Rod drop system and method of control rod driving mechanism

A driving mechanism and control rod technology, applied in the control of nuclear reactions, non-rotational vibration suppression, reactors, etc., can solve the problems of covering the active area within a certain period of time, prolonging the time of falling rods, and nuclear hazards, etc., to achieve long-term effective repeated use , avoid damage to the drive mechanism, and eliminate the troublesome effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

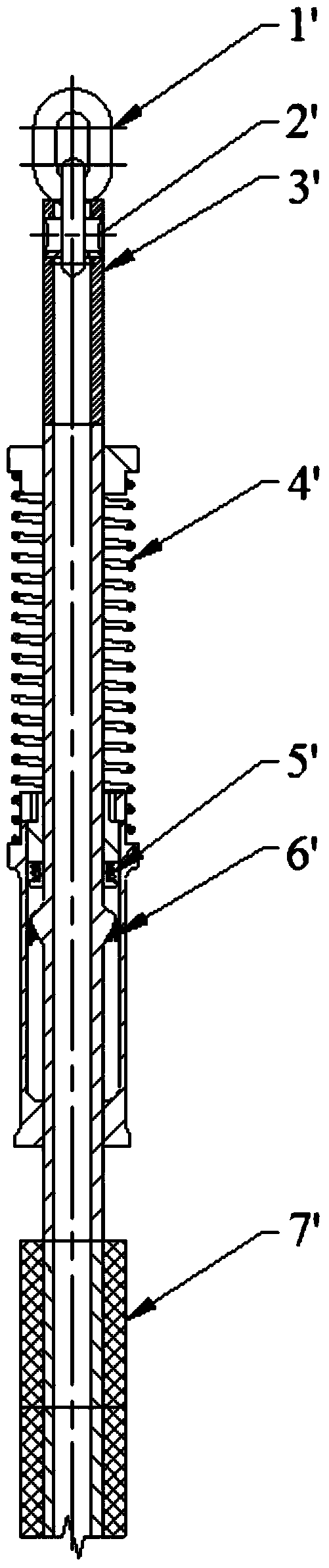

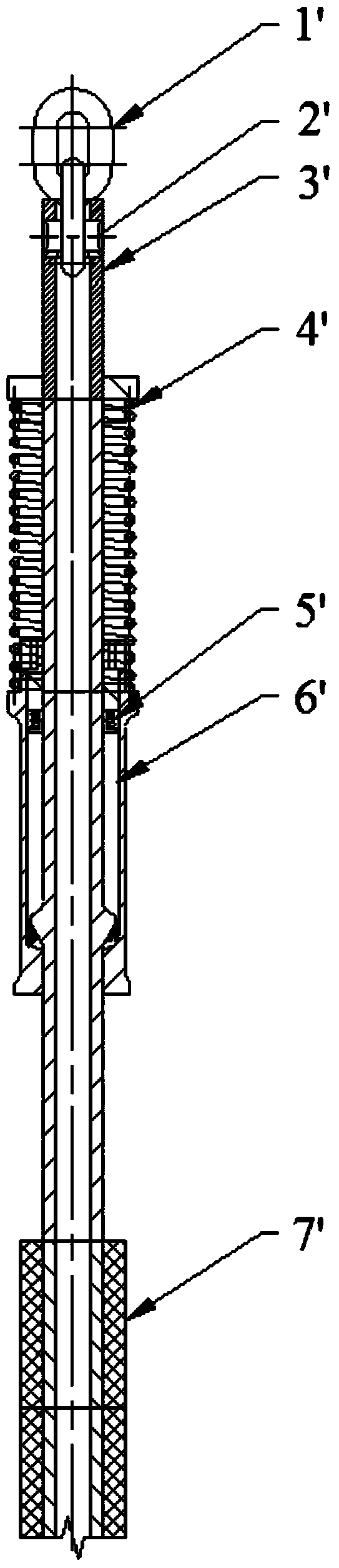

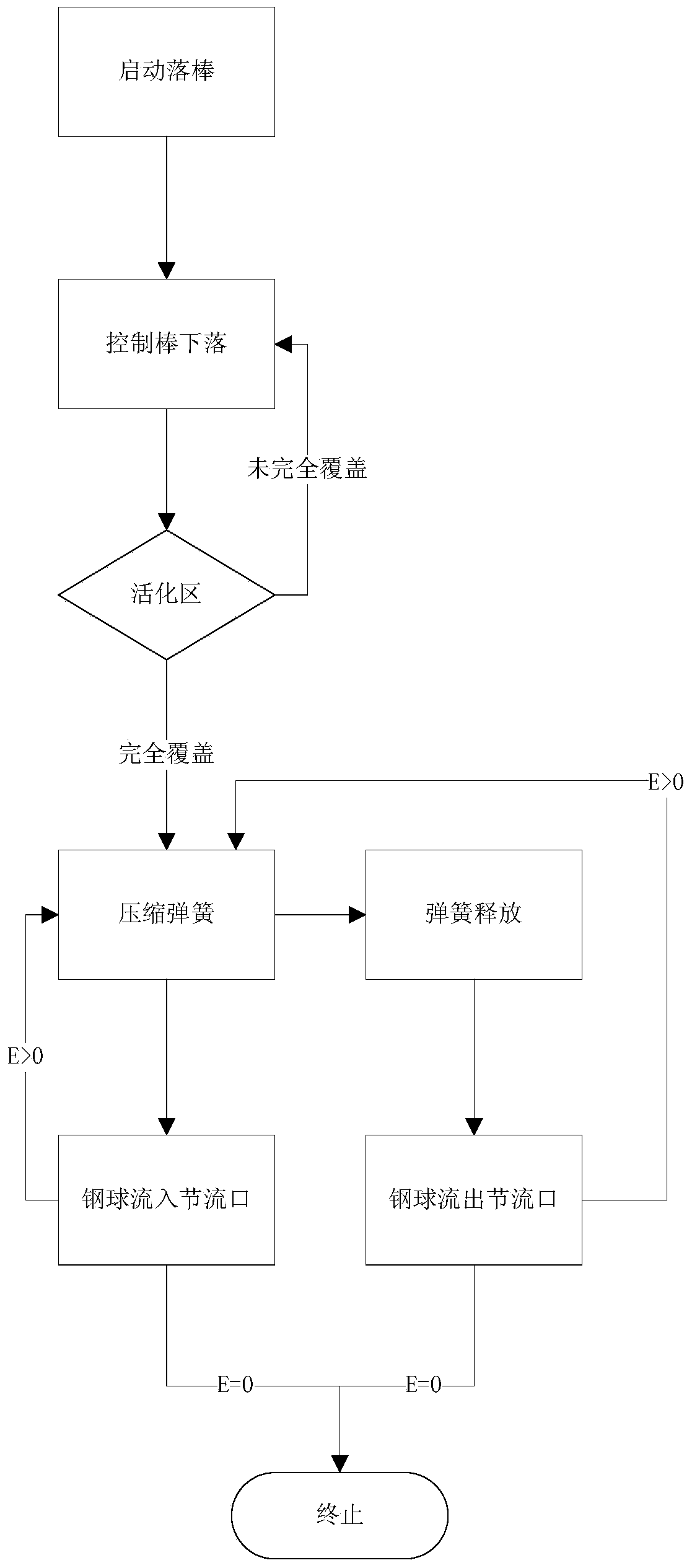

[0036] Such as image 3 As shown, the present invention is a rod drop system 100 of a control rod drive mechanism, which includes: a spring 1, two friction plates 2, a screw transmission mechanism 3 and a sleeve 5, wherein the screw transmission mechanism 3 includes a rotating friction disc 4 and screw assembly 6.

[0037] The inner wall of the sleeve 5 is provided with a dividing plate 51, thereby dividing the inner cavity of the sleeve 5 into upper and lower sections along its length extension direction; the upper surface of the dividing plate 51 is provided with a plurality of first threaded holes 52, two One of the friction plates 2 is fixed on the upper surface of the partition plate 51 by screwing into the first threaded hole 52, that is, fixed at the bottom position of the upper section of the sleeve 5; the outer wall of the lower section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com