Grain pulverizing device for agricultural processing

A technology of agricultural processing and crushing device, which is applied in the field of agricultural machinery, and can solve problems such as the unsatisfactory crushing effect and the inability to realize rapid and sufficient grinding of grain particles, and achieve the effect of high crushing and grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

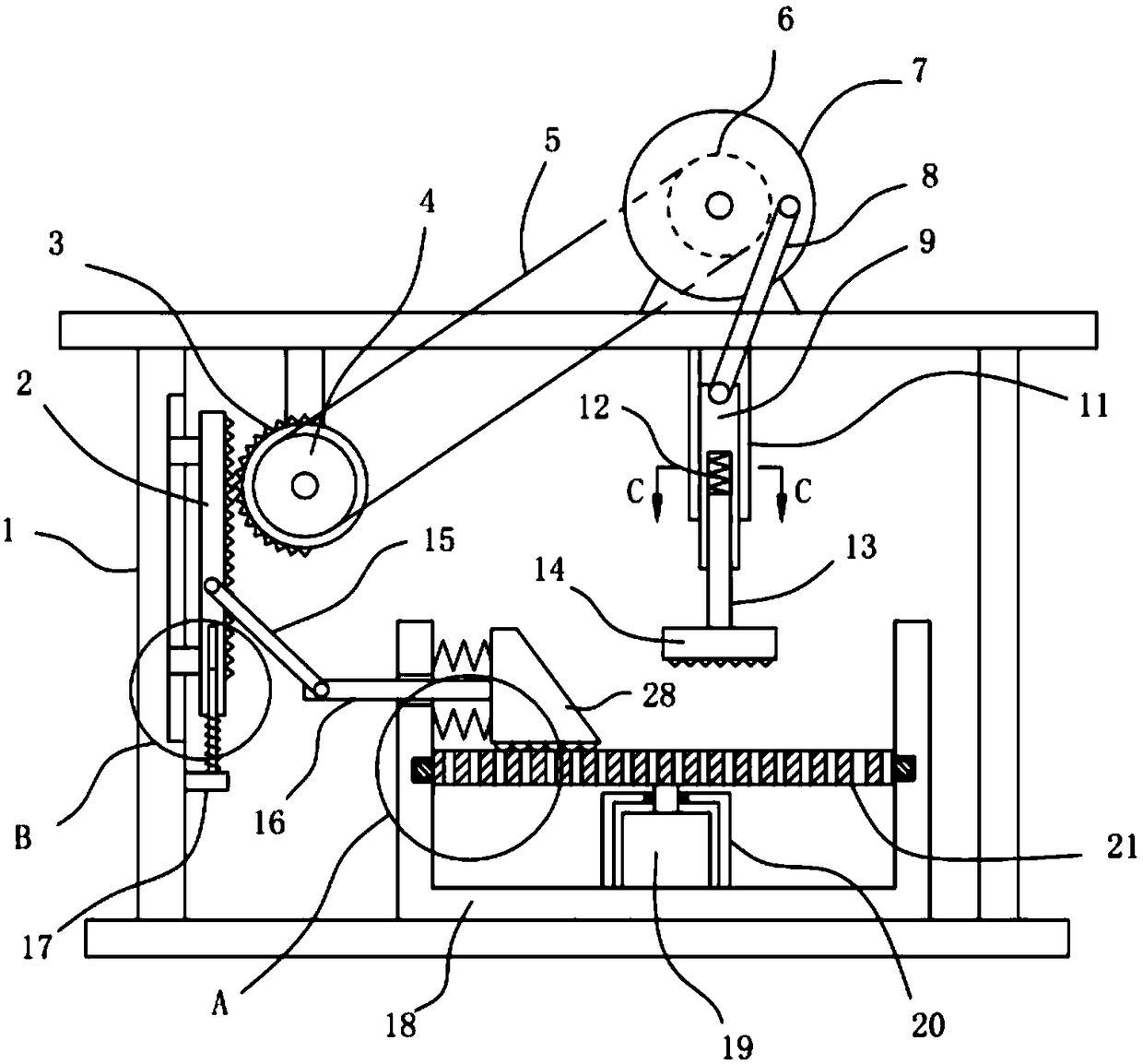

[0022] see Figure 1-4 , a grain crushing device for agricultural processing, comprising a support frame 1, the top of the support frame 1 is rotatably provided with a runner 7, the back of the runner 7 is coaxially fixed with a driving pulley 6, and a crushing groove 18 is fixedly installed in the support frame 1 A motor cover 20 is fixedly installed at the bottom of the crushing tank 18, and a reduction motor 19 is arranged in the motor cover 20. The output shaft of the reduction motor 19 is coaxially fixed with a sieve plate 21 located in the crushing tank 18. The reduction motor 19 is used to drive and rotate the sieve plate 21 .

