Full-automatic chamfering machine

A chamfering machine, fully automatic technology, applied in the direction of maintenance and safety accessories, metal processing machinery parts, metal processing, etc., can solve the problems of electric or pneumatic component erosion, affecting the service life of equipment, etc., to prevent powder erosion and facilitate Cleaning and maintenance, avoiding the effect of dust erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

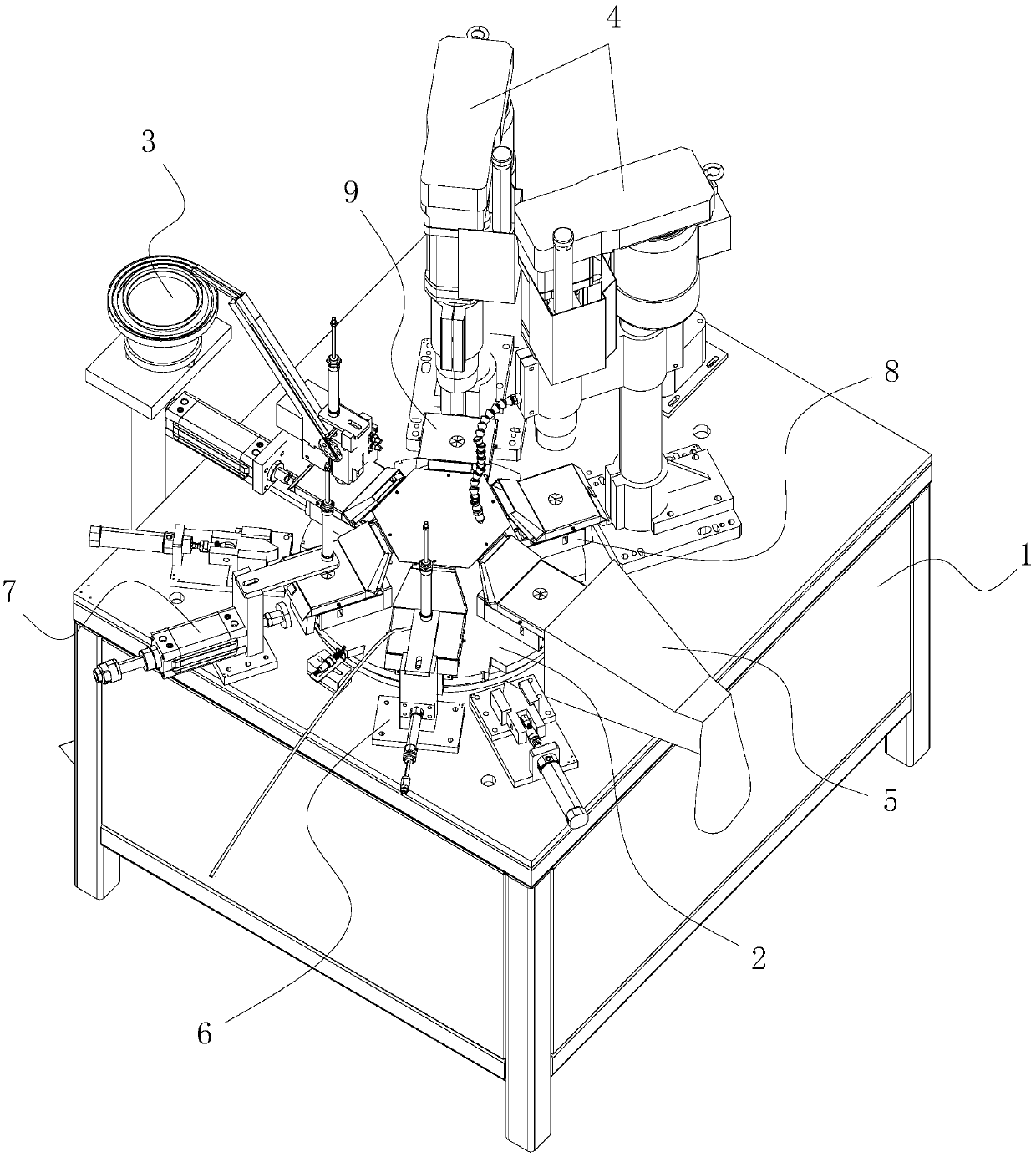

