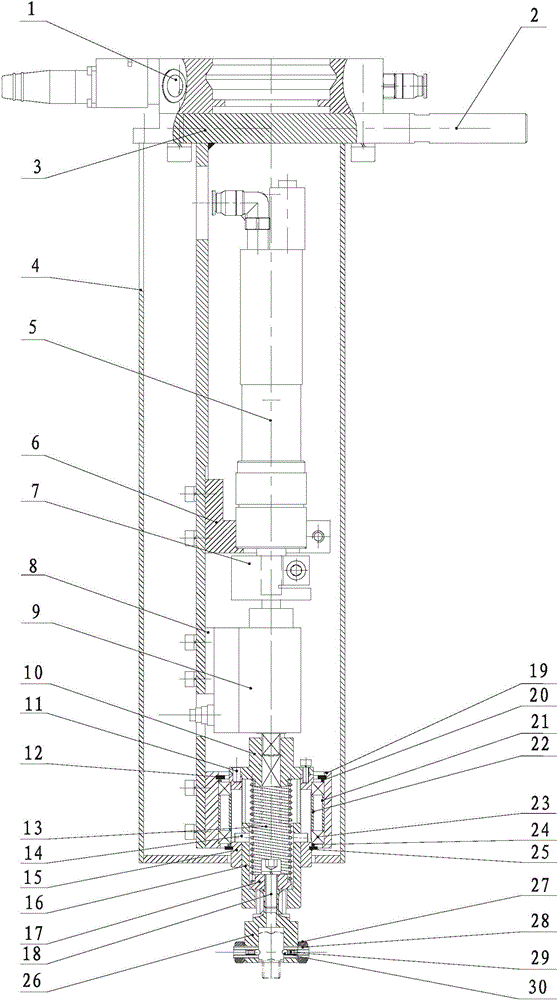

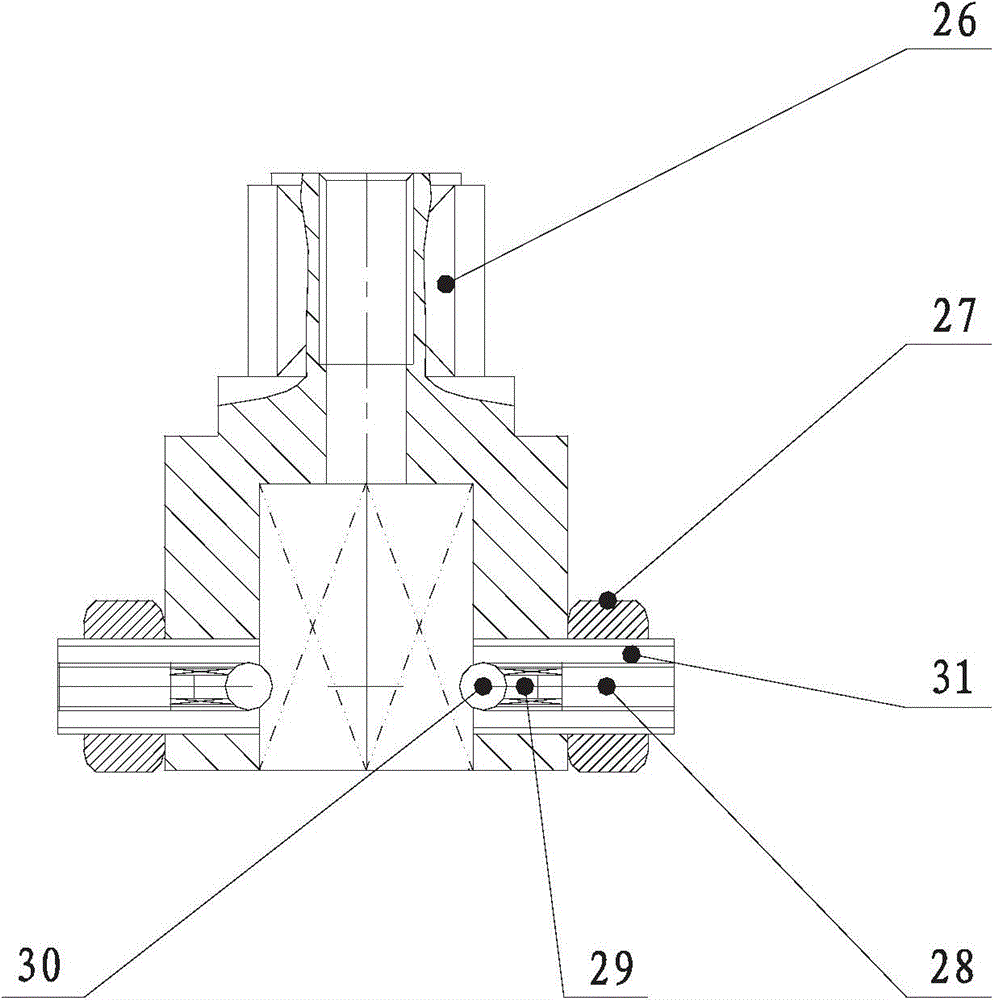

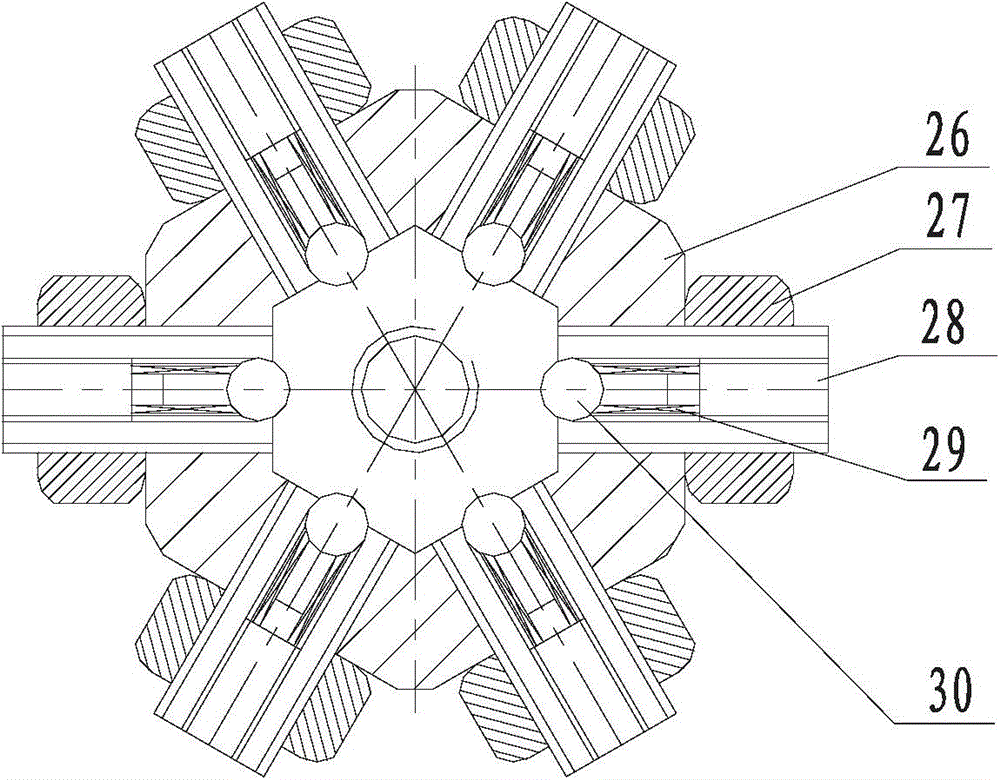

Axial bolt tightening device

A bolt and axial technology, applied in the field of automated assembly, can solve the problems of difficult operation, limited internal space, lack of human eyes, etc., to achieve the effect of reducing labor intensity, improving production efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Such as Figure 4 , Figure 5 As shown, the axial bolt 32 on the workpiece is disassembled by using the present invention and the visual recognition device. The visual recognition device includes a base II36 , a housing 40 , a transparent cover 39 , a quick-change joint II34 , a distance measuring sensor 38 , an intelligent camera 41 and a ring light source 42 . The quick-change joint II34 connects the base II36 with the robot, and the ranging sensor 38, the smart camera 41 and the ring light source 42 are installed on the base II36.

[0036] First, the visual recognition device is combined with the manipulator of the robot, and the relative position between the workpiece and the manipulator is calibrated by the smart camera 41 and the ranging sensor 38, and then the axial bolt tightening device is replaced to realize the automatic loading and unloading of the axial bolt 32. The invention is especially suitable for continuous automatic loading and unloading of bolts i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com