Multistage turbine pulverizer

A pulverizer and turbine technology, which is applied in the field of multi-stage turbine high-efficiency pulverizers, can solve the problems of low mechanical efficiency, poor load adaptability, and large power consumption, and achieve low unit cost, small power matching, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

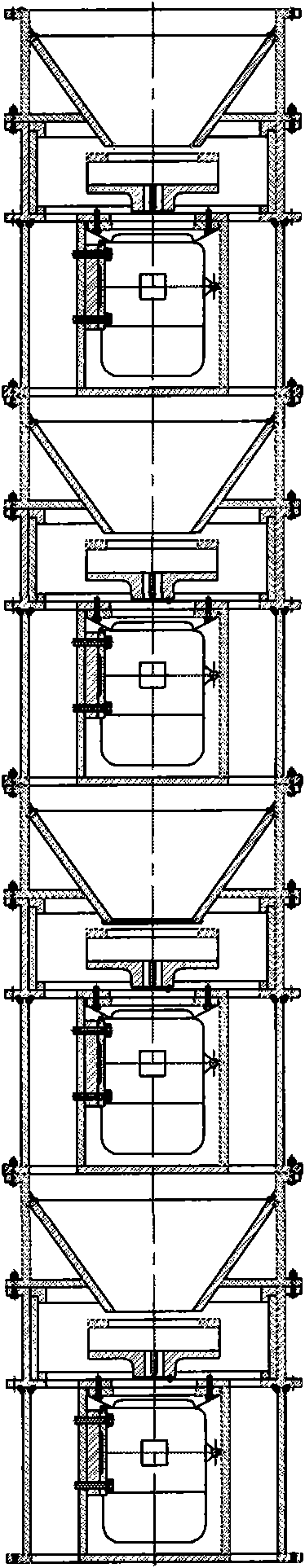

[0028] Such as figure 1 As shown: the embodiment of the multi-stage turbine pulverizer of the present invention is composed of four turbine crushers 1 superimposed and connected up and down, and the rotational speed of the turbine crushers increases sequentially from top to bottom.

