Patents

Literature

47results about How to "Zero consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

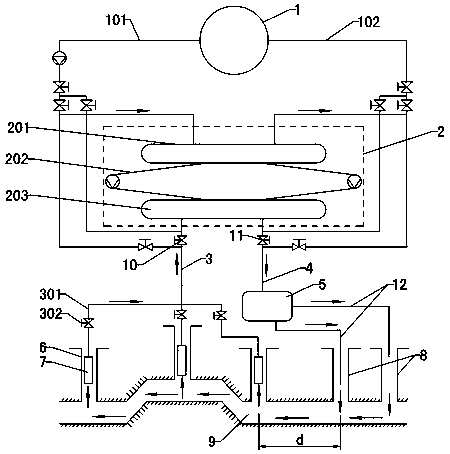

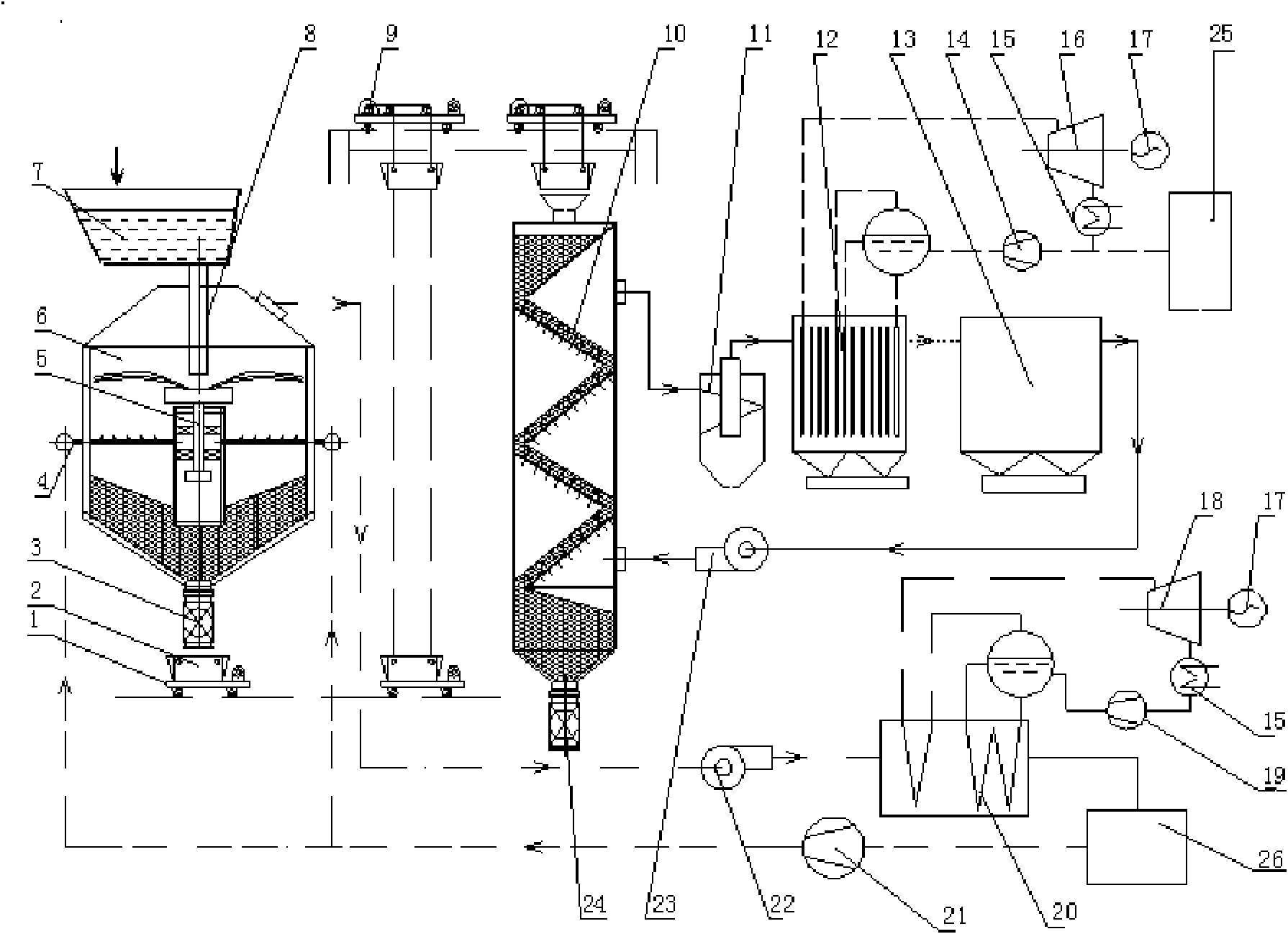

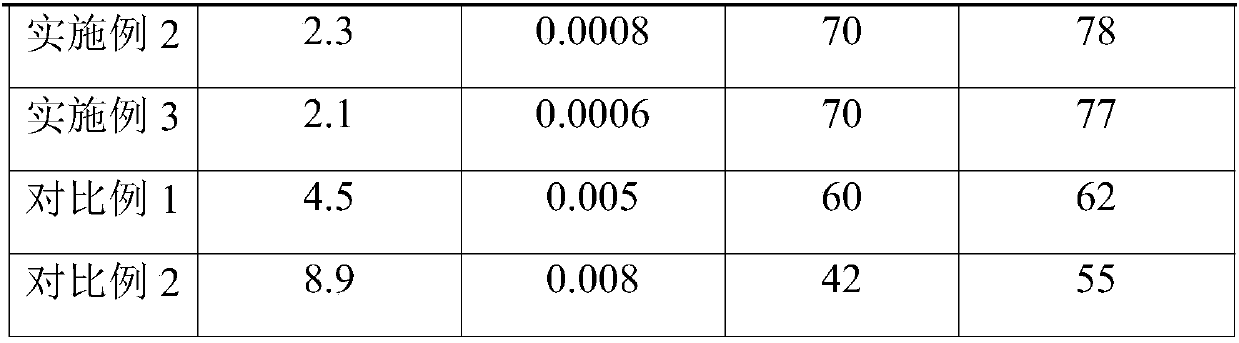

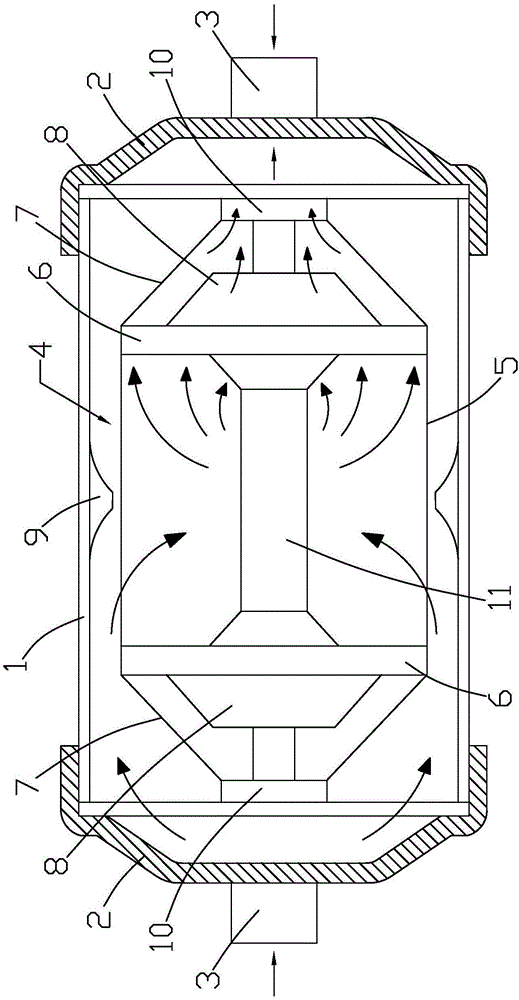

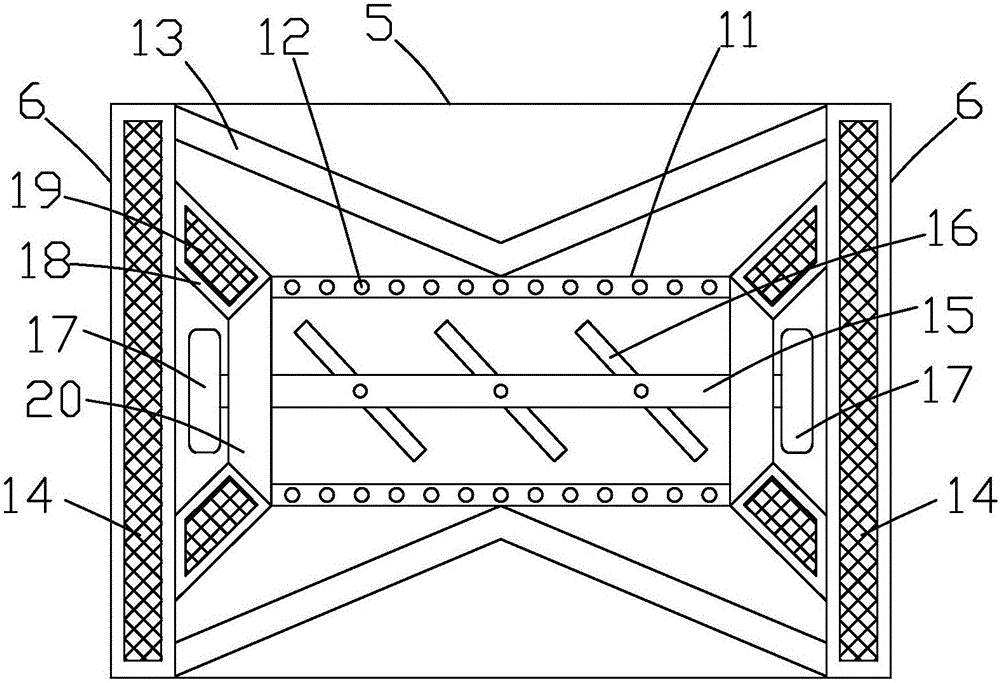

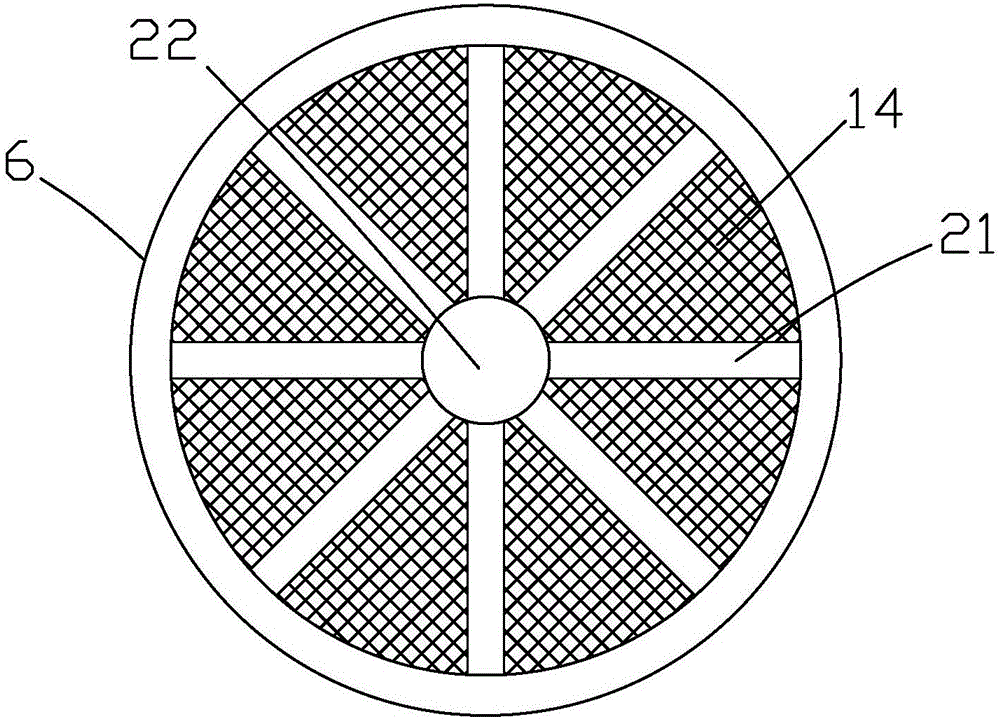

Blast furnace slag granulation and waste heat utilization process technology and equipment

