Thermal management system for lithium-ion batteries

A thermal management system, a technology for lithium-ion batteries, applied in the field of lithium-ion battery thermal management systems, can solve the problems of reducing cooling air cooling efficiency, deposition, etc., and achieve the effect of avoiding dust erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

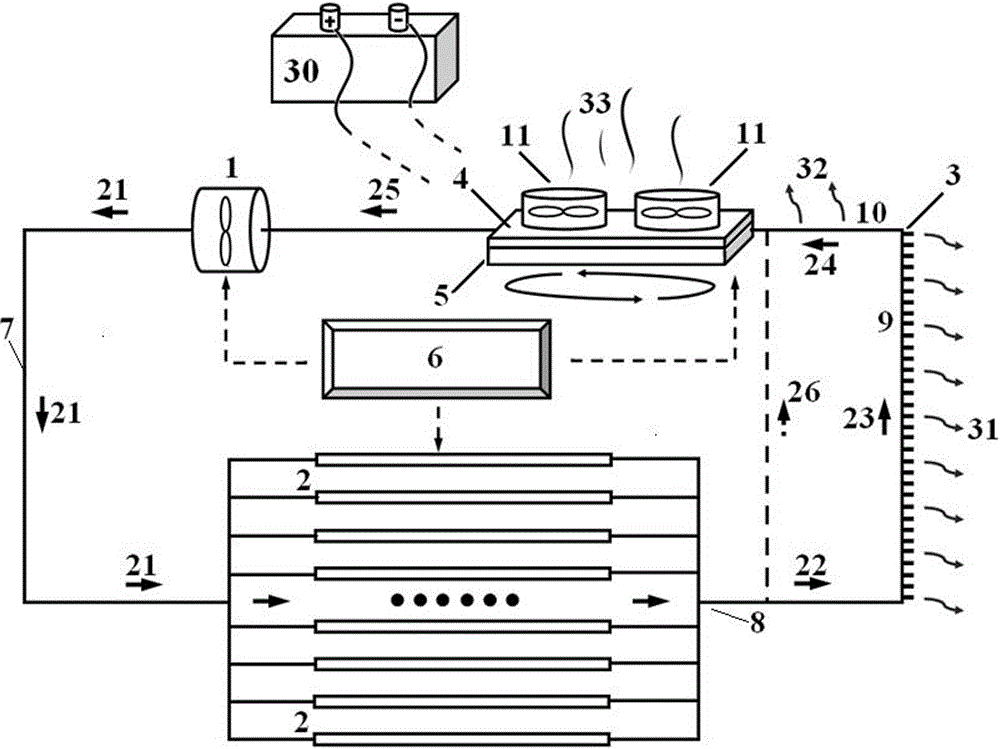

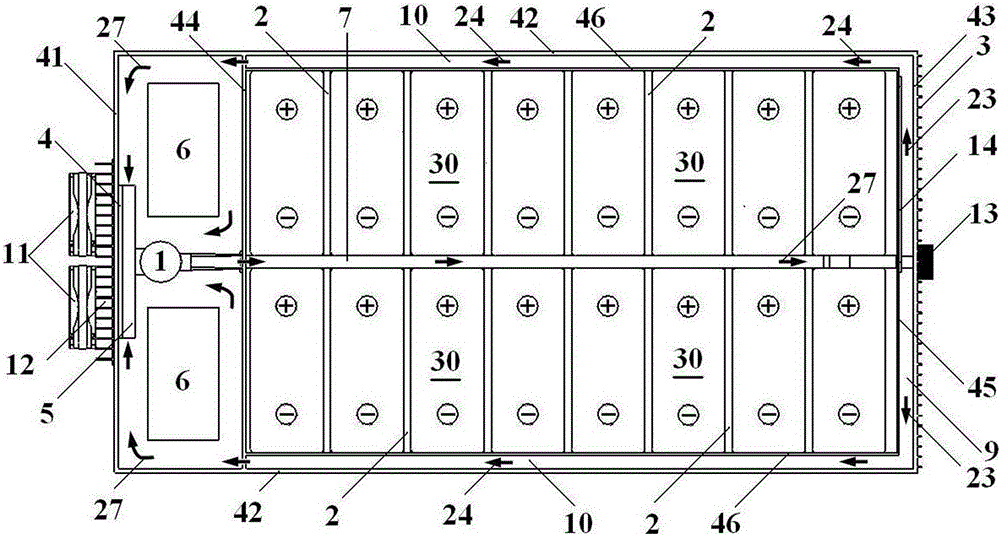

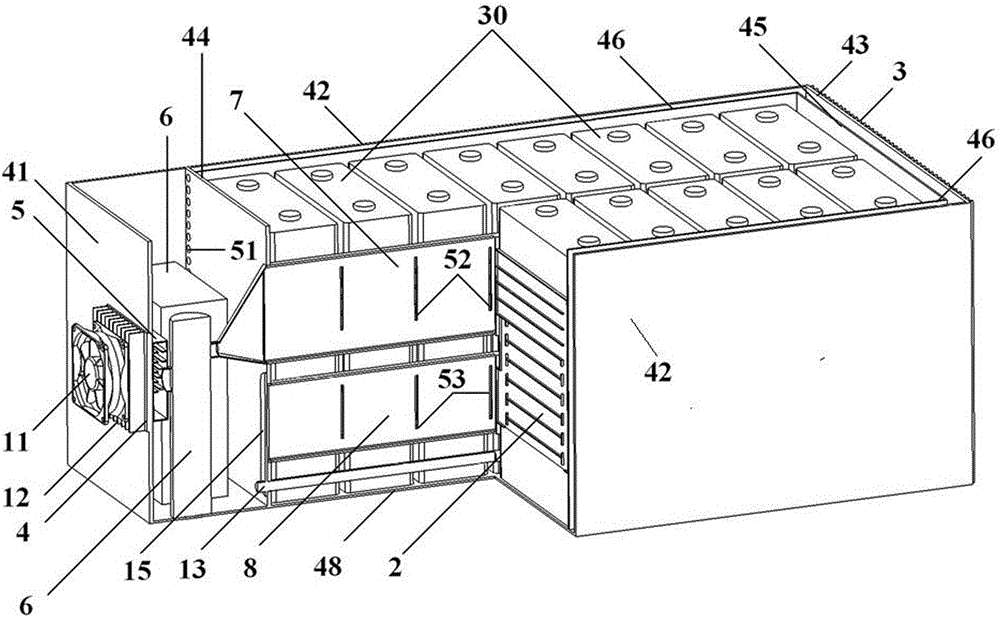

[0019] Embodiments of the lithium-ion battery thermal management system of the present invention: such as Figure 1-5 As shown, the system includes a battery box and a battery pack, an air duct system, a control system 6, and a heat exchange device. The battery box has a sealed inner cavity, and the battery pack includes two rows of battery cells. 30 are spaced in the front-to-rear direction and all are located in the lumen. The box body is composed of the front side plate 41, the left and right side plates 42, the rear side plate 43, the isolation plate 44, the air duct rear enclosure plate 45, the air duct side enclosure plate 46, the bottom plate 48 and the cover plate. Completely sealed.

[0020] The front part of the inner cavity of the battery box is provided with an air pump 1. The air pump 1 and the battery pack are separated from the front and the rear by the isolation plate 44. The space where the air pump 1 is located is the control area, and the space where the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com