Waste recovery device for nonwoven fabric processing

A technology for waste recycling and non-woven fabrics, which is applied in the field of waste recycling devices for non-woven fabric processing, and can solve problems such as potential safety hazards and affecting the crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

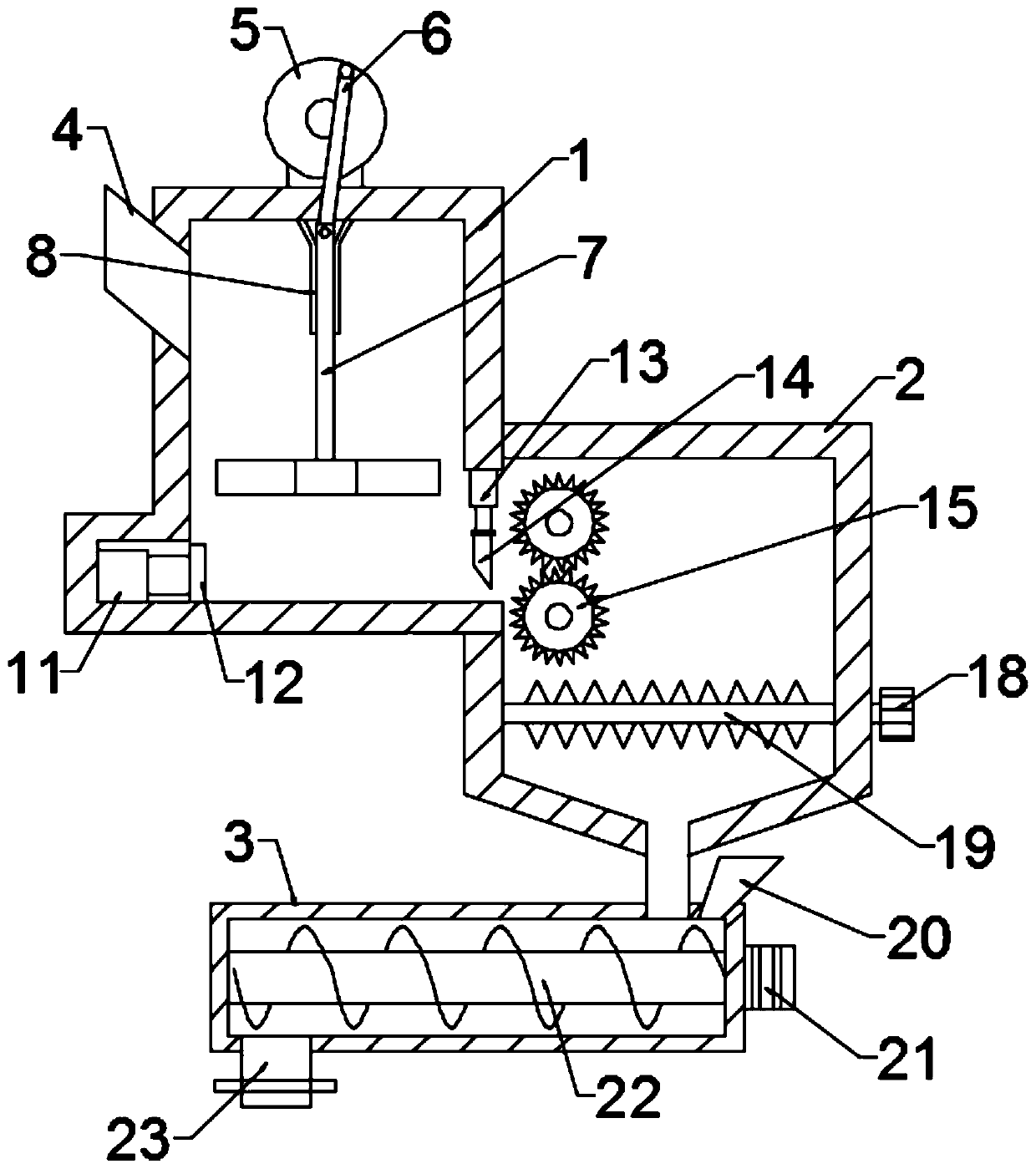

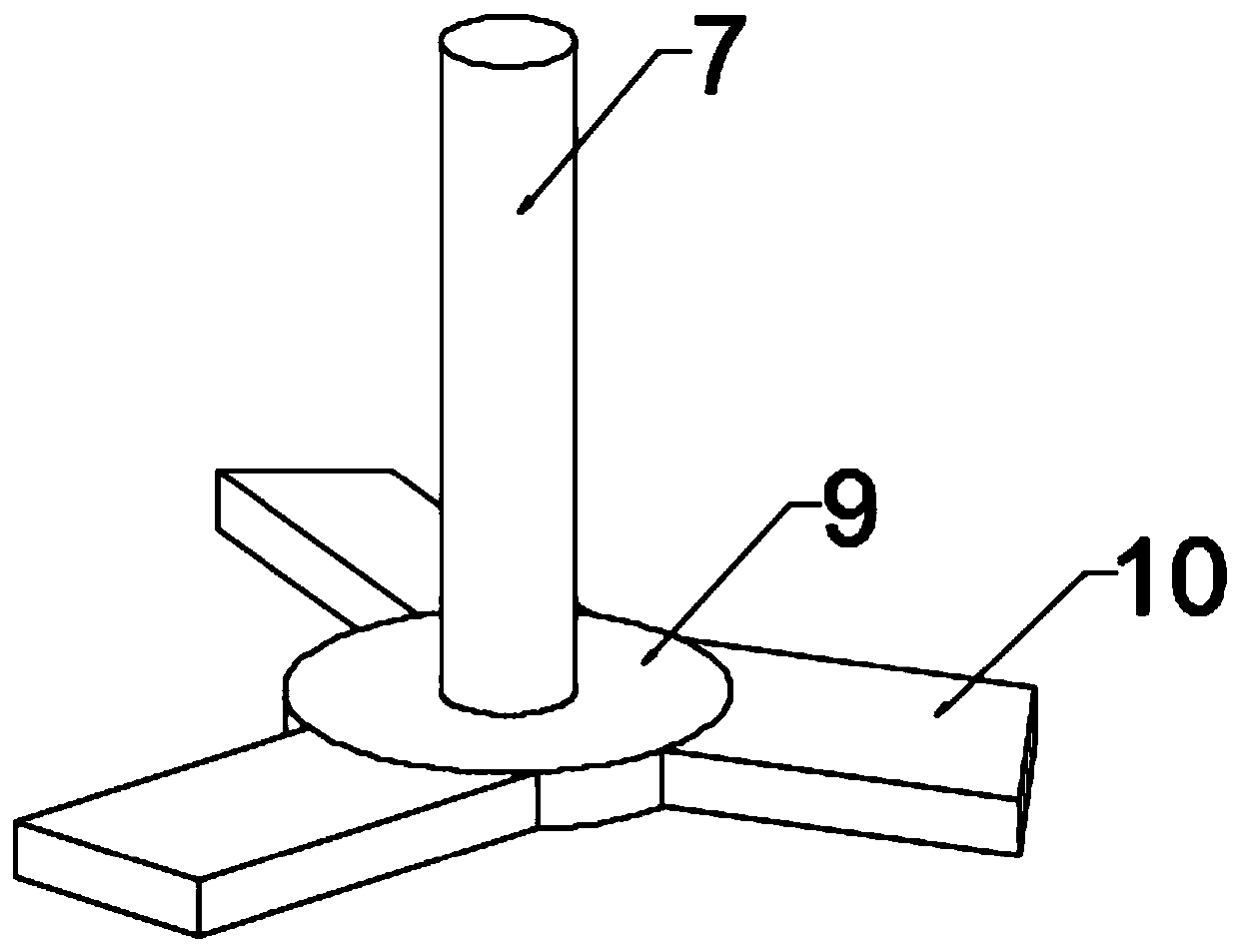

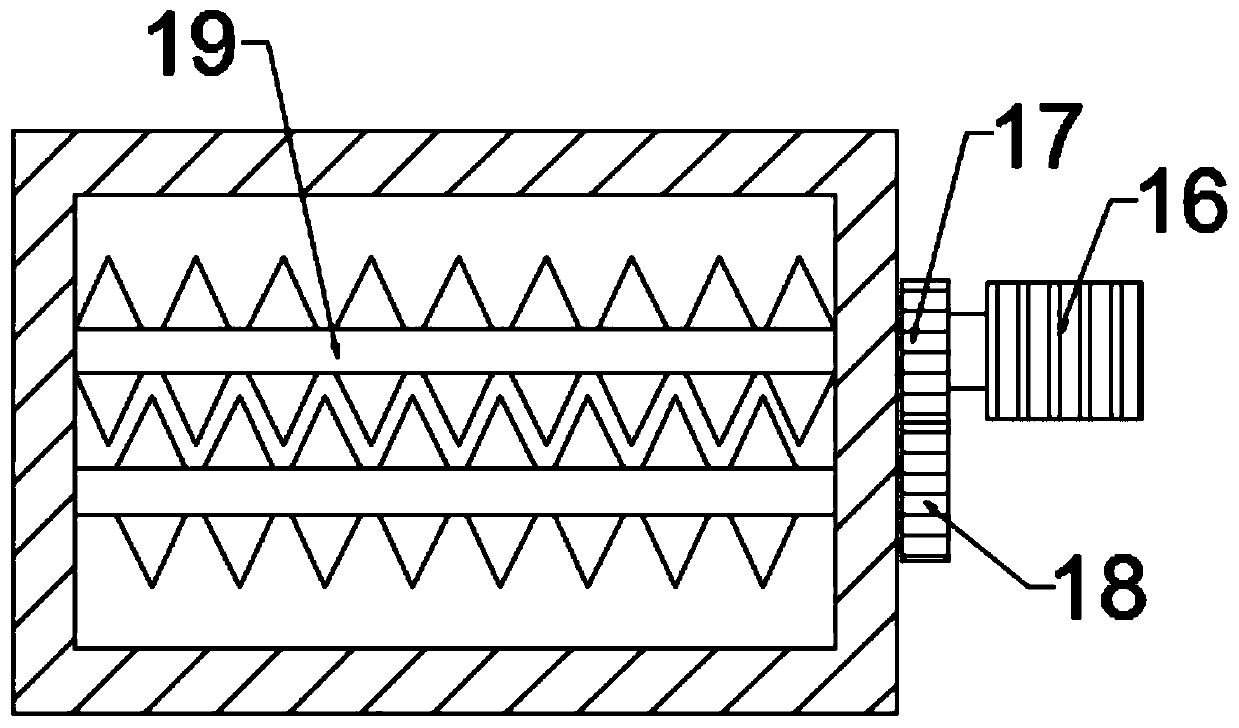

[0033] see Figure 1~3 , in one embodiment that the present invention provides, a kind of non-woven fabric processing waste material recovery device, comprises the pressing box 1 that is used for compacting non-woven fabric waste material, is used for breaking the crushing box 2 of non-woven fabric waste material and is used for heating A screw extrusion box 3 for melting