Coal slurry excavating and processing method for coal mine water warehouse

A treatment method and technology for coal slime, applied in drainage, peat mining, mining equipment and other directions, can solve problems such as low production efficiency, input a lot of manpower and material resources, increase production costs, etc., to achieve easy transportation and storage, clean and thorough cleaning, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

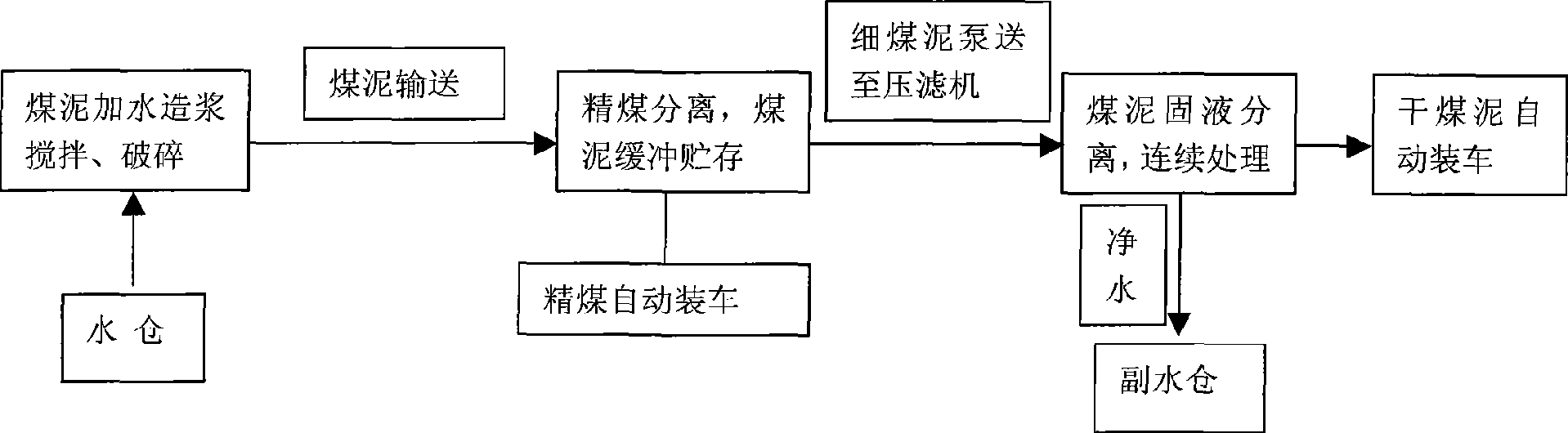

[0017] A coal mine water bin coal slime excavation and processing method, the coal slime excavation method is carried out according to the following steps:

[0018] (1) Build a cofferdam: Build a cofferdam at the rear of the coal slime in the water bin;

[0019] (2) Dilute the coal slime: break up the coal slime with high-pressure water and dilute it;

[0020] (3) Stirring and slurrying: the coal slime diluted in step (2), especially the coal slime with a large coarse particle content, is fully stirred by mechanical stirring, so that the large particle coal slime is suspended to form a coal slurry;

[0021] (4) Super-large particle slime crushing: crush the super-large particle coal slime in the coal slime that exceeds the pumping and subsequent processing requirements for pumping treatment;

[0022] (5) Coal slurry transportation: use a special coal slurry pump to transport the coal slurry to the warehouse mouth or designated processing point, and extend the coal slurry tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com