Compatible ethylene-tetrafluoroethylene copolymer nano-composite material and preparation method thereof

A nano-composite material and tetrafluoroethylene technology are applied in the field of compatible ethylene-tetrafluoroethylene copolymer nano-composite materials and their preparation, and can solve the problems of poor compatibility and agglomeration between nanoparticles and ETFE matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of a compatible ethylene-tetrafluoroethylene copolymer nanocomposite material, comprising the following steps:

[0035] Pretreating the montmorillonite nanoparticles with an organic quaternary phosphonium salt to obtain OMMT;

[0036] Using a silane coupling agent to activate and modify the surface of the OMMT to obtain an activated OMMT;

[0037] Grafting a fluorine-containing monomer onto the activated OMMT to obtain a fluorinated modified OMMT;

[0038] Mixing the fluorinated modified OMMT with ethylene-tetrafluoroethylene copolymer and polyvinylidene fluoride, extruding and granulating, and molding to obtain a compatible ethylene-tetrafluoroethylene copolymer nanocomposite material;

[0039] The mass ratio of the fluorinated modified OMMT to the ethylene-tetrafluoroethylene copolymer and polyvinylidene fluoride is 0.1-4:88-92:8-12.

[0040] In the invention, the montmorillonite nanoparticles are pretreated with an organi...

