Turbine reaction composite vertical mill

A compound vertical mill technology, which is applied in the field of material grinding machinery and equipment, can solve the problems of unstable turbine operation, left and right shaking, different degrees of turbine wear, difficulty in achieving stable operation and large-scale equipment, and achieve small power matching, The effect of improving grinding efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

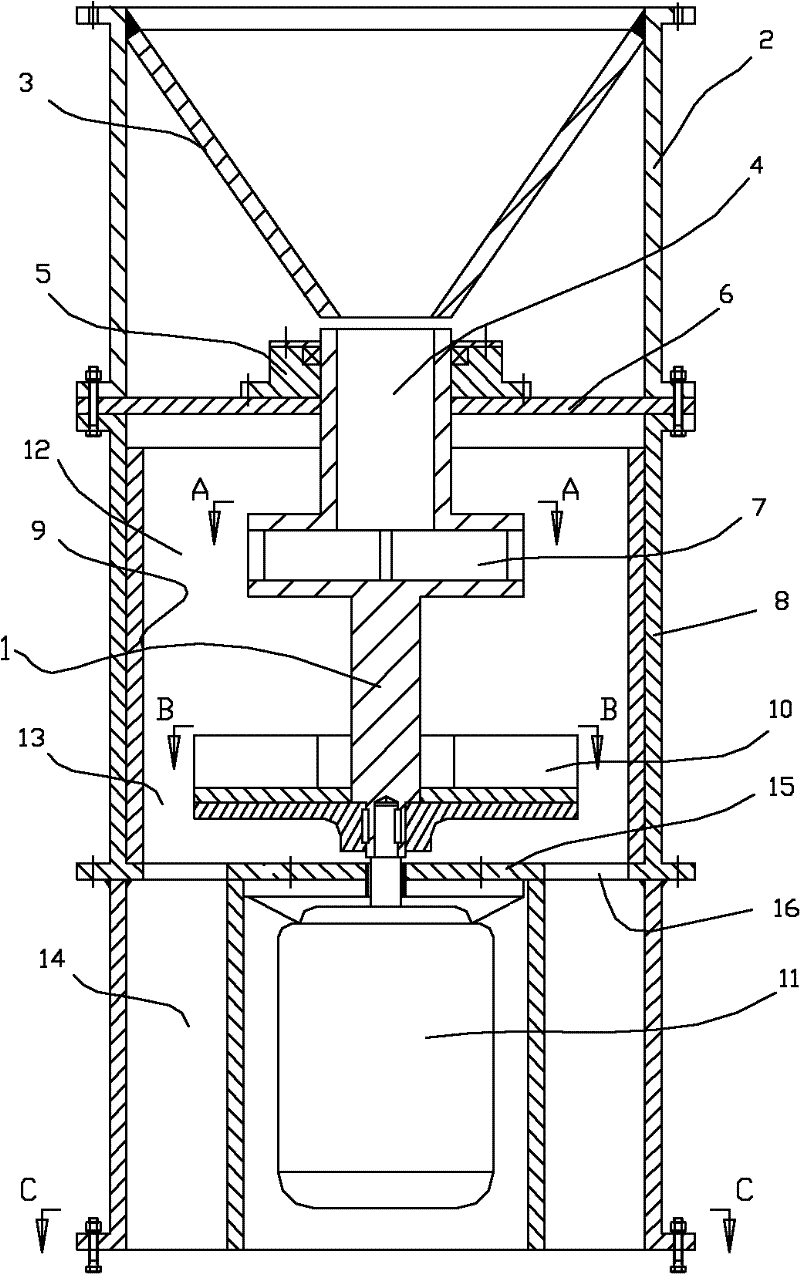

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

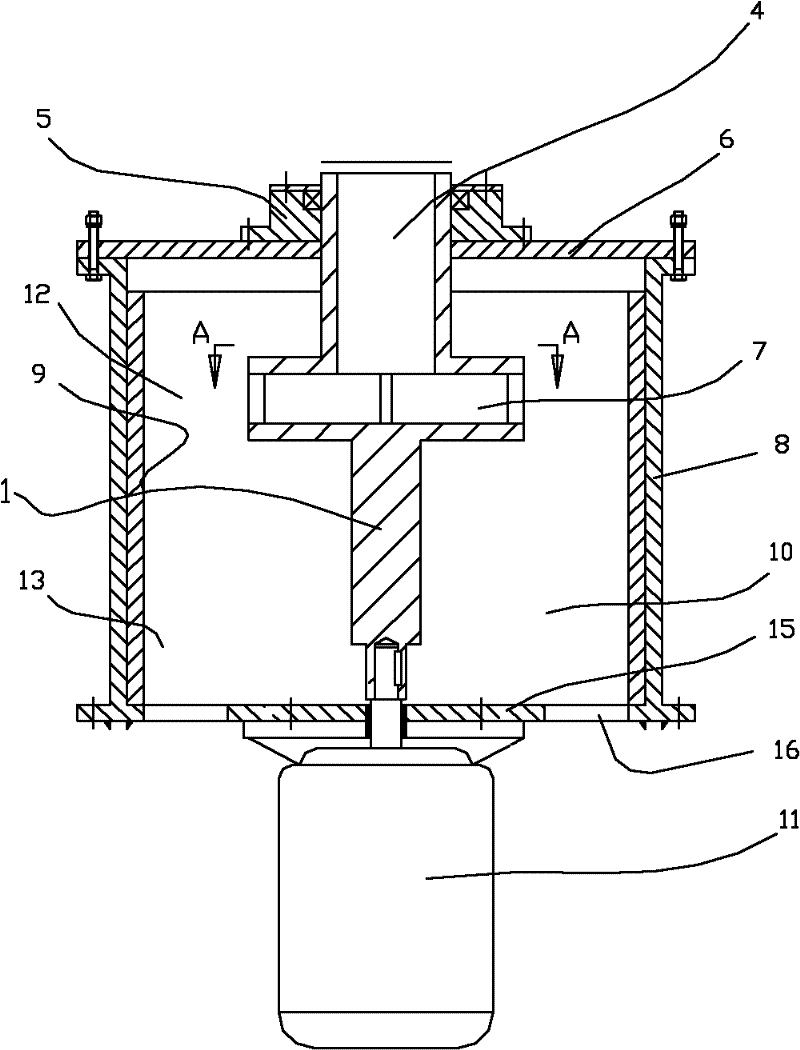

[0037] Such as figure 1 Shown: the turbine impact compound vertical mill of the present invention (also can be referred to as Liu's mill ) Embodiment 1 includes a turbine