ActiveCN102268495ASmall and uniformSmall sizeProcess efficiency improvementSteam generation using hot heat carriersMolten slagBlast furnace

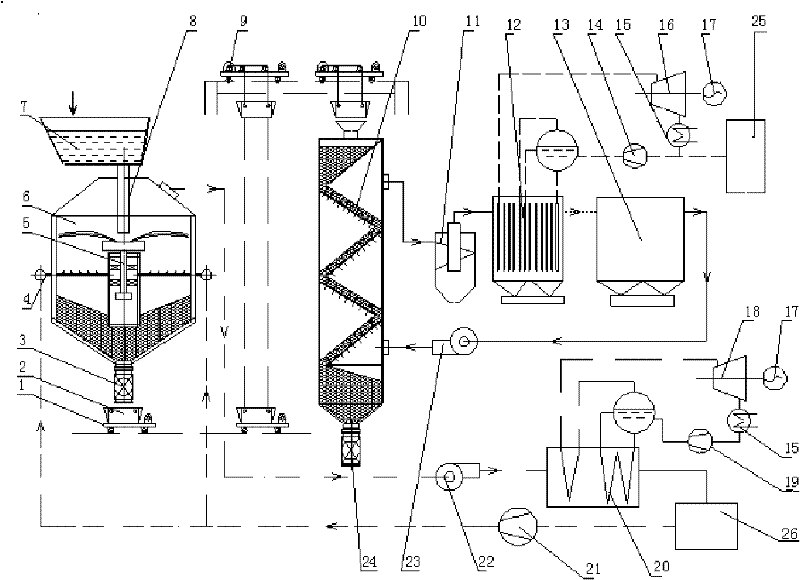

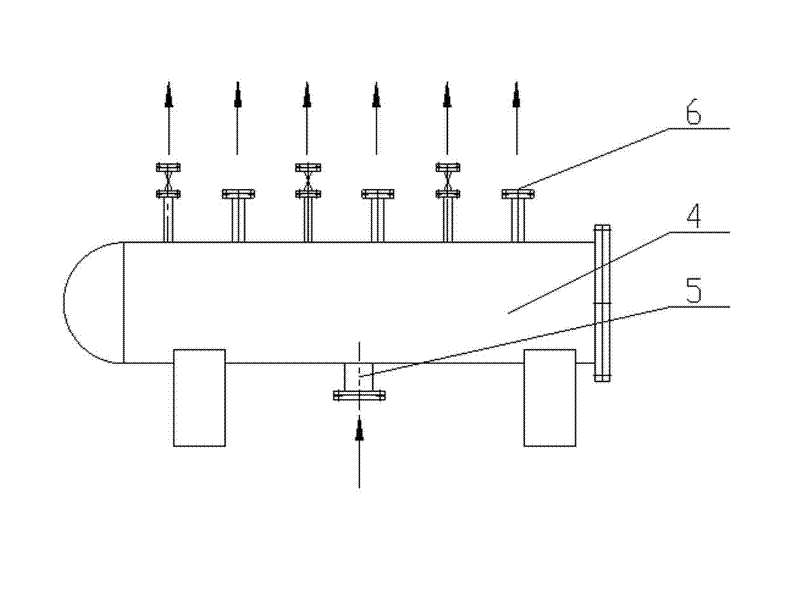

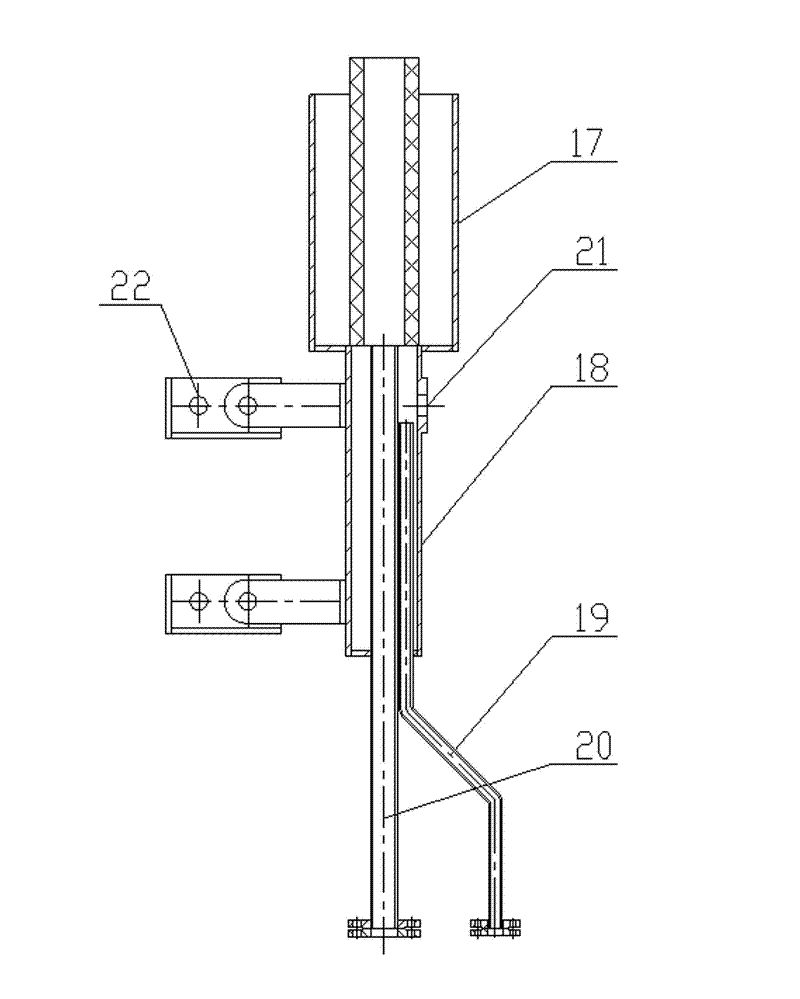

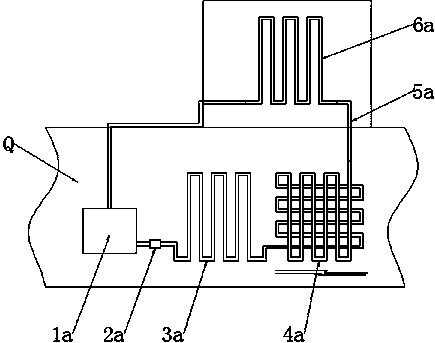

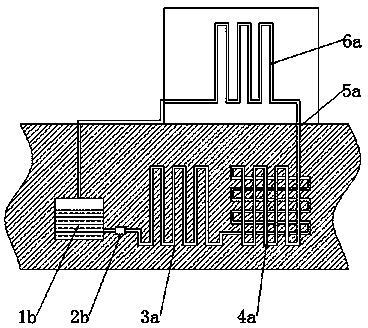

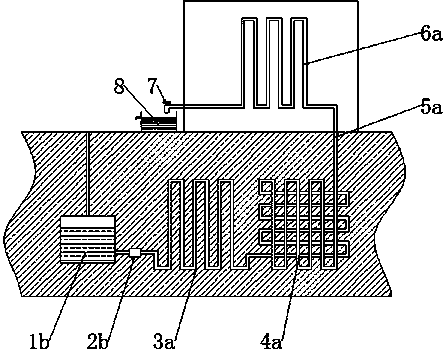

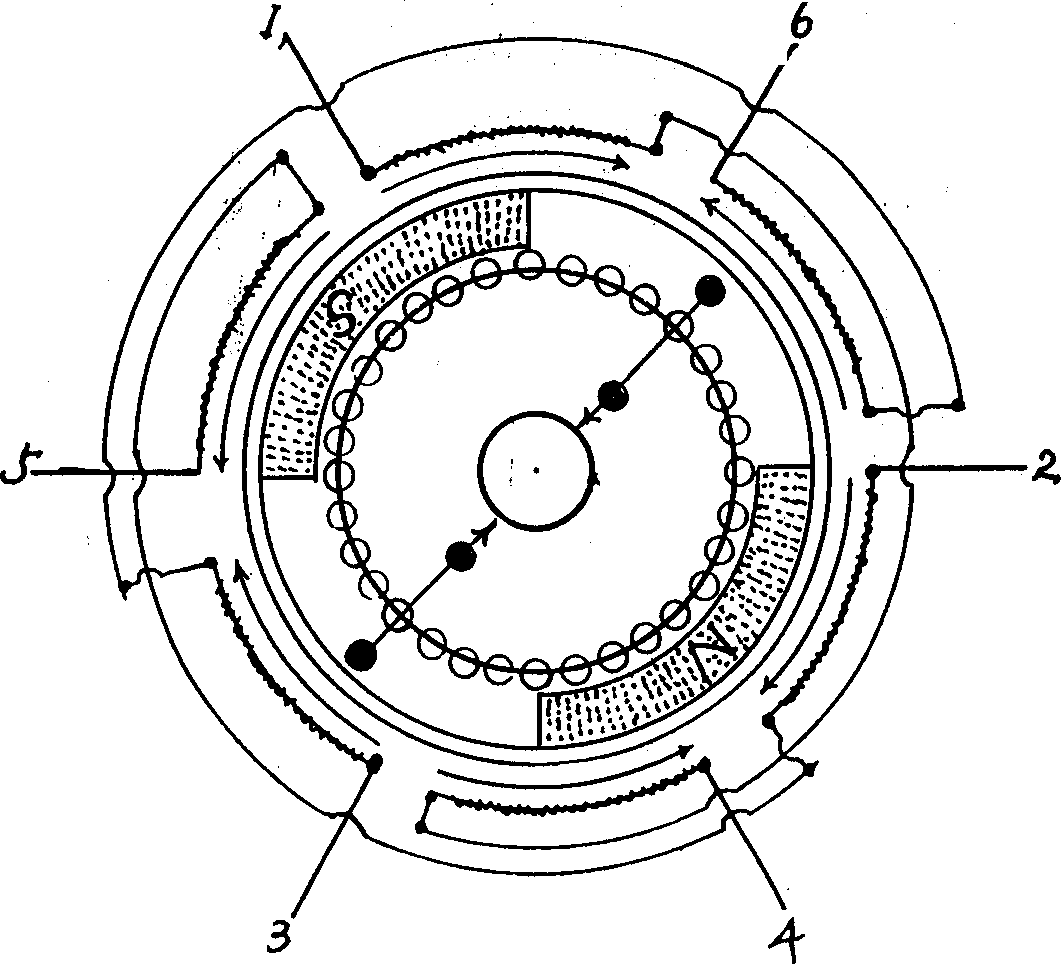

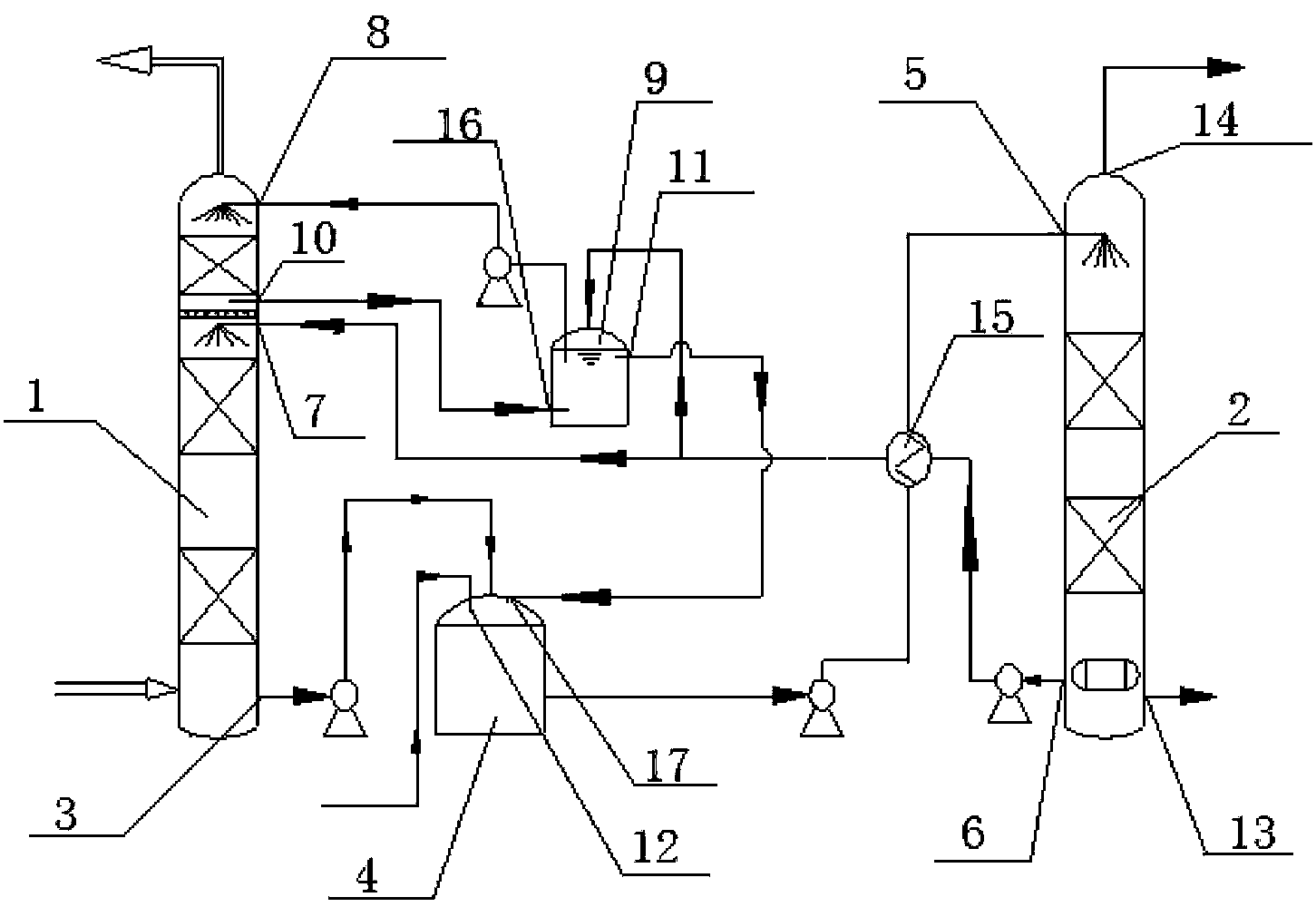

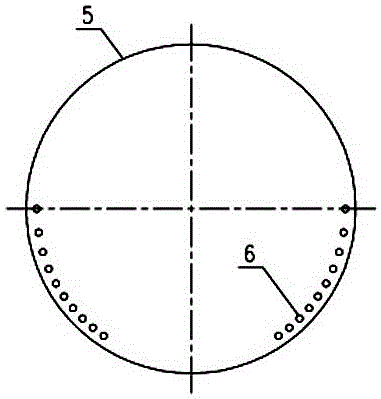

The invention provides a process technology for granulating blast-furnace slag and utilizing waste heat. The process technology is characterized by comprising the following steps of: performing primary cooling and triple granulation on high-temperature molten slag from a blast furnace in a slag primary cooling device to form fine granules with diameter of less than 3mm and temperature of about 800-1,000 DEG C; discharging the fine granules through a high-temperature slag discharge valve; entering a slag basket and conveying to the upper part of a slag secondary cooling device; falling to the lower part of the slag secondary cooling