Flexible-stripping and pressure-friction type soybean breeding thresher

A thresher, soybean technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of severe vibration, loud noise, broken soybean stalks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

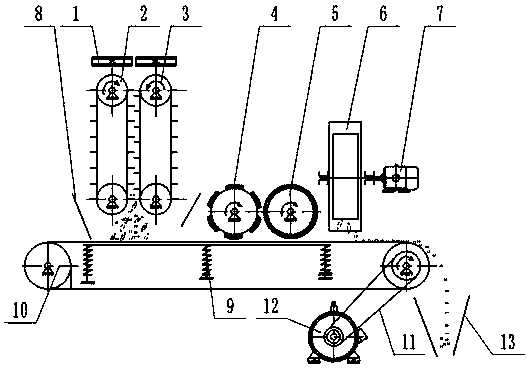

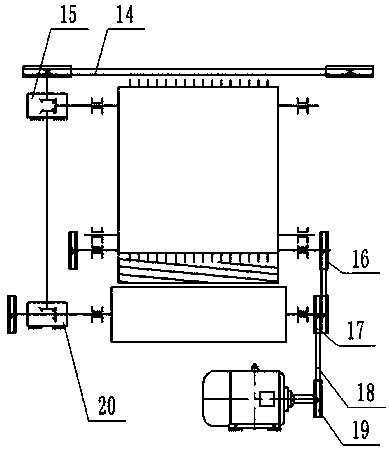

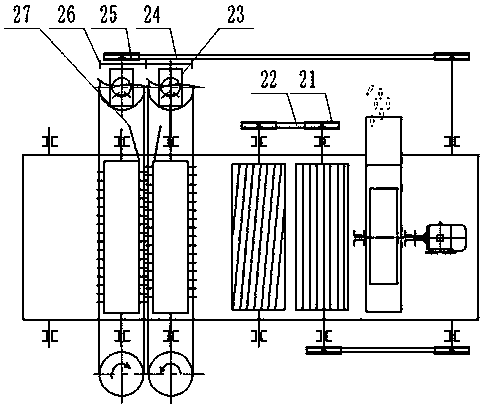

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] Flexible stripping and rubbing type soybean breeding thresher, the machine is mainly composed of clamping conveying device 1, stripping device 1, stripping device 2 3, pressing and rubbing threshing roller 4, re-stripping roller 5, and horizontal conveying device 10 , flexible spring support 9, dust suction fan 6, material collection port 8, seed trough 13, gearbox 1 15, gearbox 2 20, gearbox 3 23 and conventional transmission parts are fixed on the machine through locking devices Stand (not shown in the figure) constitutes. Clamping conveying device 1 is made up of two clamping belts 14 and 4 pulleys and transmits power by gearbox one 15, gearbox two 20, gearbox three 23. The stripping device 1 2 and the stripping device 2 3 are composed of two differential vertical conveyor belts with rubber nail teeth, and the driving force transmitted throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com