Alignment film drying device and method

A drying device and drying method technology, applied in the direction of drying solid materials, dry goods handling, drying room/container, etc., can solve the problems of liquid crystal molecule arrangement influence, uneven alignment film, lower quality and qualified rate of liquid crystal panel, etc., to achieve Effect of improving display characteristics, improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, for a detailed description as follows:

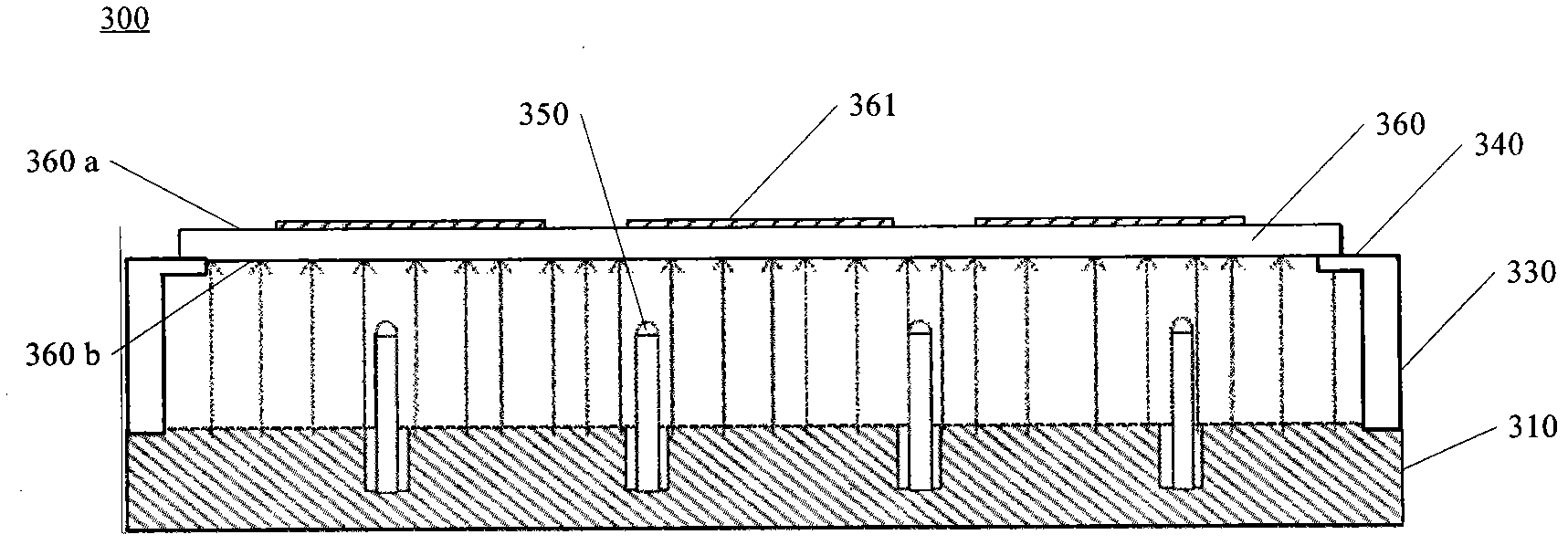

[0050] Such as image 3 Shown is a schematic structural diagram of an alignment film drying device in the present invention. An alignment film drying device 300 is used to dry an alignment film material formed on a first surface (i.e., upper surface) 360a of a substrate 360 and diluted with a solvent. The alignment film drying device 300 includes: a heating table 310, used for A second surface (i.e. the lower surface) 360b of 360 is heated, and a number of air holes are evenly distributed on the heating platform 310; the peripheral support mechanism 330 is arranged around the heating platform 310, and in this specific embodiment, the peripheral The support mechanism 330 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com