Device for measuring axial internal clearance of matched angular contact ball bearing

A measuring device, the technology of axial clearance, applied in the direction of mechanical clearance measurement, etc., can solve the problems of low measurement accuracy and complex structure of the measuring device, and achieve the effects of ensuring measurement accuracy, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

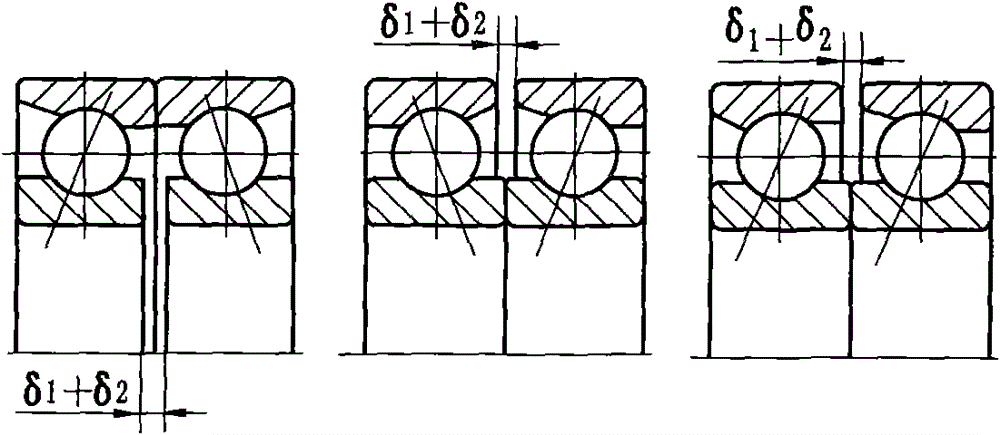

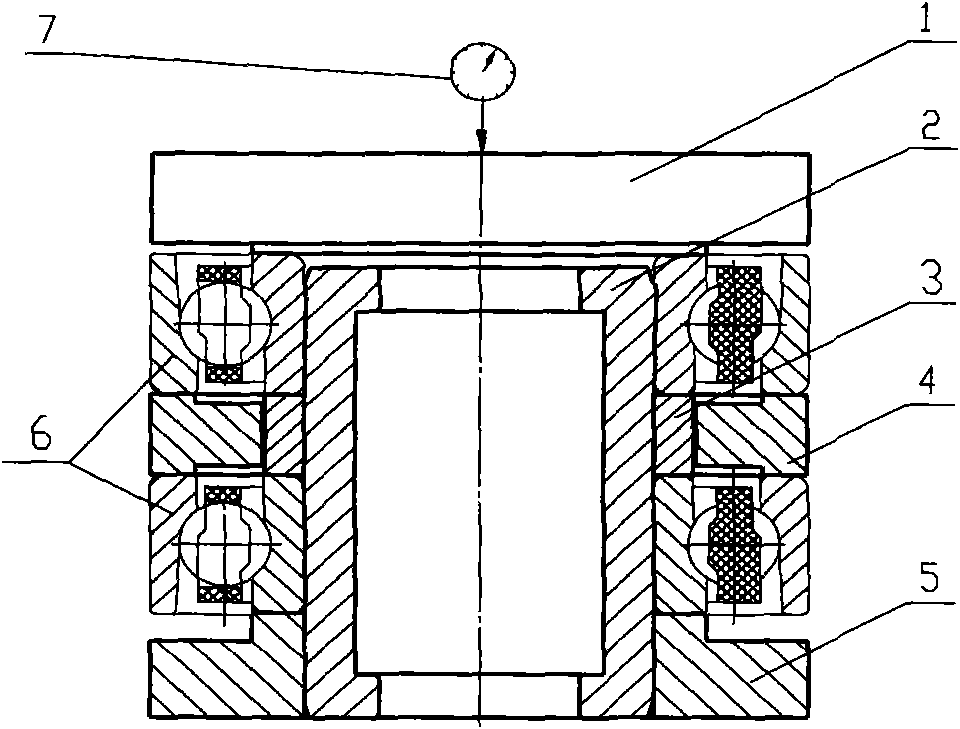

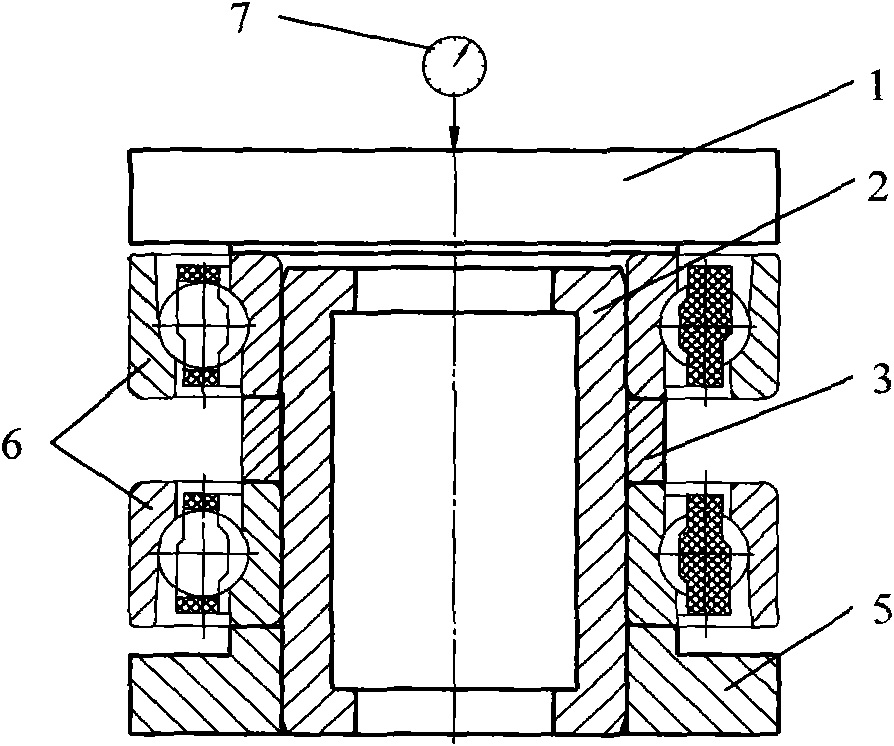

[0028] Measuring instrument 7 adopts G905 height measuring instrument. According to different pairing methods of bearings, on the G905 height measuring instrument, the bearing 6 to be tested is measured with accessories such as measuring load. In this embodiment, the process of measuring the axial clearance of bearings in the back-to-back DB assembly mode is taken as an example to illustrate as follows:

[0029] Firstly, design the special measurement load and accessories according to the specifications of the tested bearing 6, in which the outer spacer is a double-half ring type, the outer spacer is higher than the inner spacer, and its value is a=0.15~0.3mm; secondly, according to figure 2 Place the tested bearing and measuring accessories on the G905 instrument as shown, and zero the instrument; finally, remove the outer spacer 4, as shown in image 3 As shown, write down the reading of the instrument at this time, and use this reading to subtract the height difference a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com