Spirulina tablet, and preparation method thereof

A technology of spirulina tablets and spirulina tablets, applied in the field of medicine, can solve problems such as unqualified disintegration indicators, achieve the effect of shortening the disintegration time and facilitating the absorption of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

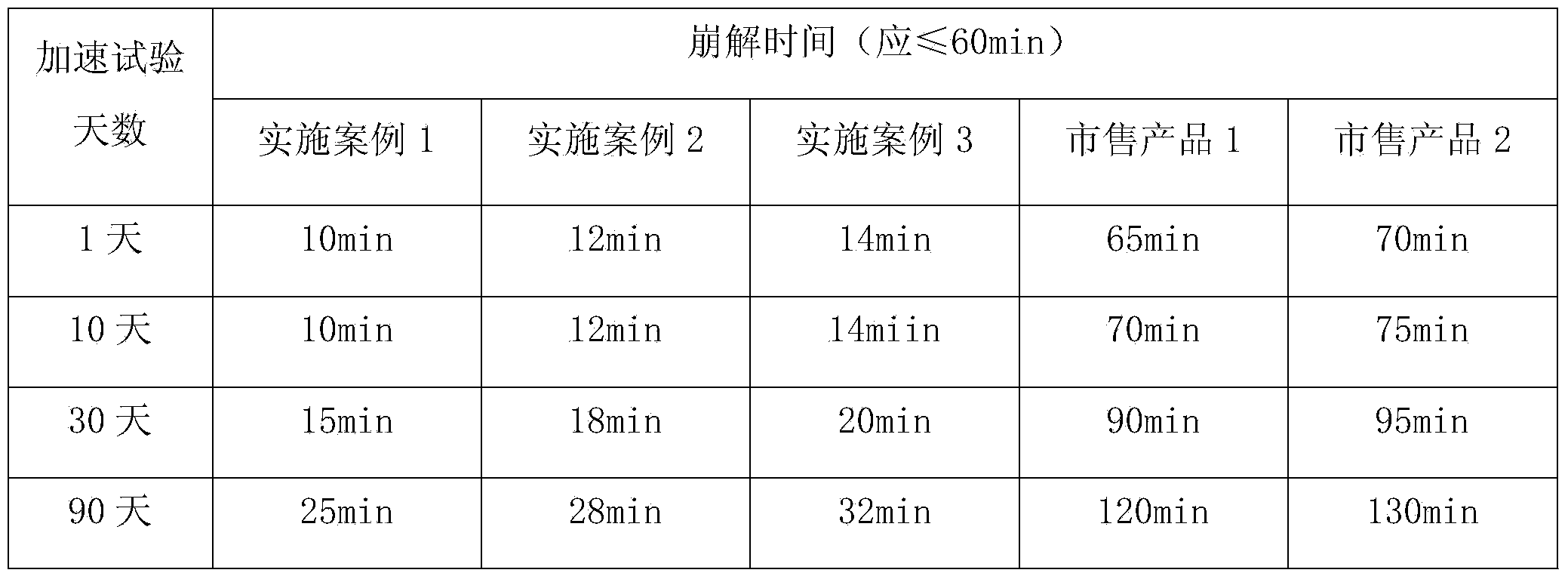

Examples

Embodiment 1

[0031] (1) Screening of raw materials: Pass 75% of spirulina powder, 8% xylooligosaccharides, and 10% isomaltulose, which account for the mass ratio of the tablet, through an 80-mesh sieve. (2) Making soft materials: Dissolve hydroxypropyl methylcellulose in 30% ethanol as a wetting agent after treatment with spirulina powder, xylooligosaccharides, and isomaltulose after (1) to make A hydroxypropyl methylcellulose ethanol solution with a mass concentration of 0.5% was prepared.

[0032] (3) Humidification granules: Pass the soft material prepared in (2) through a 30-mesh sieve to make granules.

[0033] (4) Drying: Dry the soft material prepared in (3) at a temperature of 60°C for 60 minutes until the particle moisture is 2-4%.

[0034] (5) Grain sizing: Pass the dry granules prepared in (4) through a 30-mesh sieve.

[0035] (6) Total blending: Add 0.8% polyethylene glycol 6000, 5% sodium carboxymethyl starch, and 0.2% magnesium stearate to the dry granules after sieving (5)...

Embodiment 2

[0038](1) Screening of raw materials: Pass 82% spirulina powder, 6% xylooligosaccharide, and 6% isomaltulose, which account for the mass ratio of the tablet, through an 80-mesh sieve.

[0039] (2) Making soft materials: Dissolve hydroxypropyl methylcellulose with 40% ethanol as a wetting agent after treatment with spirulina powder, xylooligosaccharides, and isomaltulose after (1) to make A hydroxypropyl methylcellulose ethanol solution with a mass concentration of 0.5% was prepared.

[0040] (3) Humidification granules: Pass the soft material prepared in (2) through a 30-mesh sieve to make granules.

[0041] (4) Drying: Dry the soft material prepared in (3) at a temperature of 65°C for 50 minutes until the particle moisture is 2-4%.

[0042] (5) Grain sizing: Pass the dry granules prepared in (4) through a 30-mesh sieve.

[0043] (6) Total blending: Add 0.5% polyethylene glycol 6000, 3% sodium carboxymethyl starch, and 0.5% magnesium stearate to the dry granules after sievin...

Embodiment 3

[0046] (1) Screening of raw materials: pass 88% spirulina powder, 4% xylooligosaccharide, and 4% isomaltulose, which account for the mass ratio of the tablet, through an 80-mesh sieve.

[0047] (2) Making soft materials: Dissolve hydroxypropyl methylcellulose in 30% ethanol as a wetting agent after treatment with spirulina powder, xylooligosaccharides, and isomaltulose after (1) to make A hydroxypropyl methylcellulose ethanol solution with a mass concentration of 0.5% was prepared.

[0048] (3) Humidification granules: Pass the soft material prepared in (2) through a 30-mesh sieve to make granules.

[0049] (4) Drying: Dry the soft material prepared in (3) at a temperature of 60°C for 60 minutes until the particle moisture is 2-4%.

[0050] (5) Grain sizing: Pass the dry granules prepared in (4) through a 30-mesh sieve.

[0051] (6) Total blending: add 0.5% polyethylene glycol 6000, 2% sodium carboxymethyl starch, and 1% magnesium stearate to the dry granules after sieving (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com