Micro nuclear battery with protection ring structure and manufacturing method thereof

A protection ring and nuclear battery technology, which is applied in the fields of semiconductors, nuclear physics and micro-energy, can solve the problems of low sensitivity and energy conversion efficiency, and achieve the effects of improving energy conversion efficiency, increasing open circuit voltage, and increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

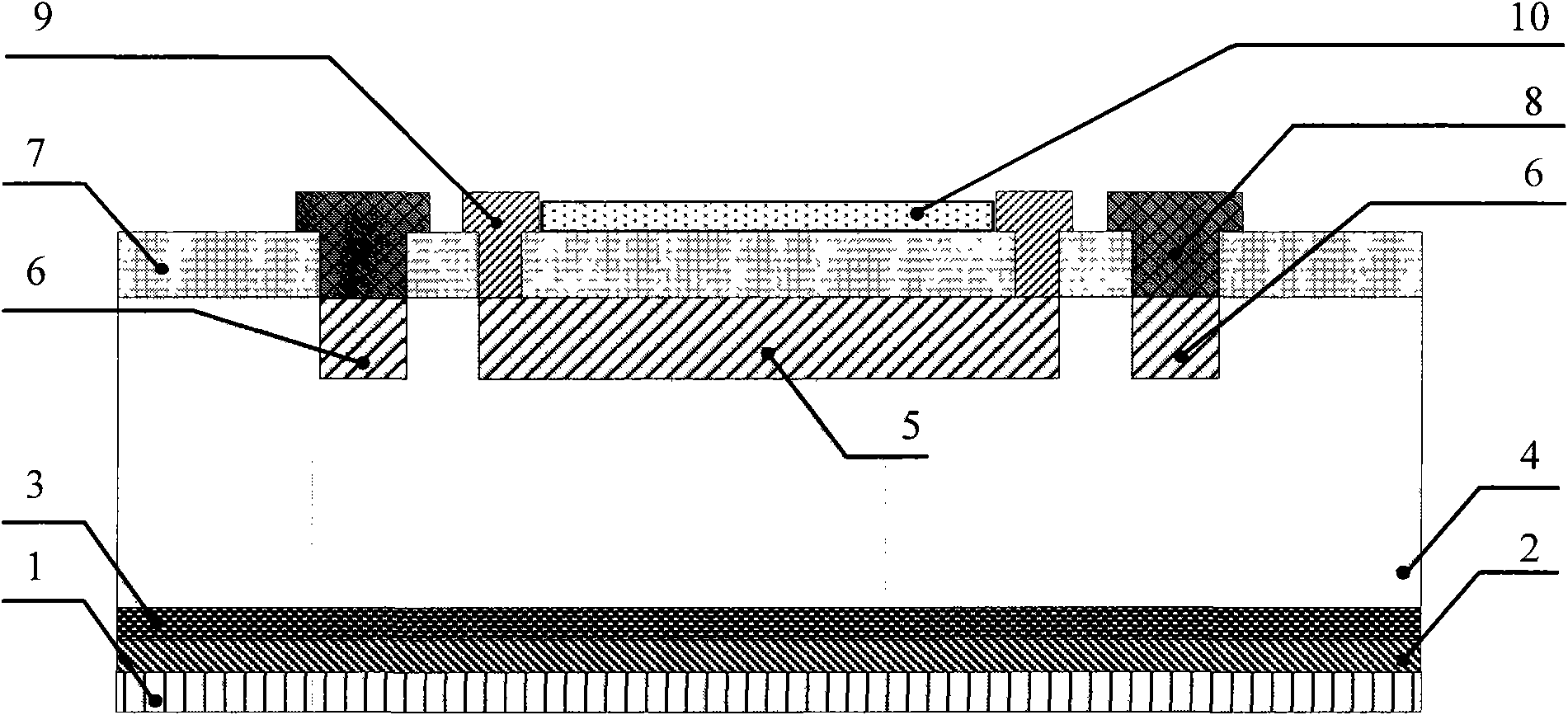

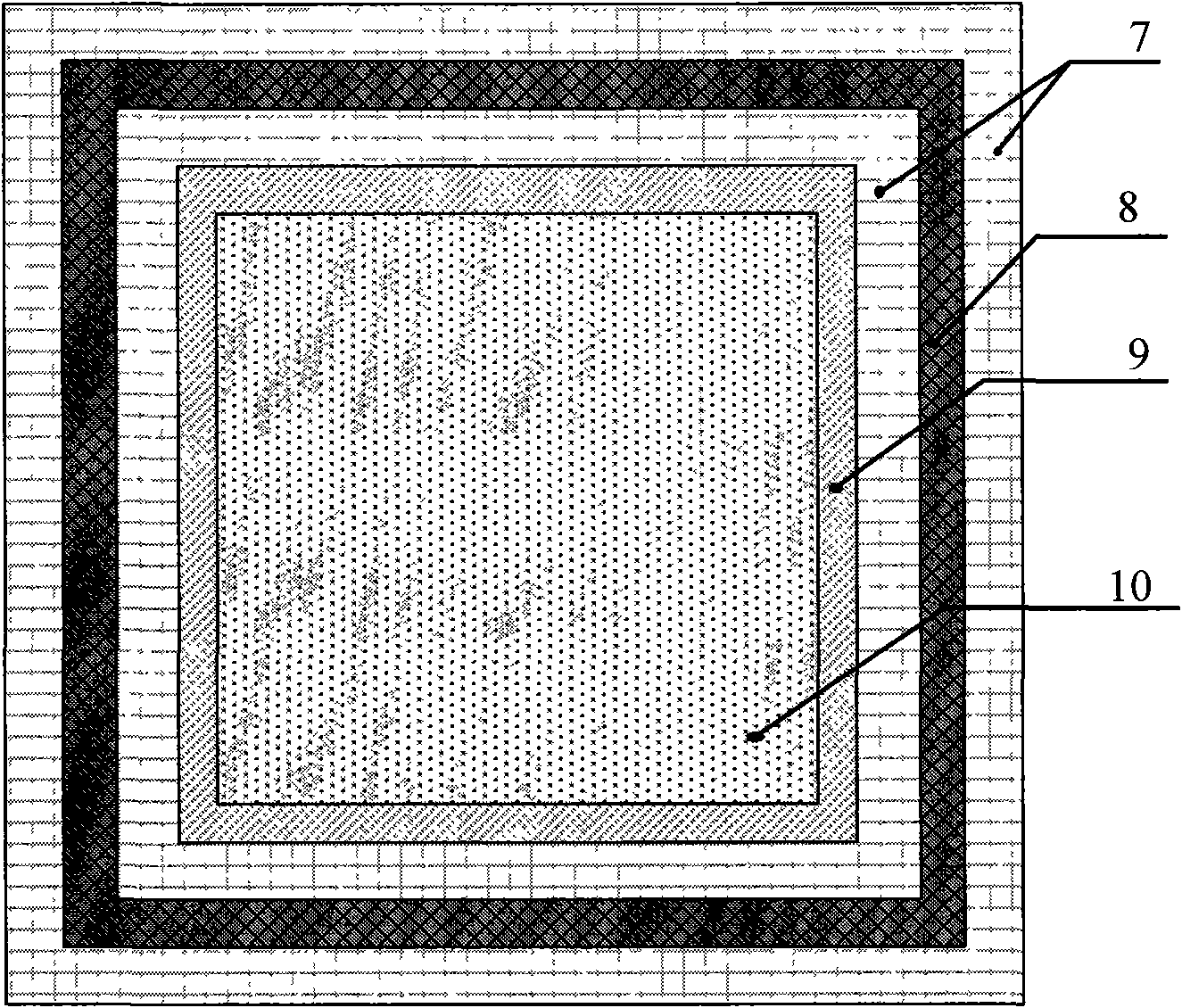

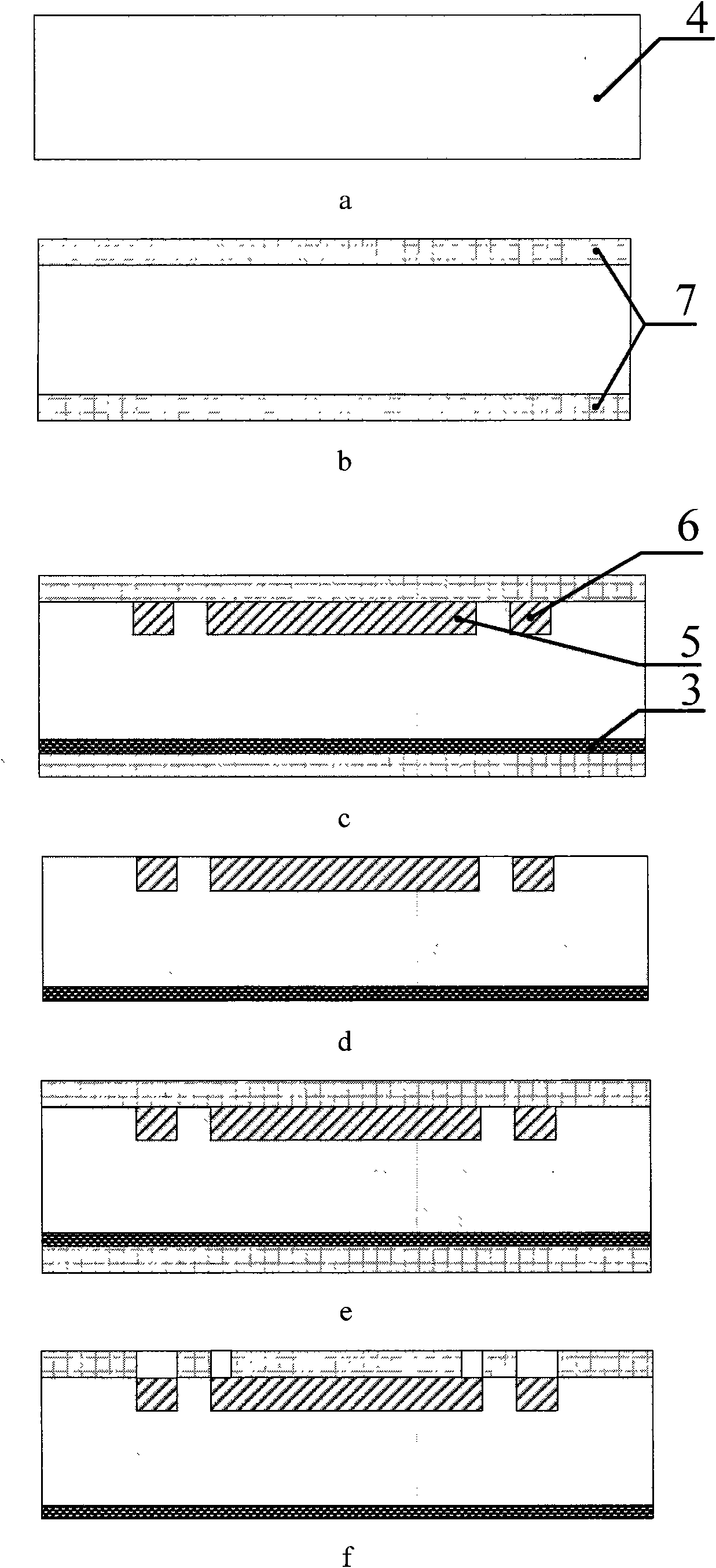

[0039] refer to figure 1 and figure 2 , the present embodiment is a micro-nuclear battery based on a silicon material PIN junction structure with a guard ring, which sequentially includes an isotope 10, an upper electrode metal layer 9, a guard ring contact electrode 8, a passivation layer 7, a