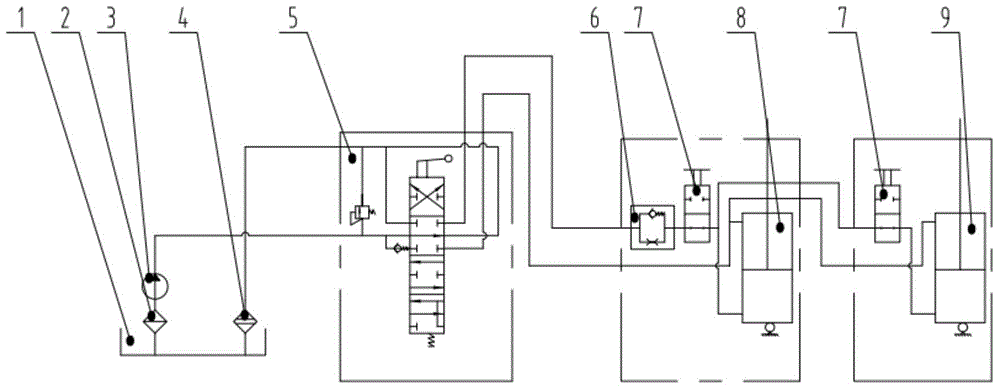

Forced compression device of low power roller tractor

InactiveCN104782258AControlled descent speedImprove protectionAgricultural machinesAdjusting devicesCompression devicePosition control

The invention discloses a forced compression device of a low power roller tractor. The device comprises a lifter, a hydraulic oil cylinder is arranged in the lifter, the lifter is connected with a lifting rod, the lower end of the lifting rod is hinged to a lower link, the device further comprises an oil absorption filter, an oil absorption gear pump, an oil return filter, a floating multiway valve, a right oil cylinder and a left oil cylinder, one end of the oil absorption gear pump is connected to the hydraulic oil cylinder through the oil absorption filter, the other end of the oil absorption gear pump is connected with the inlet path of the floating multiway valve, the floating multiway valve is connected with the right oil cylinder and the left oil cylinder in sequence, the upper end of the right oil cylinder and the upper end of the left oil cylinder are both hinged to the lifting rod, a loop of the floating multiway valve is connected to the hydraulic oil cylinder through the oil return filter, a position control operation handle is further installed on the lifter, and the operation handle is connected with the floating multiway valve through a Q-shaped support. By means of the device, the problems that it is difficult for the low power roller tractor to break ground in hard soil, and the ploughing depth is shallow are solved.

Owner:SHANDONG CHANGLIN DEUTZ FAHR MACHINERY

Hair drier motor and hair drier

The invention relates to the technical field of hair driers and particularly relates to a hair drier motor adopting a magnetic bearing. The hair drier motor comprises a stator and a rotor, wherein the rotor comprises a rotor permanent magnet and a rotor shaft; the rotor shaft is sleeved with at least one radial magnetic bearing and at least one axial magnetic bearing; the rotor permanent magnet is arranged at the end part close to the rotor shaft; the radial magnetic bearing and the axial magnetic bearing are arranged at one end, extending outwardly from the rotor permanent magnet, of the rotor shaft; a groove is arranged in the axial magnetic bearing; the rotor shaft is provided with a bulge accommodated in the groove; and through match between the groove and the bulge, deflection of the rotor shaft along the axial direction is limited. The hair drier comprises the hair drier motor. According to the hair drier motor and the hair drier, the problem that the rotation speed can not be improved when the existing motor suffers from bearing limitations can be solved, the operation is reliable, the service life is greatly prolonged, and the working efficiency is improved.