device along a plurality of layers of baffle heat exchange components which are arranged in the slag secondary cooling device; and cooling to about 200 DEG C and discharging through a low-temperature slag discharging valve, wherein waste heat of normal pressure steam of 200 DEG C can be recovered by the slag primary cooling device; and waste heat of hot circulating air of over 600 DEG C can be recovered by the slag secondary cooling device. The invention provides equipment for granulating blast-furnace slag and utilizing waste heat. The equipment mainlycomprises the slag primary cooling device, the slag secondary cooling device, a waste heat boiler and the like. The process technology and the equipment have the advantages of good granulation effectof the molten slag, small and uniform size of slag granules, almost zero new water consumption and low environmental pollution.

Owner:北京中冶设备研究设计总院有限公司

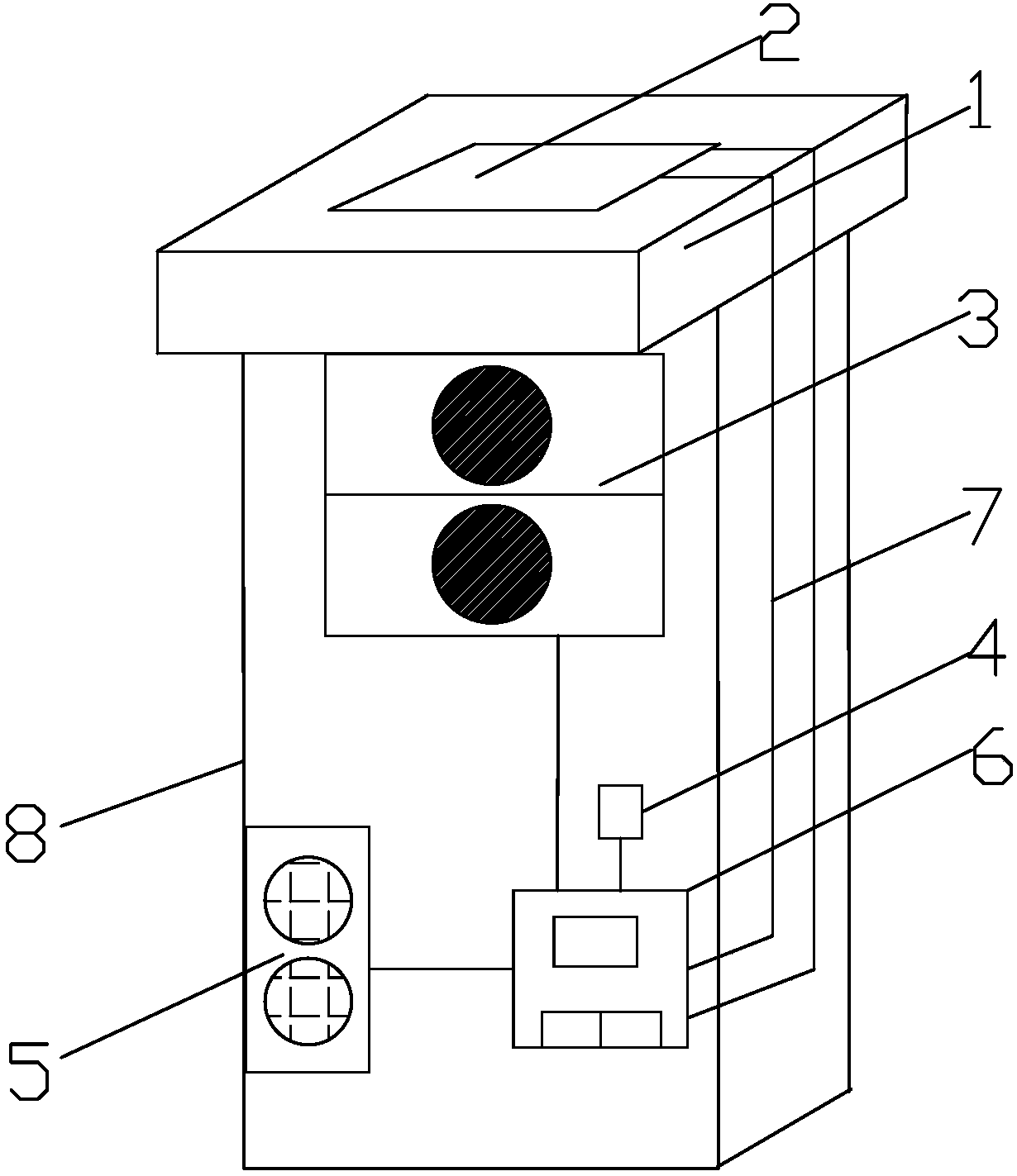

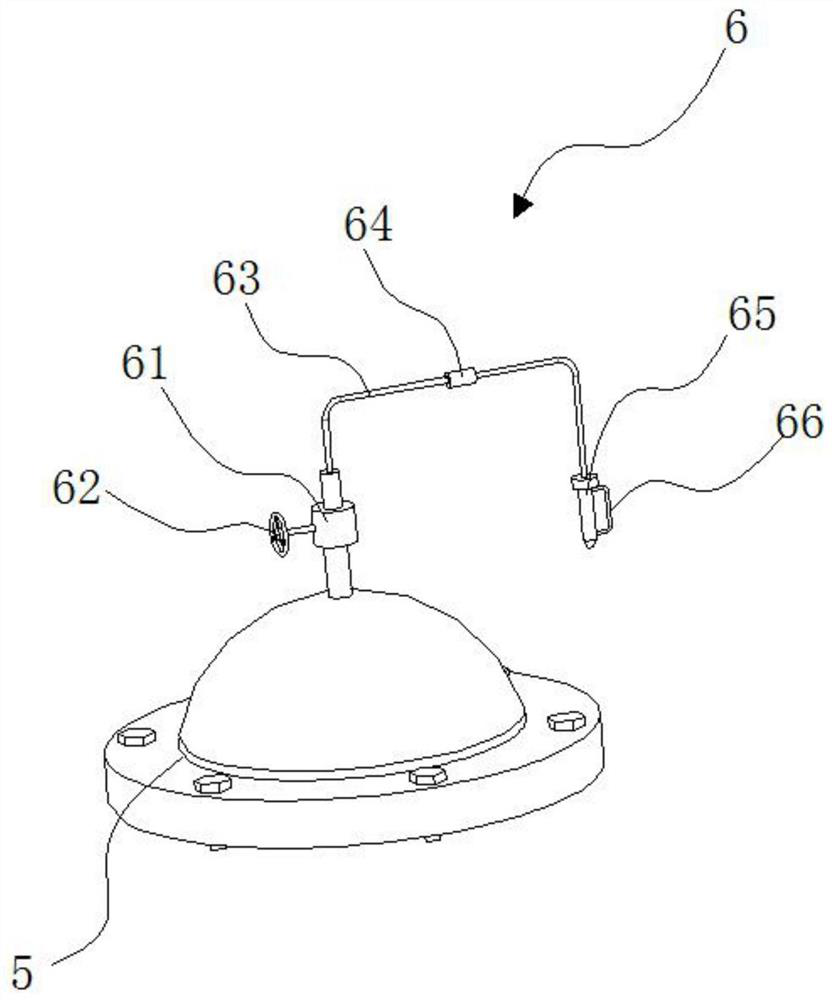

New Blast Furnace Gas Dispersion and Automatic Ignition System

ActiveCN102261664AZero consumptionBlast furnace detailsIncinerator apparatusCombustion systemEngineering

