Method and device for drying ceramic products

A ceramic molding and drying technology, which is applied to electric heating devices, clay products, ceramic molding machines, etc., and can solve problems such as uneven microwave energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

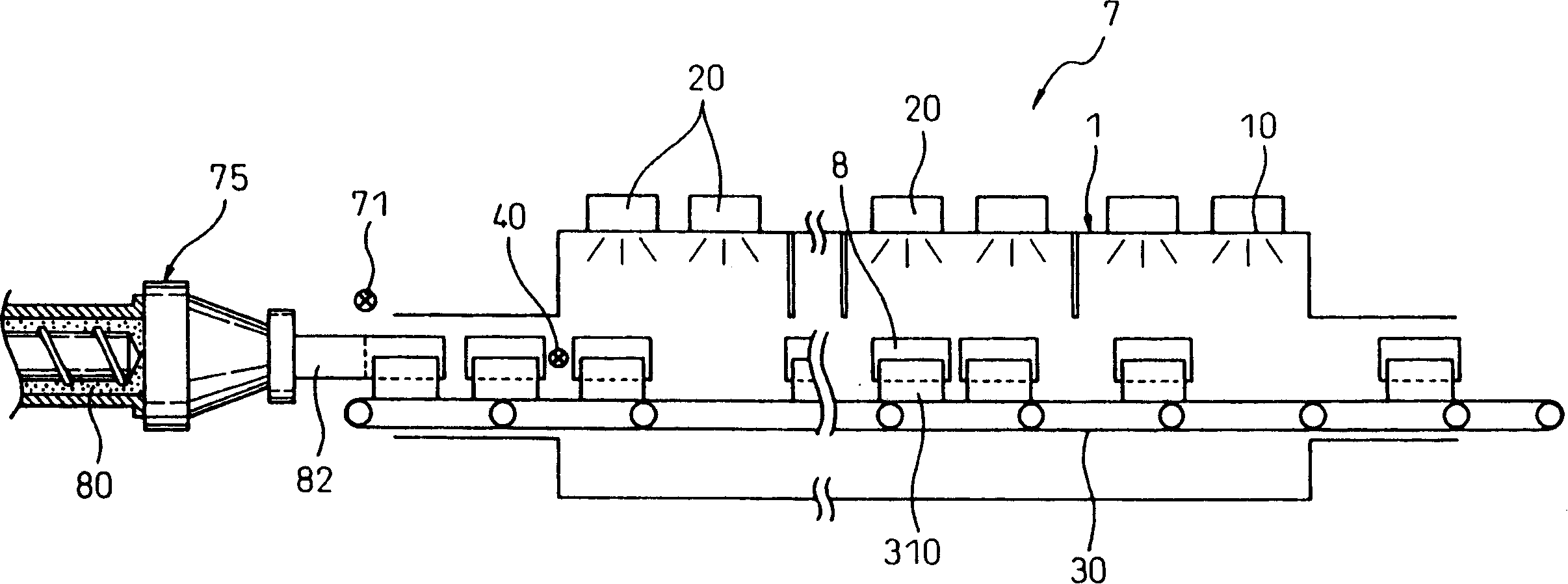

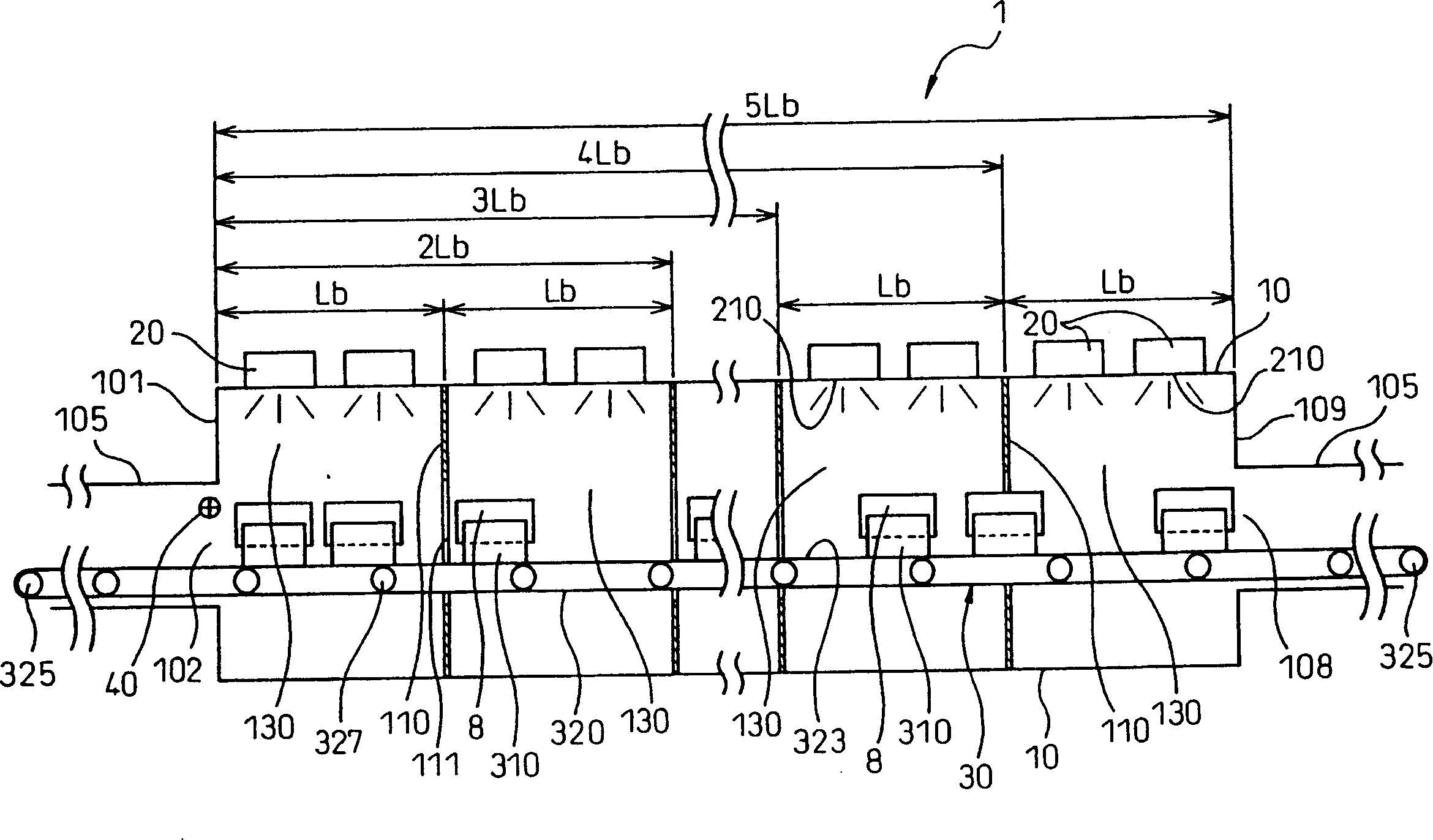

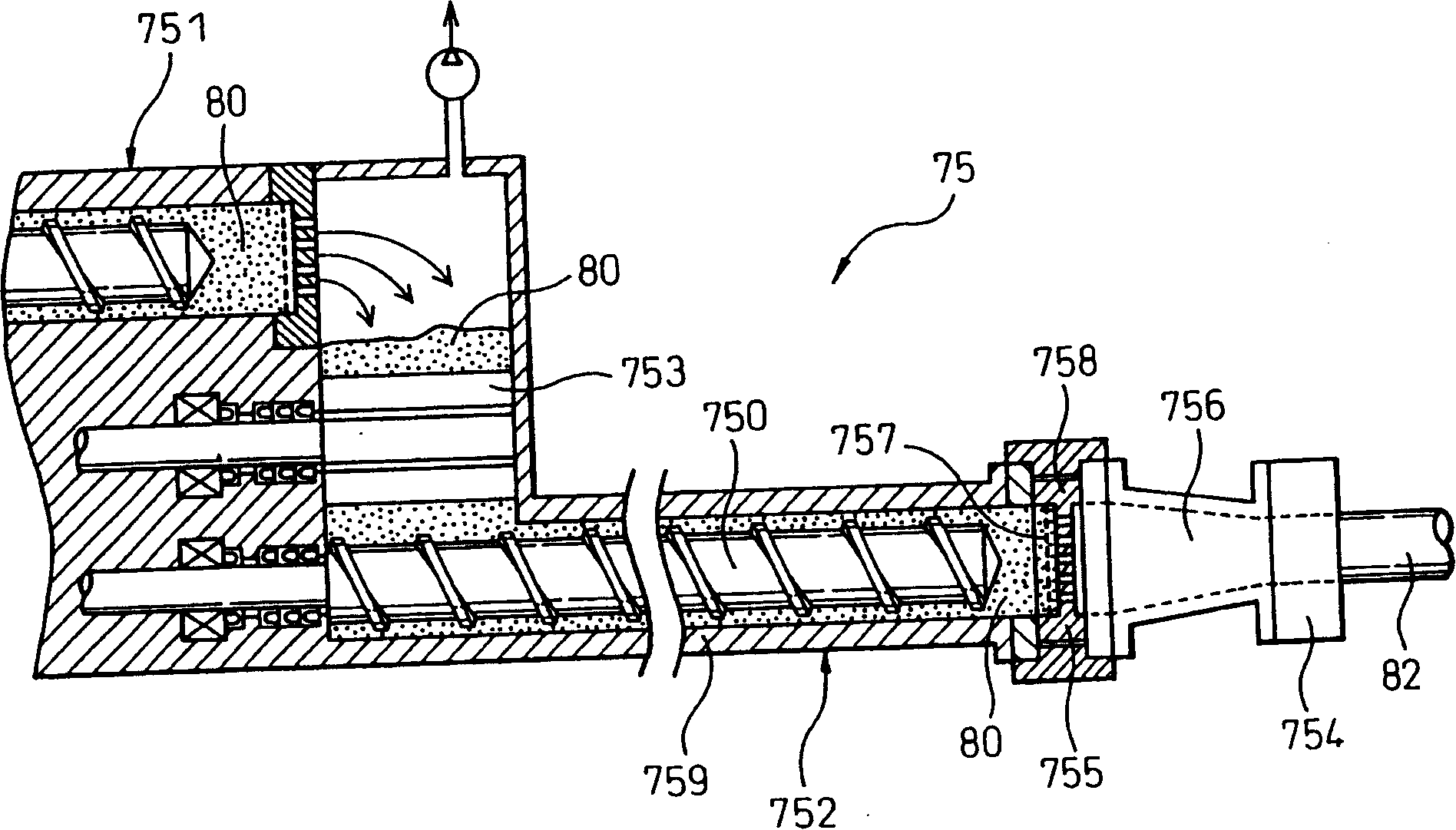

[0039] refer to Figure 1-5 A drying apparatus for ceramic molded articles according to one embodiment of the present invention is explained.

[0040] Such as figure 2 As shown, the drying device 1 according to this embodiment includes a Figure 4 ) drying chamber 10, a plurality of microwave generators 20 for supplying microwave energy in the frequency range of 300MHz to 300GHz to the drying chamber 10, and a conveyor 30 through which ceramic moldings 8 are continuously loaded and conveyed Through and out of the drying chamber 10 .

[0041] A plurality of microwave generators 20 and sensors 40 for detecting distribution of ceramic molded articles 8 in the drying chamber 10 are arranged in the drying chamber 10 along the conveying direction of the conveyor 30 .