Owner:KINGCLEAN ELECTRIC

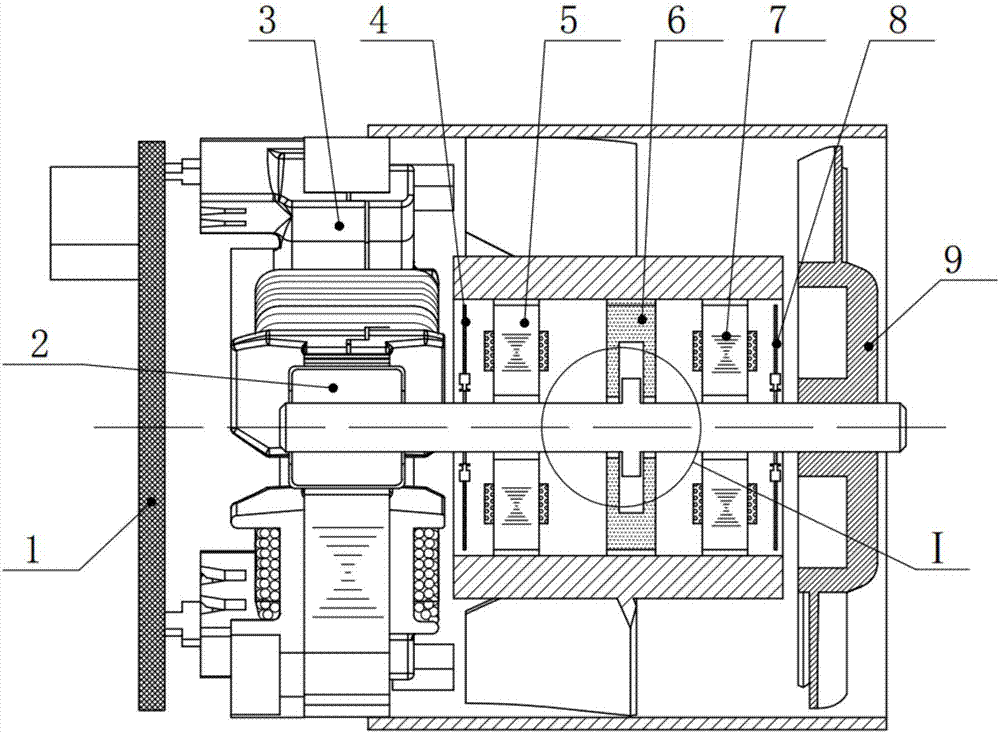

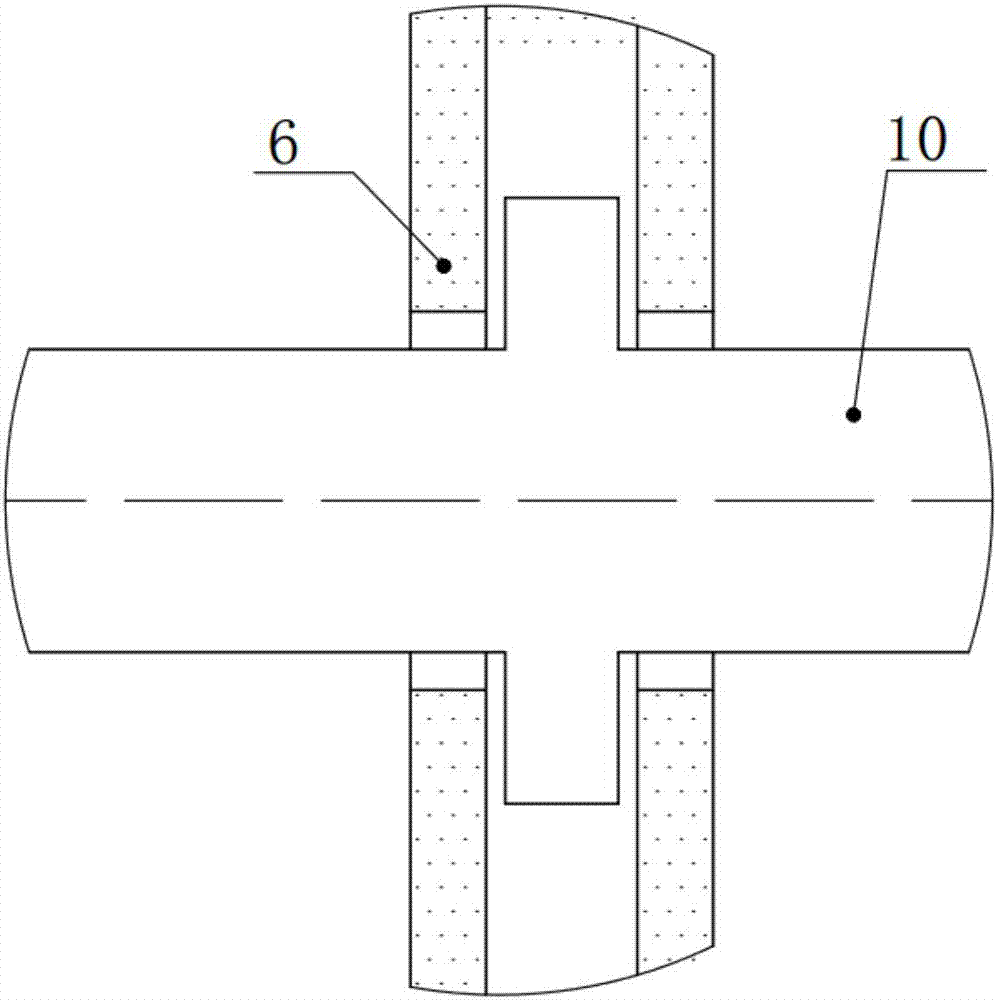

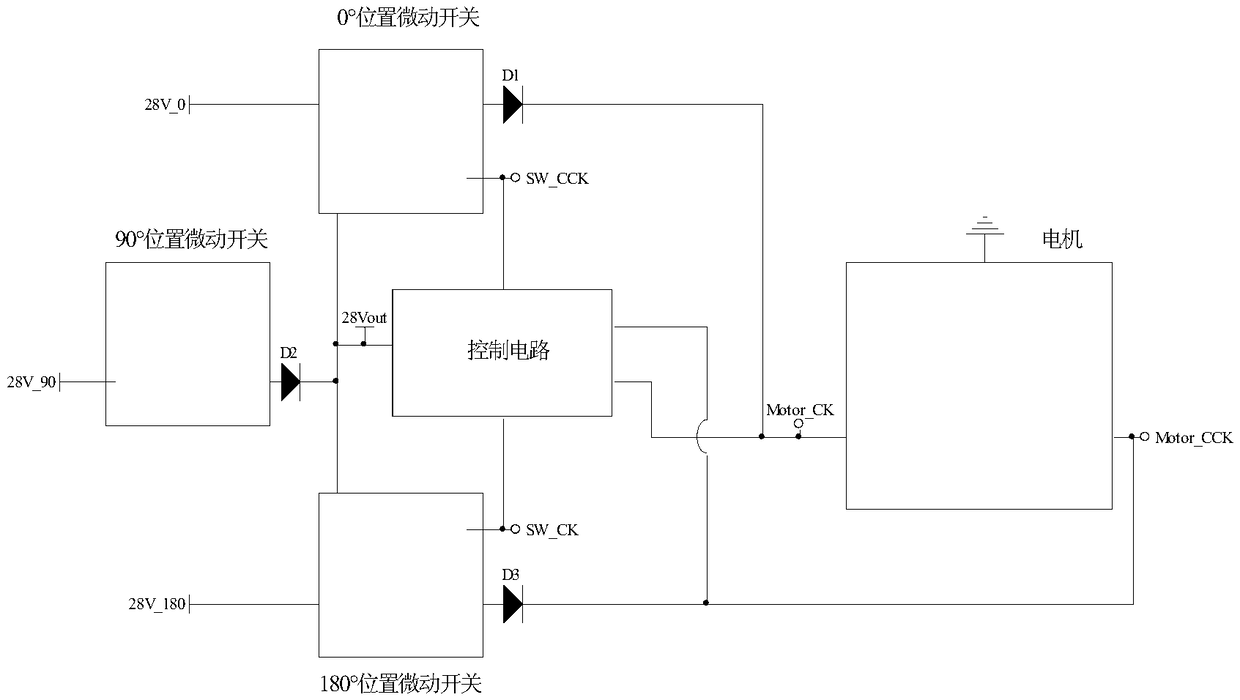

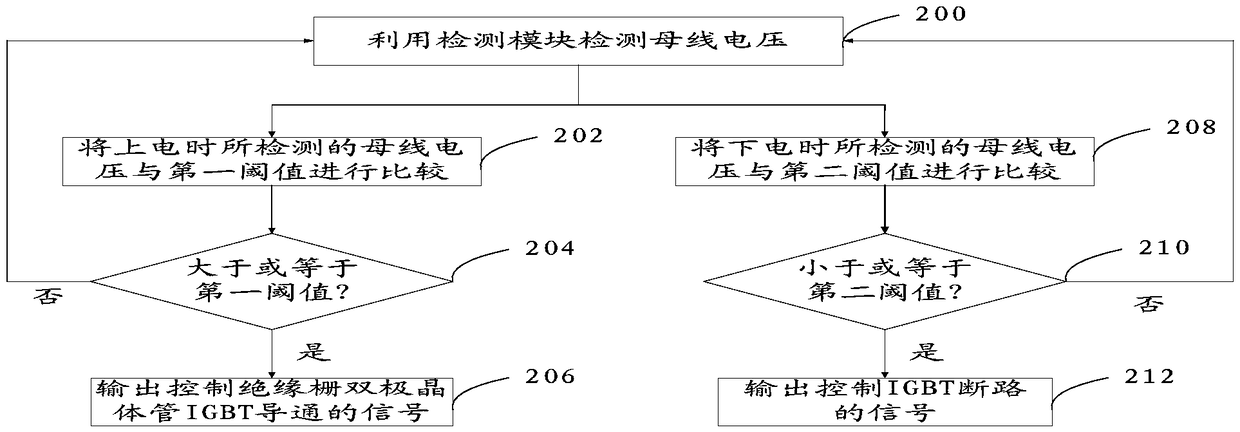

A control system and method of a three-position electric mechanism

ActiveCN109194211ARealize position controlAvoid administrative costsDC motor rotation controlControl systemEngineering

The invention provides a control system and control method of a three-position electric mechanism. The control method adopts a pure hardware mode to realize the three-position control of the mechanism. The control system comprises a control circuit, a microswitch and a DC motor. The motor output shaft drives the mechanism to rotate in the range of 0-90DEG-180DEG. It is required that the six working modes of 0-90DEG, 90 DEG-180 DEG, 0-180 DEG, 90 DEG-0, 180 DEG-90 DEG and 180 DEG-0 DEG can rotate normally. When 28V_0 power is supplied to the system, the electric mechanism shall be rotated fromany current position to 0 DEG position, from 0 DEG or 180 DEG position to 90 DEG position when the system is powered on 28V_90, and from any current position to 180 DEG position when the system is powered on 28V_180. Thus, the invention not only realizes the three-position control of the mechanism, but also adopts the pure hardware control method, avoiding the design and management cost brought bythe software control, realizes the three-position control of the mechanism by the method, and can effectively reduce the cost and complexity of the system.

Owner:BEIJING POWER MACHINERY INST

Variable-stiffness driving and controlling integrated robot rotary joint module

PendingCN109551480ARealize torque controlAchieve compliant controlProgramme-controlled manipulatorJointsVariable stiffnessElectricity

The invention relates to a variable-stiffness driving and controlling integrated robot rotary joint module. The variable-stiffness driving and controlling integrated robot rotary joint module comprises a joint shell, a joint output rotary disc, a drive controller, a transmission mechanism, a torque sensor, a variable-stiffness module, a first encoder and a second encoder; the transmission mechanism comprises a frameless motor, a transmission shaft and a harmonic reducer, the frameless motor includes a stator and a rotor, the stator is fixed in the joint shell, the transmission shaft is connected with the rotor in a matched manner, and one end of the transmission shaft is connected with a wave generator of the harmonic reducer; a steel wheel of the harmonic reducer is fixedly connected withone end of the variable-stiffness module, and the other end of the variable-stiffness module is fixedly connected with the joint output rotary disc through the torque sensor; the first encoder is used for measuring angular displacement information of the joint output rotary disc, and the second encoder is used for measuring the angular displacement information of the rotor; and the control end ofthe frameless motor is electrically connected to the drive controller, and the torque sensor, the first encoder and the second encoder are electrically connected to the drive controller. By means ofthe variable-stiffness driving and controlling integrated robot rotary joint module, rigidity control and torque output control of the joint module are achieved.