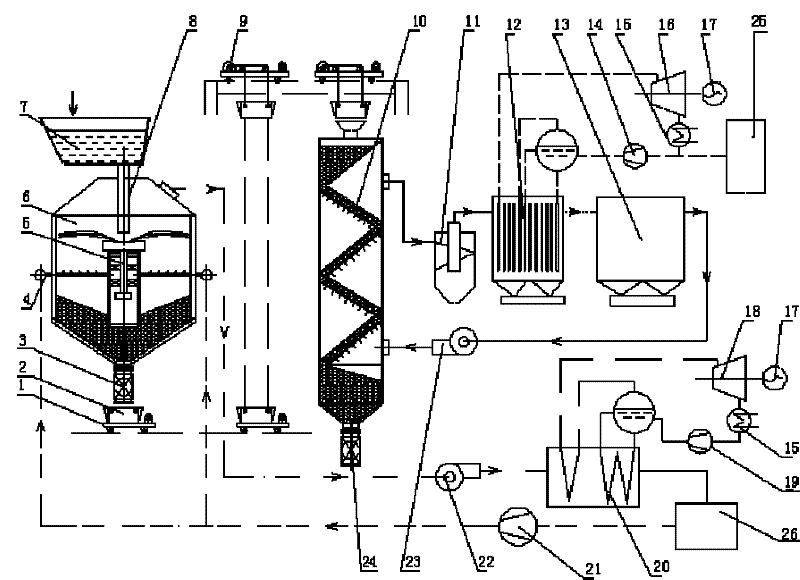

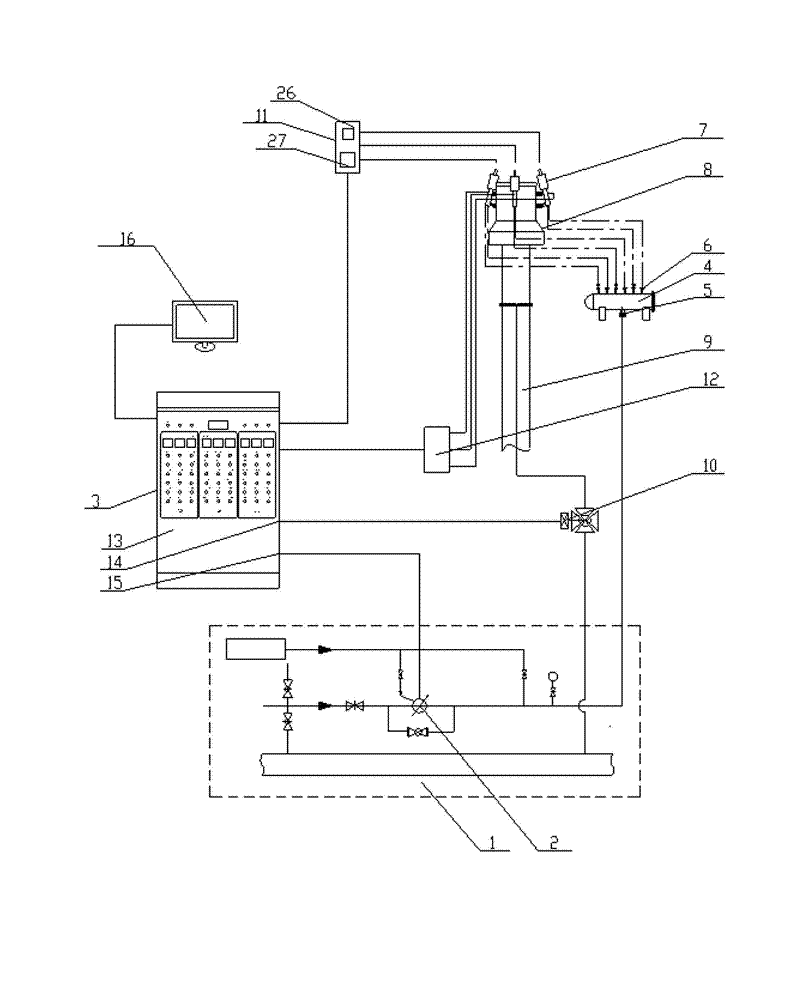

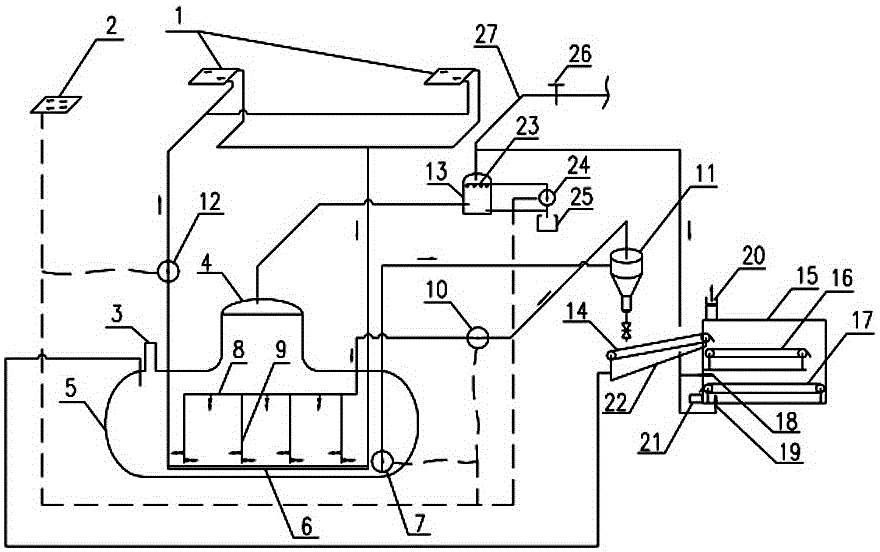

The invention relates to a novel blast furnace gas diffusion and automatic ignition system which comprises a blast furnace gas main pipe network, wherein the blast furnace gas main pipe network is communicated with a storage tank of a gas distributor, the gas distributor also comprises three groups of gas valves, the three groups of gas valves are respectively connected with three high-altitude auxiliary combustors, the high-altitude assisted combustors are fixed on the upper part of a main combustor through a fixed support, the top of the main combustor is connected with a fire detecting device, the fire detecting device is connected with a blast furnace gas diffusion management system, the bottom of the main combustor is connected with a diffusion pipe, the diffusion pipe is connected with the blast furnace gas main pipe network, the blast furnace gas main pipe network is provided with a pneumatic fast switch valve, the pneumatic fast switch valve is connected with the blast furnacegas diffusion management system, the diffusion pipe is also connected with an adjustment valve which is connected with the blast furnace gas diffusion management system, the high-altitude auxiliary combustors are connected with a lift arcing device, and the lift arcing device is connected with the blast furnace gas diffusion management system. The invention has the following advantages: in the working scheme of the full-automatic ignition auxiliary combustion system, the consumption of the system is approximately zero, thus the system is energy-saving and environmentally-friendly.

Owner:QIDONG HAIXIN MACHINERY

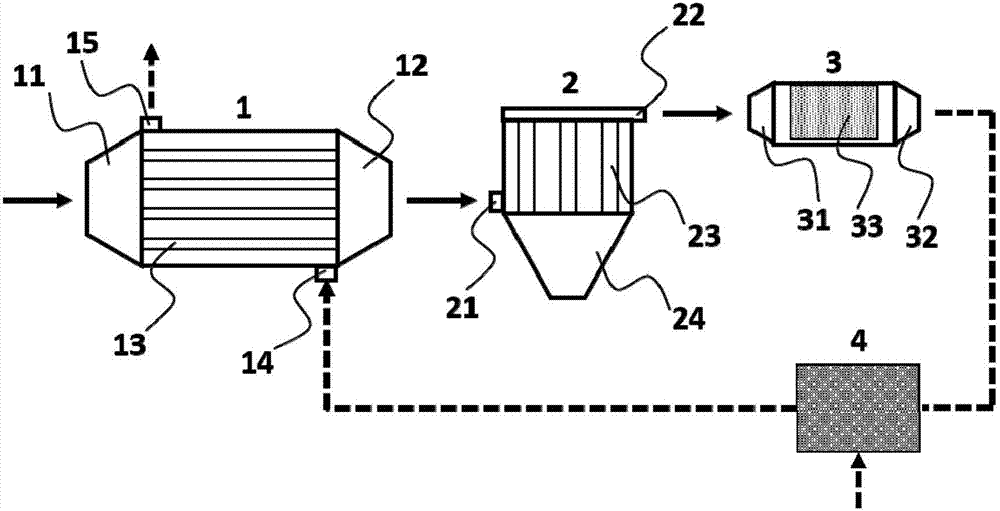

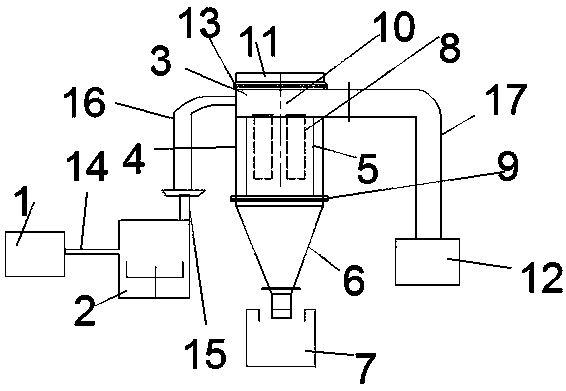

Method and system for drying and incinerating urban household garbage through dry-process rotary kiln

ActiveCN103951293AAddress the adverse effects of combustionConducive to production increaseSolid waste disposalCement productionSlagCement kiln

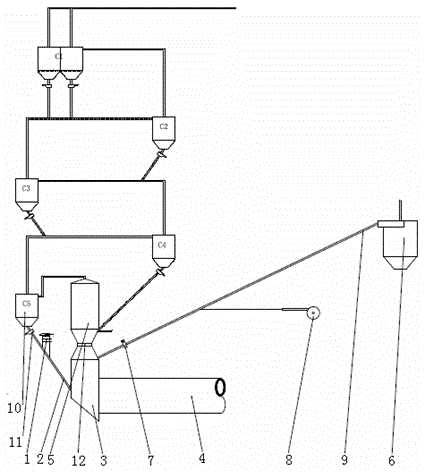

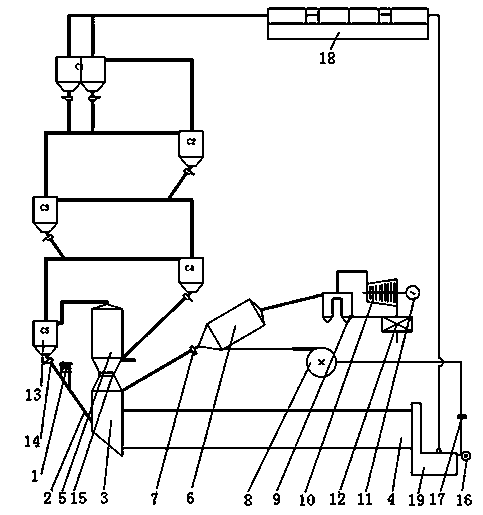

The invention provides a method and system for drying and incinerating urban household garbage through a dry-process rotary kiln. The method comprises the following steps: feeding wet garbage into a C5 blanking pipe, fast drying and alkalizing the garbage by utilizing high-temperature powder in the C5 blanking pipe, enabling the dry and easily-combustible garbage to enter in a kiln tail smoke chamber along with the powder, so as to be fast gasified and combusted, pumping high-temperature steam and combustion waste gas generated due to combustion through a bypass flue, mixing cold wind through a bypass fan so as to be mixed and regulate the temperature, and collecting dust through a dust collector, wherein the residual heat of dust-removed waste gas is used for power generation of a cement kiln waste heat power generation system, or productive drying, or can be discharged after dust is finely collected; calcining untimely burnout garbage and burnout slag into clinker in the rotary kiln along with raw materials; and enabling untimely burnout hydrocarbon compounds to ascend into a decomposing furnace for continuously burning. The invention further comprises the system for drying and incinerating urban household garbage through a dry-process rotary kiln. According to the method and system, the problems that the urban household garbage causes the influence on a kiln condition and the increase of coal consumption can be solved, and the sticking and plugging of a kiln system caused by the water in the garbage and chlor-alkali can be effectively eliminated.