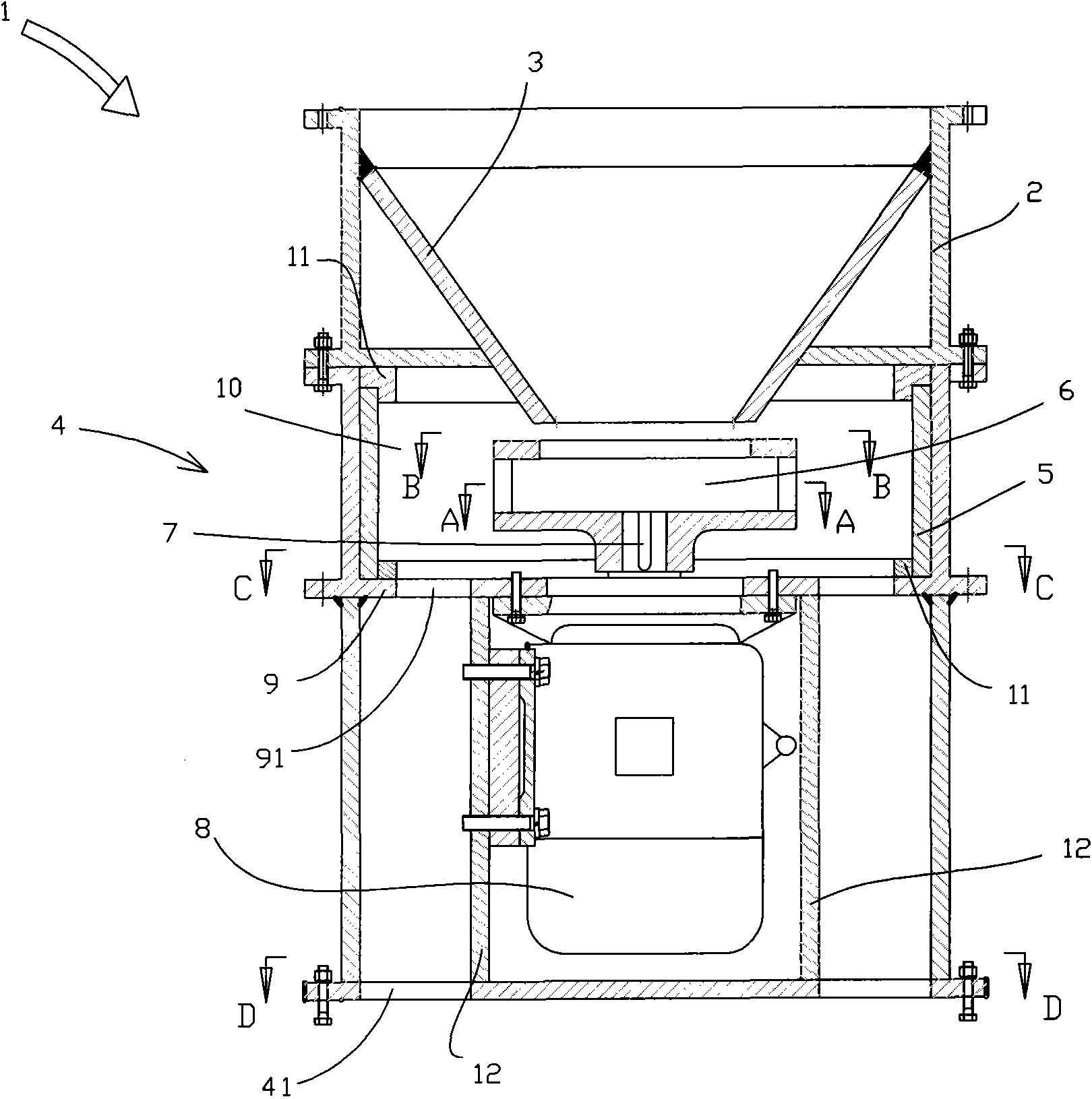

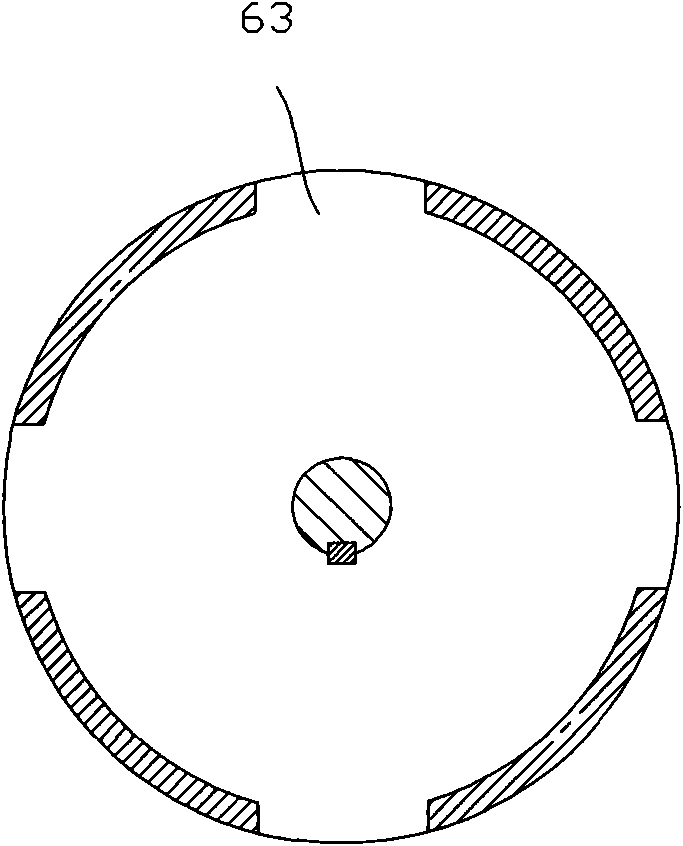

[0029] see you again Figure 2 to Figure 6 , each turbine crusher 1 includes from top to bottom: an upper feeding cylinder 2 with an opening facing upwards and two ends with connecting flanges, a conical feeding hopper 3 is arranged inside the cylinder, and the opening at the bottom of the cylinder corresponds to the hopper Outlet; a crushing cylinder 4 with connecting flanges at both ends facing upwards, the upper end flange and the bottom flange of the upper feeding cylinder. The upper part of the body constitutes a crushing chamber 10, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com