Owner:GUANGDONG UNIV OF TECH

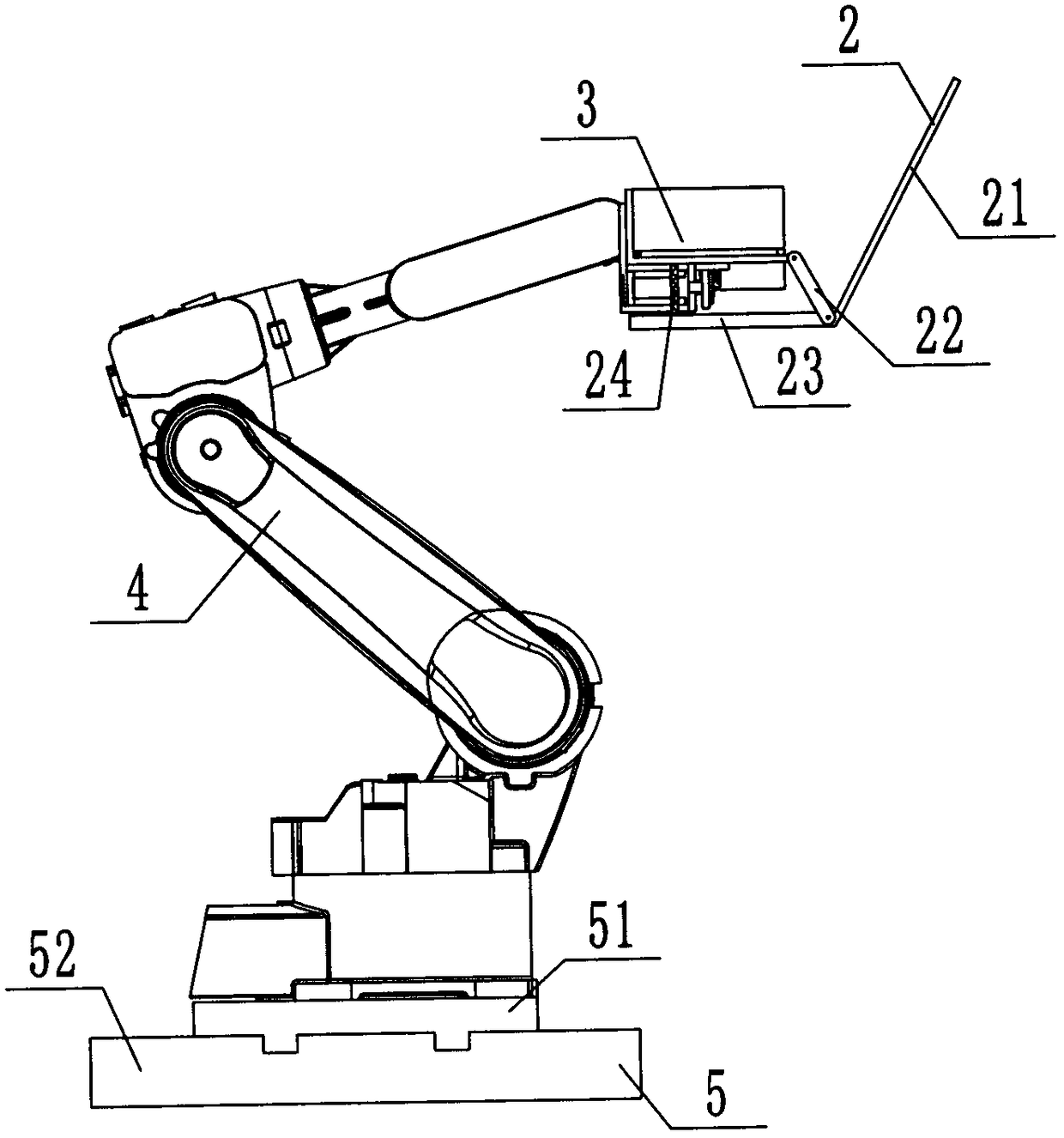

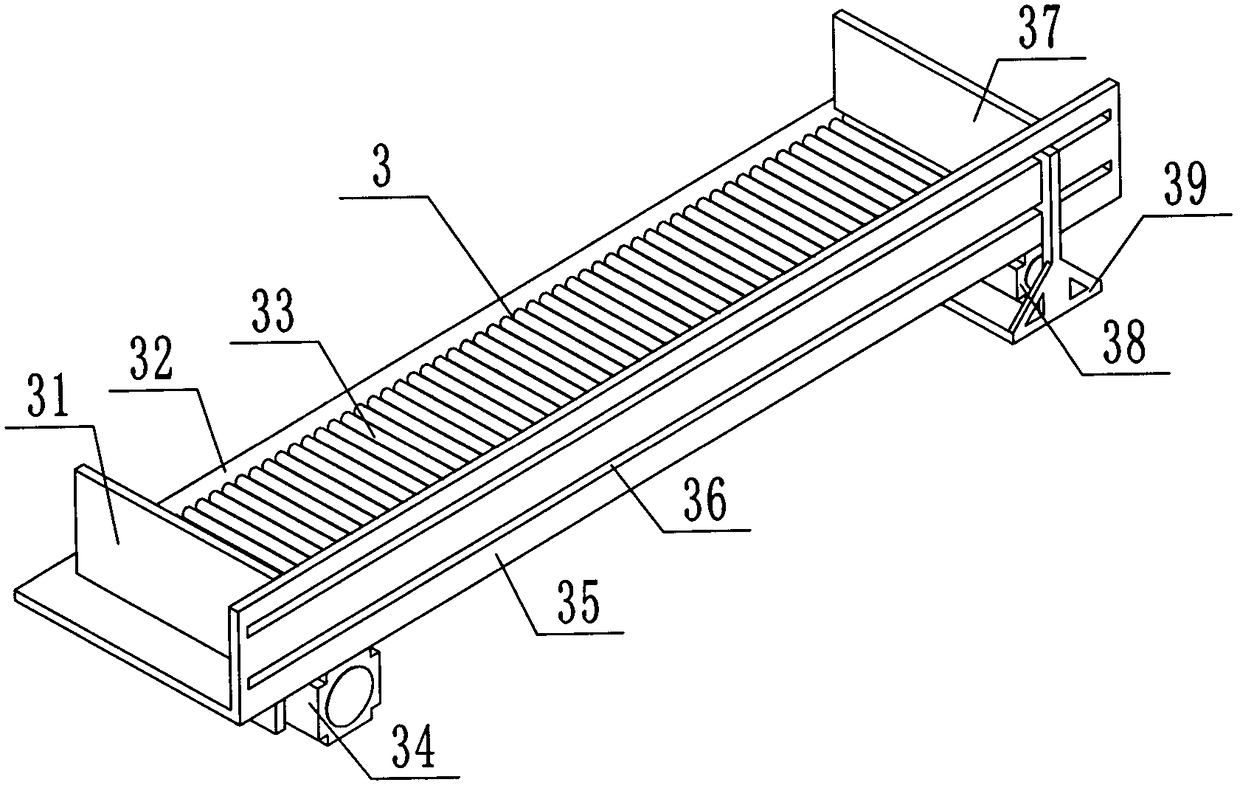

A robot that automatically picks up eggs

InactiveCN105145407BRealize automatic pickingSave manpower and material resourcesBird housingsEngineeringSlide plate

The invention provides a robot capable of automatically picking up eggs and belongs to the field of poultry breeding. The robot comprises a robot body and a motion assembly. The motion assembly comprises a sliding plate and a fixed sliding rail. The robot body is installed on the sliding plate. Sliding rail bodies are arranged on the fixed sliding rail. The robot is characterized by further comprising a square egg barrel assembly and an egg rack assembly; the lower end of the robot body is connected with the motion assembly, and the square egg barrel assembly is arranged at the upper end of the robot body, the egg rack assembly is arranged on a coop. The effect of automatically picking up the eggs can be achieved, and a large quantity of manpower and material resources are saved.

Owner:SHANGHAI ZHONGHONG ELECTRONICS TECH

Single-coordinate small-stroke feeding power box

InactiveCN105108206ACompact structureSmall sizeOther manufacturing equipments/toolsDriving apparatusEngineeringMechanical engineering

The invention provides a single-coordinate small-stroke feeding power box which comprises a power box body arranged on a rack. The power box body is internally provided with an eccentric sleeve, the eccentric sleeve is internally provided with a main shaft, one end of the main shaft is connected with a big belt wheel, and the big belt wheel is connected with a power source through a belt to obtain power. A power rotating drive mechanism is arranged outside the eccentric sleeve, and the power rotating drive mechanism is connected with the outer wall of the eccentric sleeve to drive the eccentric sleeve to rotate. A flexible tension mechanism is further arranged beside the belt and makes contact with the belt to tension the belt. An eccentric sleeve principle is adopted for the single-coordinate small-stroke feeding power box, through the scheme that the eccentric sleeve is driven to rotate to drive the main shaft or a workbench to move, the function of changing the linear movement of the main shaft in the direction of one coordinate into micro rotation in one direction is achieved, and single-link large-speed-ratio transmission combination segmented deviation correction is used, so that the mechanical structure is greatly reduced while mechanism rigidity and movement accuracy in one direction are greatly increased.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

