Automatic pipeline robot patrolling and dredging device and method

A pipeline robot and automatic inspection technology, applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of secondary deposition, blockage, desilting and poor targeting, so as to improve pertinence and adaptability performance and improve cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments.

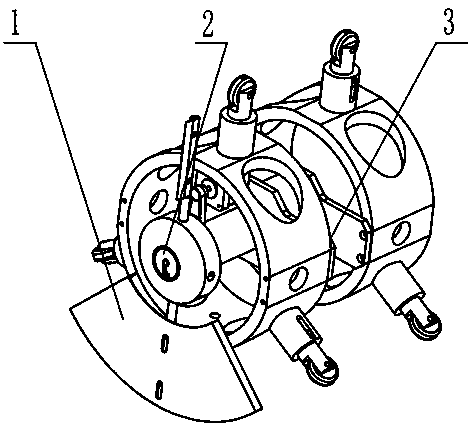

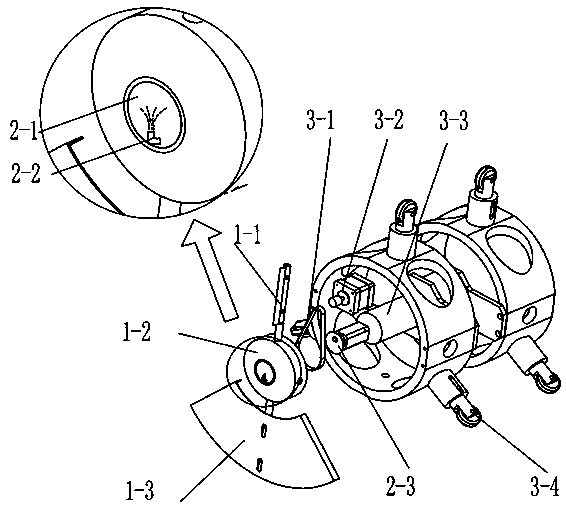

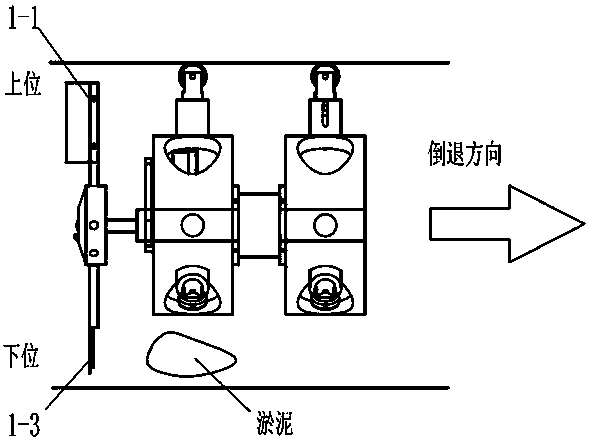

[0029] Such as Figure 1 to Figure 7 In the pipeline robot automatic inspection and dredging device shown, first, the pipeline robot equipped with sensors and waterproof cameras 2-3 is manually inserted into the pipeline, and then the sensors and waterproof cameras 2-3 detect the size and distance of the silt in the pipeline , to drive the robot to move towards the silt, and then the stepper motor 3-2 drives the scraper knife group 1-1 to rotate to scrape off the silt, and then controls the blade to press the silt to the middle and lower parts of the pipeline in a pendulum cutting manner, at the same time Ensure that the height of the sludge does not exceed the center of the pipe.

[0030] Since the projected area of the desilting knife group 1-3 in the direction of the pipeline section is much larger than that of the desilting knife group 1-1, first turn the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com