Owner:长沙紫宸科技开发有限公司

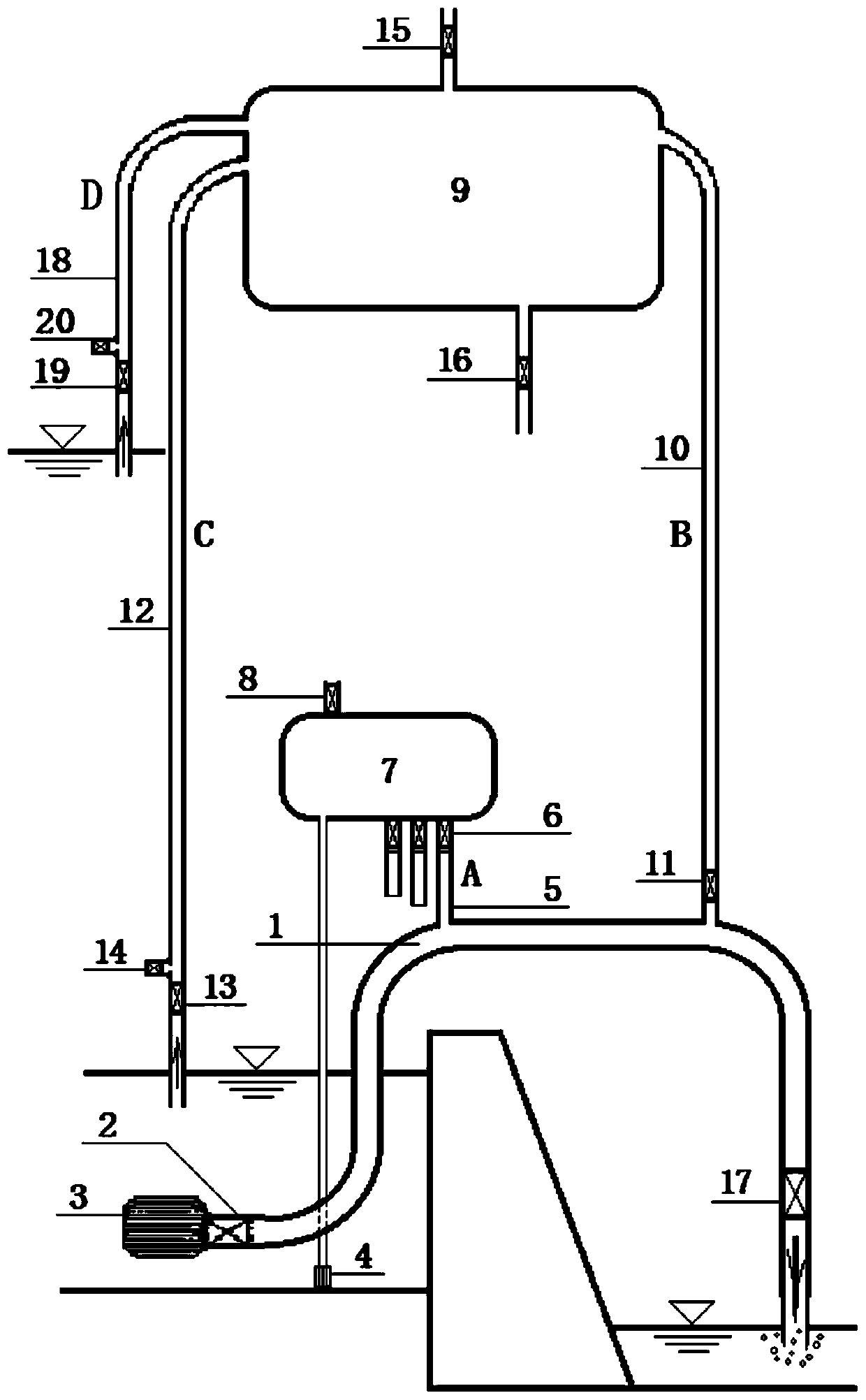

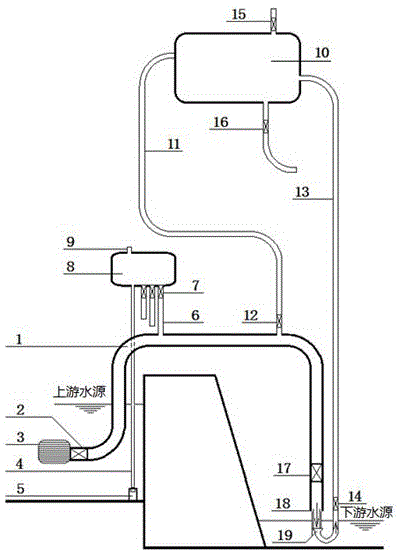

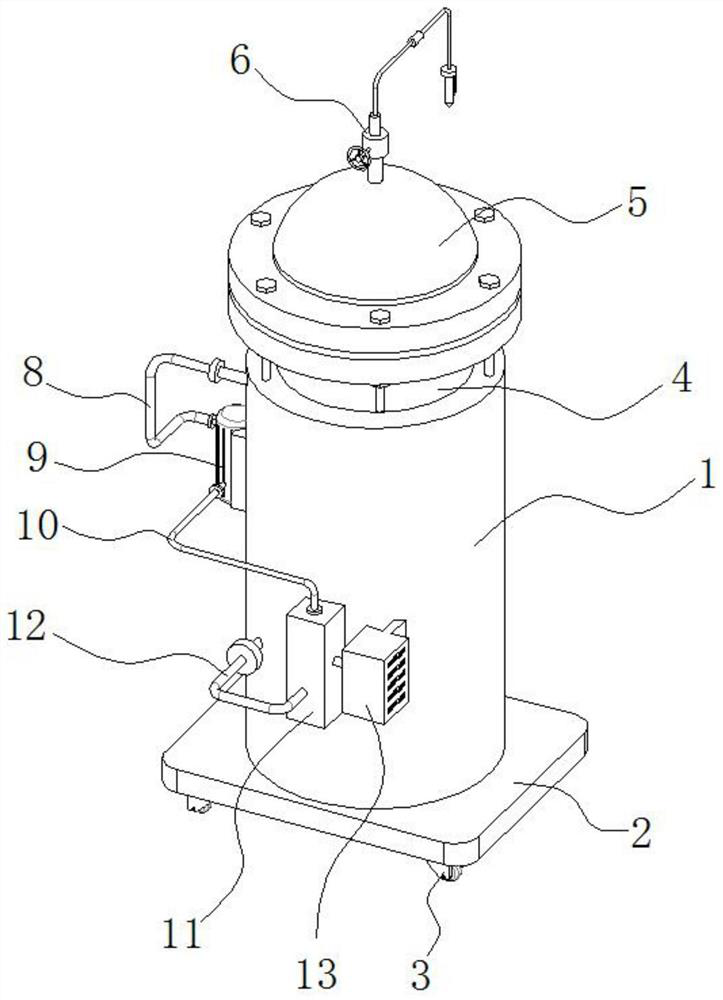

Water drawing device and water drawing method using water drawing device

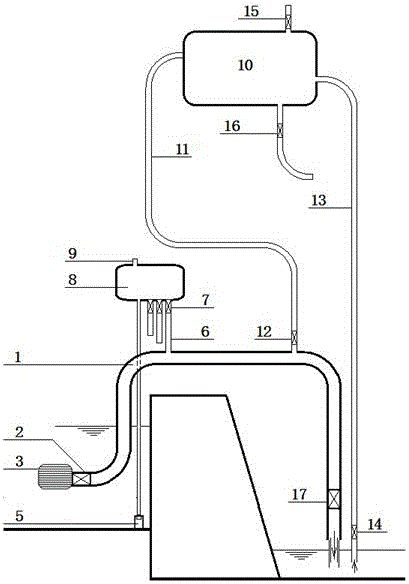

InactiveCN105134545AZero consumptionReduce expensesPositive displacement pump componentsConstructionsWater sourceEngineering

The invention provides a water drawing device and a water drawing method using the water drawing device. The water drawing device comprises a water delivery device, a water source tank and a water pump. The water delivery device comprises a water delivery pipe and a sealed water tank. When the water drawing device runs, multiple places can be irrigated at the same time or water can be drained through multiple pipes at the same time, time is saved, the irrigation efficiency and the water draining efficiency are improved, and then the losses caused when irrigation or water draining is not carried out in time are reduced; and energy consumption can tend to zero, unattended water drawing can be achieved, running can be safe, the related expense of pump station managing persons is greatly reduced, and unmanned management of pump stations is really achieved.

Owner:WUHAN UNIV

Bypass power generation process and system of dry-process rotary kiln cooperative processing of wet garbage

ActiveCN103939912AThe process is simple and reliableFlexible processDispersed particle separationIncinerator apparatusHydrocotyle bowlesioidesCo-processing

The invention discloses a bypass power generation process and system of dry-process rotary kiln cooperative processing of wet garbage. According to the process, the wet garbage is fed into a C5 discharge pipe, high-temperature alkali powder inside the C5 discharge pipe rapidly dries and alkalifies the garbage, the dry and combustible garbage enters a kiln tail smoke chamber along with the powder to be rapidly gasified and combust, high-temperature steam and combustion emissions generated by combustion are pumped into a bypass settlement flue, are processed by the bypass settlement flue and a bypass draught fan and are mixed into exhaust gas waste heat of a grate cooler head, then the blast capacity and the blast temperature are adjusted, then a steam boiler produces steam power for power generation, garbage not combusting out in time and ash combusting out enter a rotary kiln along with raw power materials to be combusted to be clinker, and hydrocarbon not combusting out in time ascends into a decomposing furnace to continue to combust out. The invention further discloses the bypass power generation system of the dry-process rotary kiln cooperative processing of the wet garbage. The method and system can solve the problems that urban life garbage affects the kiln condition and coal consumption is increased, and can effectively eliminate the problem that a kiln system is blocked by water and chlor-alkali in the garbage.

Owner:长沙紫宸科技开发有限公司

System based on cold-warm/dry-wet and purifying environment in ground temperature adjusting space

ActiveCN104165429ASave electricityImprove heating effectLighting and heating apparatusSpace heating and ventilation detailsGround temperatureEngineering

The invention discloses a system based on a cold-warm / dry-wet and purifying environment in a ground temperature adjusting space. According to the system, preliminary heat exchange is performed on inside storage water or air through a storage tank, the sufficient water or air is provided for an electric pump, electric energy is saved, most of heat is exchanged, dissipated or absorbed through M planar cool-heat exchangers, deep heat exchange is carried out through an M-type stereoscopic absorber, and an air-conditioning outdoor unit can be replaced, so that the temperature of the water or the air is kept to be equal to the temperature of a geothermal source, a cold-warm / dry-wet and purifying adjuster conveys absorbed geothermal energy to the space which needs refrigerating, heating or / and air dry-wet adjustment and purification, an air-conditioning indoor unit can be replaced, and the system saves energy and is environmentally friendly. Outside air or water is used for heat transfer, only geothermy is used instead of underground water, the system belongs to the advanced energy-saving technology without using underground water, and various zero-pollution, zero-discharge and zero-consumption geothermal systems are created, and benefits are brought to mankind.