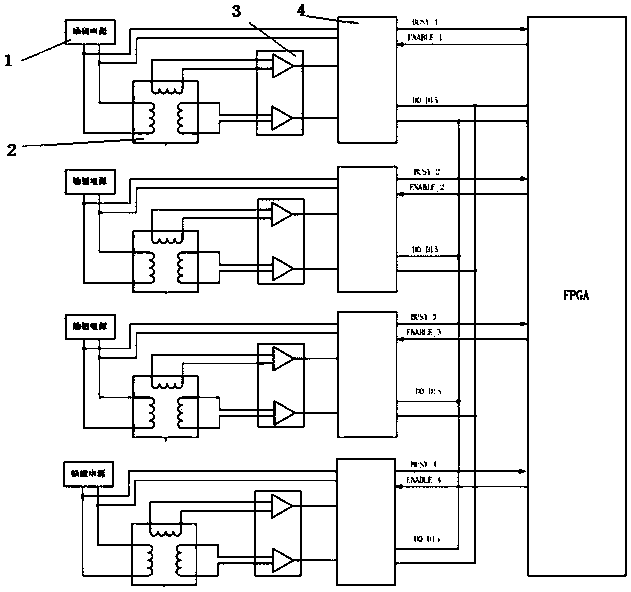

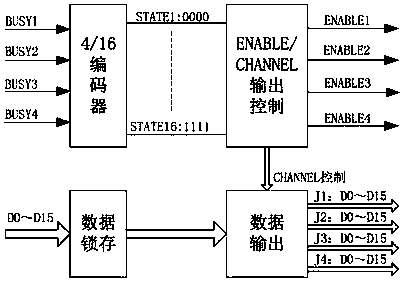

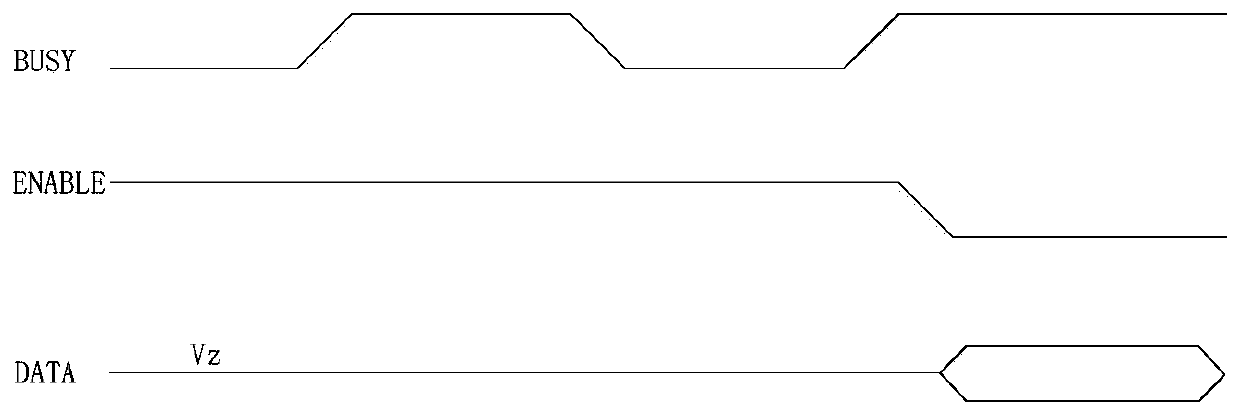

Parallel data acquisition circuit and an automatic acquisition method for a plurality of rotary transformers

ActiveCN109828717AScalableRealize acquisitionAnalogue-digital convertersInput/output processes for data processingField programmable logic devicesData information

The invention discloses a parallel data acquisition circuit and an automatic acquisition method for a plurality of rotary transformers, and relates to an acquisition circuit for data output of a plurality of rotary transformers and an automatic acquisition method for data output. The problem that data transmission speed is low when serial data output is adopted for simultaneously collecting data output of a plurality of rotary transformers is solved. Wherein the acquisition circuit comprises a plurality of excitation power supplies, a plurality of rotary transformers, a plurality of differential filter circuits, a plurality of AD2S80A chips and a field programmable gate array; 16-bit parallel output data of the AD2S80A is hung on the same data bus; The circuit is connected to an IO pin ofa field programmable logic device FPGA. Through automatic acquisition and switching of BUSY and ENABLE signals related to each AD2S80A, multiple 16-bit parallel data information acquisition of independent rotary transformers is realized, and the method is widely applied to the field of multi-axis sensor systems integrated with robot driving and control and multi-channel parallel data conversion needing to be rapidly acquired.

Owner:HARBIN INST OF TECH

Variable-stiffness driving-controlling integrated robot swing rotation joint module

ActiveCN109551481AImprove securityImprove self-protection performanceProgramme-controlled manipulatorJointsElectricityVariable stiffness

A variable-stiffness driving-controlling integrated robot swing rotation joint module comprises a base, a joint output piece, a driving controller, a transmission mechanism, a torque sensor, a variable-stiffness module, a first encoder and a second encoder; the base comprises an installation part and a transmission part; the transmission part is provided with a transmission cavity; the transmission mechanism comprises a frameless motor, a transmission shaft and a harmonic reducer; a stator of the frameless motor is fixed into the transmission cavity, the transmission shaft is connected with the rotor of the frameless motor in a matched mode, one end of the transmission shaft is transmitted to one end of the variable-stiffness module through the harmonic reducer, and the other end of the variable-stiffness module is fixedly connected with the joint output piece through the torque sensor; the first encoder is used for measuring the angular displacement information of the joint output piece, and the second encoder is used for measuring the angular displacement information of a rotor; and the control end of the frameless motor is electrically connected with the driving controller, andthe torque sensor, the first encoder and the second encoder are electrically connected with the driving controller. According to the variable-stiffness driving-controlling integrated robot swing rotation joint module, stiffness control and torque output control of the joint module are achieved.

