Graphite powder multi-stage grinding equipment for novel power battery production

A graphite powder and new energy technology, which is applied in the field of graphite powder multi-stage grinding equipment for new energy battery production, can solve the problems of insufficiently crushed graphite, etc., and achieve the effects of long service life, strong corrosion resistance and acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

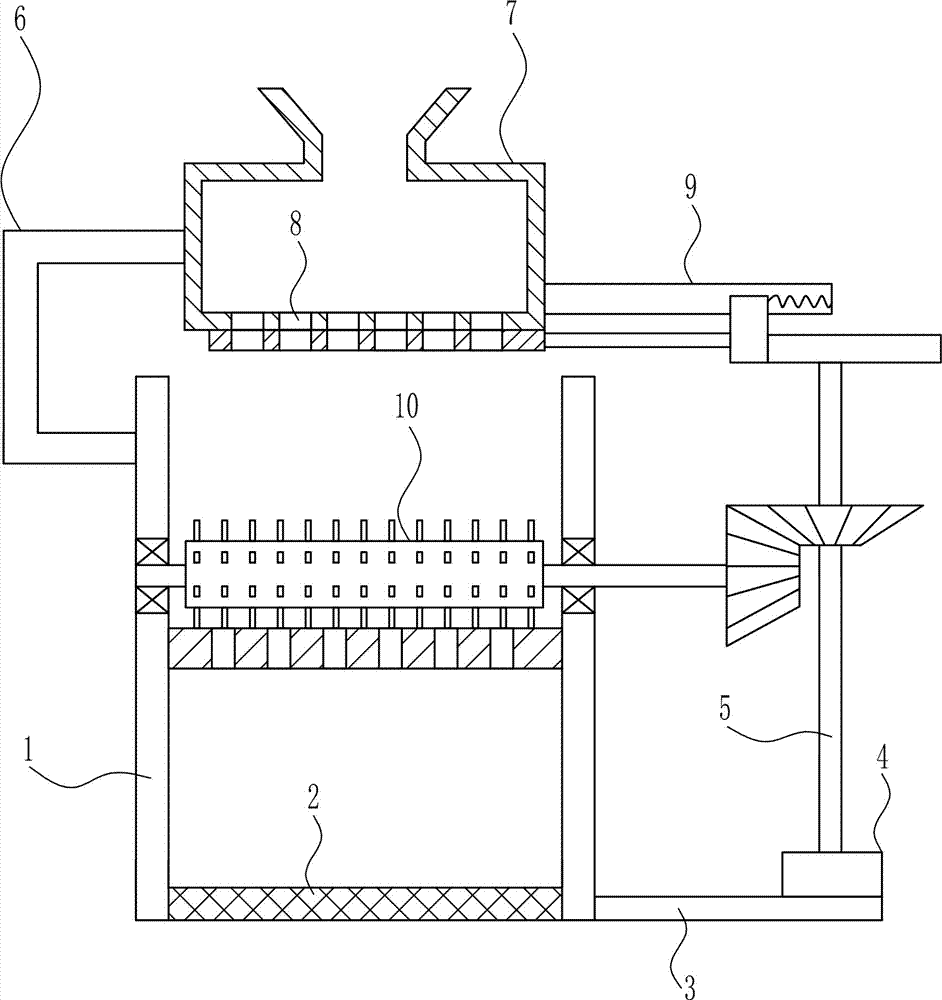

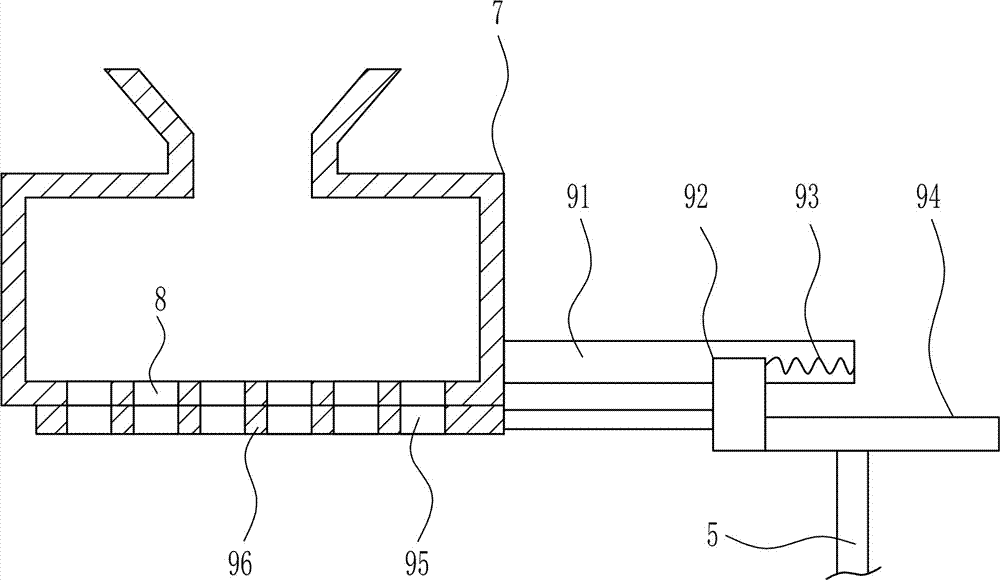

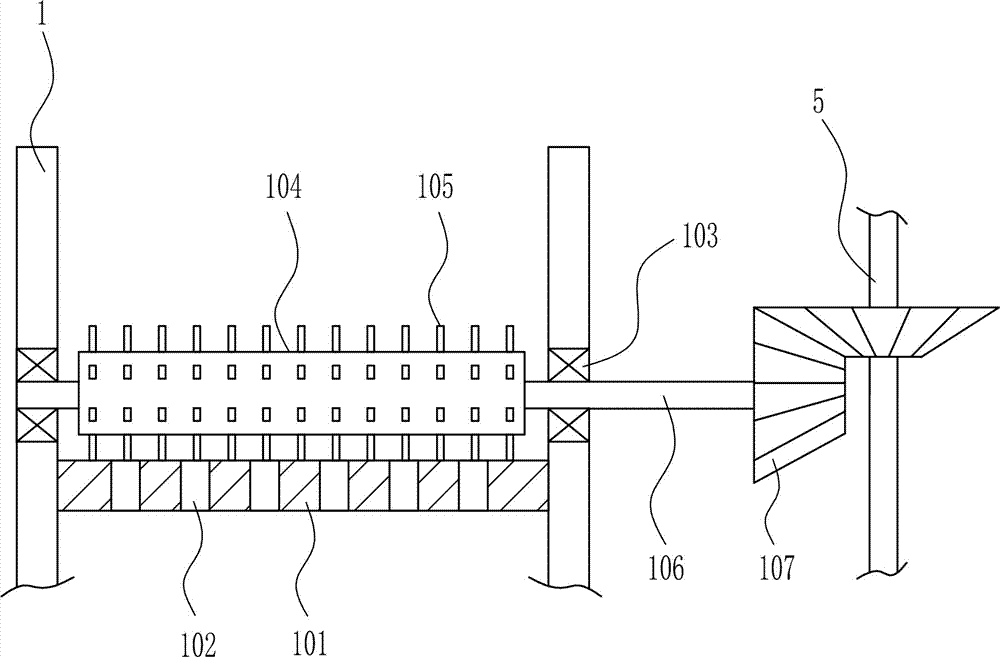

[0035] A multi-stage grinding equipment for graphite powder used in the production of new energy batteries, such as Figure 1-5 As shown, it includes a box body 1, a filter screen 2, a mounting plate 3, a motor 4, a first rotating rod 5, a connecting rod 6, a storage box 7, a moving mechanism 9 and a grinding mechanism 10, and the bottom wall of the box body 1 is connected with a filter Net 2, the lower side of the right wall of the box body 1 is connected with the installation plate 3, the motor 4 is installed on the right side of the top of the installation plate 3, the first rotating rod 5 is connected on the output shaft of the motor 4, and the upper side of the left wall of the box body 1 is connected with a connection Rod 6, the right end of connecting rod 6 is connected with storage box 7, and storage box 7 is positioned at the top of box body 1, and the bottom of storage box 7 evenly has first through hole 8, and storage box 7 right wall bottom is connected with moving ...

Embodiment 2

