Method for preparing fuel gas by fluidized bed co-gasification of biomass and coal

A biomass and fuel gas technology, applied in the direction of granular/powdered fuel gasification, etc., can solve problems such as inability to stabilize fluidization alone, low energy density of biomass, and inability to supply stably, achieving high production efficiency, wide distribution, The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

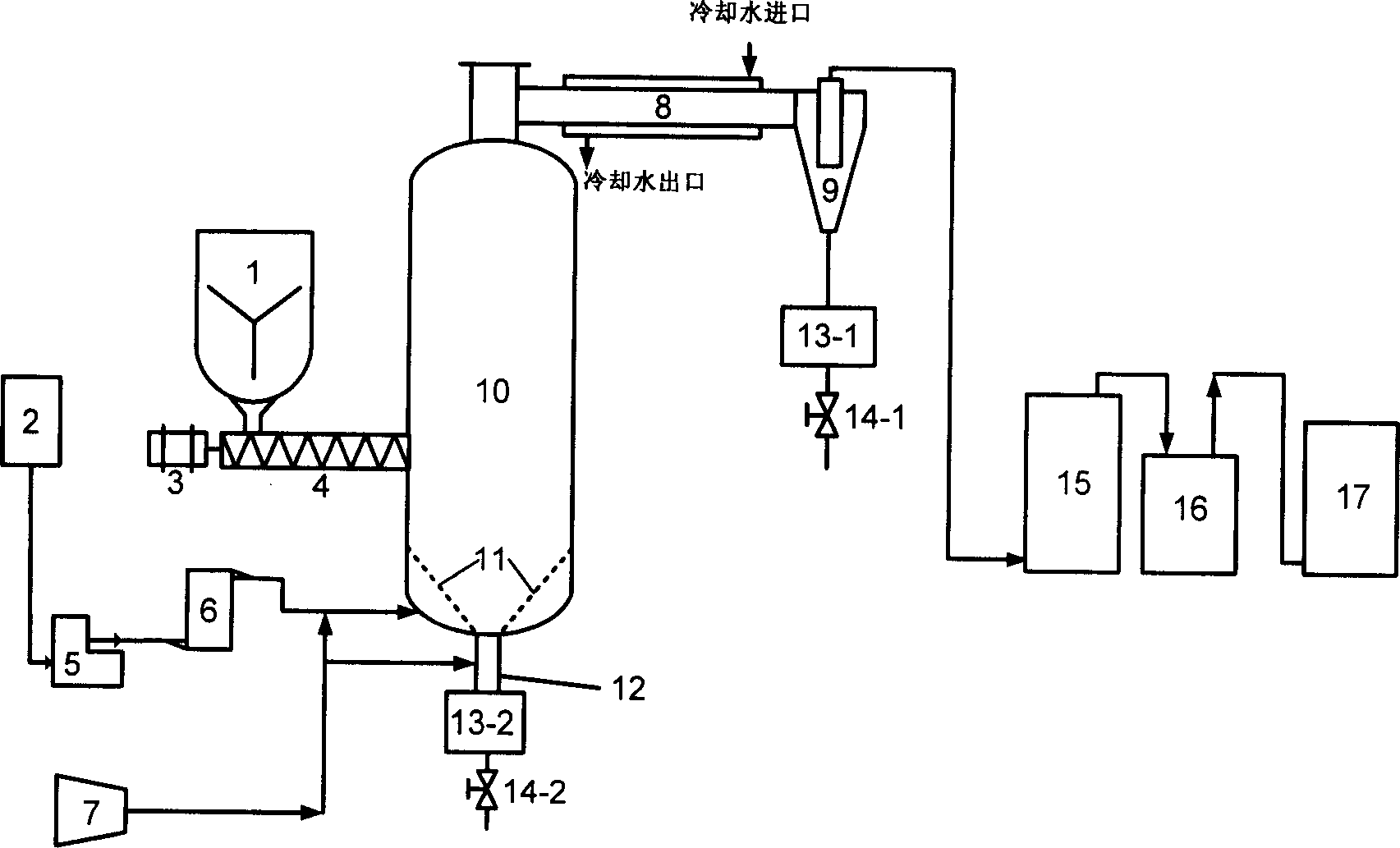

[0018] The mixture of rice straw and coal is used as raw material for gasification. The rice straw does not need to be sorted and purified. It is crushed to a particle size of less than 5mm and mixed with coal particles with a particle size of less than 2mm. The mass percentage of straw in the mixture is 5%. The material is added to the silo 1 with a stirring device for use. Insert the flame spray gun into the furnace from the bottom of the gasification furnace 10, feed in the liquefied gas and the air required for complete combustion, heat the gasification furnace 10 to 700-800°C, stop heating, turn on the speed regulating motor 3, and feed through the screw The device 4 puts the mixed materials into the gasifier 10, and the compressed air generated by the air compressor 7 enters the gasifier 10 through the distribution plate 11 and the central pipe 12 respectively, and the total amount of air entering the furnace is equal to the mixture raw material of biomass and coal. Th...

Embodiment 2

[0024] The mixture of rice straw and coal is used as raw material for gasification. The rice straw does not need to be sorted and purified. It is crushed to a particle size of less than 5mm and mixed with coal particles with a particle size of less than 2mm. The mass percentage of rice straw in the mixture is 33%. The material is added to the silo 1 with a stirring device for use. Insert the flame spray gun into the furnace from the bottom of the gasification furnace 10, feed in the liquefied gas and the air required for complete combustion, heat the gasification furnace 10 to 700-800°C, stop heating, turn on the speed regulating motor 3, and feed through the screw The device 4 puts the mixed materials into the gasifier 10, and the compressed air generated by the air compressor 7 enters the gasifier 10 through the distribution plate 11 and the central pipe 12 respectively, and the total amount of air entering the furnace is equal to the mixture raw material of biomass and coal....

Embodiment 3

[0030] The mixture of rice straw and coal is used as the raw material for gasification. The rice straw does not need to be sorted and purified. It is crushed to a particle size of less than 5mm and mixed with coal particles with a particle size of less than 2mm. The mass percentage of rice straw in the mixture is 50%. The material is added to the silo 1 with a stirring device for use. Insert the flame spray gun into the furnace from the bottom of the gasification furnace 10, feed in the liquefied gas and the air required for complete combustion, heat the gasification furnace 10 to 700-800°C, stop heating, turn on the speed regulating motor 3, and feed through the screw The device 4 puts the mixed materials into the gasifier 10, and the compressed air generated by the air compressor 7 enters the gasifier 10 through the distribution plate 11 and the central pipe 12 respectively, and the total amount of air entering the furnace is equal to the mixture raw material of biomass and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com