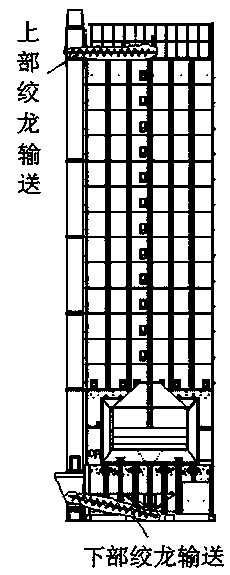

Vertical dryer free of packing auger

A drying machine and drying mechanism technology, applied in the direction of drying machine, drying, non-progressive drying machine, etc., can solve the problems of low grain processing efficiency, grain crushing, auger wear, etc., and achieve a remarkable drying effect , low cost, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

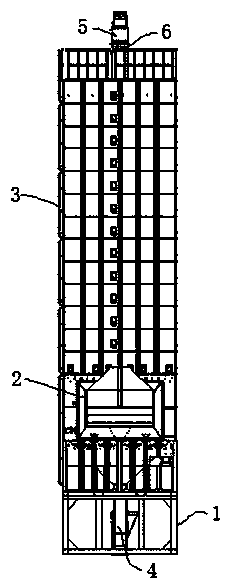

[0028] refer to Figure 3-6 , an up and down non-screw dryer, comprising a hoist 5, a drying bin 2 and a grain storage bin 3, the drying bin 2 is located below the grain storage bin 3, and the inside of the drying bin 2 is provided with Drying mechanism, the grain stored in the grain storage bin 3 is evenly dried by the drying mechanism, and then directly introduced into the interior of the elevator 5 through the inclined downflow pipe 4, and is carried by the elevator 5 from bottom to top. The grain is transported to the top of the dryer, and then the grain is transported to the internal storage of the grain storage bin 3 through the upstream pipe 6 to complete the cycle processing action of the entire grain production.

[0029] In this embodiment, it is worth noting that the bottom of the drying bin 2 is fixed with a support frame 1, the bottom end of the support frame 1 is flush with the bottom end of the hoist 5, and the top end of the hoist 5 is Higher than the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com