Owner:GUANGDONG UNIV OF TECH

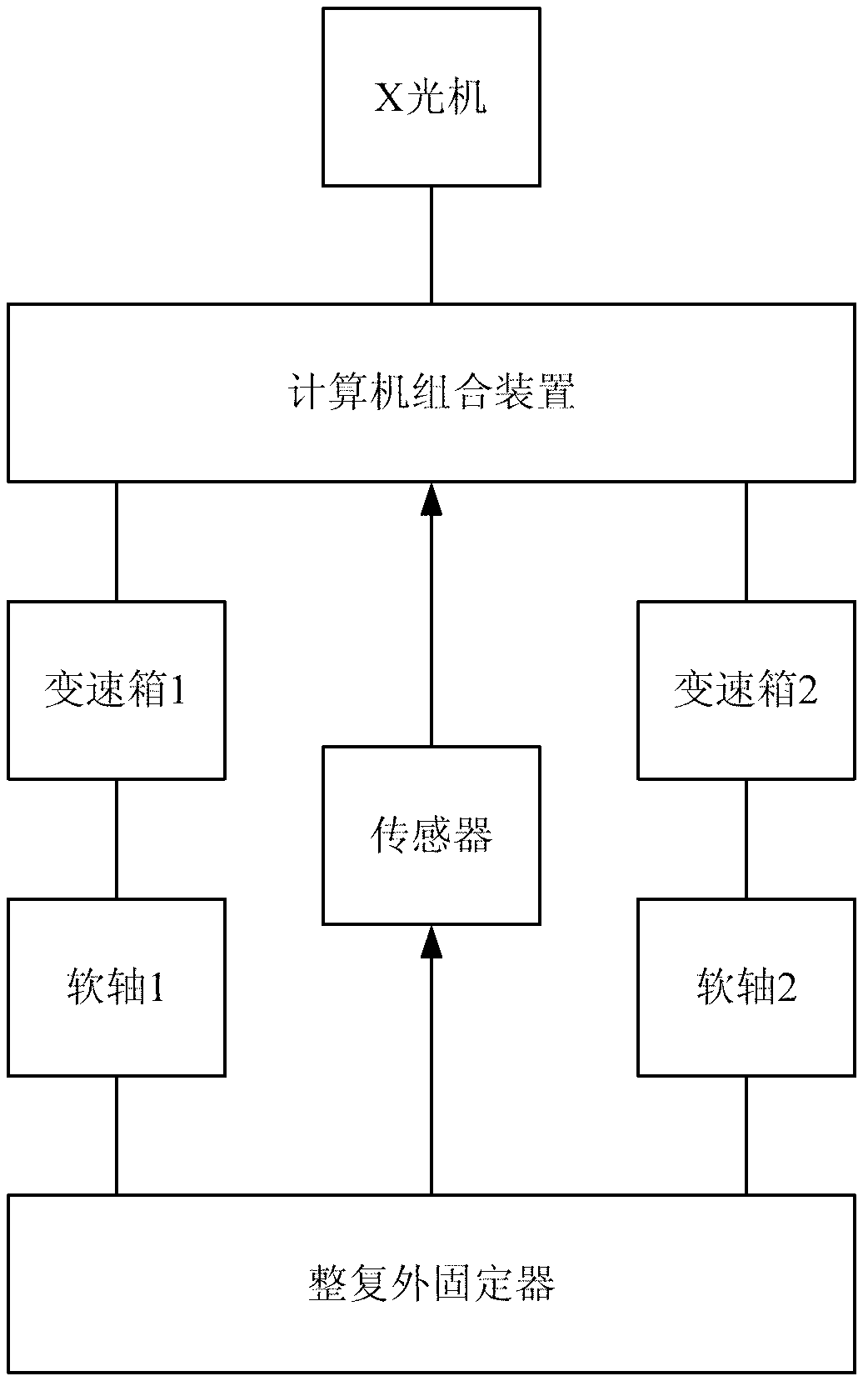

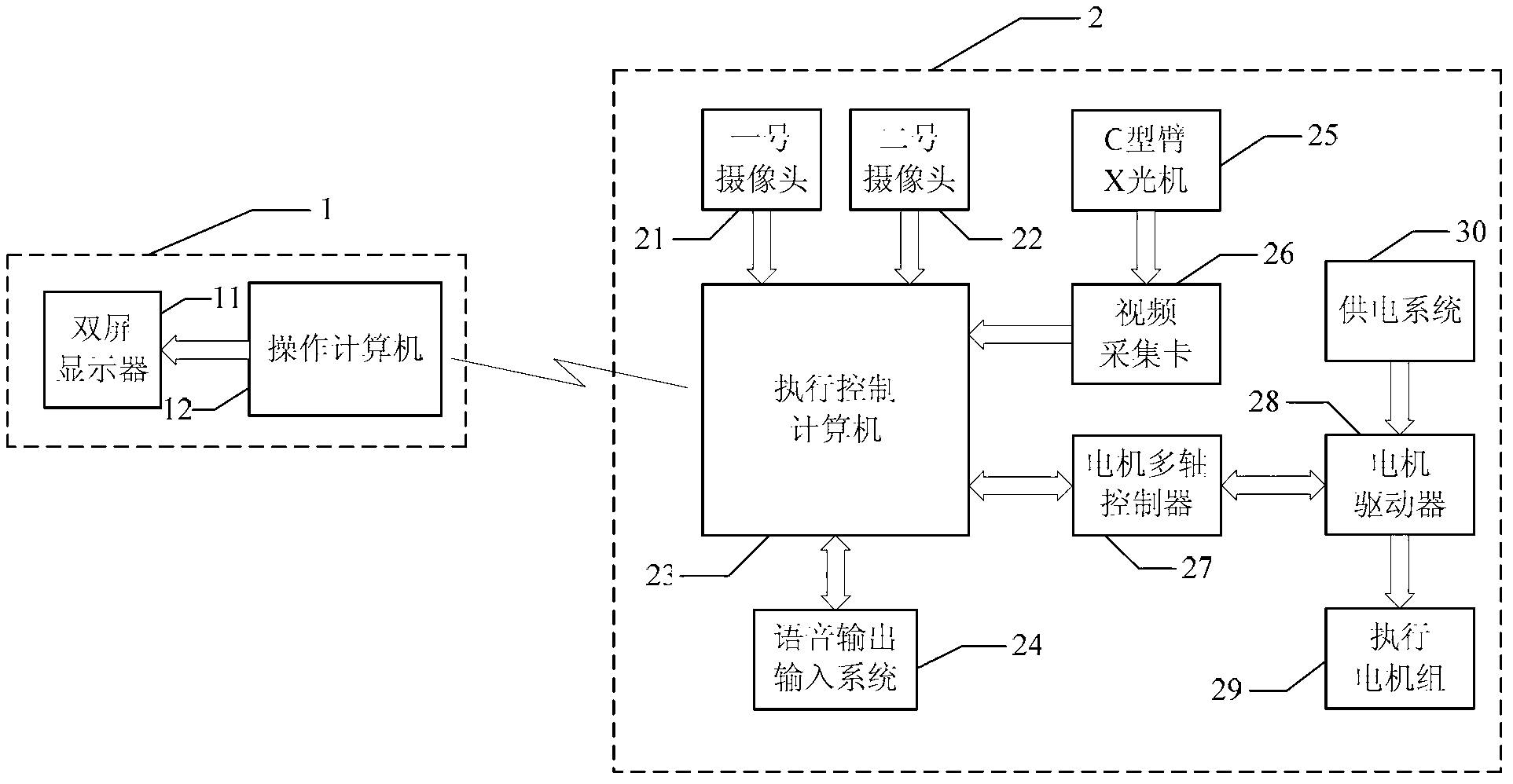

Osteopathy robot remote control system

InactiveCN103190957ARealize remote controlRealize position controlDiagnosticsSurgical robotsMotor driveControl system

The invention discloses an osteopathy robot remote control system which relates to a robot remote control system, and aims at solving the problem that remote control on an osteopathy robot cannot be realized currently. The remote control system comprises a remote monitoring unit and a control unit in an operating room; the display signal input end of a double-screen display is connected with the display signal output end of an operating computer; the pickup signal input ends of two cameras are respectively connected with the two pickup signal input ends of an execution control computer; a video capture card captures video signals of a C-type arm X-ray machine and outputs the video signals to the execution control computer; the motor multi-shaft control signal output or input end of the execution control computer is connected with the motor multi-shaft control signal input or output end of a motor multi-shaft controller; and the motor driving signal input or output end of the motor multi-shaft controller is connected with the motor driving signal output or input end of a motor driver; and the motor driver is used for driving each motor in an execution motor set to work. The osteopathy robot remote control system is applicable to remote control on a osteopathy robot.