[0037] A multi-stage grinding equipment for graphite powder used in the production of new energy batteries, such as Figure 1-5 As shown, it includes a box body 1, a filter screen 2, a mounting plate 3, a motor 4, a first rotating rod 5, a connecting rod 6, a storage box 7, a moving mechanism 9 and a grinding mechanism 10, and the bottom wall of the box body 1 is connected with a filter Net 2, the lower side of the right wall of the box body 1 is connected with the installation plate 3, the motor 4 is installed on the right side of the top of the installation plate 3, the first rotating rod 5 is connected on the output shaft of the motor 4, and the upper side of the left wall of the box body 1 is connected with a connection Rod 6, the right end of connecting rod 6 is connected with storage box 7, and storage box 7 is positioned at the top of box body 1, and the bottom of storage box 7 evenly has first through hole 8, and storage box 7 right wall bottom is connected with moving ...

Embodiment 3

[0040] A multi-stage grinding equipment for graphite powder used in the production of new energy batteries, such as Figure 1-5 As shown, it includes a box body 1, a filter screen 2, a mounting plate 3, a motor 4, a first rotating rod 5, a connecting rod 6, a storage box 7, a moving mechanism 9 and a grinding mechanism 10, and the bottom wall of the box body 1 is connected with a filter Net 2, the lower side of the right wall of the box body 1 is connected with the installation plate 3, the motor 4 is installed on the right side of the top of the installation plate 3, the first rotating rod 5 is connected on the output shaft of the motor 4, and the upper side of the left wall of the box body 1 is connected with a connection Rod 6, the right end of connecting rod 6 is connected with storage box 7, and storage box 7 is positioned at the top of box body 1, and the bottom of storage box 7 evenly has first through hole 8, and storage box 7 right wall bottom is connected with moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com