Polyethylene/montmorillonite nanometer composite material and method for preparing same by in-situ polymerization

A nano-composite material and in-situ polymerization technology, applied in the field of polymer materials, to achieve mild reaction conditions, simple operation, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

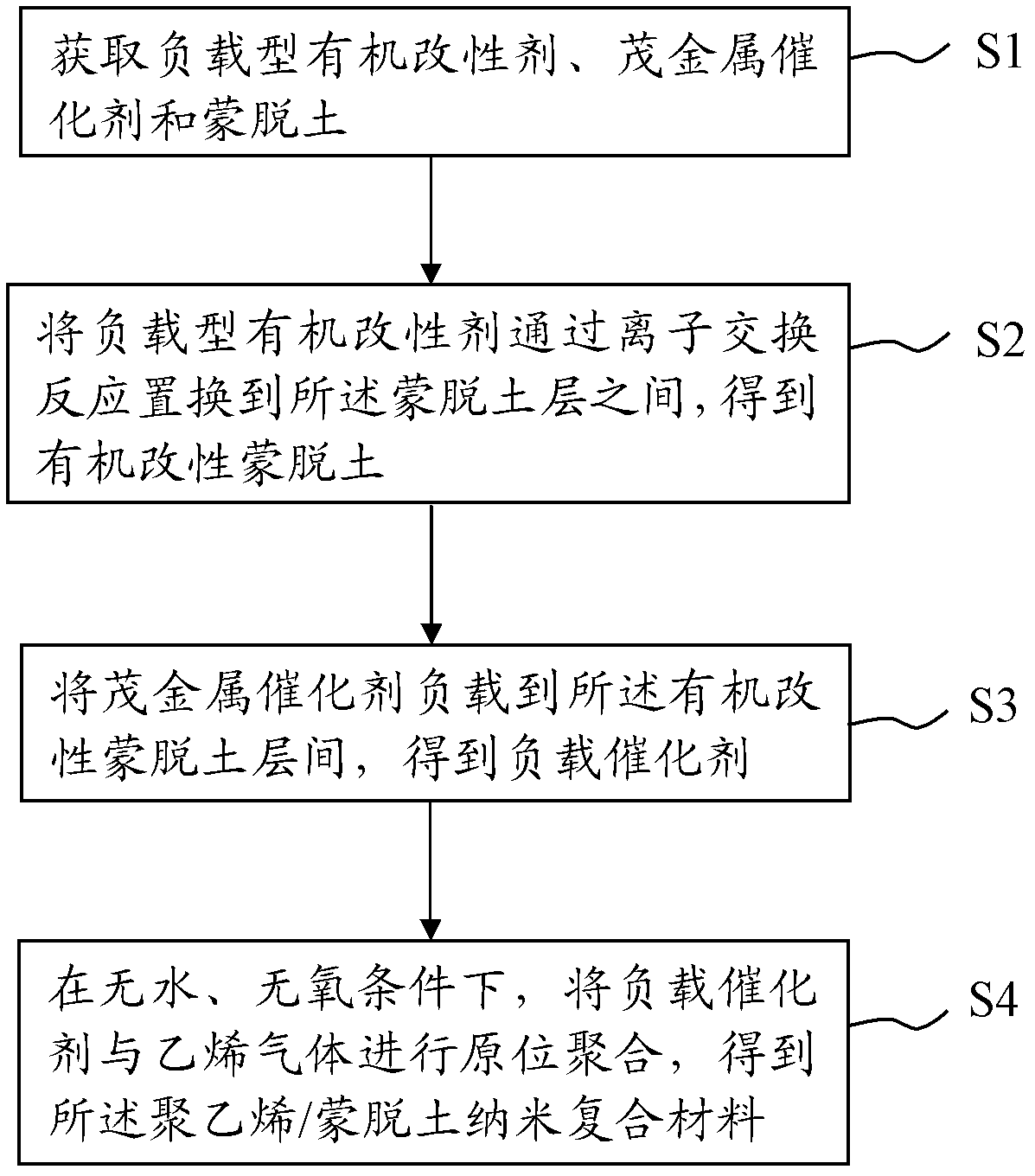

Method used

Image

Examples

Embodiment 1

[0056] The method for preparing exfoliated polyethylene / montmorillonite nanocomposites by in-situ polymerization, the specific steps are as follows:

[0057] (1) Add 100ml benzene, 2g compound 1, 1ml Et(OH) in dry 250ml two-necked bottle 2 and 0.02g TsOH. Connect a water trap to the reaction flask, reflux at 80°C for one day under magnetic stirring, and then evaporate the solvent to dryness on a rotary evaporator. The crude product was recrystallized from benzene;

[0058] (II) In a dry 250ml two-necked flask, add 0.6g undecylamine and dissolve in 100ml CH 3 CN, then add 2.0g K 2 CO 3 powder, and fitted with a condenser tube, another 3.8g of the synthetic product prepared in step (I) was dissolved in 50ml of CH 3 CN was installed in a dropping funnel, and the reaction device was placed in an ice bath, and added dropwise under magnetic stirring. After 0.5 hour, the temperature was raised to 35°C and the reaction was continued for 1 day. After the reaction, the mixed solu...

Embodiment 2

[0066] The method for preparing exfoliated polyethylene / montmorillonite nanocomposites by in-situ polymerization, the specific steps are as follows:

[0067] (1) as step (I) in embodiment 1;

[0068] (II) as step (II) in embodiment 1;

[0069] (III) get the product prepared in 3g step (II), 0.12g TsOH, 0.13g H 2 O was added to 50ml CH 3 COCH 3 , pass into N 2 To evacuate the air, react at room temperature for 3 days; evaporate the solvent to dryness after the reaction, and use Et 2 O and H 2 O for liquid separation operation, keep the organic phase, and then evaporate the solvent to obtain the crude product. The crude product was purified by column chromatography, and the eluent was purified with Et 2 O and n-C 6 h 14 Mixed solvent (1 / 3, v / v); Obtain loaded modifier;

[0070] (IV) Dissolve 4 g of load modifier compound in C 2 h 5 OH / H 2 O (3 / 7, v / v) reacts with an equivalent amount of HCl to protonate it in a mixed solvent, heats to 60° C. and conducts an ion exch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com