Owner:哈尔滨首创骨科微创医疗设备有限公司

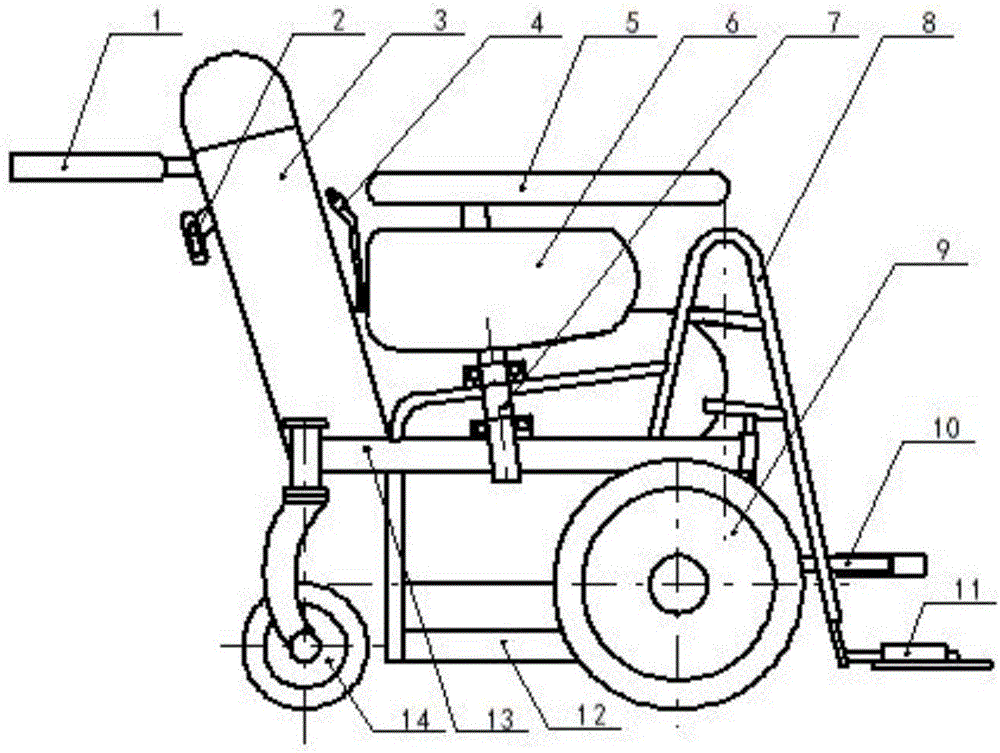

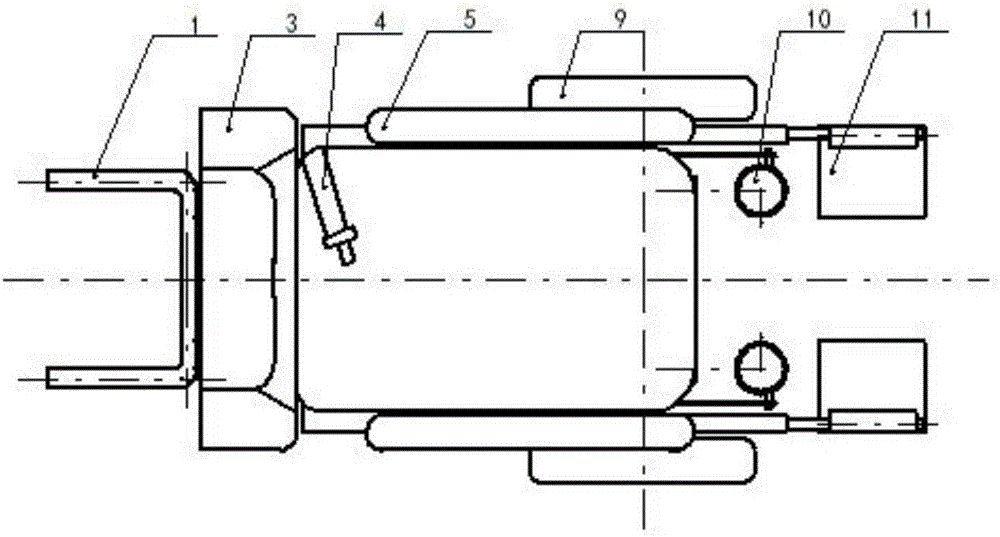

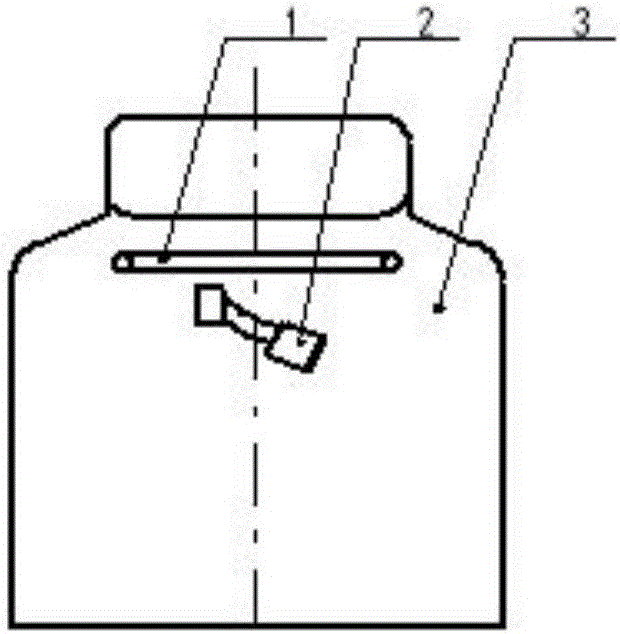

Wheelchair special for prisoners

InactiveCN106038095AAvoid aggressive behaviorSimple structureWheelchairs/patient conveyanceVehicle frameEngineering

The present invention relates to a wheelchair special for prisoners. An ejection rod motor is longitudinally fixedly arranged on one side of the part, below a chair seat and chair back portion, of a frame; a rotating rod is laterally mounted on the middle part of the frame; the two ends of the rotating rod sleeve inside sleeves fixedly arranged on the frame; foot ring rods are fixedly arranged on the parts, on both sides of the frame front part, of the frame in a longitudinally symmetric manner, and a foot ring is arranged at the front end of each foot ring rod; a pair of mounting clamping plates are fixedly arranged on the parts, corresponding to the end parts of an ejection rod of the ejection rod motor, at the lower part of the rotating rod, and the mounting clamping plates are fixedly arranged on the ejection rod ends of the ejection rod motor by bolts; and vertical plates are fixedly arranged on the upper parts of the both sides of the rotating rod, each of the two vertical plates is fixedly provided with a longitudinal pull rod by bolts, and the front ends of the pull rods are fixedly arranged on the foot rings. The wheelchair is simple in structure, scientific in design and clever in conception, and can control the action of upper and lower limbs of the prisoners in the wheelchair and avoid the occurrence of malignant accidents, thus belonging to one of indispensable facilities in prison.

Owner:TIANJIN XINCHENG NEW SCI TRADE

Foldable cable assembly for lifting platform

The invention discloses a foldable cable assembly for a lifting platform, which belongs to the technical field of signal transmission, and comprises a fixed base, a cable sorting box, a connecting cable, a mounting platform, a sealing frame, a cable folding assembly, a cable sorting assembly and a matching bracket, the cable folding assembly is arranged at the top of the cable sorting box in a rotating structure, the cable sorting assembly and the matching support are both arranged in an inner cavity of the cable sorting box, the connecting cable penetrates through the cable sorting box, the cable folding assembly, the cable sorting assembly and the matching support, and the top of the connecting cable penetrates through the top of the mounting platform. According to the invention, the structure is novel, the use is convenient, the connection cable has a good folding route, the damage to the cable core is small, the external part of the connection cable can be automatically maintained at regular time, the labor is saved, the intelligent degree is high, and the economic value is high.