Owner:李传友

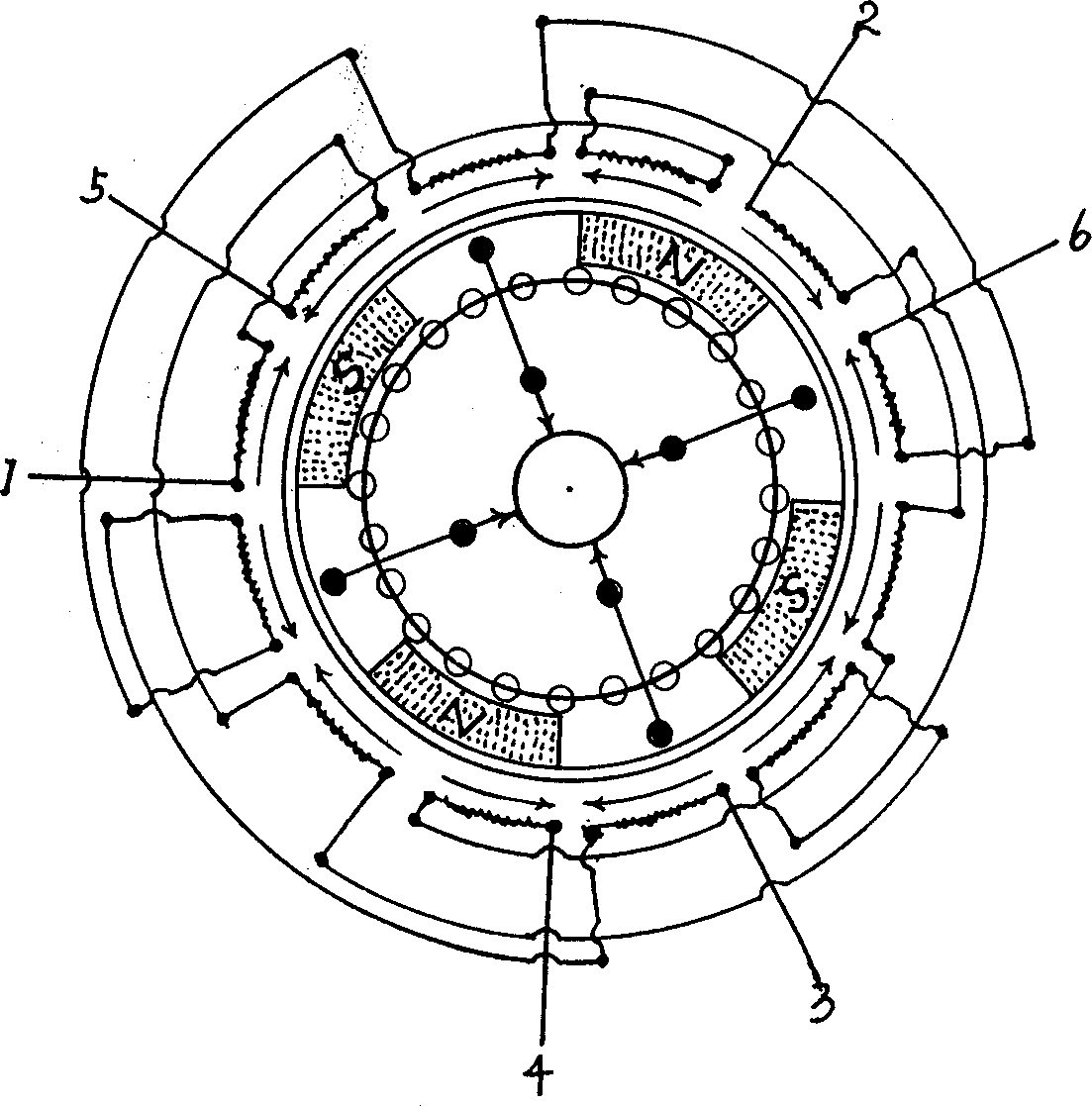

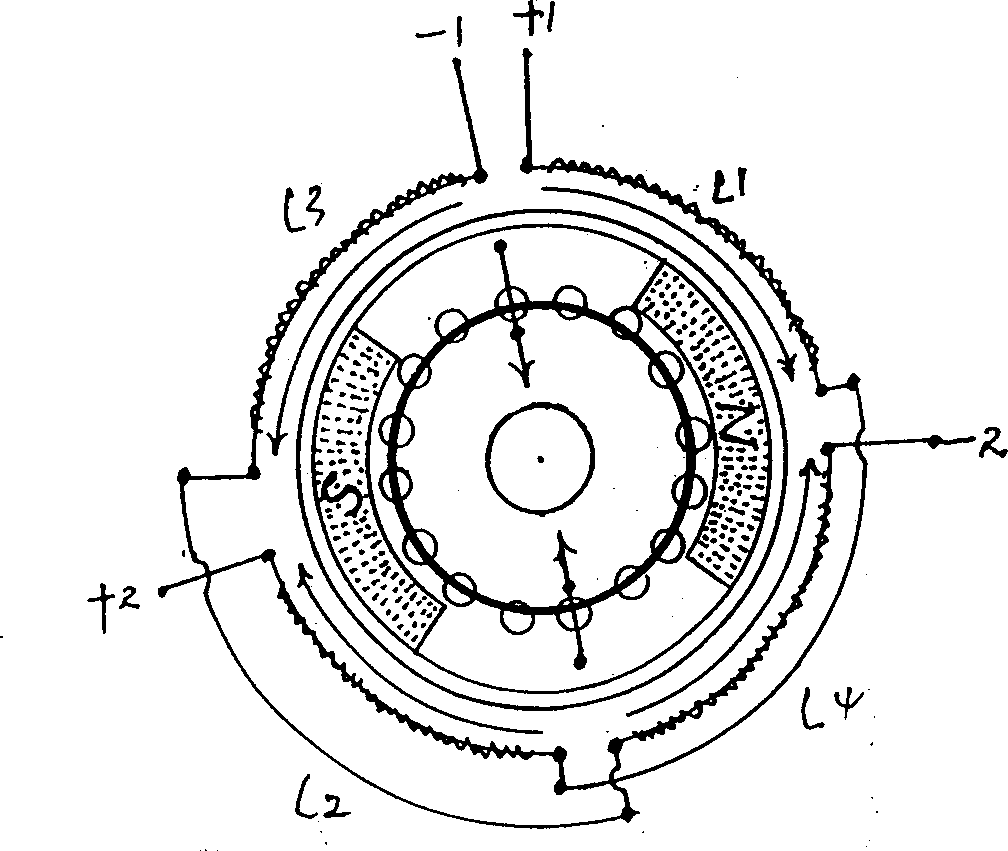

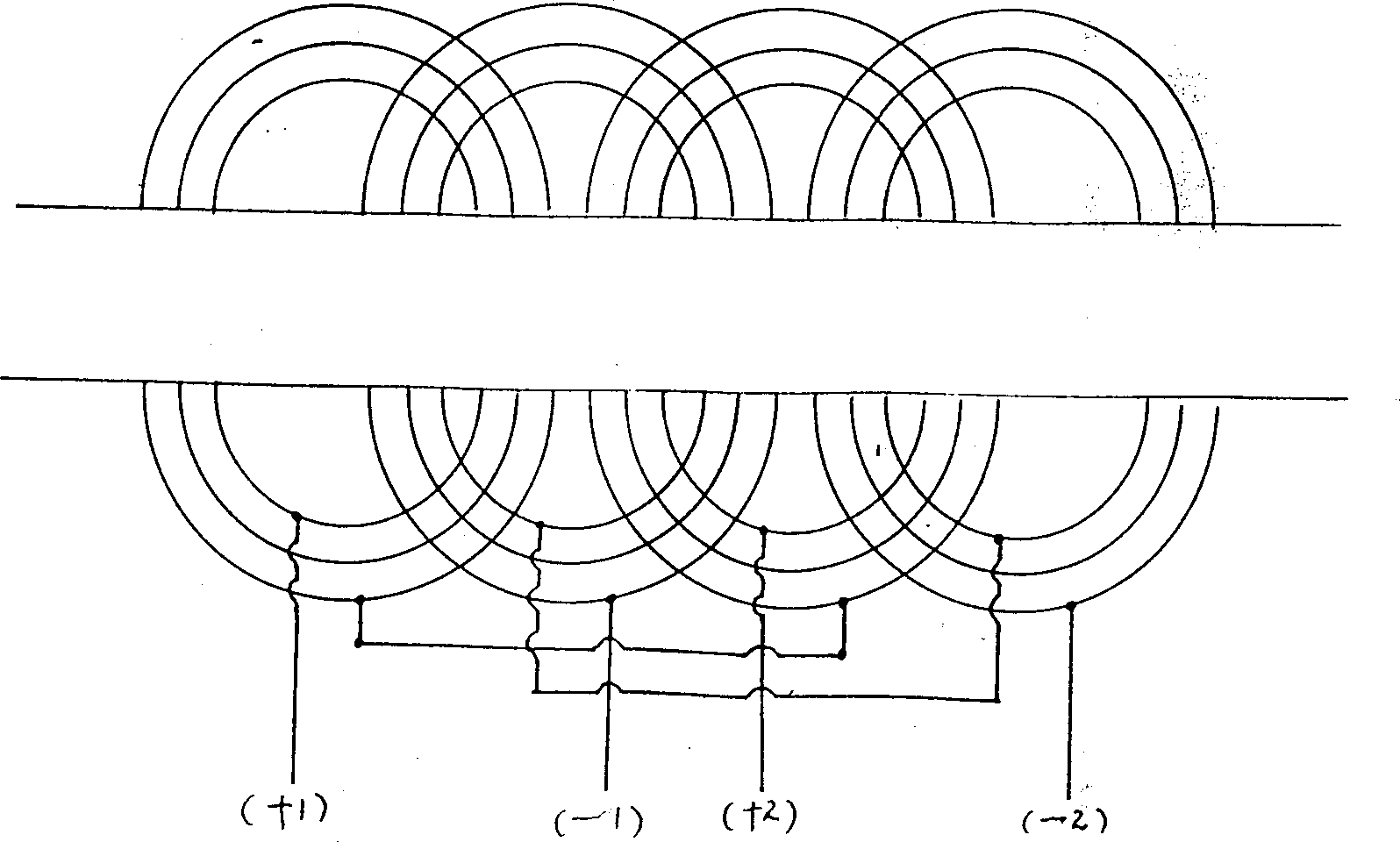

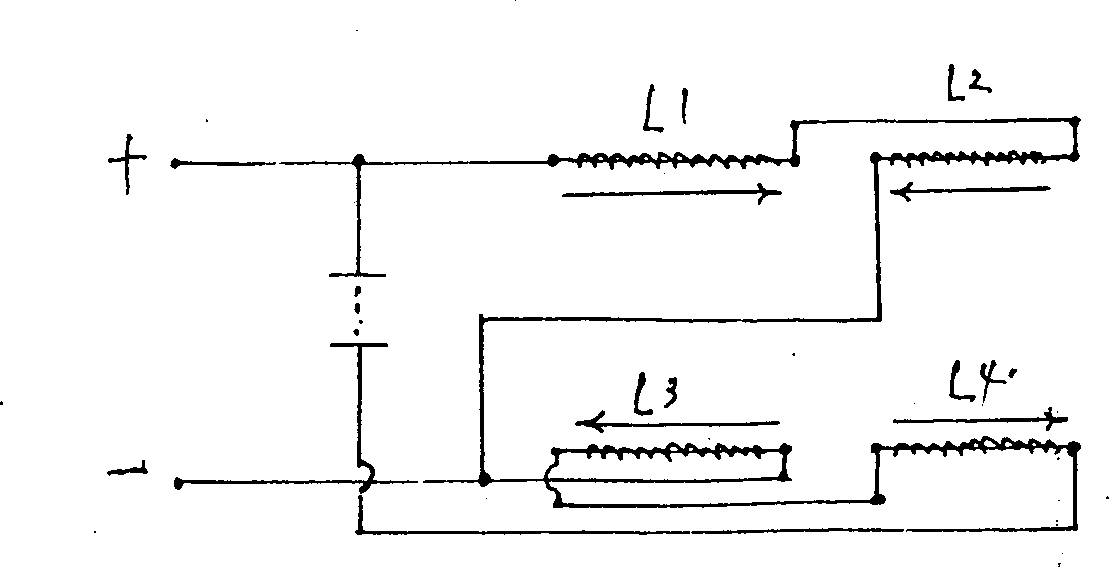

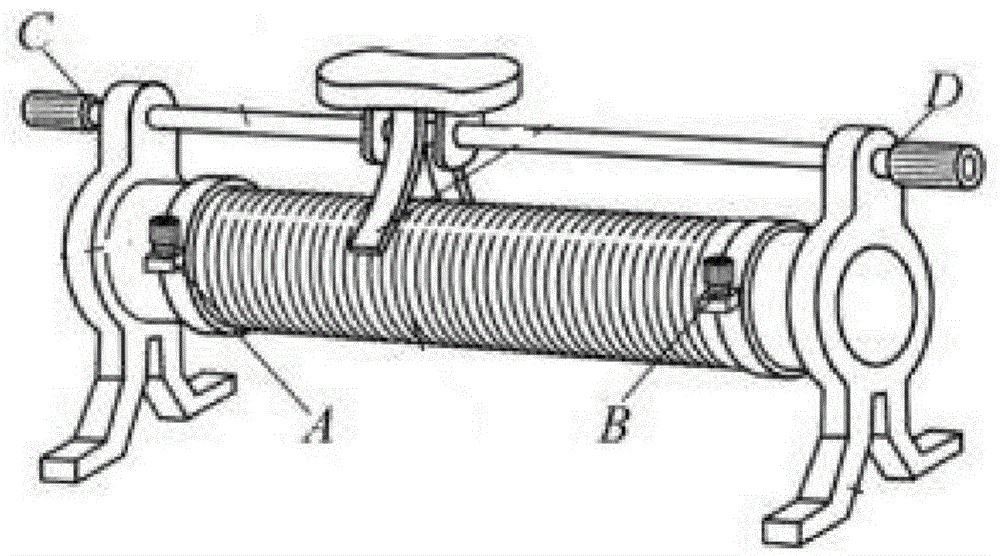

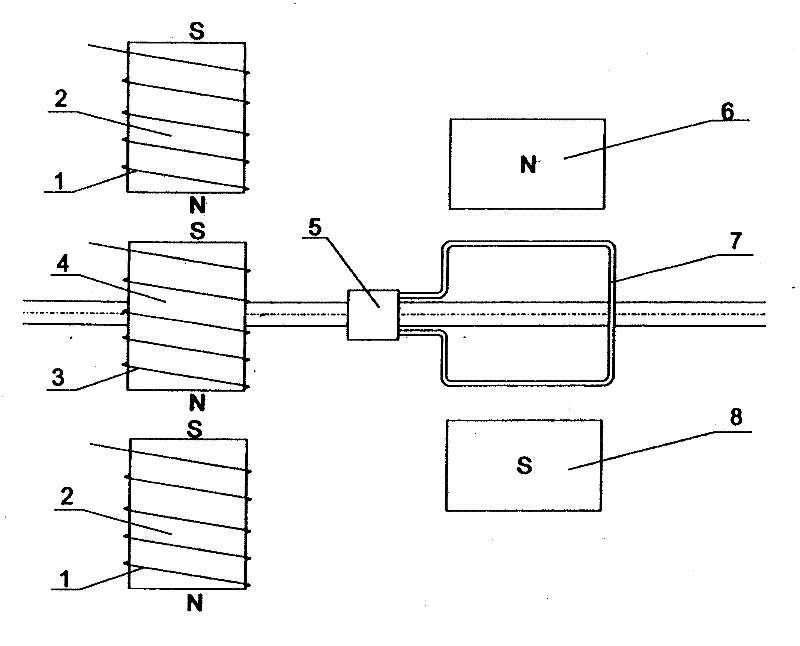

Variable-frequency speed-regualting triphase permanent-magnet synchronous motor

InactiveCN1375912AReduce internal loss problemsZero slipMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorSynchronous motor

This invention relates to a kind of three-phase AC permanent magnetic synchronous electric motor of variable-frequency timing containing a stator winding and a permanent magnet rotor etc. with the characteristics of adopting star-shaped connections by the stator winding, when designed basic frequency is 50Hz, 100Hz, 150Hz and 250Hz, and with reference of 50Hz the numbers of conductors of each phase winding of the motor stator should be 0.7, 0.58, 0.5 and 0.45 times of 50Hz, and the cross section areas of the conductors should be 1.414, 1.73, 2, and 2.24 times of 50Hz, the said rotor permanentmagnet and the magnet-conductive metal core share the perimeter of the rotor and the magnetic density generated by the permanent magnet should be one third of the density of the stator electric magnet. The numbers of the electric conductive

Owner:刘硕成 +1

Mine water waste heat extraction and utilization system

PendingCN109855221AEnergy storage for summer heatingRealize the purpose of releasing heat and energy in winterHeat pumpsHeat recovery systemsWater source heat pumpSocial benefits

The utility model relates to a mine water waste heat extraction and utilization system, and belongs to the technical field of mine waste heat utilization. The mine water waste heat extraction and utilization system is characterized in that a heat pump water source unit (2) is included, the heat pump water source unit (2) is provided with a mine circulating water feeding pipe (3) and a water returnpipe (4), the heat pump water source unit (2) is connected with a mine water lifting device through he mine circulating water feeding pipe (3), the heat pump water source unit (2) is connected with awater return pool (5) through the water return pipe (4), and the mine water lifting device communicates with a downhole roadway (9). The mine water waste heat extraction and utilization system fullyutilizes the storage function of the abandoned roadway, realizes the purposes of temperature rise for energy storage in summer and heat release for energy release in winter of a roadway water body, reasonably stores, transfers and extracts energy, can maintain the operation of the water source heat pump unit, can realize zero discharge of external circulating water and is considerable in economicand social benefit.