[0023] Sleeve 11 is vertically fixedly installed in support frame 1, and vertical sliding type is provided with slide bar 9 in the sleeve 11, and the damping spring 12 that lower end is fixed with slide shaft 13 upper ends is fixed in slide bar 9, and slide bar 9 and A transmission rod 8 is hinged between the runners 7, and the upper end of the...

Embodiment 2

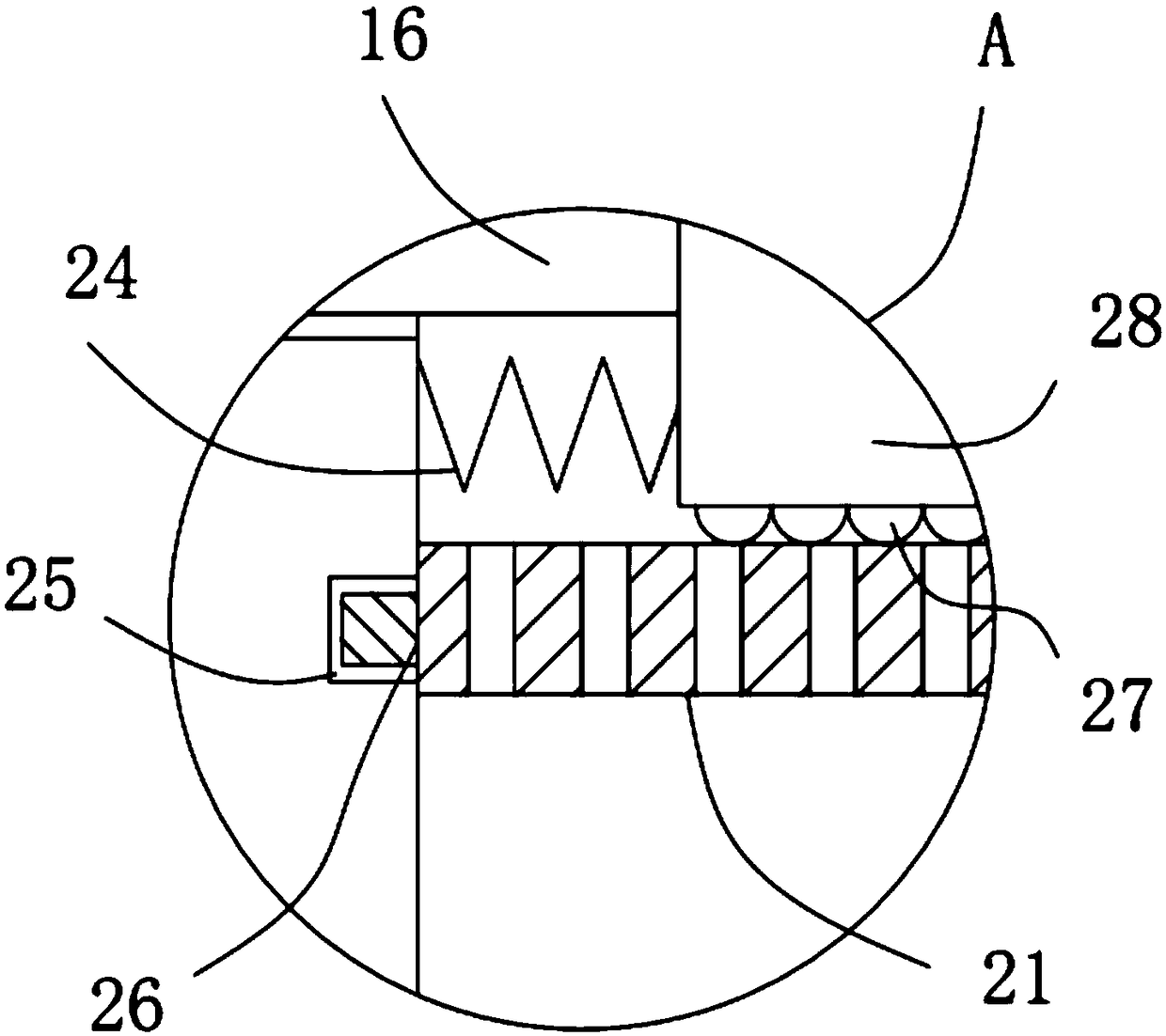

[0027] On the basis of Embodiment 1, in addition, a grinding wedge 28 is horizontally slidable in the crushing tank 18, and the bottom of the grinding wedge 28 is fixedly installed with a bump 27 abutting against the upper surface of the sieve plate 21, and the left side of the grinding wedge 28 is A guide rod 16 penetrating through the crushing groove 18 is fixedly installed on the side wall, and a lateral return spring 24 is fixedly installed between the grinding wedge 28 and the inner wall of the crushing groove 18 .