Owner:河源坚宝电缆有限公司

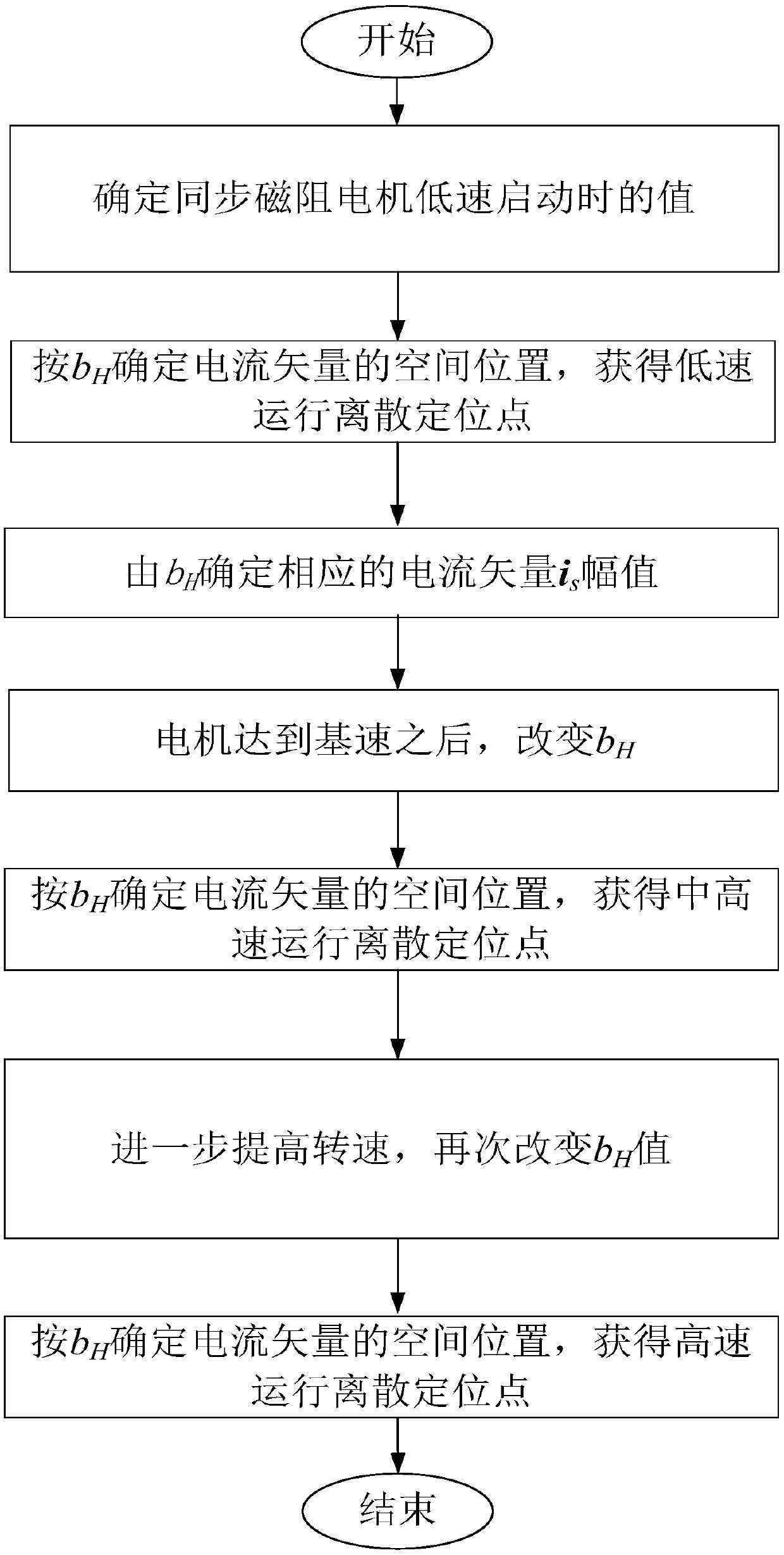

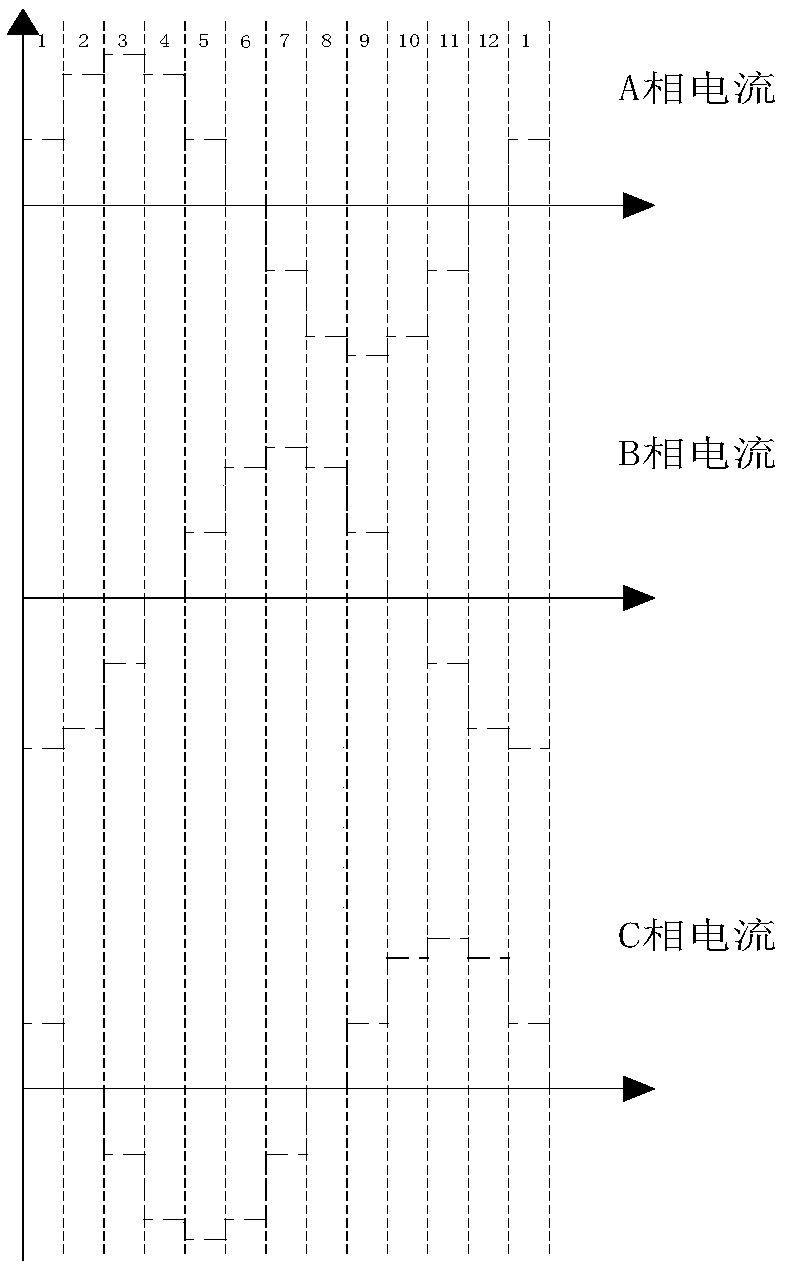

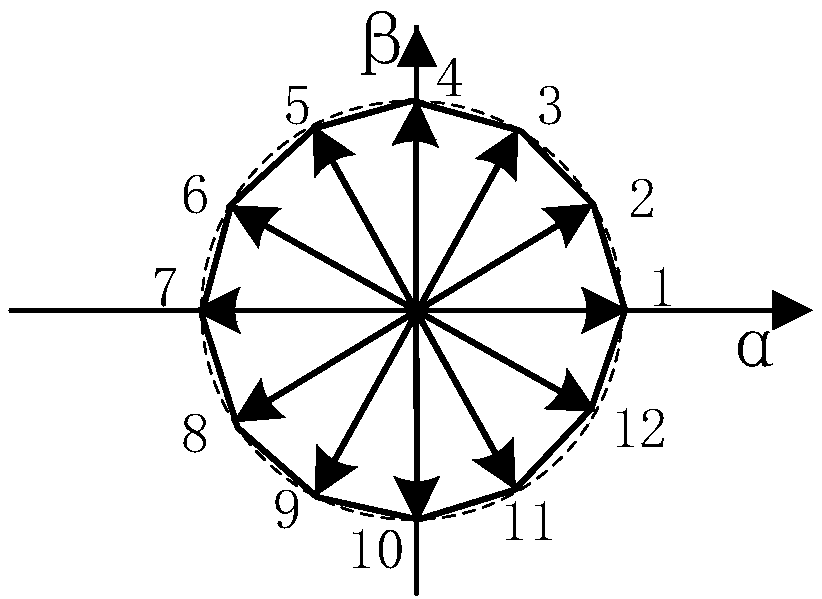

New energy vehicle synchronous reluctance motor control method based on AC stepping control

ActiveCN109660176ASolve the large torque ripple at low speedGood motor control effectElectronic commutation motor controlAC motor controlEngineeringLow speed

The invention provides a new energy vehicle synchronous reluctance motor control method based on AC stepping control. The synchronous reluctance motor control method for new energy vehicle based on ACstepping control discretely subdivides the stator current vector of three-phase current synthesis for a synchronous reluctance motor, and obtains the discrete positioning position of the space according to a certain cycle number, thereby realizing the position control of the motor by controlling the spatial position of the stator magnetic field so as to realize speed control. Synchronous reluctance motor stepping transmission control with positional characteristics provided by the synchronous reluctance motor control method is to convert the control difficulty in accurate modeling, caused bynonlinearity of the salient pole of the rotor by using the AC stepping control method, so as to realize high-accuracy positional control, and solves the problem of low speed torque ripple, complicatedstructure, and the like in the traditional control mode.