guard ring 6, and a p+ type silicon Region 5, intrinsic silicon layer 4, n+ type silicon layer 3, metal adhesion layer 2, bottom electrode metal layer 1. The intrinsic silicon layer 4 has a resistivity of 2000 ohm cm, a thickness of 300 μm, and a square shape; the upper part of the intrinsic silicon layer 4 has a doping concentration of 6×10 20 cm -3 The square area is the p+ type silicon region 5, and its thickness is 1 μm; the guard ring 6 is located on the periphery of the p+ type silicon region 5, forming a square frame of equal thickness including the p+ type silicon region 5, and the material of the guard ring 6 is the same as that of the p+ type silicon region 5. The silicon...

specific Embodiment 2

[0051] refer to Figure 4 and Fig. 5, the present embodiment is a micro-nuclear battery based on a SiC material PN junction structure with a guard ring, which sequentially includes an isotope 10, an upper electrode metal layer 9, a guard ring contact electrode 8, a passivation layer 7, a guard ring 6, p+ type SiC layer 5 , n+ type SiC layer 3 , metal adhesion layer 2 , bottom electrode metal layer 1 . Wherein the doping concentration of n+ type SiC layer 3 is 6×10 17 cm -3 , a thickness of 500 μm, a circular shape; the upper doping concentration of the n+ type SiC layer 3 is 6×10 19 cm -3 , a circular area with a radius of 5.6 mm and a thickness of 0.8 μm is the p+-type SiC layer 5; the guard ring 6 is located on the periphery of the p+-type SiC layer 5, forming an equal-thickness ring including the p+-type SiC layer 5, and the circle The difference between the inner and outer radius of the ring is 100 μm, the material of the guard ring 6 is consistent with the p+ type SiC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com