Method for fireproofing and fire retardant timber reconstituted circularly

A fire-retardant, wood-based technology, applied in the direction of humidity-adjusting wood, impregnated wood, wood impregnation, etc., can solve the problem that the performance of soft wood has not been improved or improved, affecting the economic value of recycling soft wood scraps, and limiting the use of soft wood To achieve the effect of reducing serious economic and environmental burdens, reducing casualties and losses, and preventing the spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

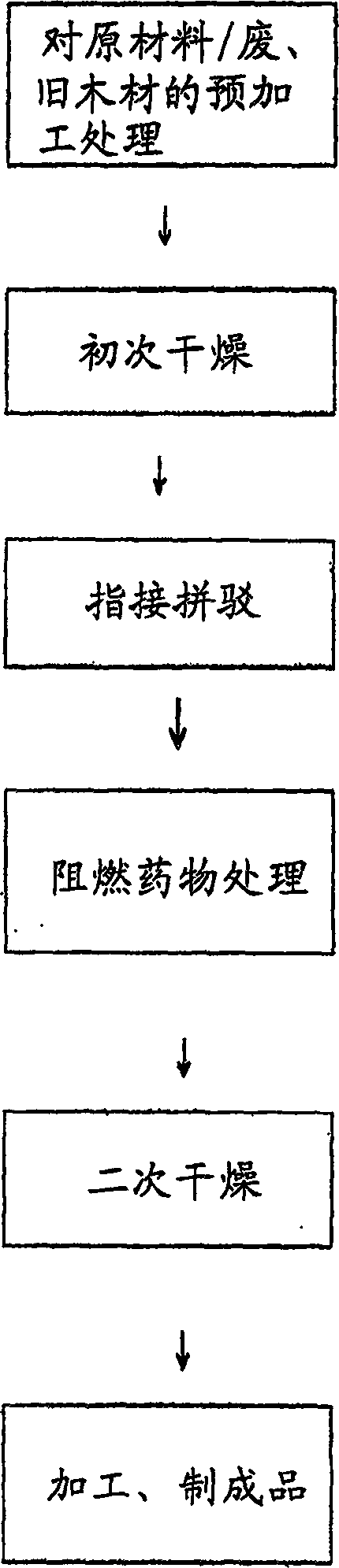

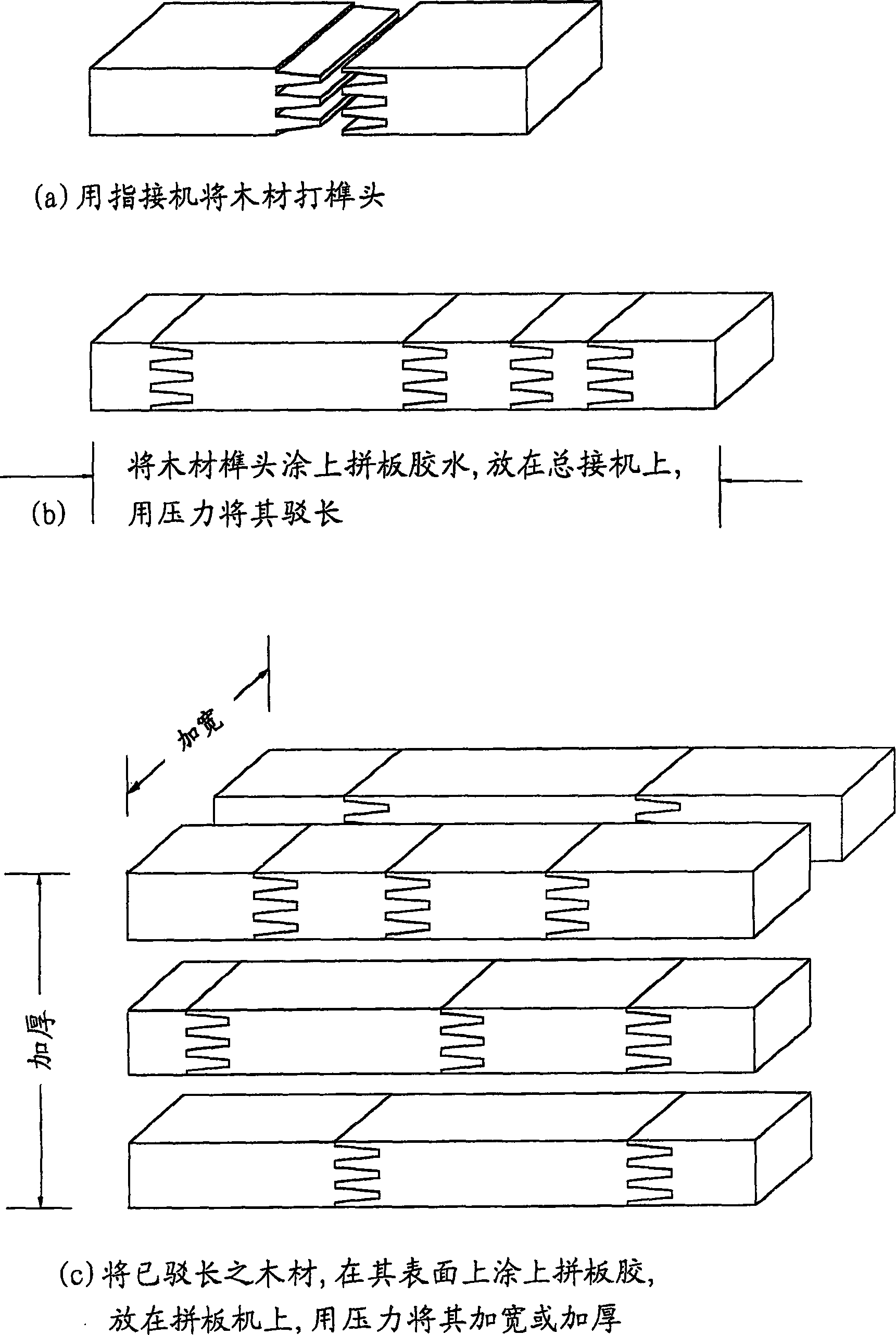

[0027] Combine the following figure 1 As shown, the production method of the recycled fire-proof and flame-retardant wood of the present invention is introduced in detail.

[0028] In the production method of the present invention, the raw materials that can be used as the recycled fire-resistant and flame-retardant wood of the present invention are very extensive, and can be discarded wood scraps and waste materials, and these woods can be soft wood or hard wood. For example, eco-friendly softwoods with a low density, or hardwoods with a higher density can be used.

[0029] These timber materials are mainly derived from:

[0030] a. Wood with defects (for example, bursts, dead knots, bug roars, etc.);

[0031] b. Defective products that need to be scrapped due to processing errors during the production process;

[0032] c. Head and tail scraps of wood;

[0033] d. Raw materials whose size is not suitable for the production of established products;

[0034] e. Wooden beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com