Oily sludge coke water slurry and preparation method thereof

A sludge water and coke slurry technology is applied in petroleum coke mixed slurry and its preparation, high stability oily sludge, and high concentration fields. Reliable, difficult to effectively separate oil and water, etc., to achieve the effect of improving rheology and stability, low cost, and high flammable components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

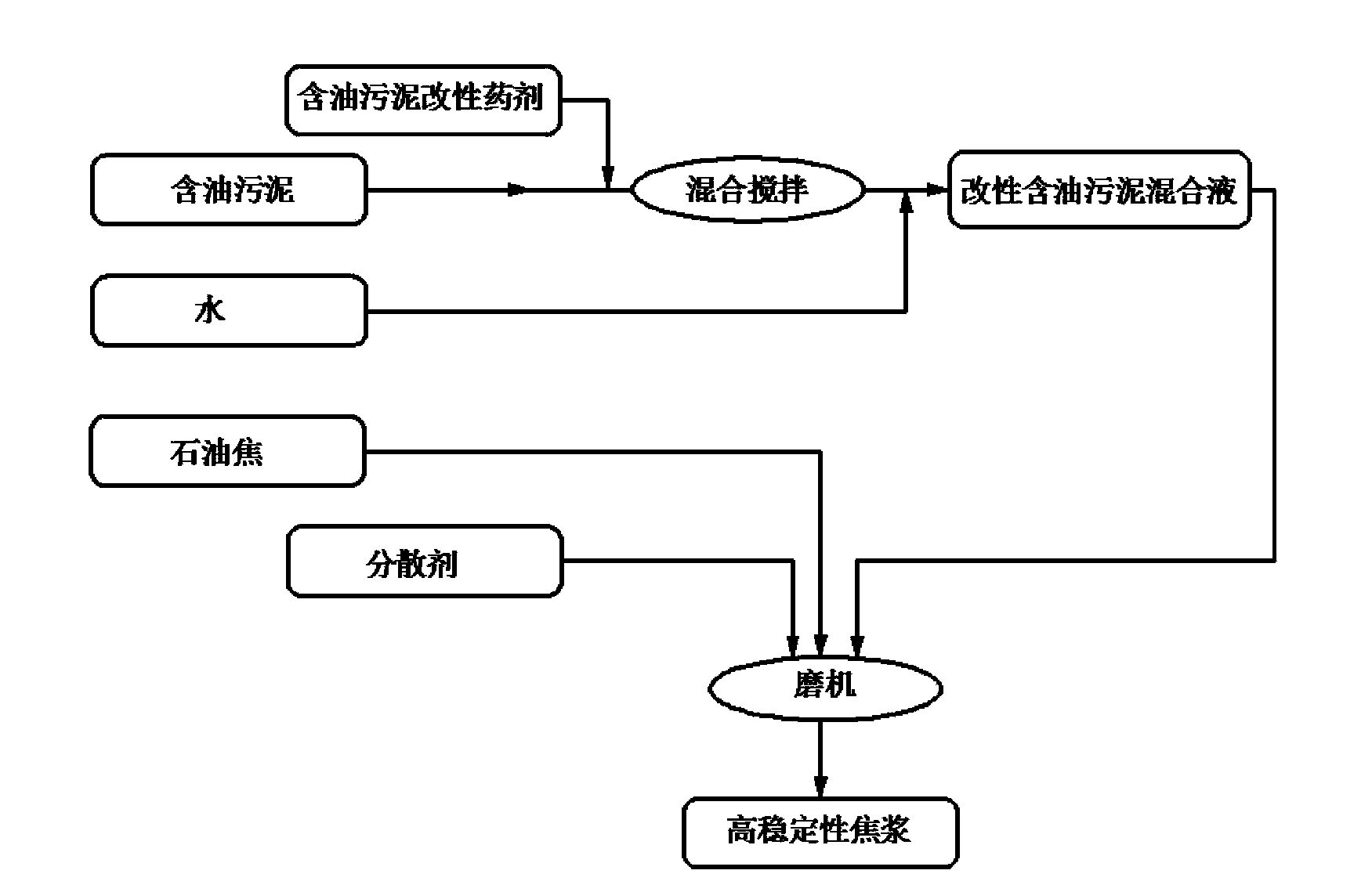

Method used

Image

Examples

Embodiment 1

[0019] 1. Raw materials

[0020] (1) The oily sludge of a refinery has a water content of 59.9wt%;

[0021] (2) Petroleum coke from a refinery, with a sulfur content of 4.88wt% and an ash content of 0.15wt%;

[0022] (3) Dispersant (sodium naphthalenesulfonate formaldehyde condensate);

[0023] (4) Sludge modifier (ferric sulfate);

[0024] (5) water.

[0025] 2. Preparation conditions

[0026] (1) Raw material ratio (mass percentage)

[0027] Petroleum coke 67.65%, oily sludge 3.38%, water 28.53%, dispersant 0.34%, sludge modifier 0.1%.

[0028] (2) Preparation method

[0029] Firstly, the oily sludge and the sludge modifying agent are mixed and stirred evenly to obtain the modified sludge. Grinding and mixing petroleum coke, water and dispersant to obtain water coke slurry.

[0030] 3. Product performance indicators

[0031] ① Appearance shape: black paste. At 25°C, the apparent viscosity is 1099mPa·s, which is good

[0032] Good fluidity, pumpable;

[0033] ②Sol...

Embodiment 2

[0037] 1. Raw materials

[0038] Same as Example 1

[0039] 2. Preparation conditions

[0040] (1) Raw material ratio (mass percentage)

[0041] 65.39% of petroleum coke, 6.54% of oily sludge, 27.54% of water, 0.33% of dispersant, and 0.20% of sludge modifier.

[0042] (2) Preparation method

[0043] Same as Example 1

[0044] 3. Product performance indicators

[0045] ① Appearance shape: black paste. At 25°C, the apparent viscosity is 1063mPa·s, which has good fluidity and can be pumped;

[0046] ②Solid content (mass%): 68%;

[0047] ③The size of solid particles in the slurry: less than 500 microns;

[0048] ④ Stability: no hard precipitation occurs within 15 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com