Wallpaper and preparation method thereof

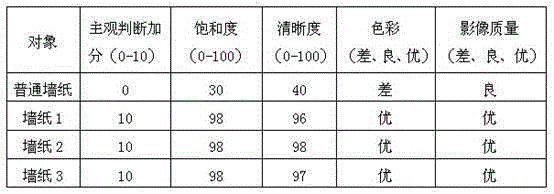

A wallpaper and pulp technology, applied in the chemical industry, can solve the problem of additional purchase of curtains, and achieve the effect of high projection effect, increased gain, and good image saturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Wallpaper 1

[0019] In the first step, take 50g of paper pulp and 12g of bark powder, mix them into the pulp tank, stir evenly and cook for 7 hours, add 3g of bleaching powder after cooling, stir and store for 15 hours, pass through a refiner for refining, filter 1000 mesh to obtain pulp ;

[0020] In the second step, take 1.5g of borosilicate, 0.5g of nano powder, 3g of bleaching powder, 5g of polycarbonate, 5g of polyethylene terephthalate, 4g of 2,6-dibenzylidene cyclohexanone, carbon fiber 3g, 5g of diethyl phthalate, 3g of glass fiber, 2g of carboxymethyl cellulose, 3g of polyacrylic acid fiber, 0.5g of defoamer, 9g of film-forming agent and 2g of dispersant were mixed uniformly to obtain mixture 1;

[0021] In the third step, mix the mixture 1 obtained in the second step and the slurry obtained in the first step for 4 hours to mix evenly, and then pass through a calender for calendering, keep the thickness at 0.5mm, and place it in an environment with ...

Embodiment 2

[0027] Example 2 wallpaper 2

[0028] In the first step, take 40g of pulp and 10g of bark powder, mix them into the pulp pool, stir evenly and cook for 5 hours, add 2g of bleaching powder after cooling, stir and store for 10 hours, pass through a refiner for refining, filter 1000 mesh to obtain pulp ;

[0029] In the second step, take 1g of borosilicate, 0.4g of nanopowder, 2g of bleaching powder, 4g of polycarbonate, 3g of polyethylene terephthalate, 3g of 2,6-dibenzylidene cyclohexanone, and 2g of carbon fiber , diethyl phthalate 3g, glass fiber filament 2g, carboxymethyl cellulose 1g, polyacrylic acid fiber 2g, defoamer 0.4g, film forming agent 8g and dispersant 1g are mixed uniformly to obtain mixture 1;

[0030] In the third step, mix the mixture 1 obtained in the second step and the slurry obtained in the first step for 3 hours to mix evenly, and then pass through a calender for calendering, keeping the thickness at 0.4mm, and place it in an environment with a temperatu...

Embodiment 3

[0036] Example 3 Wallpaper 3

[0037] In the first step, take 80g of pulp and 15g of bark powder, mix them into the pulp pool, stir evenly and cook for 10 hours, add 4g of bleaching powder after cooling, stir and store for 20 hours, pass through a refiner for refining, filter 1000 mesh to obtain pulp ;

[0038] In the second step, take 2g of borosilicate, 0.8g of nanopowder, 4g of bleaching powder, 7g of polycarbonate, 6g of polyethylene terephthalate, 5g of 2,6-dibenzylidene cyclohexanone, and 4g of carbon fiber , diethyl phthalate 6g, glass fiber filament 5g, carboxymethyl cellulose 3g, polyacrylic acid fiber 4g, defoamer 1g, film forming agent 10g and dispersant 3g are mixed uniformly to obtain mixture 1;

[0039] The third step is to mix the mixture 1 obtained in the second step with the slurry obtained in the first step for 5 hours, mix evenly, and then pass through a calender for rolling, keep the thickness at 1mm, and dry at a temperature of 100°C , that is.

[0040]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com