Polyamide-epichlorohydrin resin cylinder adhesive

A technology of epichlorohydrin and polyamide, applied in the field of polyamide-epichlorohydrin resin sticking agent, can solve the problems of tearing, tearing, paper jamming, etc., and achieve the effects of stable performance and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

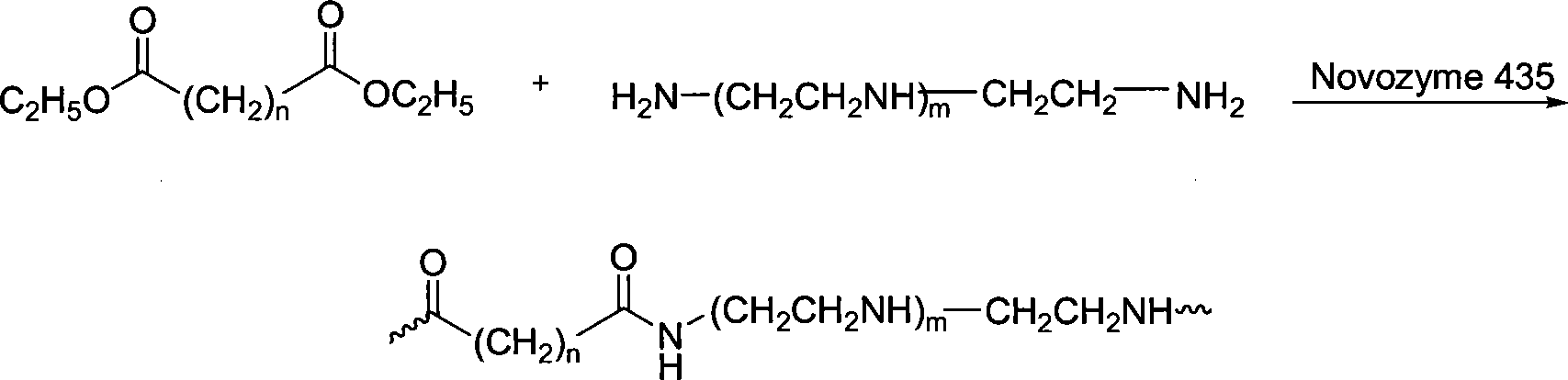

Method used

Image

Examples

Embodiment 1

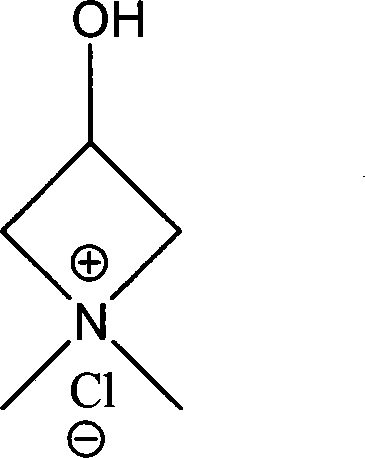

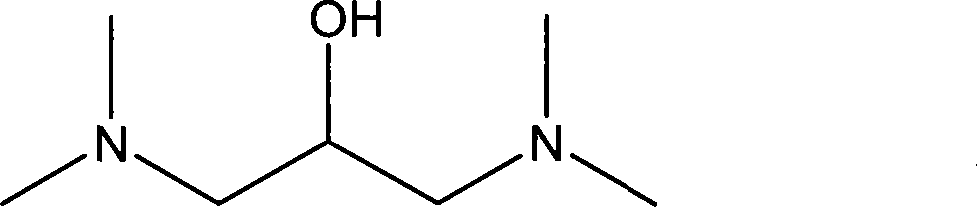

[0053] Embodiment 1: with diethylenetriamine 1mol, diethyl malonate 0.9mol, solvent-free, add catalyst lipase Novozyme435, its consumption is 1% of diethylenetriamine and diethyl malonate gross mass, generally N 2 , Stir the reaction at 45°C for 6 hours to obtain a yellow-white solid prepolymer. Add water to dissolve, so that the concentration of the solution is 30%, and filter off the catalyst. Adjust the pH to 10-11 with 25% ammonia water, and add a small amount of stabilizer phosphorous acid 1.64g. 0.35 mol of epichlorohydrin is added dropwise into the prepolymer aqueous solution, and the reaction is controlled at 65° C. until the viscosity reaches 10 to 200 cps measured by the Brookfield method. Cooling with 50% sulfuric acid to adjust pH=4.0 to obtain polyamide-epichlorohydrin resin tank adhesive.

Embodiment 2

[0054] Embodiment 2: triethylenetetramine 1mol, diethyl succinate 0.95mol, solvent-free, add Novozyme4355% (reactant raw material mass ratio), logical N 2 , Stir the reaction at 50°C for 6hr to obtain a white solid prepolymer. Add water to dissolve, so that the concentration of the solution is 25%, and filter off the catalyst. Adjust pH=10-11, add a small amount of stabilizer ammonium hypophosphite 0.83g. 0.25 mol of epichlorohydrin is added dropwise into the prepolymer aqueous solution, and the reaction is controlled at 70° C. until the viscosity reaches 10 to 200 cps measured by the Brookfield method. Cool to adjust pH=4.0, pack.

Embodiment 3

[0055] Embodiment 3: with diethylenetriamine 1mol, diethyl malonate 0.95mol, add 3ml water, catalyzer lipase Novozyme435, its consumption is 1% of diethylenetriamine and diethyl malonate gross mass, generally N 2, Stir the reaction at 45°C for 6 hours to obtain a yellow-white solid prepolymer. Add water to dissolve, so that the concentration of the solution is 30%, and filter off the catalyst. Adjust the pH to 10-11 with 25% ammonia water. 0.30 mol of epichlorohydrin is added dropwise into the prepolymer aqueous solution, and the reaction is controlled at 65° C. until the viscosity reaches 10 to 200 cps measured by the Brookfield method. Cooling with 50% sulfuric acid to adjust pH=4.0 to obtain polyamide-epichlorohydrin resin tank adhesive.

[0056] Obtain the following table of polymer resin ionic strength through using potentiometric titration (aided by ion-selective electrode assay method):

[0057] Example 1

[0058] Table 1 formula of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com