Owner:HEBEI UNIV OF TECH

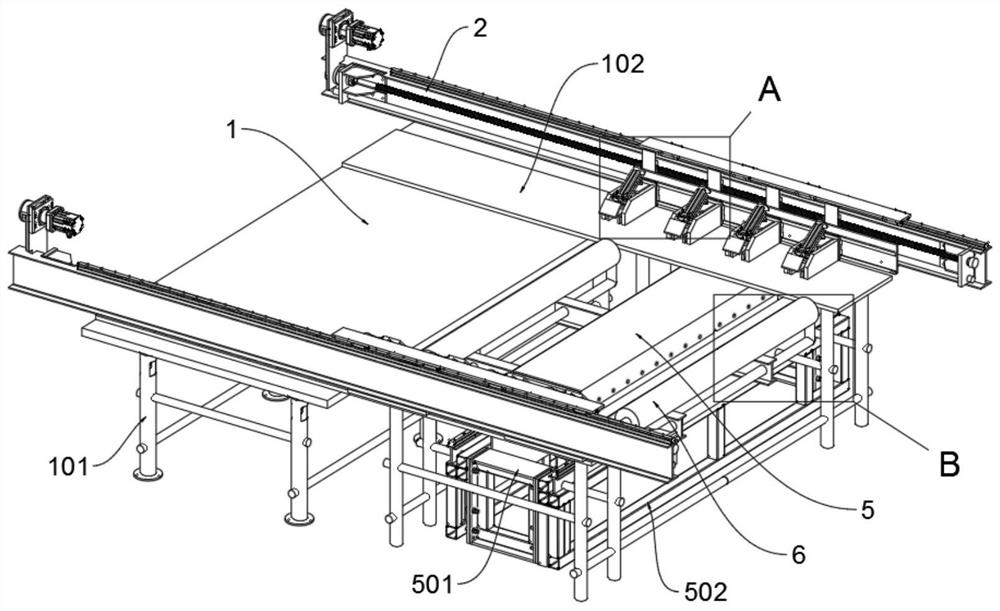

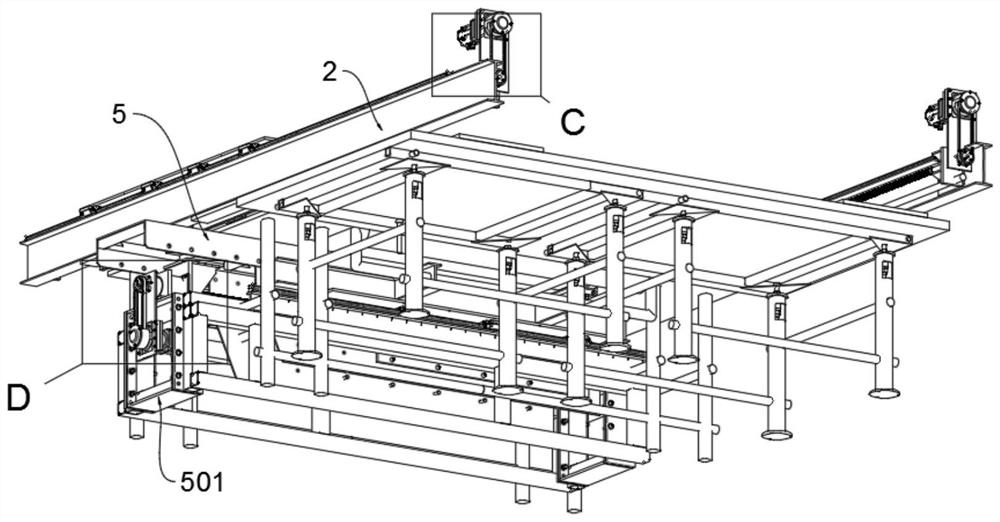

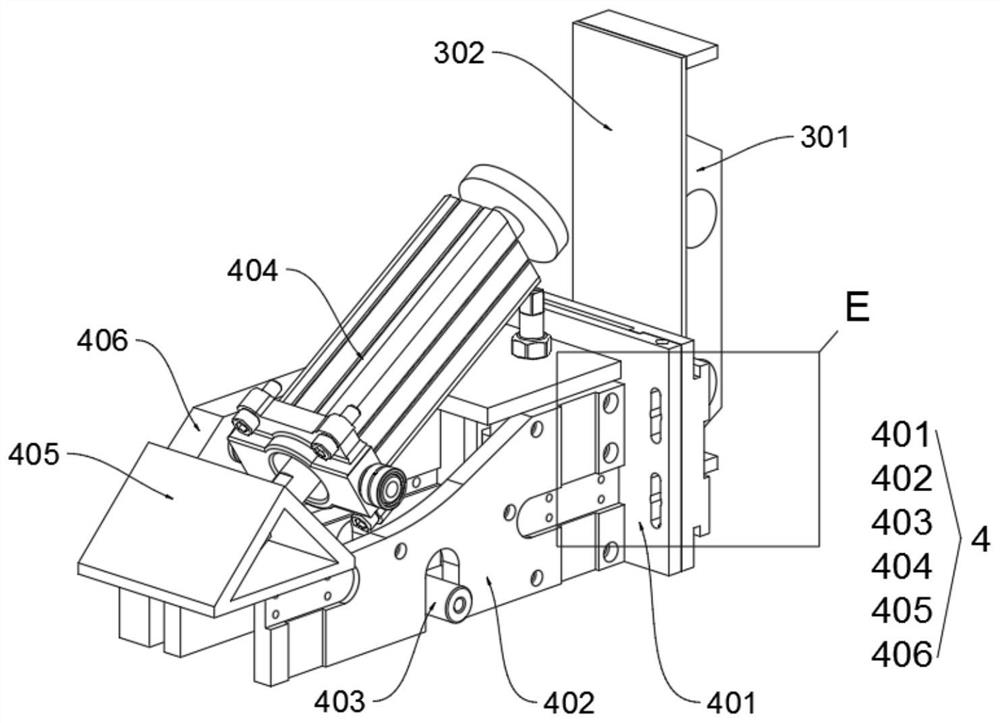

Processing equipment for fireproof layer of fireproof plate

ActiveCN114263066ARealize the delivery workAddresses an issue where teleporting jobs could not be done while clampedPhysical paper treatmentEngineeringControl circuit

The invention provides processing equipment for a fireproof layer of a fireproof plate, and relates to the technical field of fireproof plate processing. The top face of the main table body is fixedly connected with a fixing support, and the bottom face of the main table body is fixedly connected with a round rod support. The opposite sides of the fixing supports are movably connected with connecting pieces. The inner side of the connecting piece is movably connected with a pressing device in a clamped mode. The pressing device is electrically connected with an external control circuit of the main table body, after the pressurizer is started, pressure is applied to the pressing block downwards, after the front end of the pressing block is attached to the top face of the auxiliary table face, pressurization continues to enable the bottom face of the pressing block to be completely attached to the top face of the auxiliary table face, the pressing block rotates through a shaft at the tail end of the pressurizer, and the pressurizer rotates through a rotating rod. After a pressing block is tightly attached to the top face of the auxiliary table top, kraft paper can be pressurized, a pressing device can move left and right on the inner side of a sliding groove plate through an external control circuit, kraft paper conveying work is achieved, and the problem that conveying work cannot be conducted during clamping is solved.

Owner:响水海智科技有限公司

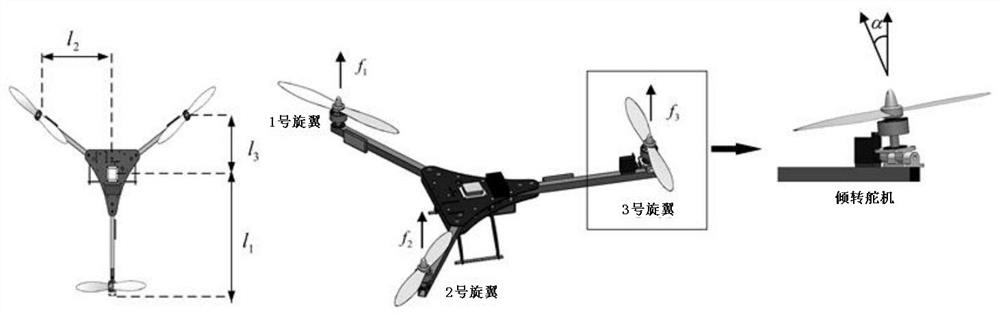

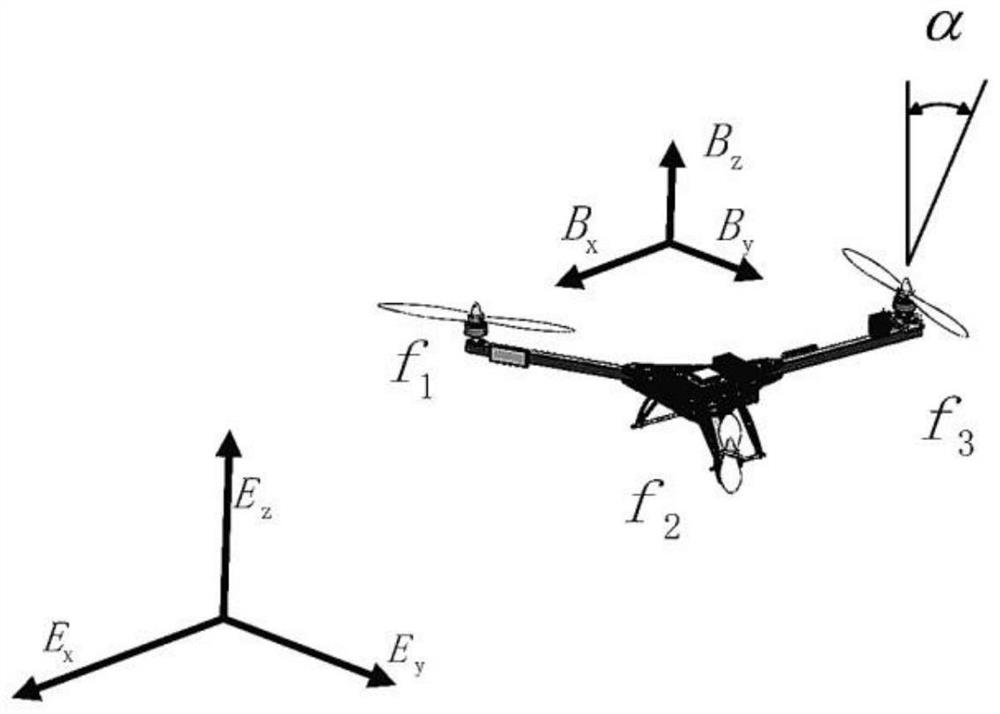

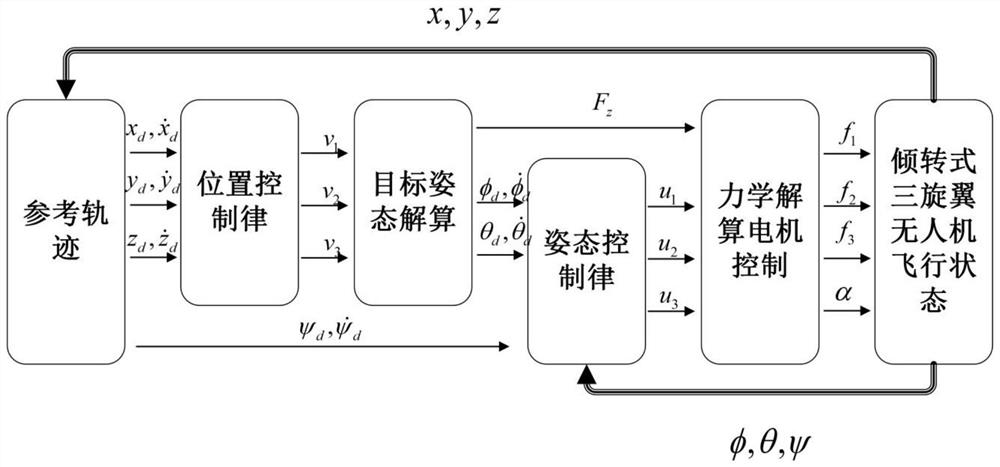

Robust Control Method for Position Control of Tilting Trirotor UAV

InactiveCN108445895BRealize position controlImprove control stabilityAttitude controlPosition/course control in three dimensionsLoop controlDynamic models

The invention relates to the nonlinear control of the position of the tilting three-rotor UAV. In order to propose the inner and outer loop control strategy for the tilting three-rotor UAV, a class of tilting three-rotor UAV position subsystem and The controller of the attitude subsystem, for this reason, the present invention is used for the robust control method of position control of the tilting three-rotor UAV, and the steps are as follows: 1) establish the relevant coordinate system of the tilting three-rotor UAV: 2 ) Establish the dynamic model of the position and attitude of the tilt-rotor UAV: 3) Design the nonlinear controller a) Design the position subsystem controller b) Design the attitude subsystem controller. The invention is mainly applied to the occasion of nonlinear control of the position of the three-rotor UAV.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com