Synthetic low-carbon ultrahigh temperature grease and preparation method

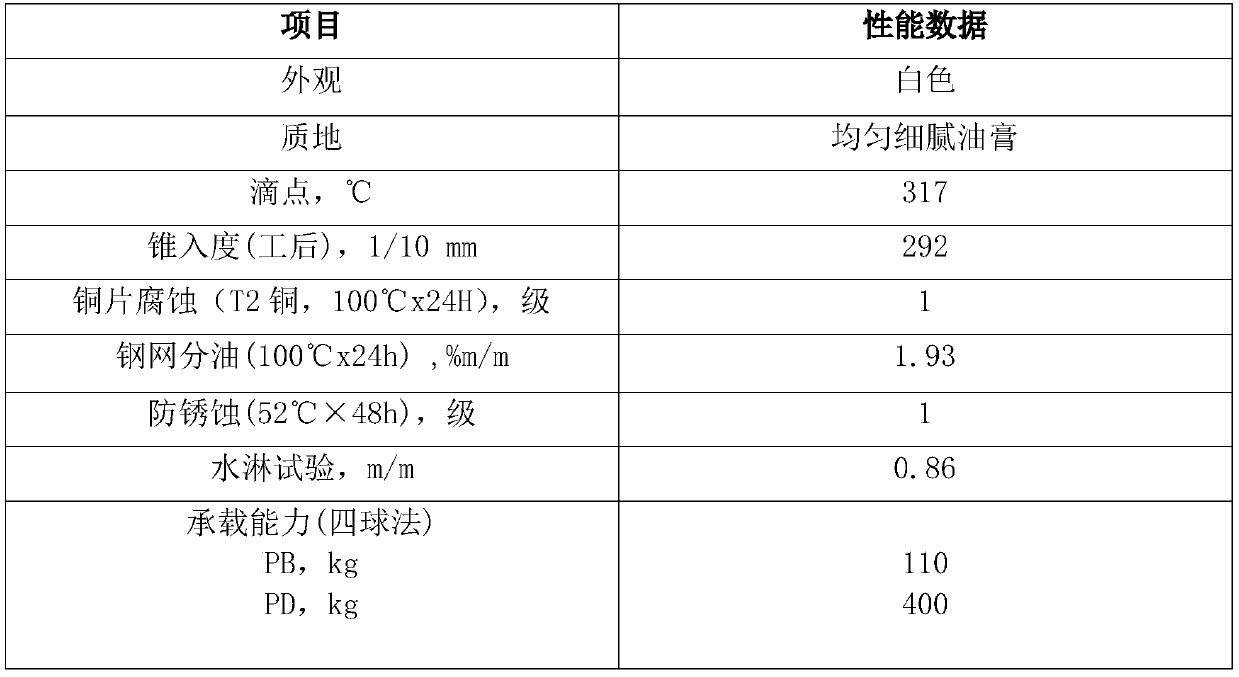

An ultra-high temperature, lubricating grease technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of unsatisfactory service conditions, low service temperature, metal corrosion, etc., and achieve excellent comprehensive performance, good anti-friction and anti-wear properties , the effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 of the present invention provides a synthetic low-carbon type ultra-high temperature lubricating grease, the components and weight-to-number ratios of the lubricating grease are:

[0035] 100kg of synthetic urea grease: 85kg for trimellitate, 10kg for polyisobutylene, 5kg for polyurea;

[0036] 12.9kg of functional additives: 0.5kg of high-temperature antioxidant, 0.3kg of anti-copper corrosion additive, 0.1kg of ferrous metal anti-rust and preservative, 2kg of flame-retardant lubricant, 5kg of flame-retardant smoke suppressant, and 5kg of ultra-high temperature solid lubricant;

[0037] In 5kg of polyurea, MDI is 2kg, tallow amine is 2kg, and cyclohexylamine is 1kg.

[0038] The preparation method of the synthetic low-carbon type ultra-high temperature lubricating grease of embodiment 1 is:

[0039] 1) According to the production volume, accurately measure 51-76.5kg of trimellitate and 10kg of polyisobutene into the fat-making kettle, stir and heat up to ...

Embodiment 2

[0048] Embodiment 2 of the present invention provides a synthetic low-carbon type ultra-high temperature lubricating grease, the components and weight-to-number ratios of the lubricating grease are:

[0049] 100kg of synthetic urea grease: 84kg for trimellitate, 10kg for polyisobutylene, 6kg for polyurea;

[0050] 20.4kg of functional additives: 0.8kg of high-temperature antioxidant, 0.3kg of anti-copper corrosion additive, 0.3kg of ferrous metal anti-rust and preservative, 3kg of flame-retardant lubricant, 8kg of flame-retardant smoke suppressant, and 8kg of ultra-high temperature solid lubricant;

[0051] In 6kg of polyurea, MDI is 2.4kg, tallowamine is 2.4kg, and cyclohexylamine is 1.2kg.

[0052] The preparation method of the synthetic low-carbon type ultra-high temperature lubricating grease of embodiment 2 is:

[0053] 1) According to the production volume, accurately measure 50.4-75.6kg of trimellitate and 10kg of polyisobutene into the fat-making kettle, stir and heat u...

Embodiment 3

[0062] Embodiment 3 of the present invention provides a synthetic low-carbon ultra-high temperature lubricating grease, the components and weight-to-number ratios of the lubricating grease are:

[0063] 100kg of synthetic urea grease: 81g of trimellitate, 11.5kg of polyisobutylene, and 7.5kg of polyurea;

[0064] 26.7kg of functional additives: 1kg of high temperature antioxidant, 0.3kg of anti-copper corrosion additive, 0.4kg of ferrous metal antirust and preservative, 5kg of flame retardant lubricant, 10kg of flame retardant and smoke suppressant, and 10kg of ultra-high temperature solid lubricant;

[0065] In 7.5kg of polyurea, MDI is 3kg, tallowamine is 3kg, and cyclohexylamine is 1.5kg.

[0066] The preparation method of the synthetic low-carbon type ultra-high temperature lubricating grease of embodiment 3 is:

[0067] 1) According to the production volume, accurately measure 48.6-72.9kg of trimellitate and 11.5kg of polyisobutylene into the fat-making kettle, stir and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com