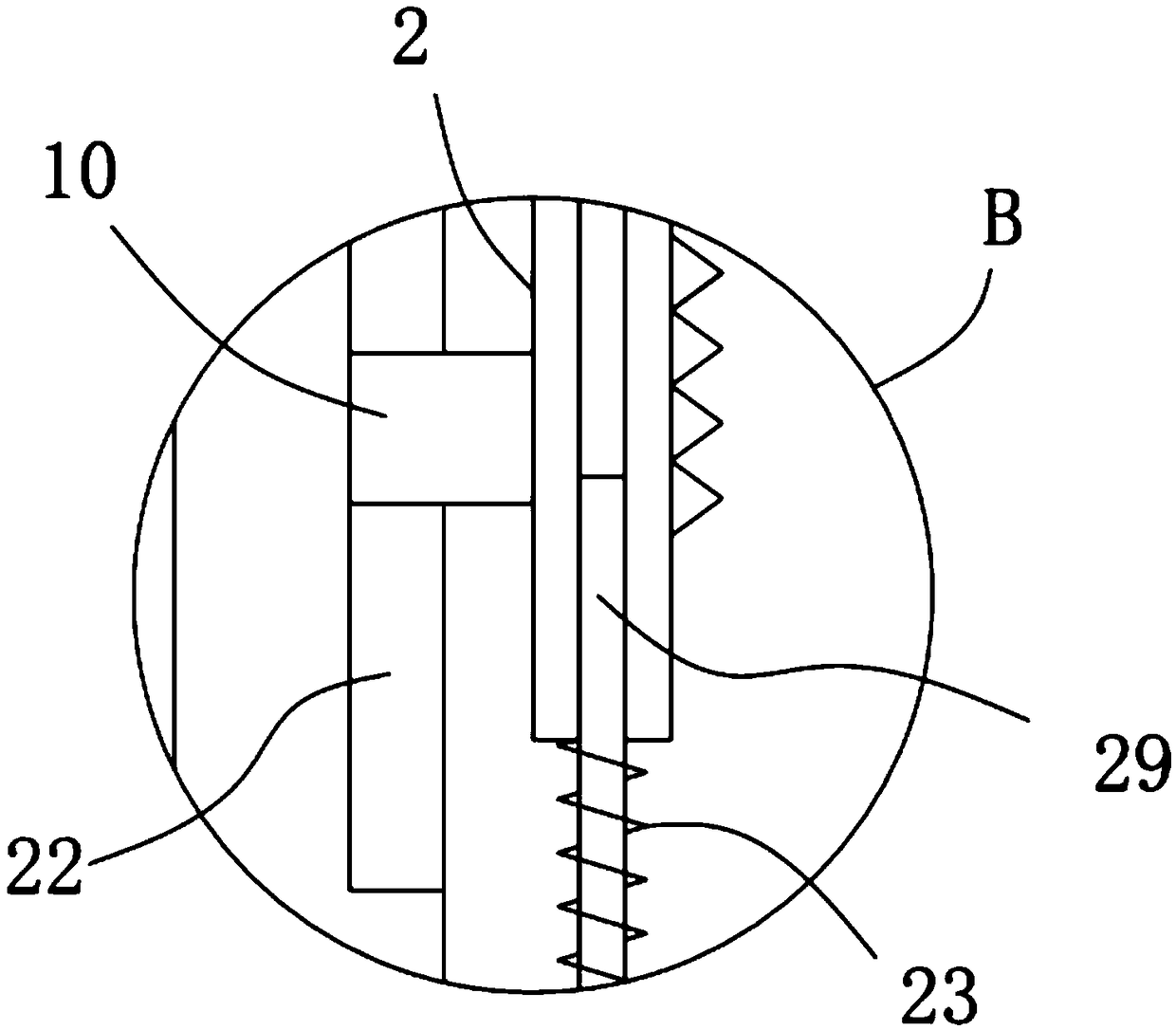

[0028] Further, an incomplete gear 3 is rotatably provided on the support frame 1, and the driven pulley 4 connected to the driving pulley 6 is coaxially fixed on the incomplete gear 3 through the transmission belt 5, and the side wall of the support frame 1 is vertical. The sliding type is provided with a spur rack 2 meshed with an incomplete gear 3, and a connecting rod 15 is hinged between the spur rack 2 and the guide rod 16.

[0029] The rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com