Preparation method of Pt-Co/C-single-layer graphene for fuel cell

A single-layer graphene, fuel cell technology, applied in graphene, battery electrodes, circuits, etc., can solve the problems of expensive metal Pt, scarce resources, hindering the industrial production of fuel cells, etc., achieve excellent physical properties, and improve the degree of exfoliation. , the effect of excellent oxygen reduction electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Using natural flake graphite as raw material, oxidize it by Hummers method to obtain graphite oxide, the specific steps are as follows:

[0020] Add 2.5g each of potassium persulfate and phosphorus pentoxide into a 25mL concentrated sulfuric acid flask, stir and reflux in an oil bath at 40-180°C until it dissolves, then slowly add 1.0-5g of graphite powder, stir and heat for 2-10h. Natural flake graphite is pretreated, filtered and washed to neutral to obtain treated graphite; put the treated graphite into 50-200g concentrated sulfuric acid and stir evenly in an ice bath, slowly add 8-30gKMnO 4Then stir in an ice bath for 1-10 hours; transfer to an oil bath at 35±3°C, stir for 20-120 minutes, then slowly add 100-300mL of distilled water to the above mixture dropwise; when the mixture cools to room temperature, take it out and put it in In a 2-5L large beaker, add 500-1500mL distilled water and 5-60mLH 2 o 2 , continue to stir until no bubbles are produced, and the...

Embodiment 2

[0025] The difference between this example and Example 1 is that the mass ratio of GO to XC-72 is controlled to be 2:1 and 1:1, respectively to obtain Pt 1 -Co 1 / rGO 2 -XC-72 1 and Pt 1 -Co 1 / rGO 1 -XC-72 1 catalyst.

Embodiment 3

[0027] In order to compare the effect of the addition of activated carbon XC-72 on the performance of the catalyst, a set of comparative experiments was specially done. Catalysts supported solely by graphene were prepared under the same reaction conditions.

[0028] (1) The preparation of graphite oxide refers to step (1) of Example 1;

[0029] (2) Weigh 60 mg of graphite oxide powder, add it into a mixed solution of 60 mL of ethylene glycol and 10 mL of isopropanol, and disperse it in an ice bath with ultrasound for 35 minutes to form a uniform suspension of graphene oxide in ethylene glycol.

[0030] (3) Refer to step (4) of Example 1 to obtain Pt by microwave-assisted ethylene glycol method 1 -Co 1 / rGO catalyst.

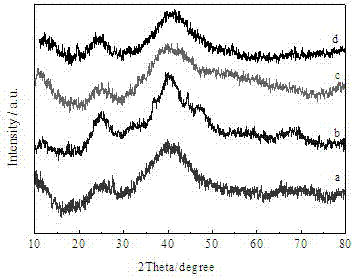

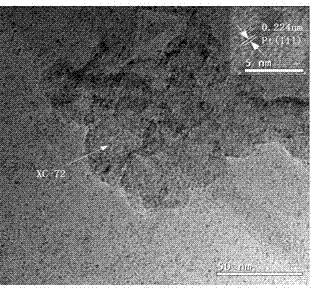

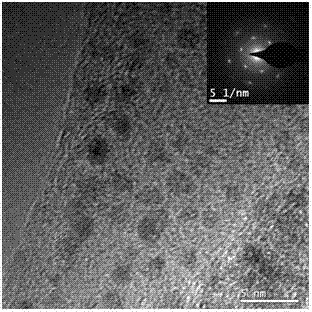

[0031] The obtained dry catalyst was ground into powder and characterized by XRD. figure 1 Activated carbon with different mass ratios (1:1(a), 2:1(b), 4:1(c) and 1:0(d)) when the atomic mass ratio of Pt to Co is 1:1 Catalyst Pt obtained from XC-72 and graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com