Owner:山东许厂煤矿有限公司

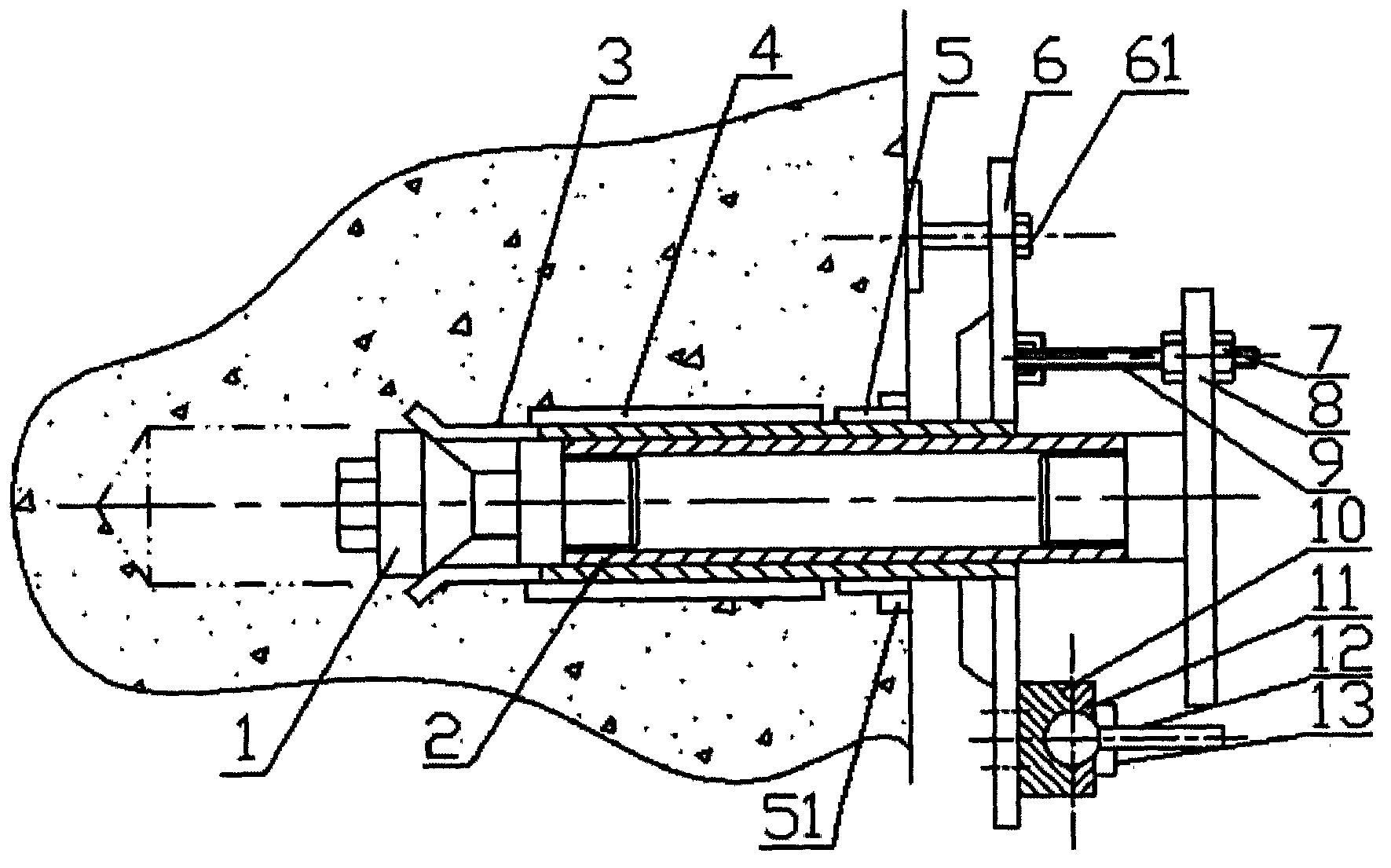

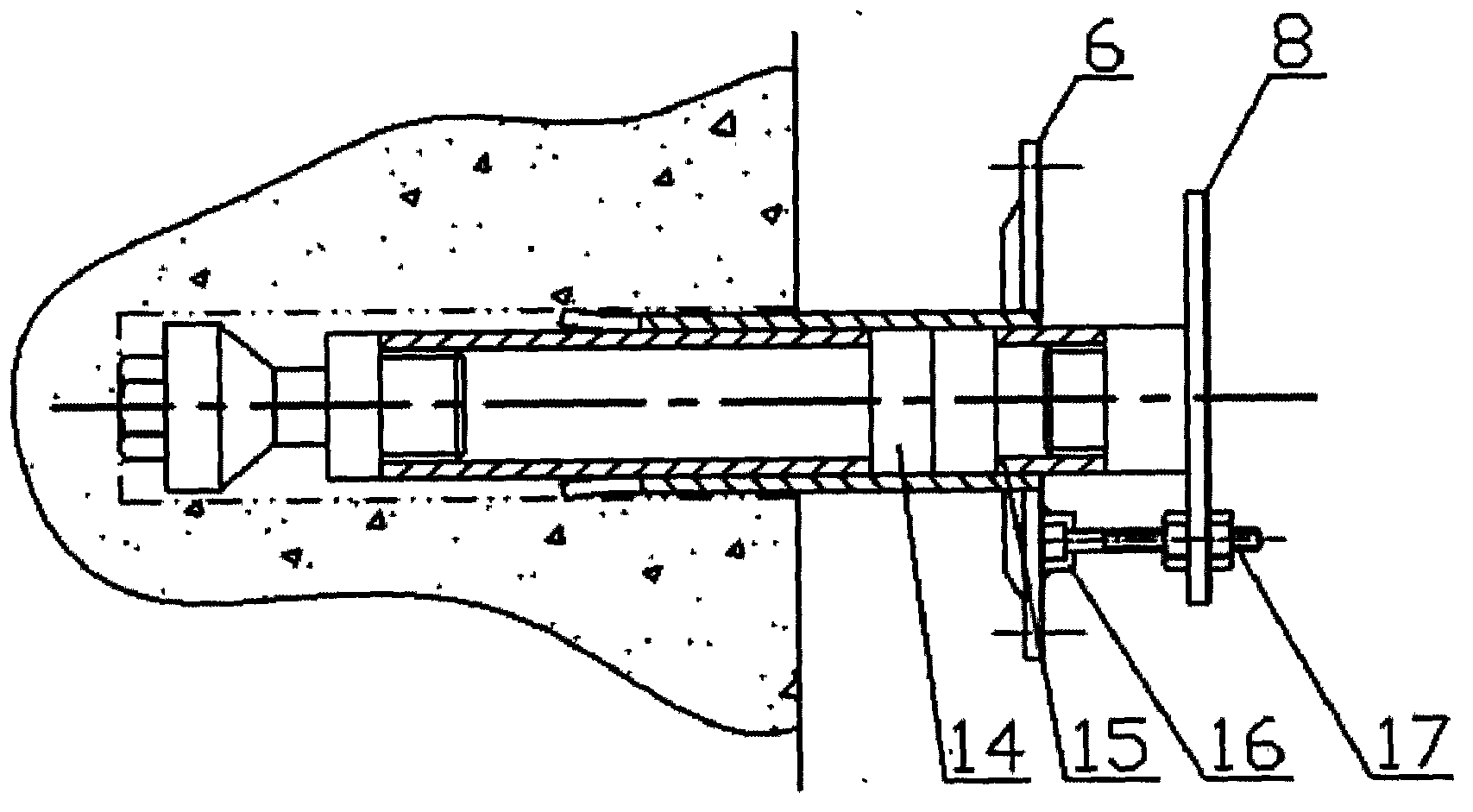

Detachable universal composite anchor rod of high-altitude road along cliff

The invention belongs to the technical field of construction of roads along a cliff, and particularly relates to a detachable universal composite anchor rod of a high-altitude road along a cliff. The anchor rod comprises an inner tube and an outer sleeve arranged outside the inner tube in a sleeving mode, wherein an expansion tip is connected to the head portion of the inner tube, an inner tube end plate is connected to the tail portion of the inner tube, multiple grooves are formed in the head portion of the outer sleeve, an outer sleeve end plate is connected to the tail portion of the outer sleeve, and a damping tube is arranged outside the outer sleeve in a sleeving mode. The anchor rod is detachable, reusable and high in bearing capacity. An anchor rod rotary table shaft which has a direction adjusting function and is used for installation of a frame bar component is arranged on the end face of the anchor rod. The anchor rod and a submerged hole are fixed together through mechanical force, encapsulation solidification or curing is not needed, subsequent construction can be conducted instantly, the anchor rod can be detached for repeated use, consumption of anchoring materials is approximately zero, and the cost of a heavy-load anchor point is reduced by 70% averagely. The anchor rod fundamentally solves a lot of problems existing during construction of the high-altitude roads along a cliff, has revolutionary significance, and has broad application prospects in the technical field of construction of the high-altitude roads along a cliff.

Owner:福建华航建设集团有限公司

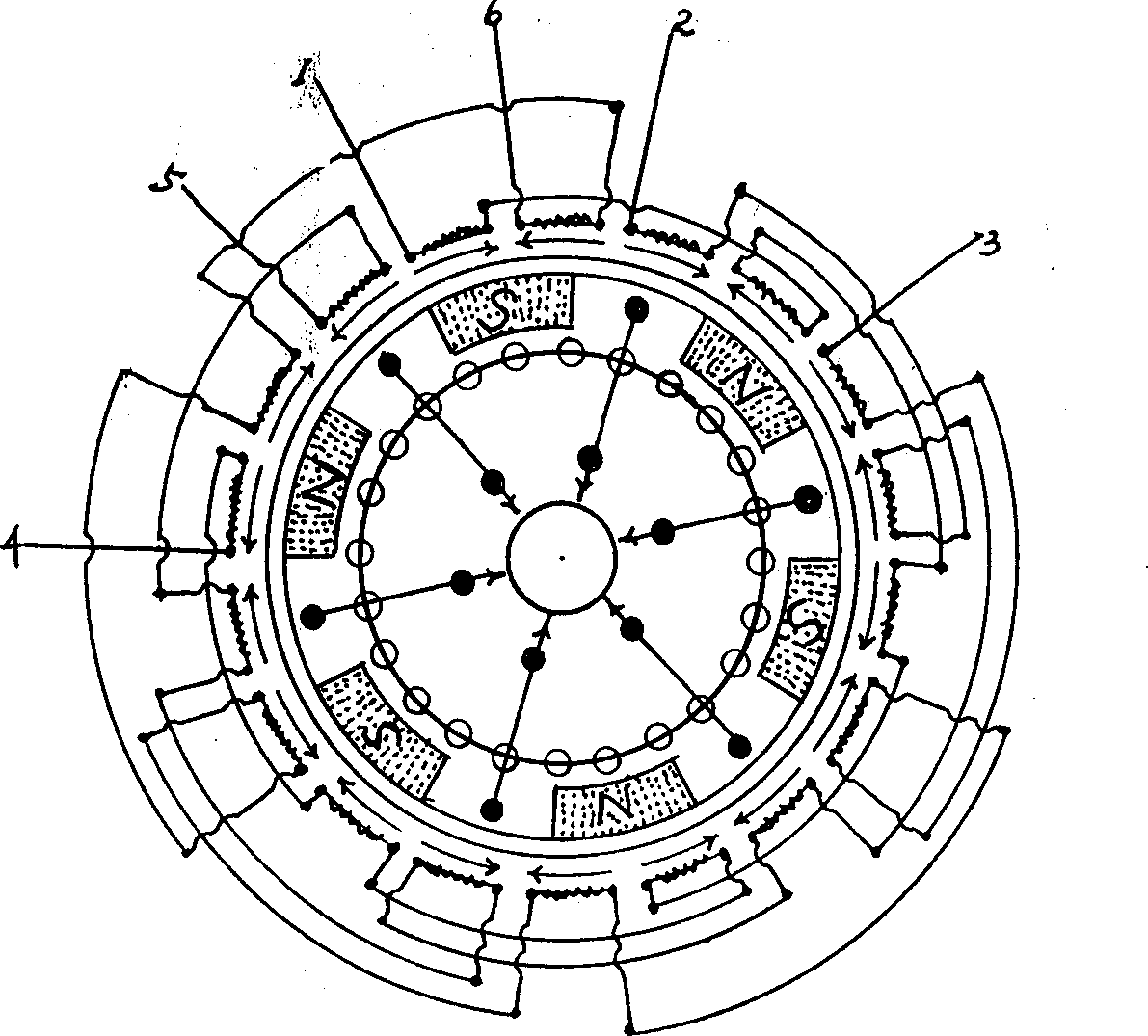

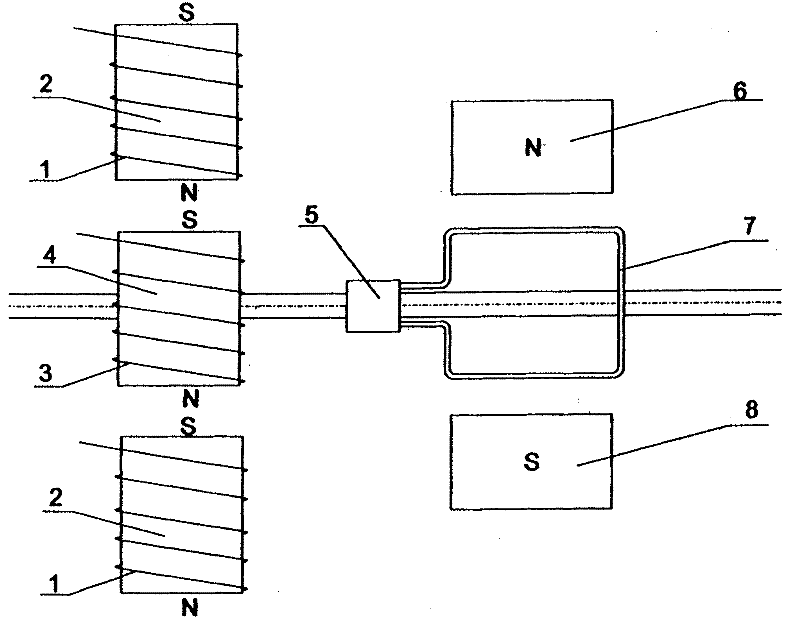

Single-phase AC permanent-magnet synchronous motor

InactiveCN1375911AImprove efficiency and power factorReduce the induction currentMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPhysicsSynchronous motor

