Impact-resistant flame-retardant floor and preparation method thereof

A technology of impact resistance and floor, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problem that the performance cannot meet the application, and achieve good film forming, good flame retardant performance, high The effect of specific bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

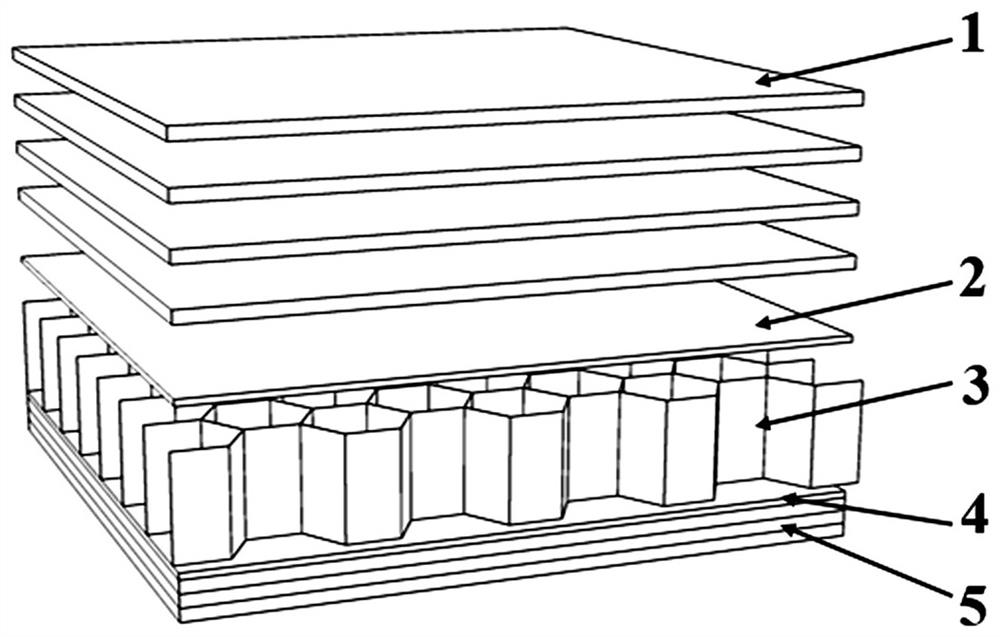

[0063] Such as figure 1 As shown, the impact-resistant and flame-retardant floor described in this embodiment includes:

[0064] Phenolic resin composite upper panel 1, upper adhesive layer 2, honeycomb core 3, lower adhesive layer 4, phenolic resin composite lower panel 5;

[0065] The honeycomb core 3 is a Nomex honeycomb core, and the density of the honeycomb core is 144kg / m 3 , the diameter of the inscribed circle of the honeycomb core is 3.2 mm, and the thickness of the honeycomb core is 10.7 mm.

[0066] The upper adhesive layer 2 and the lower adhesive layer 4 are epoxy film, and the surface weight of the epoxy film is 300g / m 2 .

[0067] The upper panel of phenolic resin composite material and the lower panel of phenolic resin composite material are prepared from phenolic resin prepreg, and the area weight of phenolic resin prepreg is 420g / m 2 The raw materials for the preparation of phenolic resin prepreg include phenolic resin and reinforcing material. In the phe...

Embodiment 2

[0089] Such as figure 1 As shown, the impact-resistant and flame-retardant floor described in this embodiment includes:

[0090] Phenolic resin composite upper panel 1, upper adhesive layer 2, honeycomb core 3, lower adhesive layer 4, phenolic resin composite lower panel 5;

[0091] The honeycomb core 3 is a Kevlar honeycomb core, and the density of the honeycomb core is 144kg / m 3 , the diameter of the inscribed circle of the honeycomb core is 4.8mm, and the thickness of the honeycomb core is 10.8mm.

[0092] The upper adhesive layer 2 and the lower adhesive layer 4 are epoxy film, and the surface weight of the epoxy film is 200g / m 2 .

[0093] The upper panel of phenolic resin composite material and the lower panel of phenolic resin composite material are prepared from phenolic resin prepreg, and the area weight of phenolic resin prepreg is 460g / m 2 The raw materials for the preparation of phenolic resin prepreg include phenolic resin and reinforcing material. In the phenol...

Embodiment 3

[0116] Such as figure 1 As shown, the impact-resistant and flame-retardant floor described in this embodiment includes:

[0117] Phenolic resin composite upper panel 1, upper adhesive layer 2, honeycomb core 3, lower adhesive layer 4, phenolic resin composite lower panel 5;

[0118] The honeycomb core 3 is a Nomex honeycomb core, and the density of the honeycomb core is 144kg / m 3 , the diameter of the inscribed circle of the honeycomb core is 3.2 mm, and the thickness of the honeycomb core is 10.7 mm.

[0119] The upper adhesive layer 2 and the lower adhesive layer 4 are epoxy film, and the surface weight of the epoxy film is 300g / m 2 .

[0120] The upper panel of phenolic resin composite material and the lower panel of phenolic resin composite material are prepared from phenolic resin prepreg, and the area weight of phenolic resin prepreg is 420g / m 2 The raw materials for the preparation of phenolic resin prepreg include phenolic resin and reinforcing material. In the phe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com