non-woven fabric waste, the pressing box 1, crushing box 2 and screw extrusion box 3 are connected successively; the top side wall of the pressing box 1 is provided with a feed inlet 4, and the pressing The interior of the box 1 is provided with a repeated pressing mechanism, and the bottom of the pressing box 1 is provided with a push-out mechanism; the crushing box 2 is provided with a two-stage crushing mechanism; the screw extrusion box 3 is provided with a shear extrusion mechanism. mechanism.

[0034] The waste recycling device for non-woven fabric processing can carry out a comprehensive recovery proc...

Embodiment 2

[0047] see Figure 1~3 , in another embodiment provided by the present invention, the bottom of the crushing box 2 is connected with the top of the screw extrusion box 3, and the top of the screw extrusion box 3 is provided with a hopper 20; the screw A second motor 21 is fixed on the right side wall of the extrusion box 3, and the output end of the second motor 21 is driven and connected with a screw 22 through a coupling, and the screw 22 is located inside the screw extrusion box 3. The bottom end of the screw extrusion box 3 is provided with a discharge port 23 .

[0048] The fully crushed non-woven fabric waste enters the inside of the screw extrusion box 3, uses the hopper 20 to put in new raw materials, starts the second motor 21 to drive the screw 22 to rotate, and under the action of the screw 22, the components of the waste and the components of the new material are processed. Sufficient shearing and mixing, using the barrel (not shown in the figure) of the screw ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com