Embodiment 1

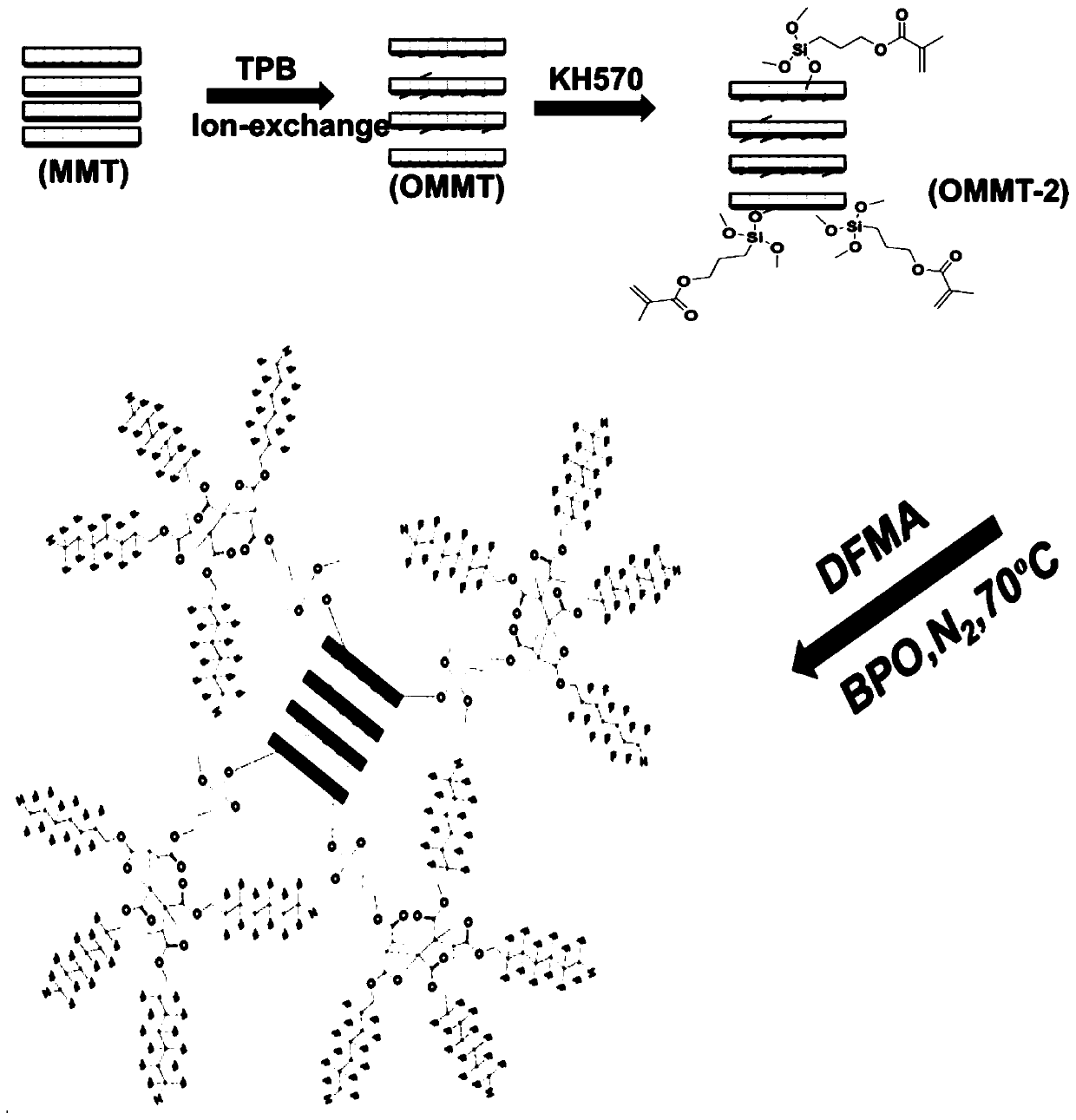

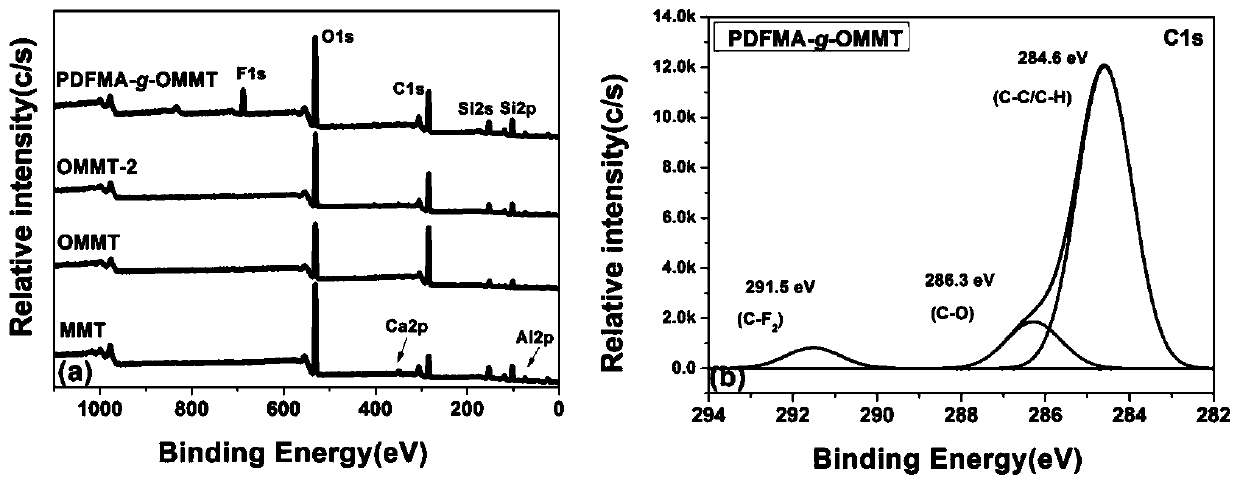

[0053] A montmorillonite-based fluorinated nanoparticle with a structure of PDFMA-g-OMMT, the synthesis route is as follows figure 1 shown;