[0042] The output of each microwave generator 20 is adapted to vary according to the distribution of the ceramic molded product 8 detected by the sensor 40 .

[0043] The structure of the device will be described...

no. 2 example

[0111] According to this embodiment, a plurality of drying areas adapted to move with the operation of the conveyor are formed instead of the drying sections fixedly arranged in the drying chamber in the first embodiment.

[0112] In this example, if Figure 10 As shown, a plurality of reflectors 345 for reflecting microwave energy are mounted on a part of the support instead of the partition wall of the drying chamber according to the first embodiment. The reflector 345 forms the drying area 340 in the drying chamber 10 . Warm, the ceramic moldings 8 placed on the support are arranged vertically instead of horizontally.

[0113] This embodiment is described in more detail below.

[0114] In the drying device 1 according to this embodiment, a substantially plate-shaped reflector 345 for reflecting microwave energy is mounted on the end of each of at least a part of the supports along the conveying direction and substantially at right angles to the conveying direction. .

...

no. 3 example

[0160] This embodiment relates to a case in which at least one radio wave absorber is arranged on the inner wall of the drying chamber instead of the partition wall that limits the radiation range of microwave energy in the drying device according to the first embodiment.

[0161] In the drying device 1 according to this embodiment, as Figure 13 As shown, a plurality of radio wave absorbers 440 are installed on the inner wall of the drying chamber 10 . The radio wave absorber 440 limits the microwave radiation range of each microwave generator 20 .

[0162]Specifically, in the drying chamber 10 having the radio wave absorber 440 installed on its inner wall, microwaves supplied into the drying chamber 10 rarely reach far points by being repeatedly reflected. Through this drying chamber 10, as Figure 12 As shown, the microwave energy constituting the direct wave generated from the microwave generator can dry the ceramic molding 8 .

[0163] According to this embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com