disc 7 with a feed pipe 4 on its top, a first bearing support on the outside of the feed pipe 4 , and the bottom of the turbine disc 7 is directly connected to the output shaft of the drive motor 11 . The structure of the turbine disc 7 is: a hollow disc, with a feed opening for docking with the feed pipe in the middle of the top surface, a flat plate on the bottom surface, a material distribution blade between the upper and lower sides, and a material rejection opening on the side.

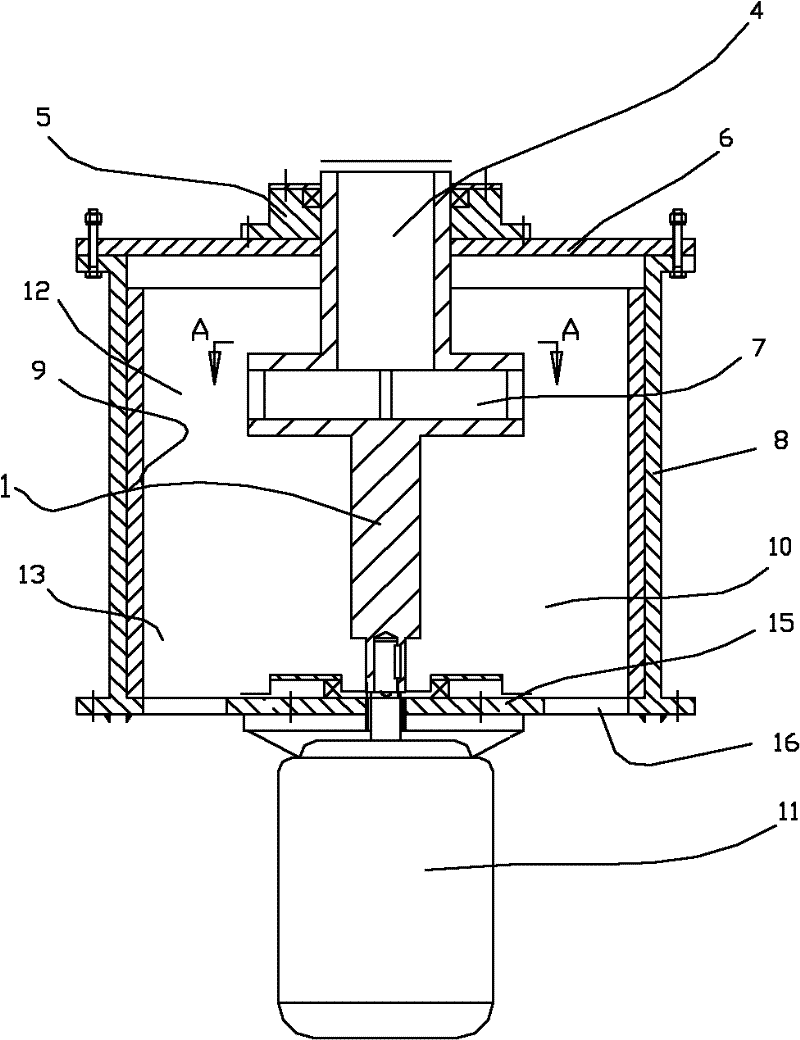

[0038] The bottom of the turbine disk 7 can also be connected with the output shaft of the drive motor after setting the second bearing support, see figure 2 Middle embodiment two. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com