Organic exhaust-gas processing method

An organic gas and organic technology, applied in the field of absorption and treatment of organic volatile gases, can solve problems such as waste, high emission standards, and investment income can not be optimized, and achieve convenient operation, easy acquisition, local and remote control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

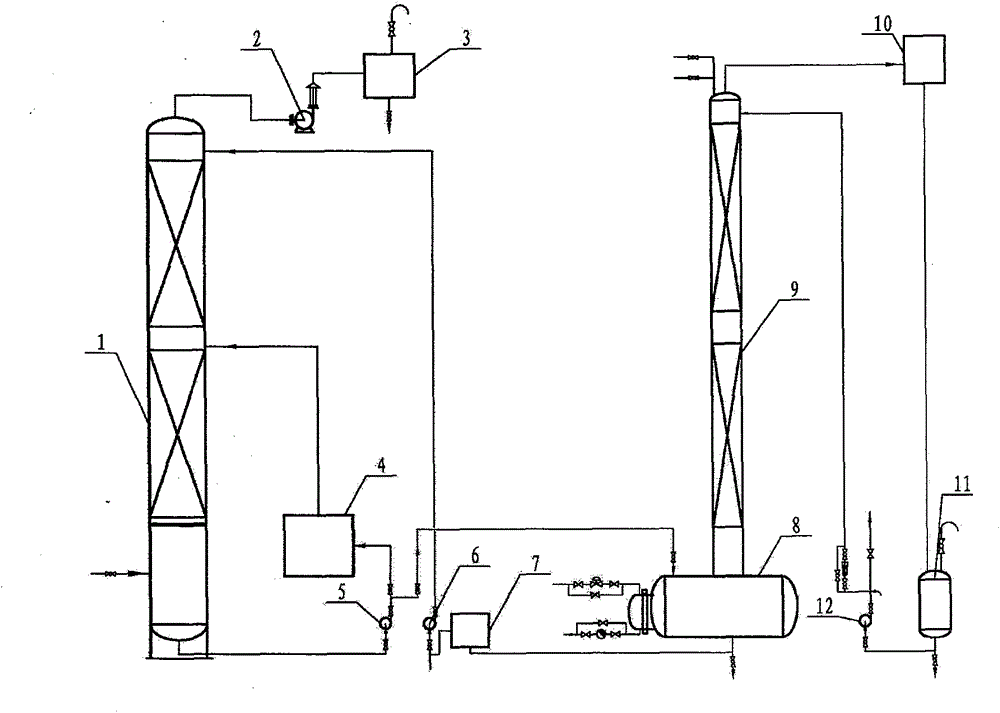

[0020] The present invention will be further described below in conjunction with the accompanying drawings, and the embodiments are not intended as a restrictive description of the present invention documents.

[0021] Before the exhaust gas is introduced, the feed pump 6 is turned on to add an appropriate absorption solution to the absorption tower 1. When the absorption solution overflows the exhaust gas inlet and meets the requirements, adjust the flow rate of the incoming absorbent to the required size to meet the spraying requirements. Density is 10.4m 3 / (m 2 .h). The waste gas is collected into the absorption tower through the pipeline, and part of the waste gas is absorbed by the solution in the lower part of the tower. Because the contact area between the waste gas and the absorption liquid is small, a large amount of waste gas rushes out of the absorption liquid and continues upward during the contact period. The surface is in contact and is fully absorbed by the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com