Hybrid drawing cushion facility

A deep-drawing pad and electric drive technology, applied in the field of deep-drawing pad devices, can solve the problems of no structure space, large structure space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

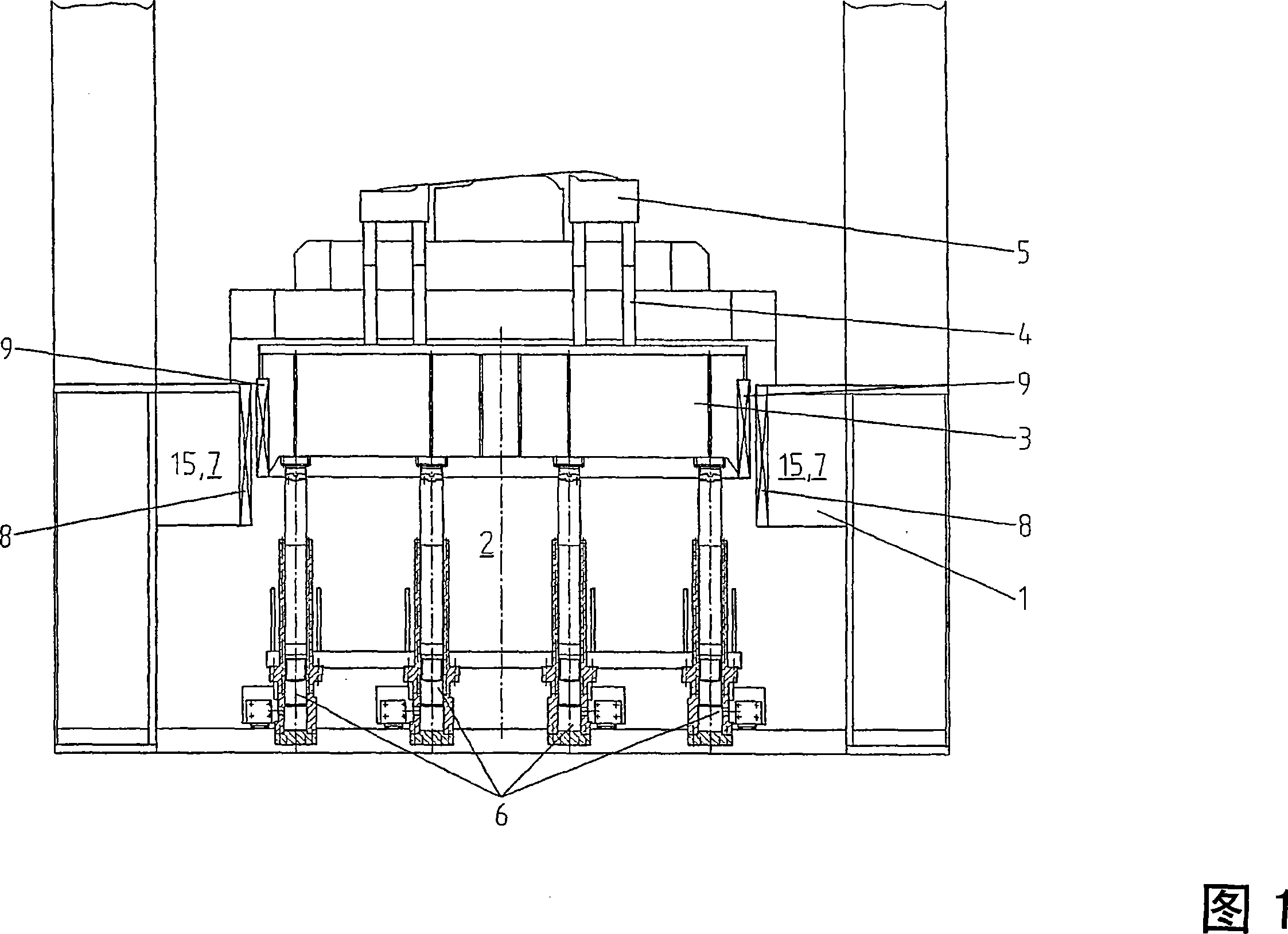

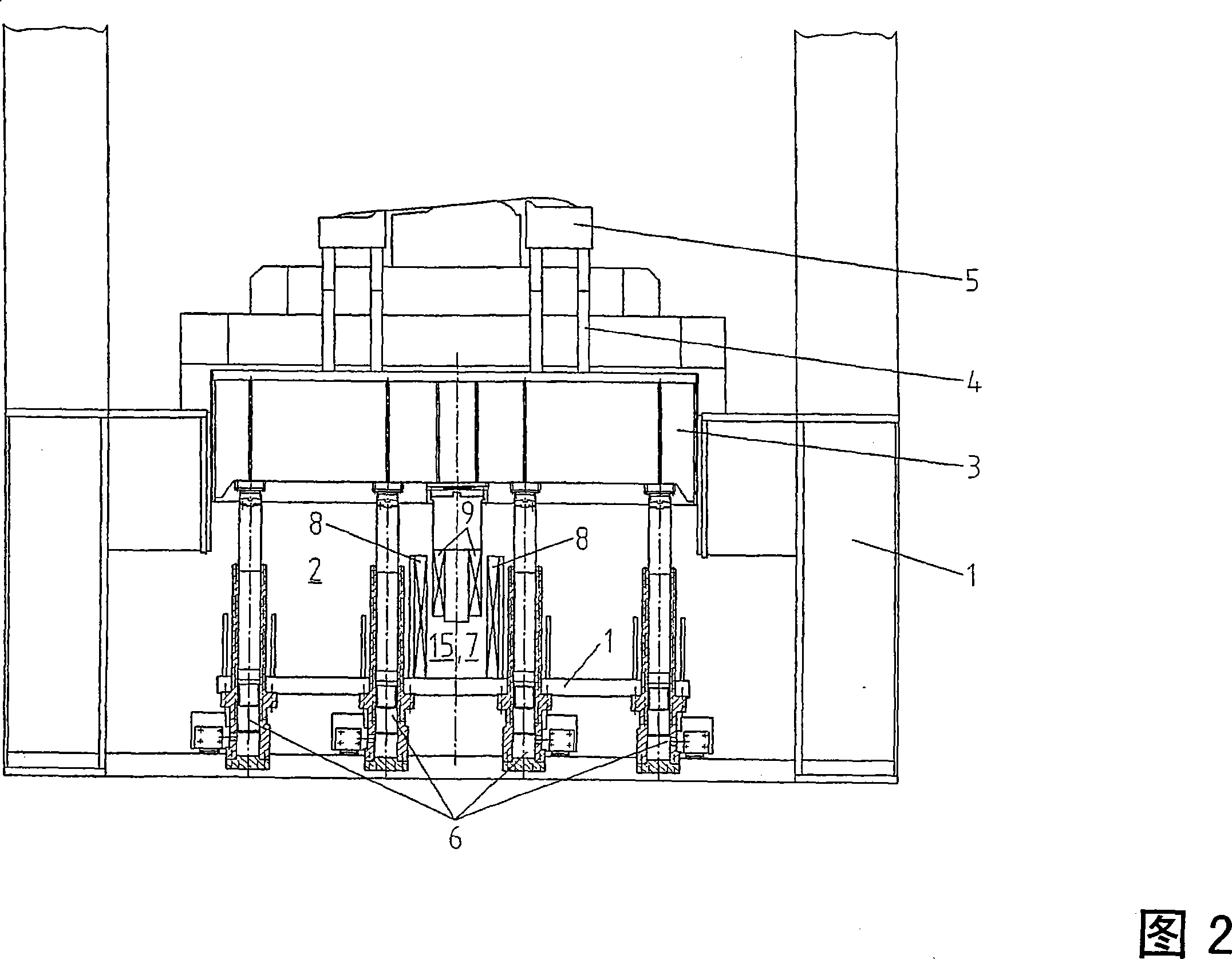

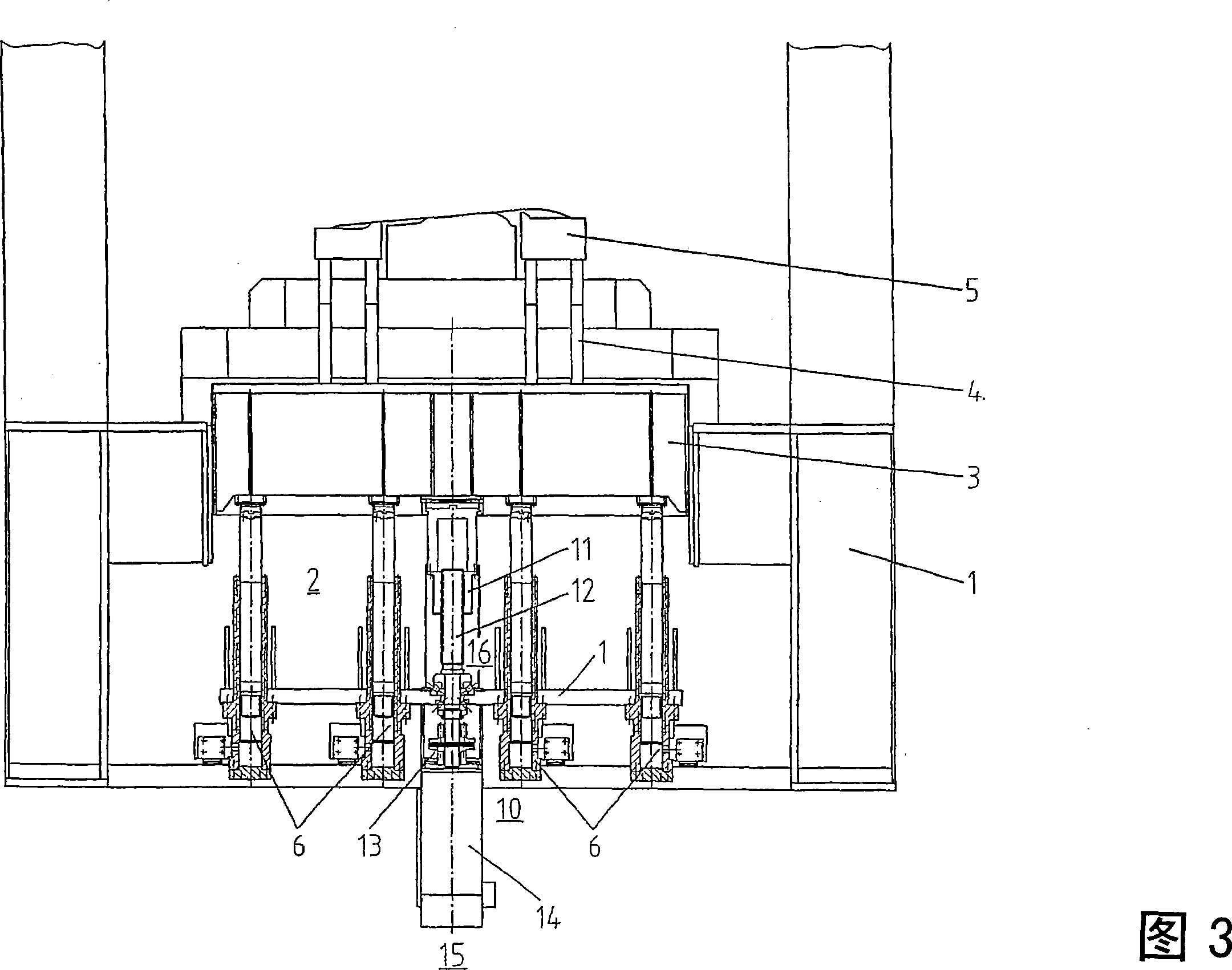

[0025] FIG. 1 shows a section of a press in a simplified illustration with a drawing pad arrangement 2 arranged in a press table 1 as a multipoint structure.

[0026] A pressure plate 3 guided longitudinally in the press table 1 is operatively connected via a pressure pin 4 to a sheet metal holder 5 of the lower tool. A fluid cylinder 6 is arranged between the press platen 3 and the press table 1 in order to generate the sheet holding force required for the deep-drawing process directed towards the upper die in the press ram, not shown. Here, the sectional illustration shows a first row of four fluid cylinders 6 of a total of eight-point drawing device. During the drawing phase of the sheet metal part, the pressing plate 3 is moved downward by the movement of the pressing rod, wherein the adjustment of the sheet holding force along the drawing stroke takes place by valve-controlled discharge of fluid out of the fluid cylinder 6 .

[0027] In order to generate the actively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com