Hair drier motor and hair drier

A hair dryer and rotor shaft technology, applied in the field of hair dryers, can solve the problem that the motor cannot increase the speed of rotation, etc., and achieve the effects of reliable operation, prolonging service life, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The traditional motor is composed of a stator and a rotor. The stator and the rotor are connected by mechanical bearings or have mechanical contact, so there is mechanical friction during the movement of the rotor. Mechanical friction causes the components to wear, produces mechanical vibration and noise, and can cause the components to heat up, which will deteriorate the performance of the lubricant. In severe cases, the air gap of the motor will be uneven, the winding will heat up, and the temperature rise will increase, thereby reducing the efficiency of the motor and shortening the motor. service life.

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

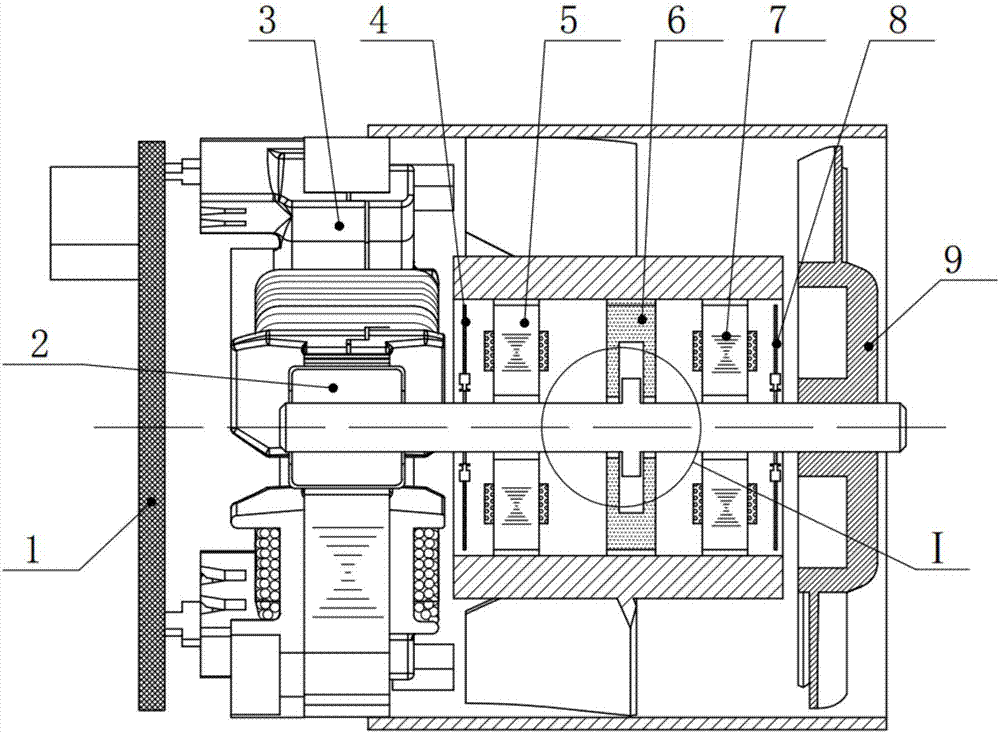

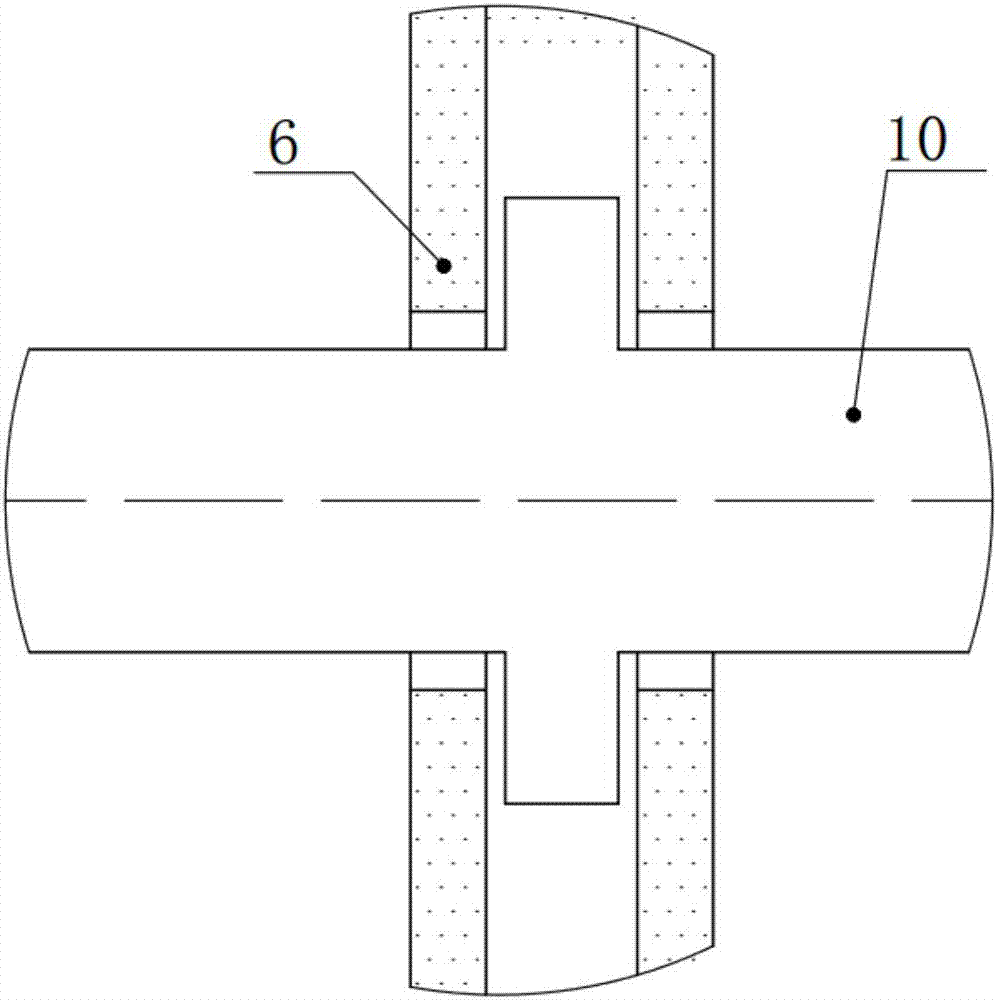

[0025] like figure 1 As shown, a hair dryer motor provided by an embodiment of the present invention includes a stator 3, a rotor 2 rotatably arranged in the stator 3, the rotor 2 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com