Biomass pellet fuel and preparation method thereof

A biomass particle and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of low heat and short burning time, and achieve long burning time, easy to burn and burn out, and low ash content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

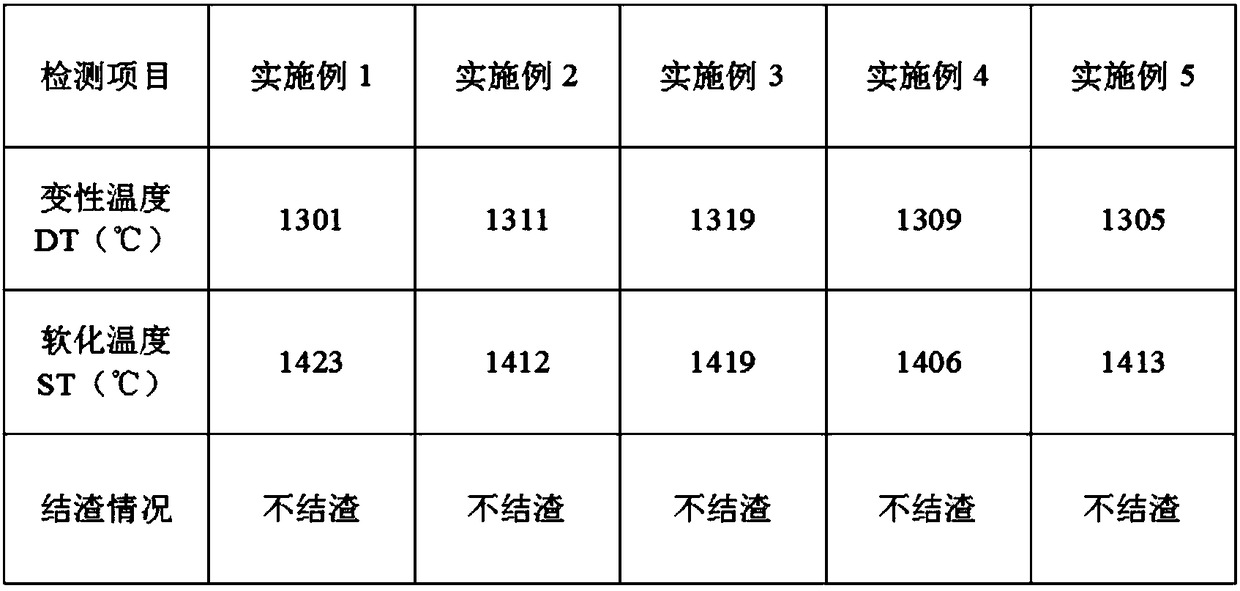

Examples

Embodiment 1

[0029] A biomass pellet fuel, comprising the following raw materials in parts by weight: 30 parts of rice straw, 20 parts of peanut shells, 10 parts of cotton stalks, 20 parts of yellow tobacco stalks, 30 parts of cashew nut shells, 20 parts of hawthorn cores, 1 part of machine oil, potassium chlorate 0.5 parts, 0.4 parts of potassium nitrate, 0.5 parts of diatomaceous earth and 0.6 parts of kaolin.

[0030] A preparation method of biomass particle fuel, the preparation method comprises the following steps:

[0031] (1) Air-dry rice straw, peanut shells, cotton stalks, yellow tobacco stalks, cashew nut shells and hawthorn cores until the moisture content is 15%, and then pulverize them with a pulverizer to obtain pulverized materials, which are passed through a sieving machine Sieve to obtain a particle size of 50 mesh sieves;

[0032] (2) Put the sieving material, mechanical oil, potassium chlorate, potassium nitrate, diatomaceous earth and kaolin obtained in step (1) into a...

Embodiment 2

[0036] A biomass granular fuel, comprising the following raw materials in parts by weight: 35 parts of wheat straw, 25 parts of peanut shells, 12 parts of cotton stalks, 22 parts of yellow tobacco stalks, 35 parts of cashew nut shells, 25 parts of hawthorn cores, 1.5 parts of castor oil, potassium chlorate 0.7 parts, 0.7 parts of potassium nitrate, 0.8 parts of diatomaceous earth and 0.8 parts of kaolin.

[0037] A preparation method of biomass particle fuel, the preparation method comprises the following steps:

[0038] (1) Air-dry wheat straw, peanut shells, cotton stalks, yellow tobacco stalks, cashew nut shells and hawthorn cores until the moisture content is 18%, and then pulverize them with a pulverizer to obtain pulverized materials, which are passed through a sieving machine Sieve to obtain a particle size of 60 mesh sieves;

[0039](2) Put the sieving material, castor oil, potassium chlorate, potassium nitrate, diatomaceous earth and kaolin into the blender of step (...

Embodiment 3

[0043] A biomass pellet fuel, comprising the following raw materials in parts by weight: 40 parts of corn stalks, 30 parts of peanut shells, 15 parts of cotton stalks, 25 parts of yellow tobacco stalks, 40 parts of cashew nut shells, 30 parts of hawthorn cores, 2 parts of tallow, 1 part of potassium chlorate 1 part, 1 part of potassium nitrate, 1 part of diatomaceous earth and 1 part of kaolin.

[0044] A preparation method of biomass particle fuel, the preparation method comprises the following steps:

[0045] (1) Air-dry corn stalks, peanut shells, cotton stalks, yellow tobacco stalks, cashew nut shells and hawthorn cores until the water content is 20%, and then pulverize them with a pulverizer to obtain pulverized materials, which are passed through a sieving machine Sieve to obtain a particle size of 65 mesh sieves;

[0046] (2) Put the sieving material, tallow, potassium chlorate, potassium nitrate, diatomaceous earth and kaolin obtained in step (1) into a blender and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com