Internal-winding-heating vacuum and vacuum pressure paint immersion equipment

A technology of vacuum pressure impregnation and internal heating, which is applied in electric components, inductance/transformer/magnet manufacturing, coil manufacturing, etc. It can solve the problems of poor impregnation paint permeability, low production efficiency, and easy existence of air bubbles, etc., and achieve the quality of insulation treatment Improvement, production efficiency improvement, permeability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

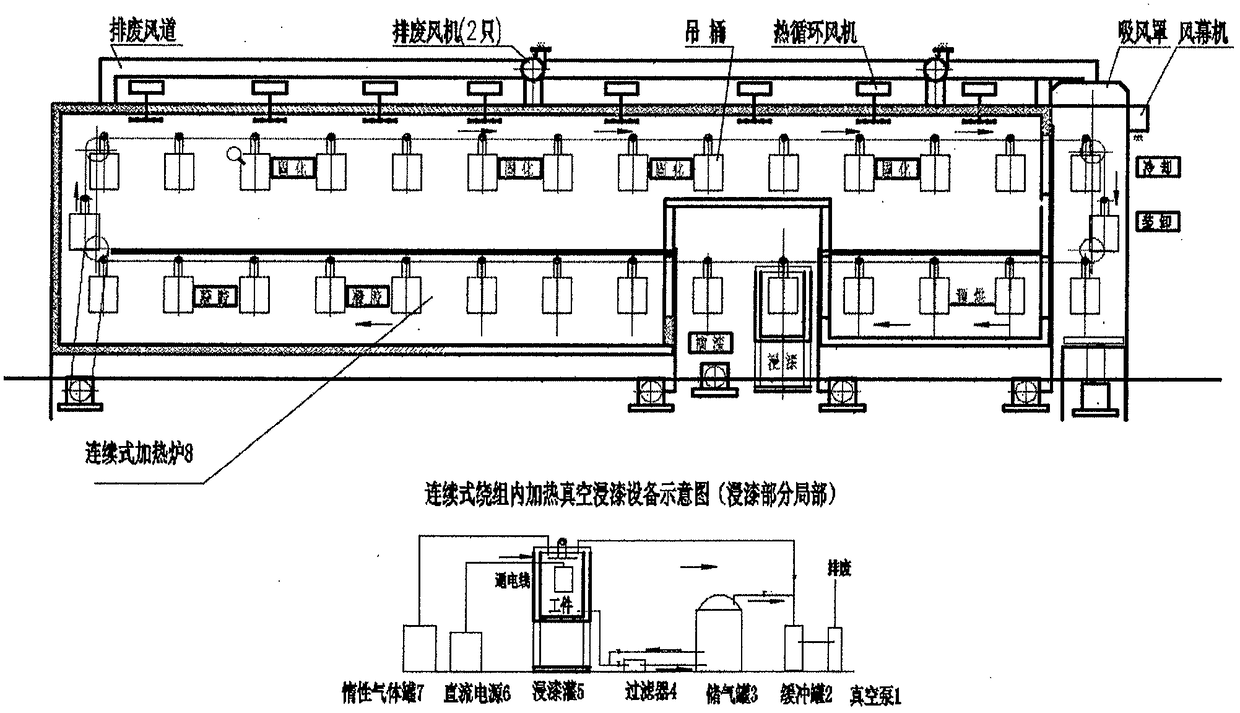

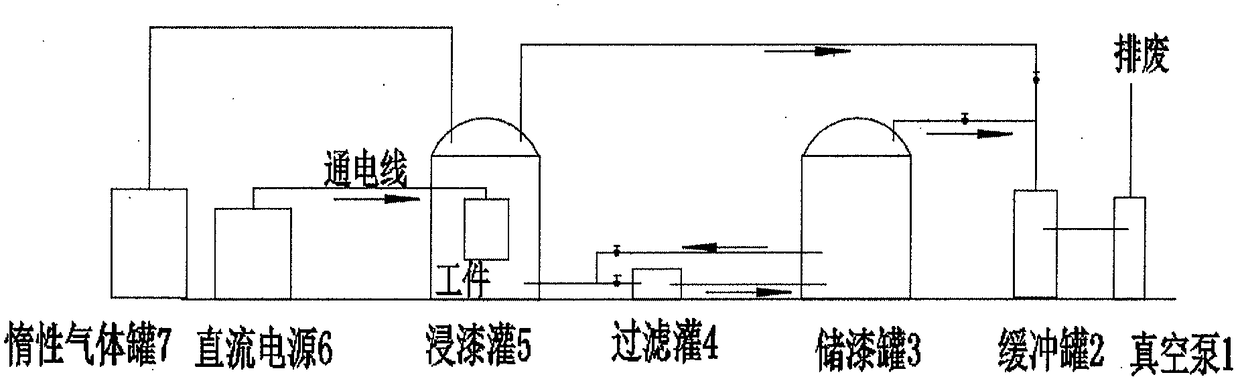

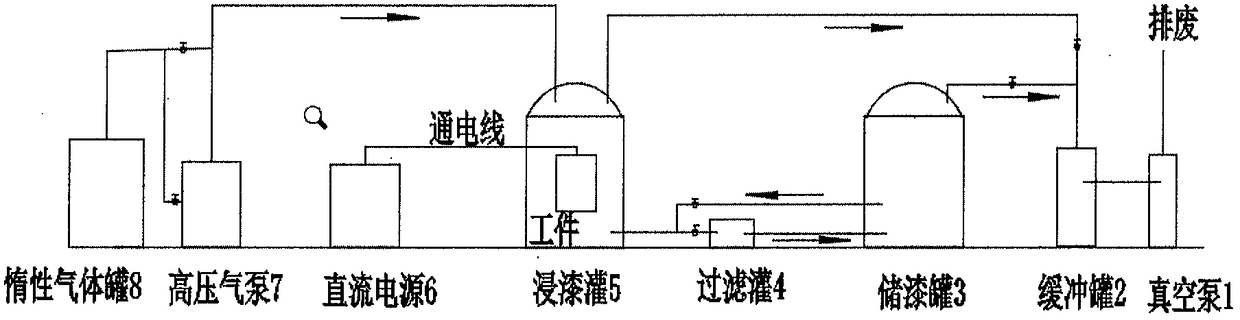

[0009] In-winding heating vacuum impregnation equipment, using vacuum impregnation equipment, vacuum pressure impregnation equipment, continuous vacuum impregnation equipment, adopts internal heating technology in the winding during the impregnation process, uses a dedicated DC power supply, and provides windings with a voltage lower than 80V 1500A When the winding temperature reaches the solidification temperature of the insulating varnish, the surrounding insulating varnish begins to solidify. At this time, when the winding leaves the insulating varnish, the insulating varnish around the winding will not be lost, so as to achieve better immersion Paint quality.

[0010] Due to the use of heating technology inside the winding, the temperature of the winding rises to the specified temperature after power-on, and the temperature of the iron core and the surrounding environment rises slightly, so the energy consumption is significantly reduced.

[0011] When the winding is energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com