Cereal circular drying equipment

A technology for drying equipment and grain, applied in grain drying, drying, dryer and other directions, can solve the problems of low drying efficiency, poor grain drying quality, and low heat energy utilization rate, so as to improve the drying efficiency. Drying efficiency, vibration reduction, moisture and dust reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

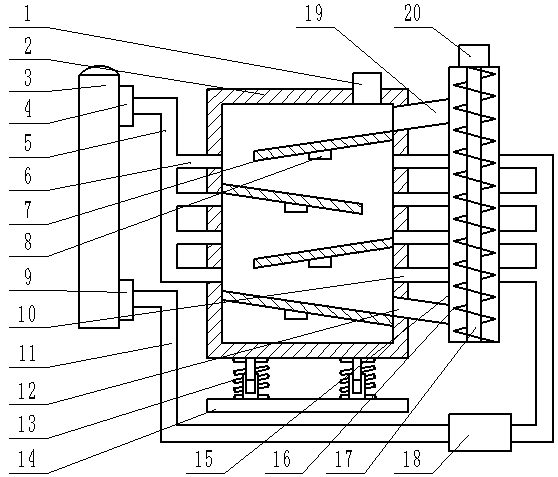

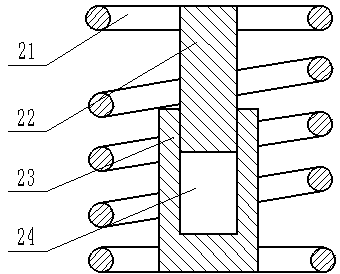

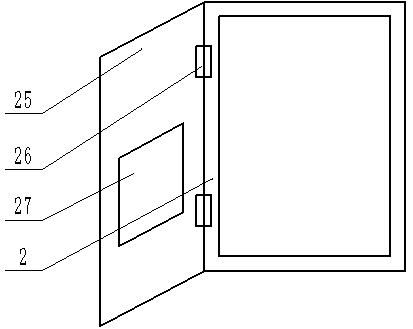

[0021] See Figure 1-4 , A grain circulating drying equipment, comprising a box body 2, a hot blast stove 3 and a lifting cylinder 15. The box body 2 is provided with a plurality of guide plates 7, and the lowermost guide plate 7 is provided at the lower end There is a discharging tube 12, the discharging tube 12 is in the same inclined direction as the lowermost guide plate 7, the discharging tube 12 communicates with the inside of the box 2, and the end of the discharging tube 12 is connected with a lifting cylinder 15; the lifting cylinder The top side of 15 is connected with a feed pipe 19, the other end of the feed pipe 19 is connected with the uppermost guide plate 7, and the feed pipe 19 is in the same tilt direction as the uppermost guide plate 7; the top of the box 2 A blanking pipe 1 is provided, and the blanking pipe 1 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com