Biosynthesis preparation method for ergothioneine, and fermentation culture medium

A fermentation medium and ergothioneine technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of difficult purification treatment, increased fermentation by-products, low fermentation yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] Embodiment 1: Ergothioneine fermentation of Hericium erinaceus CCTCC NO: M 2018567

[0138] Liquid seed medium: 4% (w / v) sucrose, 1.5% (w / v) bean cake powder, 0.2% (w / v) sodium dihydrogen phosphate, 0.1% (w / v) sodium sulfate, The rest is water, pH 4.0-4.5, sterilized at 121°C for 20 minutes.

[0139] Fermentation medium: 3% (w / v) maltose, 2% (w / v) corn steep liquor, 0.05% (w / v) sodium dihydrogen phosphate, the rest is water, pH 4.0-4.5, at 121°C Sterilize for 20 minutes.

[0140] Each bottle of liquid seed medium was inoculated with a lawn of Hericium erinaceus CCTCCNo: M 2018567 picked from the slant of the strain of about 1 × 1 cm in size, and cultivated in a shaker at 20°C at 150rpm for 7 days to obtain a seed solution. The seed liquid is inserted into the fermentation medium with an inoculation amount of 5% by volume, cultivated on a shaker at 23°C at 180rpm, and supplemented with 5mM each of the precursor substances cysteine, betaine, and methionine when fermente...

Embodiment 2

[0141] Example 2: Extraction of Ergothioneine Using Helicase and Collapsing Enzymes

[0142] After fermentation, adjust the pH of the fermentation broth to 6.5±0.1, raise the temperature to 40±2°C, add 0.005% (w / v) helicase and 0.005% (w / v) collapse enzyme, and incubate at 40±2°C for 2.5 h, after the end of the enzymolysis, the temperature of the fermentation broth was raised to 90° C. and kept for 20 minutes to inactivate the enzyme. The ergothioneine extract is obtained by centrifuging the fermented liquid after enzymolysis, taking the supernatant, and then filtering and sterilizing through a 1.2 μm fine filter paper board and a 0.22 μm filter element.

Embodiment 3

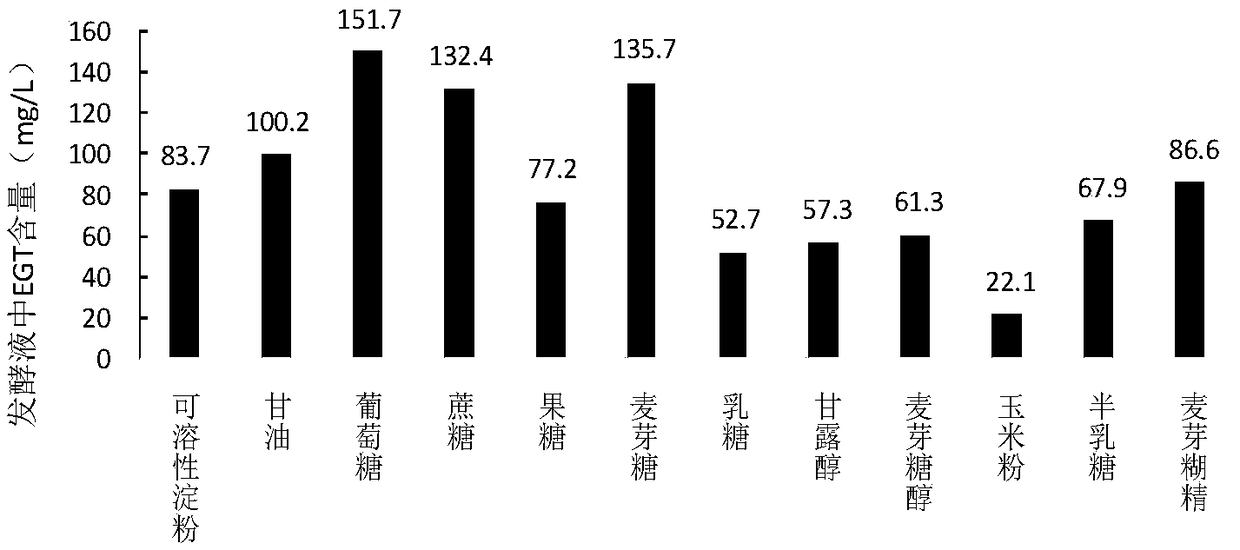

[0143] Embodiment 3: the influence of different fermentation carbon sources on the output of ergothioneine

[0144] Replace the carbon source of the above-mentioned fermentation medium with: soluble starch, glycerol, glucose, sucrose, fructose, maltose, lactose, mannitol, maltitol, corn flour, galactose, maltodextrin, according to the method of Example 1 Fermentation culture, measure the content of ergothioneine (EGT) in the fermented liquid after the end of fermentation, the results are shown in Table 1 and figure 1 . When glucose was used as the carbon source, the content of ergothioneine in the fermented liquid was 151.7mg / L, and the yield increase was relatively large. It can be used as the preferred carbon source for the production of ergothioneine by the liquid fermentation of Hericium erinaceus mycelia, followed by maltose (ergothioneine). Thioneine content is 135.7mg / L) and sucrose (ergothioneine content is 132.4mg / L).

[0145] Table 1

[0146] carbon sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com