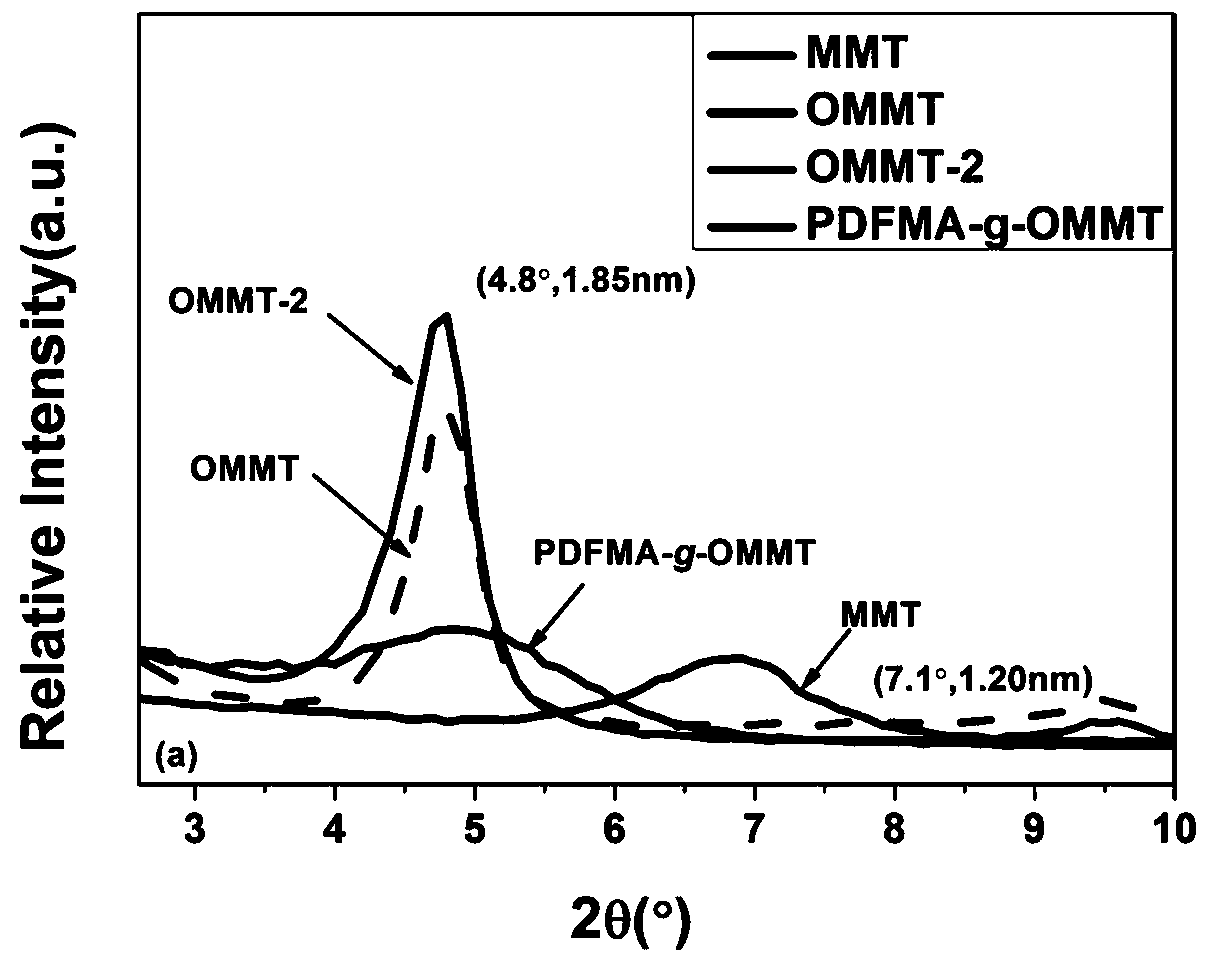

[0054] (1) Preparation of OMMT: Add 20g of montmorillonite (MMT), 200ml of deionized water, and 20g of tetraphenylphosphonium bromide (TPB) into a 500ml flask under air atmosphere, and heat to 80°C for 8h. After the reaction, cool to room temperature, remove unreacted TPB with water / ethanol (1:1) mixture, centrifuge at 8000rpm for 5min, remove the supernatant, and vacuum dry the residue at 80°C for 10h to obtain OMMT nanoparticles.

[0055] (2) Preparation of OMMT-2: Add 2 g of OMMT and 75 ml of water / ethanol (1:9) mixture into a 250 ml flask under air atmosphere, and stir at high speed (500 rpm) for 30 min. Add 30ml of γ-methacryloxypropyl trimethylsiloxane (KH-570), stir at high speed (500rpm) for 2 hours, and disperse ultrasonically for 1 hour. After the reaction is complete, wash off the unreacted KH-570 with ethanol. Centrifuge at...

Embodiment 2

[0060] Weigh the PDFMA-g-OMMT nanoparticles prepared in 0.1g embodiment 1, 90g ETFE and 10g PVDF, pre-blended by means of mechanical stirring, and then extrude using a twin-screw extruder. The extrusion temperature in each region is as follows: 1 Zone 250°C, Zone 2 265°C, Zone 3 280°C, Zone 4 285°C, Zone 5 280°C, Zone 6 275°C, Die 280°C, extrusion rate 80rpm. Finally, it is molded under a flat vulcanizer. The hot pressing temperature is 280°C, the hot pressing pressure is 8MPa, and the time is 5 minutes. The cold pressing temperature is 25°C, and the cold pressing pressure is 10MPa, and the time is 20 minutes. - Tetrafluoroethylene copolymer nanocomposites. The phase interface was measured as Figure 4 as shown, Figure 4 It is a cross-sectional morphology diagram of the compatible ethylene-tetrafluoroethylene copolymer nanocomposite prepared in Example 2 of the present invention. At this time, the sample had a yield strength of 16.5 MPa and an elongation at break of 463% a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com