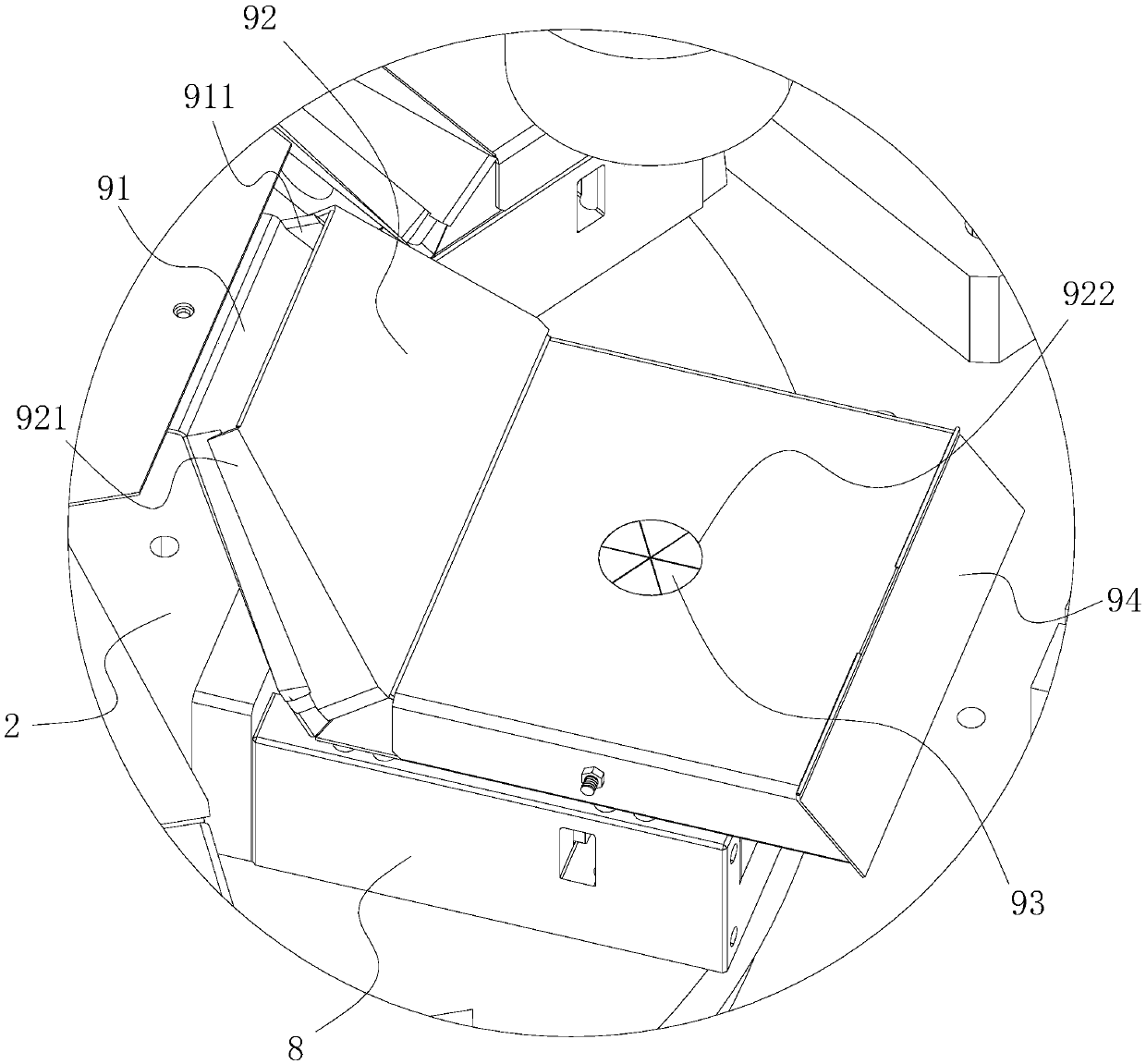

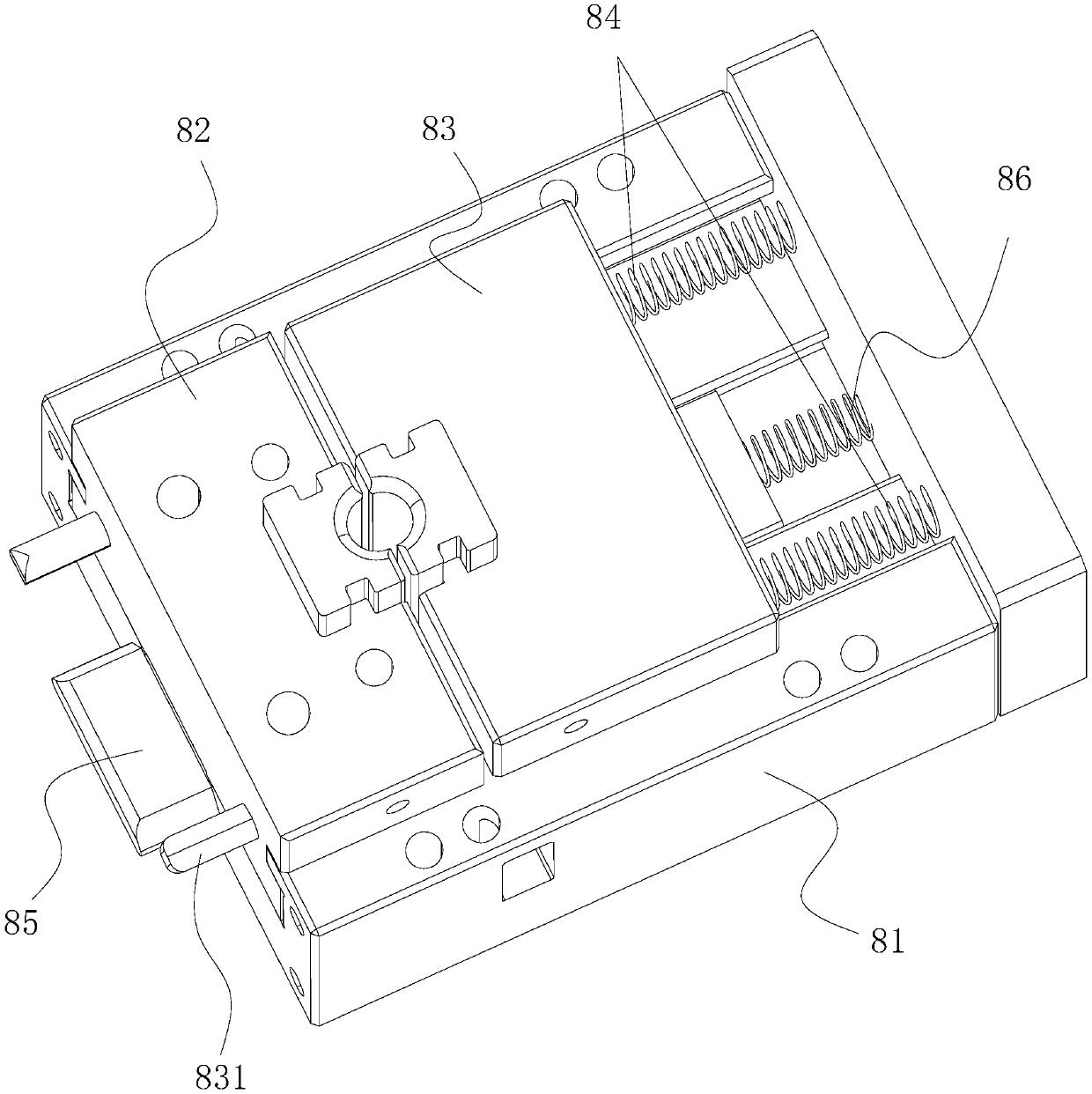

[0042] A fully automatic chamfering machine, such as figure 1 As shown, a frame 1 horizontally arranged on the ground, a turntable 2 rotatably connected to the frame 1 for intermittently conveying workpieces, and a plurality of tooling uniformly distributed on the outer edge of the turntable 2 for clamping and fixing the workpieces Fixture 8 and the feeding mechanism 3, the chamfering mechanism 4, the dust removal mechanism 5, the wire-discharging mechanism 6 and the blanking station 7 arranged on the frame 1; wherein, the chamfering mechanism 4 is provided with multiple pieces, and the feeding mechanism 3. Each piece of chamfering mechanism 4, dust removal mechanism 5, wire discharge mechanism 6 in the pipe and unloading station 7 ring turntable 2 are equidistantly arranged, and each piece of tooling fixture 8 is fixed to prevent the workpiece from c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com