Smashing device for grain processing

A crushing device and grain technology, applied in the field of grain processing, can solve problems such as dust pollution, overflow, and impact on the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

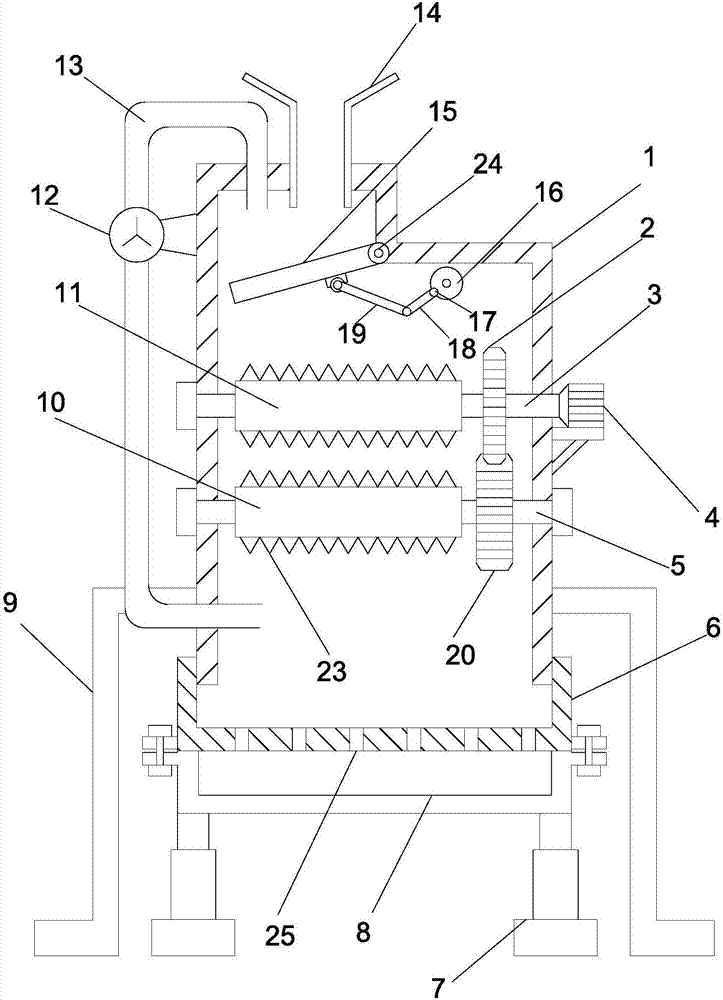

[0018] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

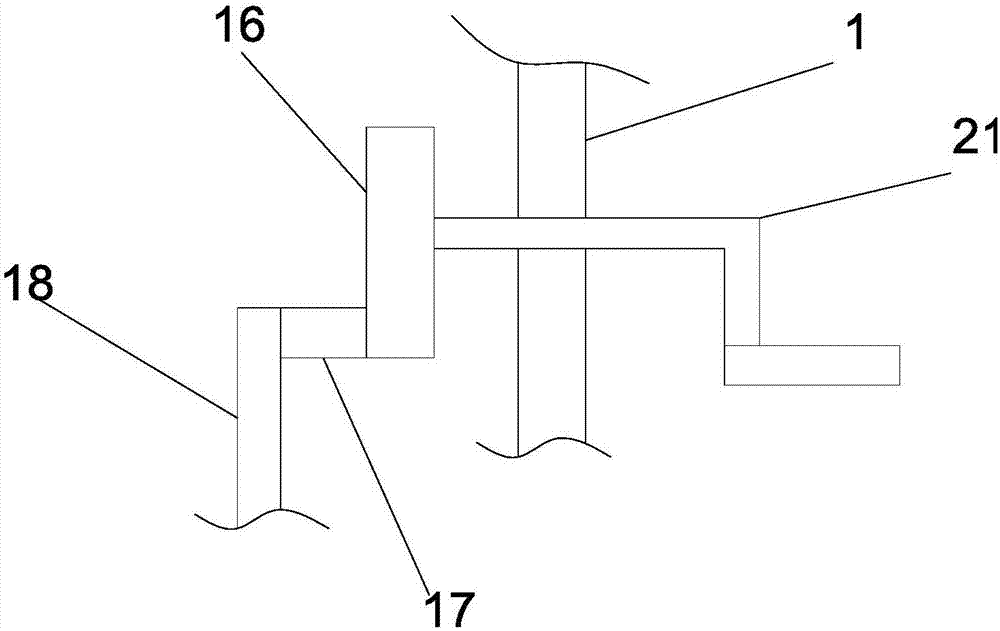

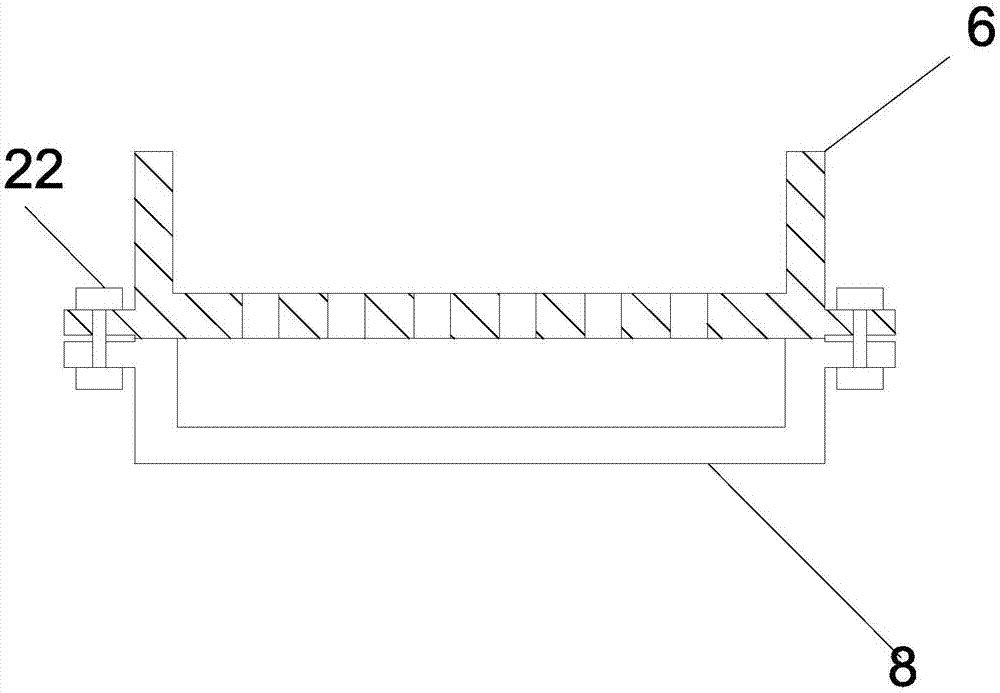

[0019] see Figure 1-3 , a crushing device for grain processing, comprising a base 1, characterized in that the base 1 is hollowed out with a number of sewage outlets 28, a water tank 3 is fixedly installed on the base 1, disinfectant water is housed in the water tank 3, and the water tank 3 A submersible pump 2 is provided, and a flexible hose 4 is connected to the water outlet of the submersible pump 2; a fixed frame 21 is fixed on the base 1, and a driving runner 20 is arranged on the fixed frame 21, and the driving runner 20 is driven to rotate by a motor, and the driving The runner 20 is provided with a second connecting rod 26, the right end of the second connecting rod 26 is connected with the first connecting rod 19, the right end of the first connecting rod 19 is hinged with a moving plate 17, and the bottom of the moving plate 17 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com