Torque loading tester and controlling system thereof

A technology of loading test and control system, applied in the field of inspection and inspection, can solve problems such as large deviation of results and difficult realization, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An example of the present invention is described as follows in conjunction with accompanying drawing:

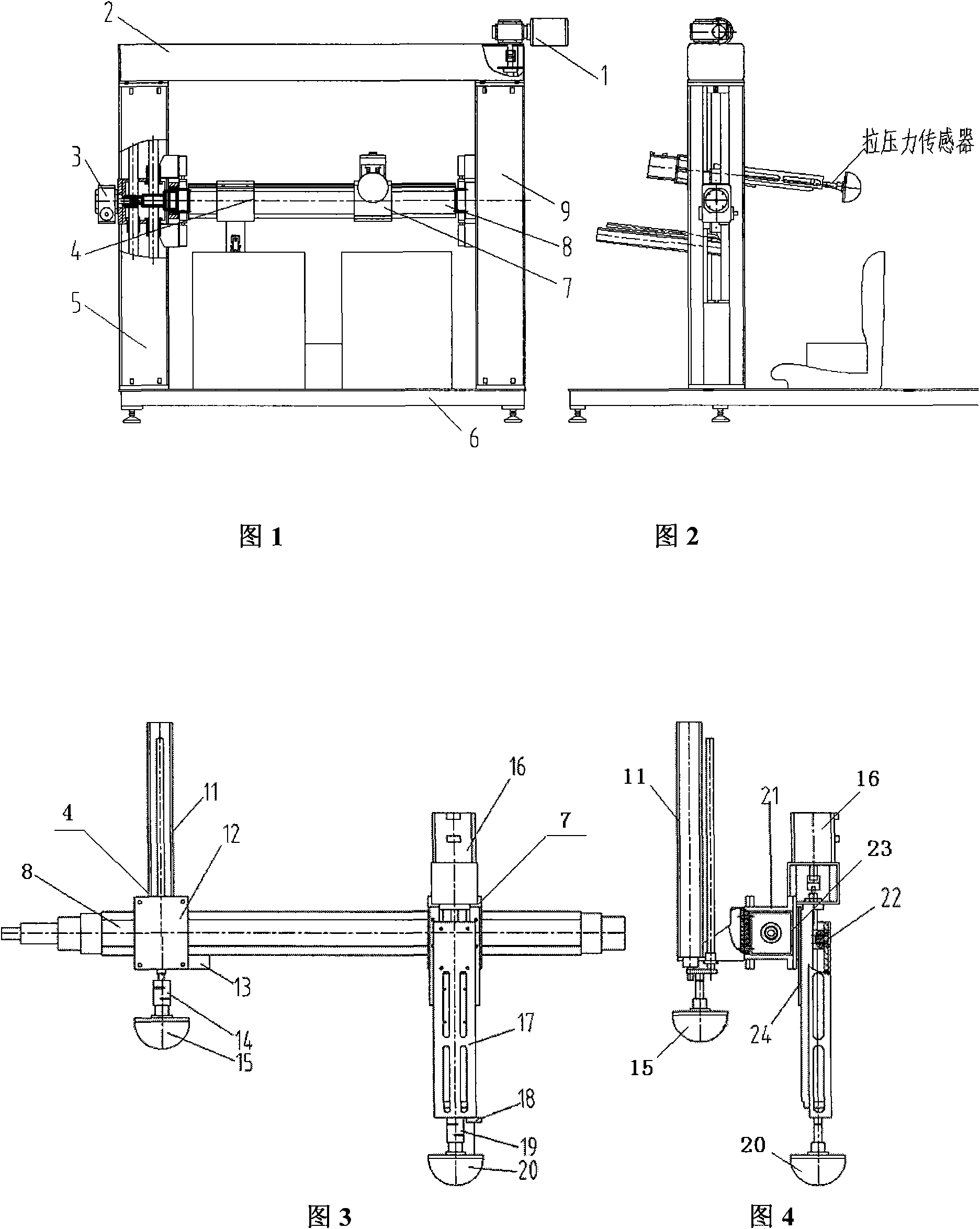

[0024] Such as figure 1 and figure 2 As shown, the multifunctional moment loading testing machine of the present invention comprises a base plate 6, a left column 5 and a right column 9 vertically fixed on the base plate 6, and an upper beam 2 fixed on the tops of the left and right columns 5 and 9, and a middle beam 8 is arranged. The two ends are respectively supported on the left and right screw rods in the left and right columns 5, 9; a motor 1 fixed on the upper beam 2 drives the middle beam 8 to move up and down through the up and down transmission mechanism; the middle beam One end of 8 is equipped with a hand wheel to drive the middle beam to rotate in the range of 0-180° through the worm gear transmission mechanism; the middle beam 8 is equipped with a cylinder loading device 4 and a servo motor loading device 7 .

[0025] The above-mentioned moving up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com