Gasification method and device for biomass and coal mixed fluidized-bed

A fluidized bed gasifier, biomass technology, applied in the direction of granular/powdered fuel gasification, etc., can solve the problems of tar treatment, increase the complexity of operation, etc. Effect of gas composition stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

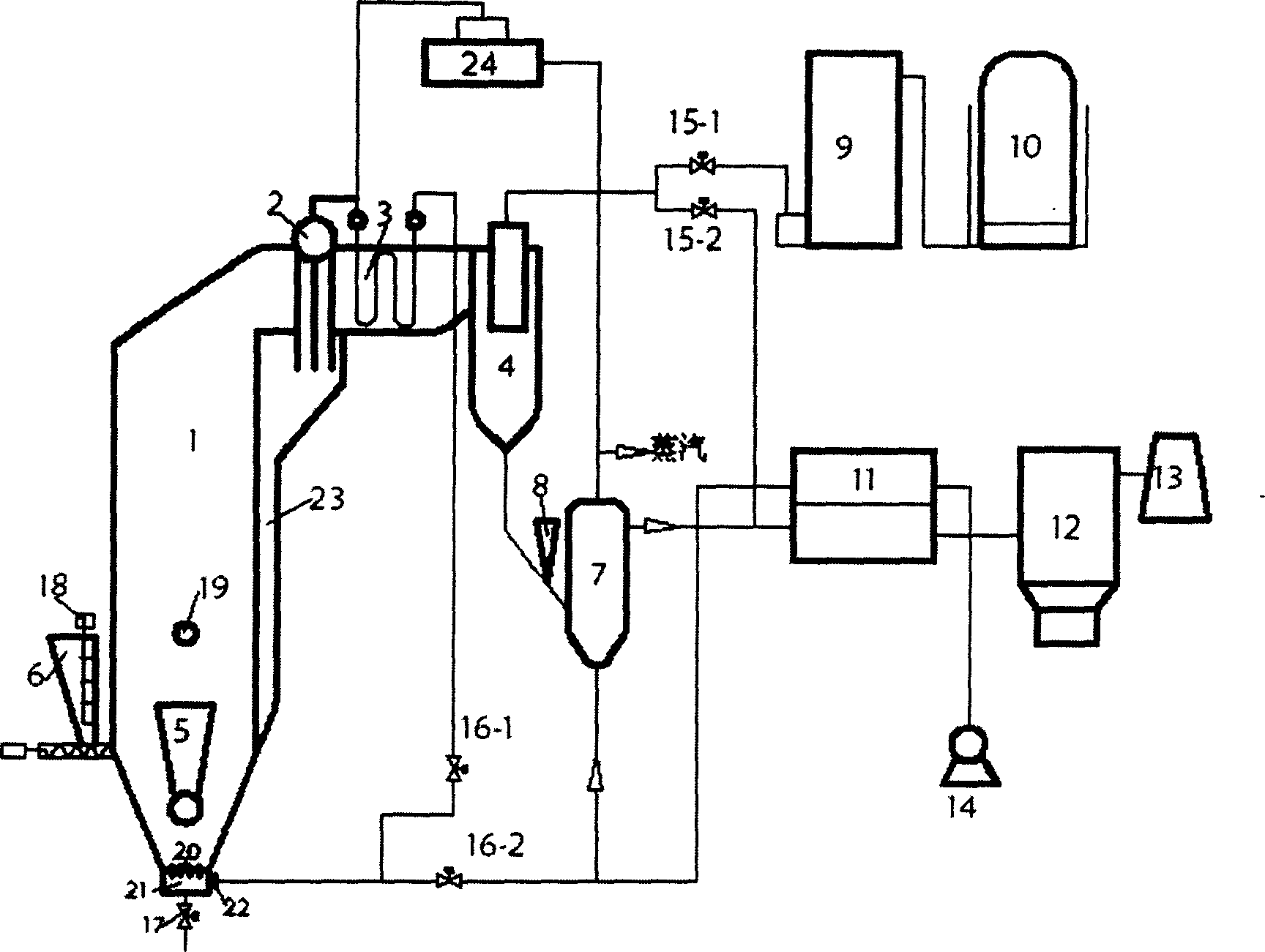

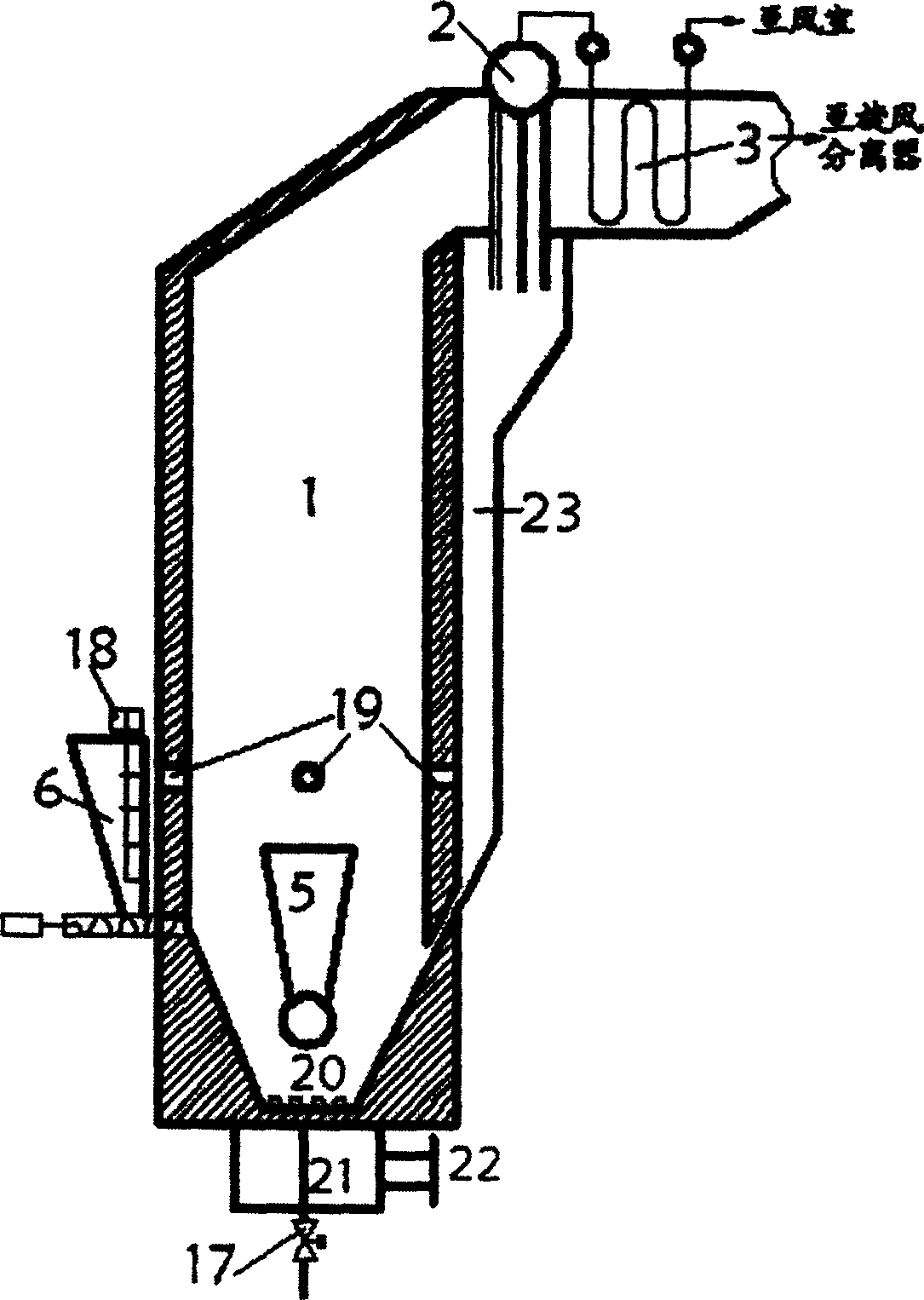

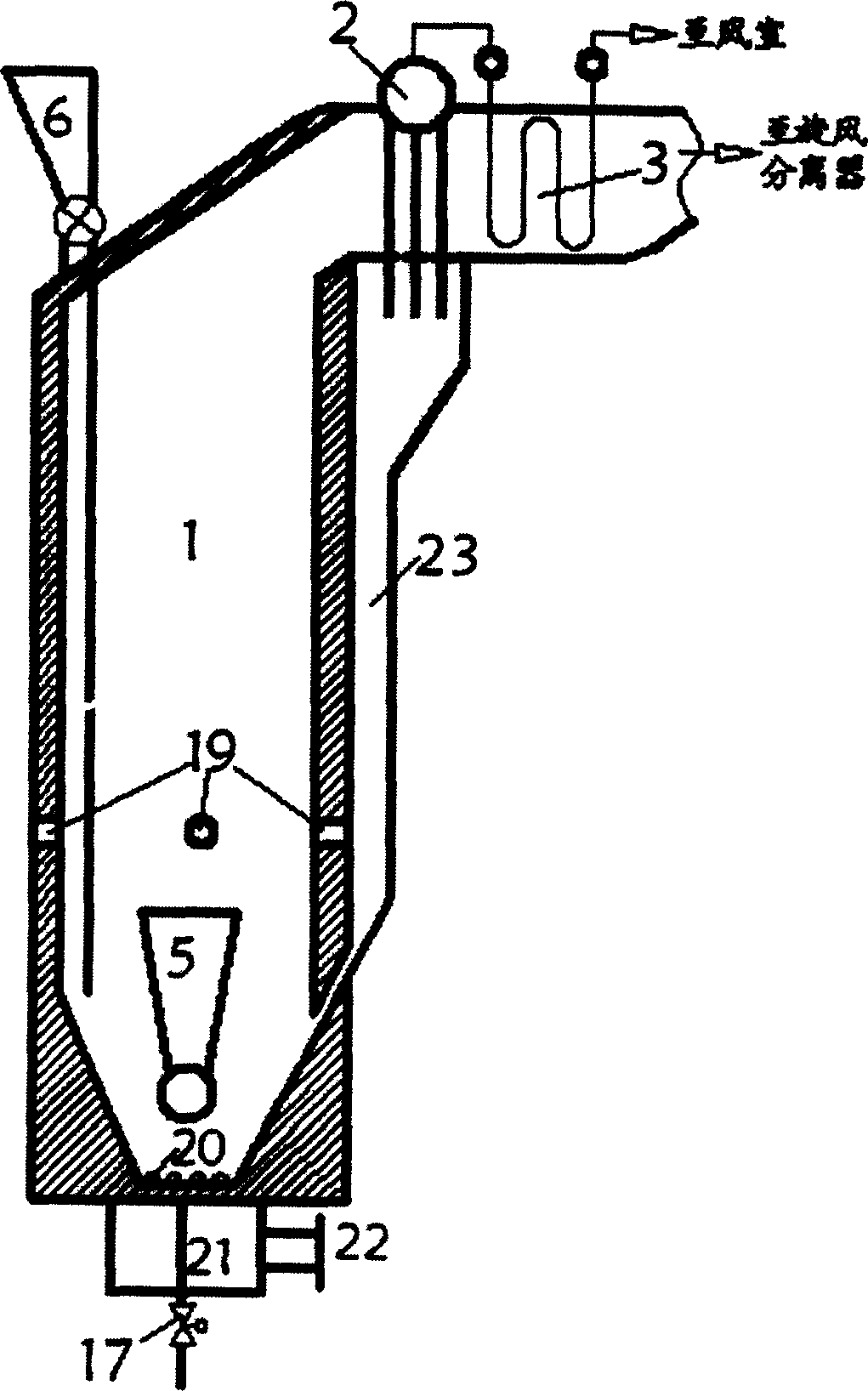

[0020] like figure 1 , figure 2As shown, the device is divided into a fluidized bed gasifier (1), a flue gas purification system, a gas purification system, an air supply system, and a steam system, wherein the upper part of the fluidized bed gasifier (1) is cylindrical, and the lower part is Inverted cone shape, the furnace body is steel plate structure with refractory lining, the lower part of the furnace body is equipped with air distribution plate (20), air chamber (21), air inlet (22), slag discharge valve (17), gasifier (1) There are two feed bins (5, 6) with screw feeding mechanism, the coal bin (5) is set at the lower part of the furnace body inverted cone; the biomass material bin (6) is set at the upper part of the furnace body inverted cone, and the top of the feed bin A stirrer (18) is provided to prevent the bridging and clogging of biomass materials; 4 secondary air nozzles (19) are arranged in the middle of the furnace body, which are evenly distributed around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com