Covering slag for beam blank continuous casting crystallizer

A special-shaped billet continuous casting and crystallizer technology, which is applied in the field of mold flux for molten steel continuous casting molds, can solve the problems affecting the lubrication and filling of mold flux, the adhesion between the billet shell and the copper wall of the mold, and the excessive stickiness of the molten slag layer. Achieve good lubricity and uniform filling, reduce surface cracks, and reduce crack rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with 8 implementations.

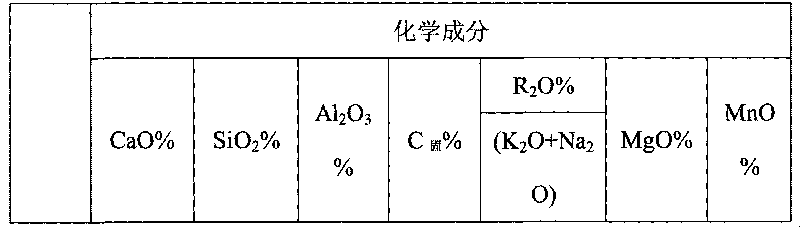

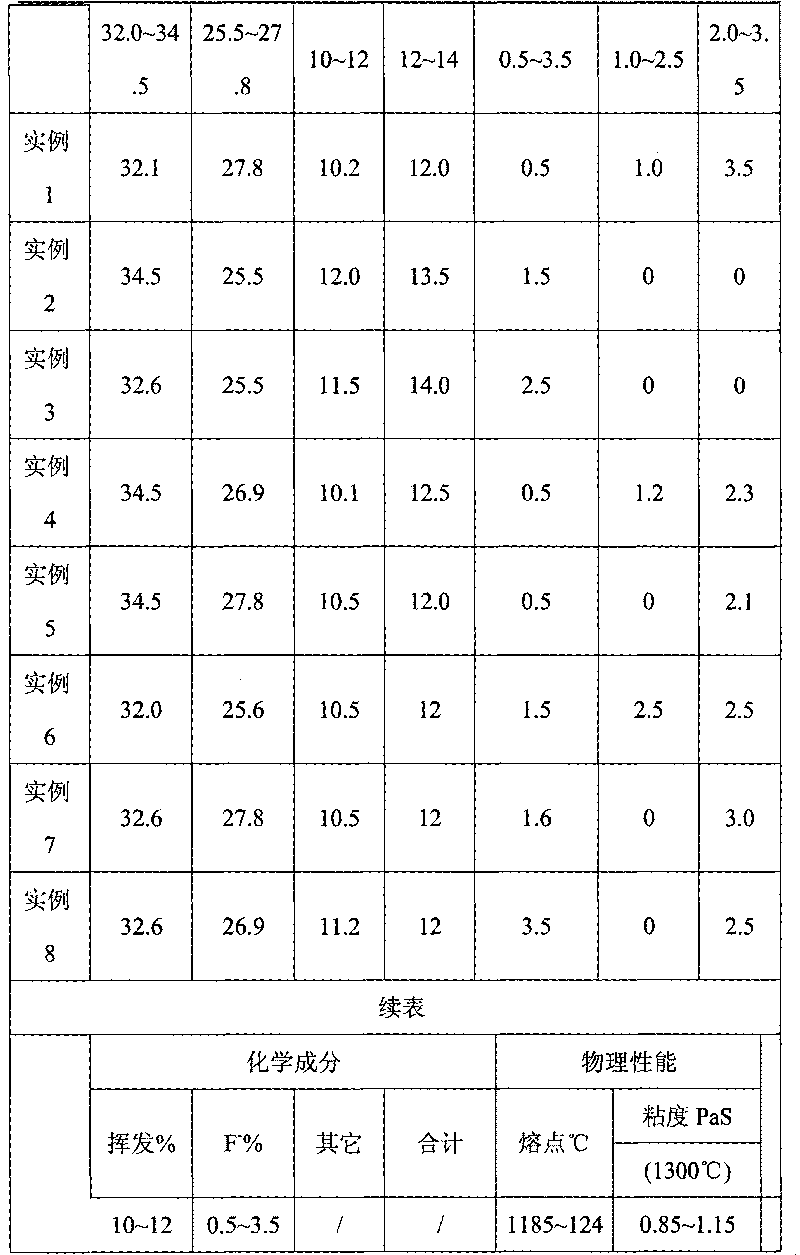

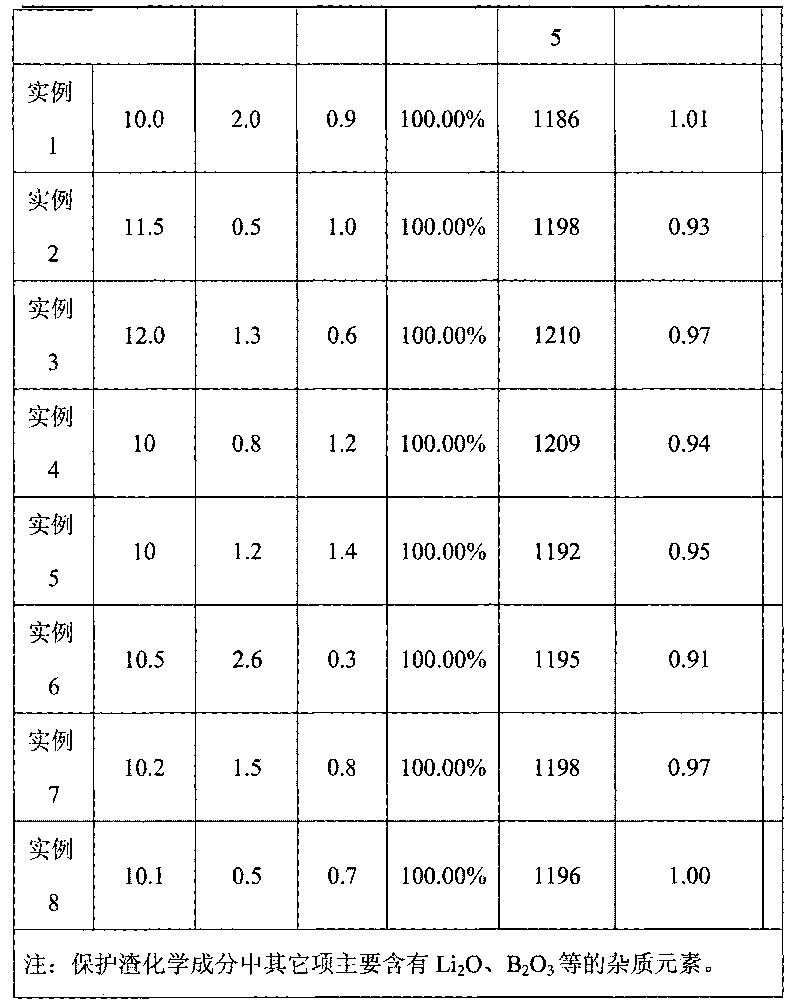

[0019] According to the chemical composition and particle size requirements listed in Table 1, the raw materials are pre-melted and sintered, mixed, crushed, granulated, dried, weighed, and bagged. After testing, the melting point °C and viscosity (1300 °C) are listed in in FIG. 1.

[0020] Table 1 Composition and properties of mold flux

[0021]

[0022]

[0023]

[0024] The mold flux of the present invention has been used to produce profiled billets for more than half a year. The production practice shows that the cracks on the surface of profiled billets are greatly reduced, and the rate of cracked rejects is significantly reduced, from 16.5kg / ton of steel to below 3.0kg / ton of steel; in the continuous casting production process , The bonding phenomenon rarely occurs, and the bonding breakout rate drops from 0.13% to 0.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com