Soy sauce flavor type Baijiu brewing process in cold and dry environments

A sauce-flavored liquor and drying technology, which is applied in the field of liquor brewing, can solve the problems of low accumulation temperature of fermented grains, difficulty in controlling the quality, and not prominent sauce aroma, etc., and achieve the effects of long aftertaste, improved liquor yield, and outstanding sauce aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

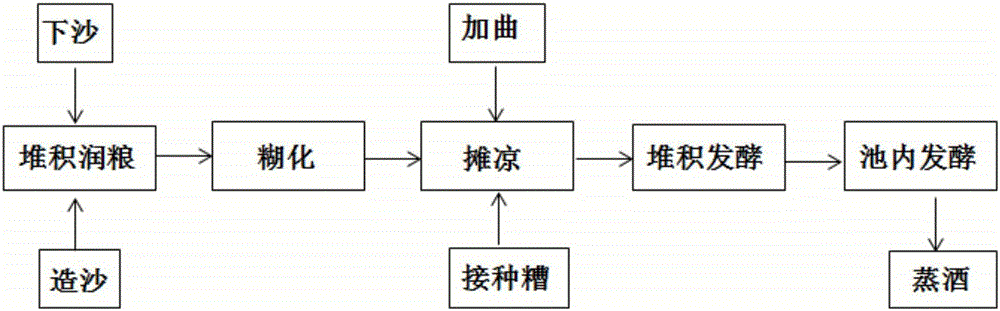

[0036] Such as figure 1 As shown, the brewing process of Maotai-flavored liquor in the cold and dry environment of this embodiment includes the processes of moistening grain, gelatinization, cooling, stacking fermentation, fermentation in the pond, and steaming wine; specifically, it includes the following steps:

[0037] a. Run grain

[0038] Moisten grain is to gather high-quality whole red sorghum into piles, and add boiling water at a temperature of 95°C while turning over. The excess water that has not been absorbed by the grain seeps out and takes away impurities and some tannins in the grain. Form a pile and pile up for 4.5 hours; then add water while turning over again, and pile up for 2 hours after adding water; the mass ratio of water consumption to red sorghum for each addition is 2:5; the pile shape is conical;

[0039] Red sorghum includes large-grain red sorghum and small-grain waxy red sorghum; among them, large-grain red sorghum is used for sand removal, and s...

Embodiment 2

[0056] Such as figure 1 As shown, the brewing process of Maotai-flavored liquor in the cold and dry environment of this embodiment includes the processes of moistening grain, gelatinization, cooling, stacking fermentation, fermentation in the pond, and steaming wine; specifically, it includes the following steps:

[0057] a. Run grain

[0058] Moisten grain is to gather high-quality whole red sorghum into piles, and add boiling water at a temperature of 95°C while turning over. The excess water that has not been absorbed by the grain seeps out and takes away impurities and some tannins in the grain. Form a pile and pile up for 4 hours; then add water while turning over again, and pile up for 2 hours after adding water; the mass ratio of water consumption to red sorghum for each addition is 3:5; the pile shape is conical;

[0059] Red sorghum includes large-grain red sorghum and small-grain waxy red sorghum; among them, large-grain red sorghum is used for sand removal, and sma...

Embodiment 3

[0076] Such as figure 1 As shown, the brewing process of Maotai-flavored liquor in the cold and dry environment of this embodiment includes the processes of moistening grain, gelatinization, cooling, stacking fermentation, fermentation in the pond, and steaming wine; specifically, it includes the following steps:

[0077] a. Run grain

[0078] Moisten grain is to gather high-quality whole red sorghum into piles, and add boiling water at a temperature of 95°C while turning over. The excess water that has not been absorbed by the grain seeps out and takes away impurities and some tannins in the grain. Form a pile and pile up for 3.5 hours; then add water while turning over again, and pile up for 1.5 hours after adding water; the mass ratio of water consumption to red sorghum for each addition is 4:5; the pile shape is conical;

[0079] Red sorghum includes large-grain red sorghum and small-grain waxy red sorghum; among them, large-grain red sorghum is used for sand removal, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com