Semi-automatic pot blending machine and blending method thereof

A semi-automatic, pot machine technology, applied in food forming, food science, application, etc., can solve the problems of occupying space, unreliable work, troublesome operation, etc., to save space, reduce failure rate, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

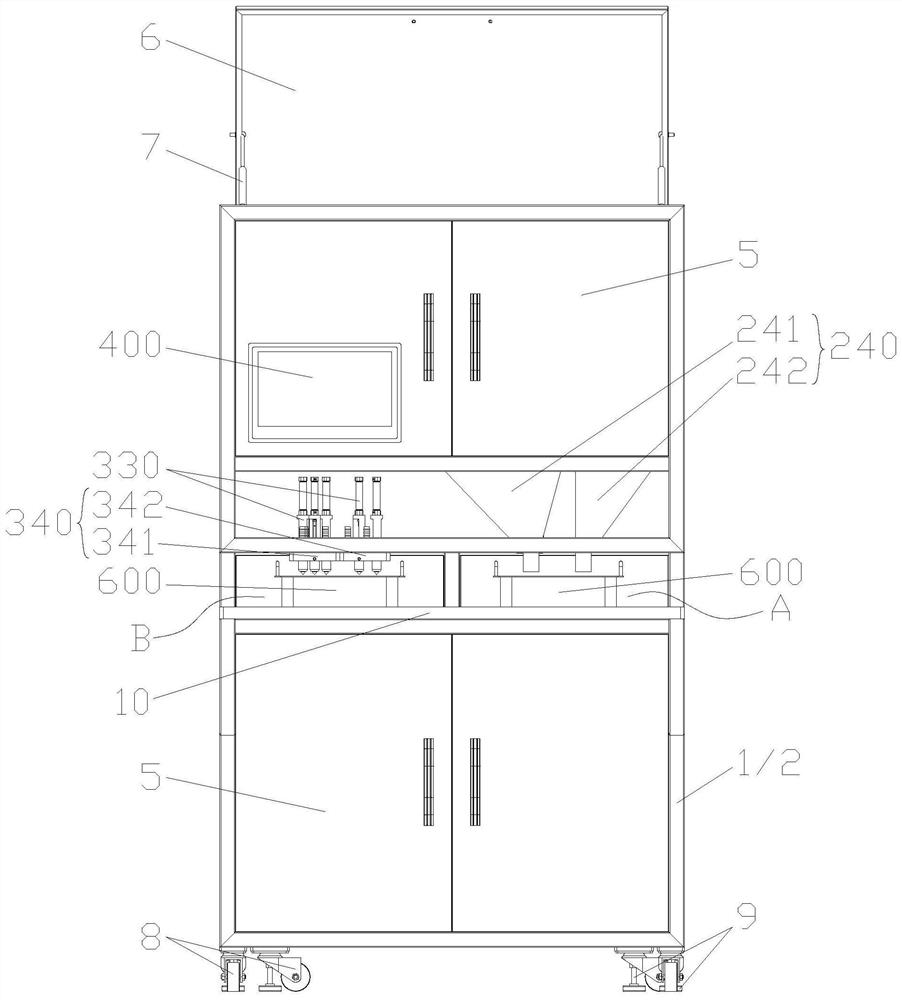

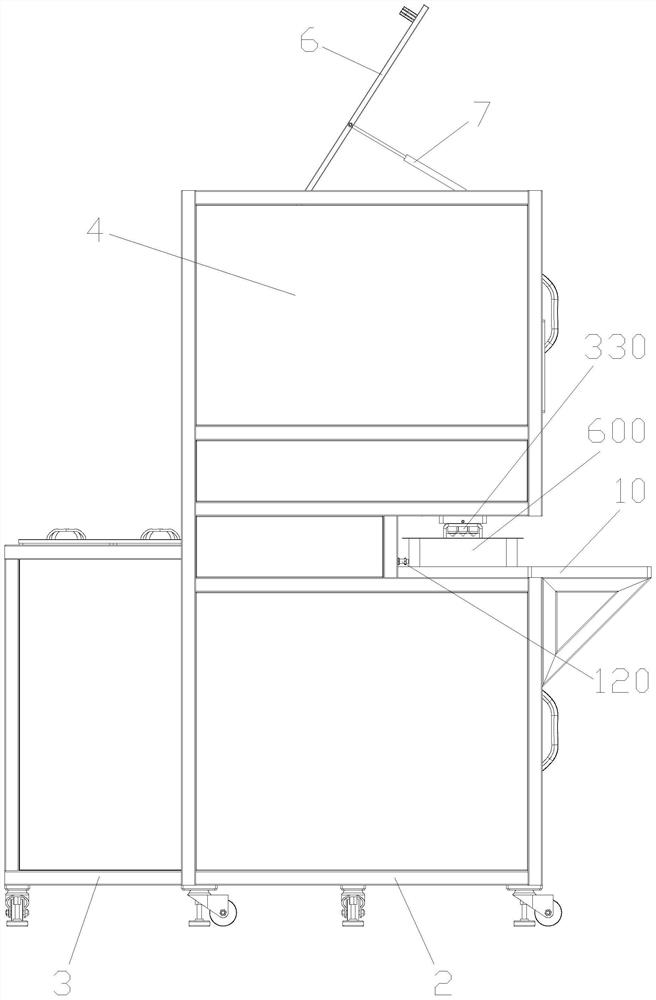

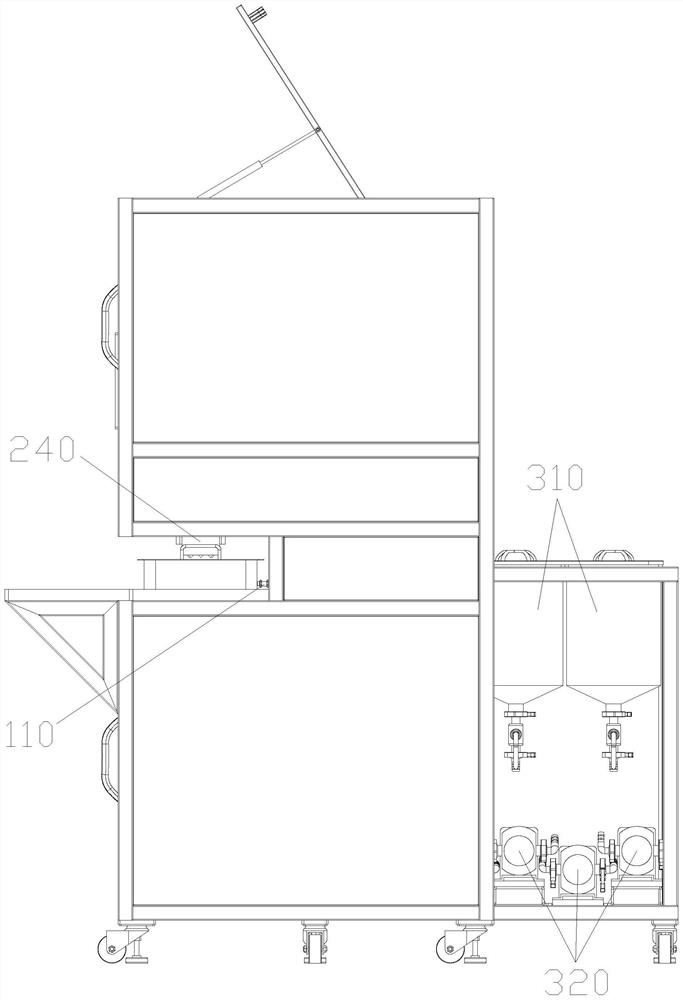

[0042] like Figure 1-14 As shown, the present embodiment provides a semi-automatic pot mixing machine, including:

[0043] The batching platform 10 is provided with a first feeding position A and a second feeding position B for placing the pot body 600;

[0044] The first pot feeding sensing device 110 is arranged at the first feeding position A, and is used to sense that the pot body 600 is delivered to the first feeding position A (for example, manually);

[0045] The seasoning powder feeding device 200 is arranged above the first feeding position A, and is used for sensing that the pot body 600 is delivered to the first feeding position A by the first pot feeding induction device 110 When the position is A, the seasoning powder is automatically put int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com