Energetic nourishing brei

A nutritional paste and high-energy technology, applied in the field of high-energy nutritional paste, can solve the problems of tight breakfast time, simplification, and easy obesity, etc., and achieve the effect of convenient drinking, high heat energy, and many varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1. The milk-flavored nutritional paste has the following components by weight: 30 wheat, 20 rice, 20 fragrant rice, 20 milk, 5 soybeans, 2-3 walnut kernels, 2-3 white sugar, and 150-250 water.

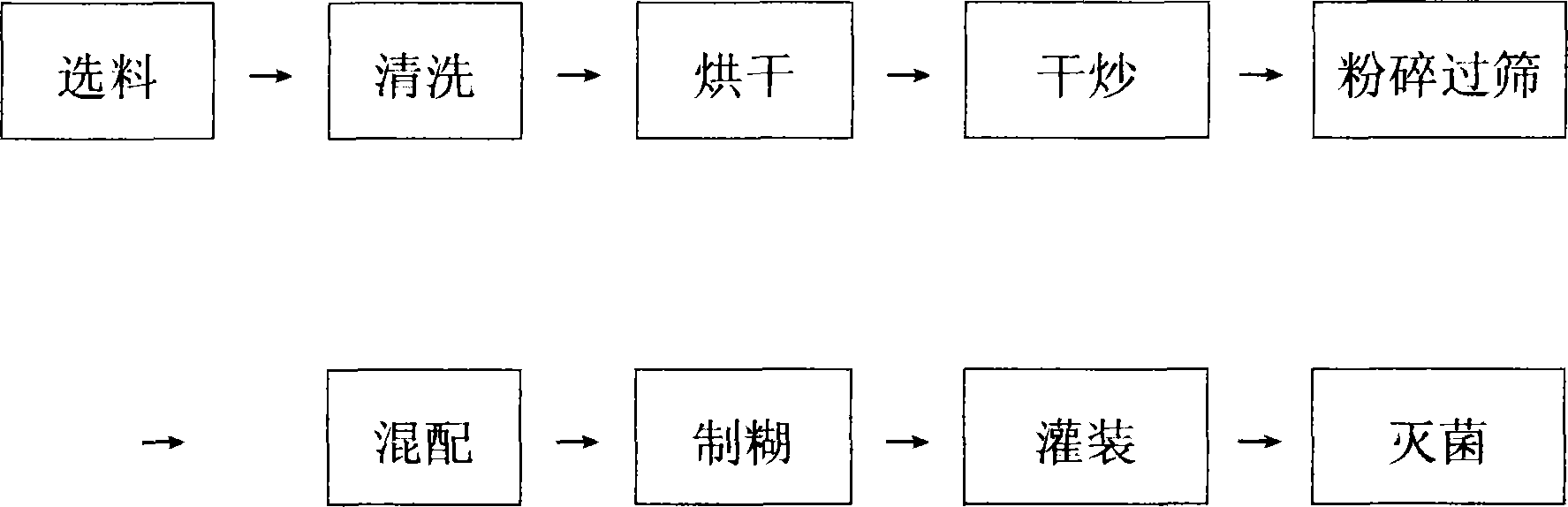

[0011] Its production process is shown in Figure 1, including material selection, cleaning, drying, dry frying, crushing and sieving, mixing, paste making, filling, and sterilization processes.

[0012] Process Description

[0013] 1. Choose materials, choose high-quality wheat, rice, fragrant rice, soybeans, walnut kernels and pure milk.

[0014] 2. Wash, wash the wheat, soybeans and walnut kernels.

[0015] 3. Drying, use a dryer to dry.

[0016] 4. Dry frying, stir-fry wheat, rice, basmati rice, soybeans and walnut kernels with a slow fire until slightly yellow and fragrant.

[0017] 5. Pulverize and sieve, pulverize the fried wheat, rice, basmati rice, soybean and walnut kernel respectively with a pulverizer, pass the grain through a 100-150 mesh sieve, and pas...

Embodiment 2

[0022] Embodiment 2, fruity type nutritional paste, its components by weight are as follows: 30 wheat, 20 rice, 20 fragrant rice, 3 soybeans, 20 fruit juice, 3 walnut kernels, 2-4 white sugar, and 150-250 water.

[0023] Its production process flow is the same as example 1, and the process description, except that components and proportioning changes, its process requirements are the same as example 1.

Embodiment 3

[0024] Embodiment 3, sweet type nutritional paste, its component weight ratio is as follows: corn 50-70, fragrant rice 20-40, adzuki bean 5-10, white sugar 2-3 water 160-300.

[0025] Its production process is the same as Example 1, and its process requirements are the same as Example 1 except that components and proportioning changes are explained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com