This invention relates to a single phase AC permanent synchronous electric motor composed of a stator winding and a permanent magnet rotor in which the stator winding contains a main winding and a sub winding the same wire gauge and conductor coil numbers composed of single-layer single lap or single-layer cross winding. The permanent magnet of the rotor and the magnet conductive core share the perimeter of the rotor and the magnetic density generated by the permanent magnet should be one third of that of the stator electric magnet and the electric-conduction metal bar numbers of the rotor squirrel-cage are determined by 0.81-0.92 times of those of the stator core slots. The invention ensures the efficiency power and torque outupt with high efficiency and electricity energy saving.

Owner:刘硕成 +1

Siphon water drawing pipeline set and water drawing method through same

PendingCN110424497AIncrease heightZero consumptionMachines/enginesDrinking water installationSiphonWater discharge

The invention provides a siphon water drawing pipeline set and a water drawing method through the same. The siphon water drawing pipeline set comprises a plurality of water drawing units composed of siphon pipelines, water source bins, water pumps and sealed water boxes. The siphon water drawing pipeline set is characterized in that each siphon pipeline is an n-shaped pipeline, the two ends of thesiphon pipeline are arranged on the upstream portion and the downstream portion of the riverbed dam section correspondingly, the siphon pipeline tail end located on the upstream portion of the riverbed is provided with a water feeding control valve, the siphon pipeline tail end located on the downstream portion of the riverbed is provided with a water discharging control valve, and the middle section of the siphon pipeline is connected with the corresponding water source bin and the sealed water box in sequence. The siphon pipeline water drawing energy-consumption-free technique is adopted, the effect that siphon energy consumption is close to zero is realized, unmanned water drawing is achieved, operation is safe, in addition, the operation expense of a siphon pipeline pump station is substantially decreased, and an unattended pump station is really achieved.

Owner:WUHAN UNIV

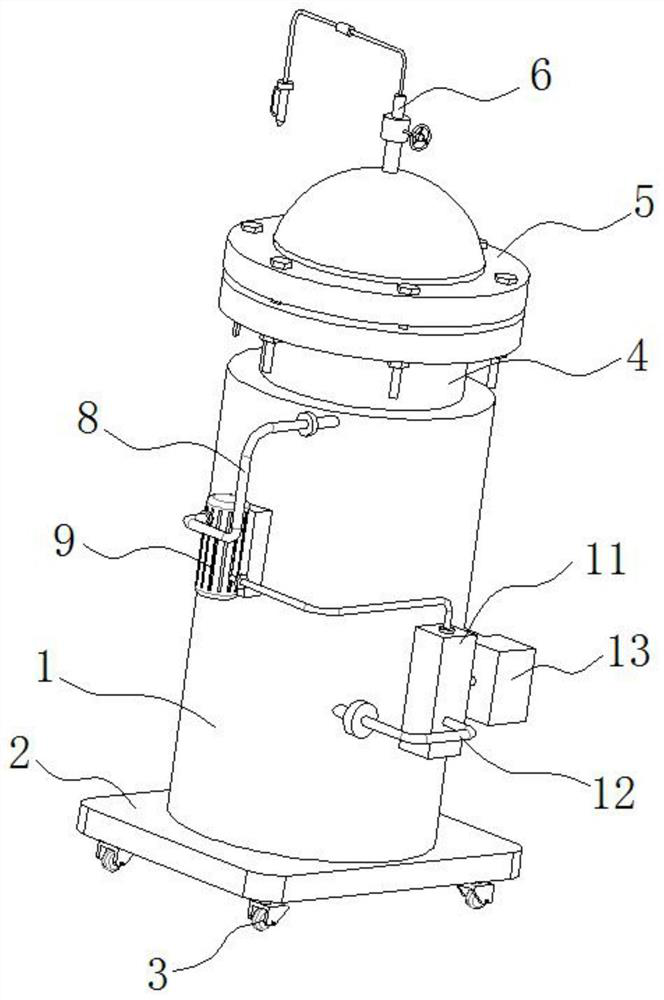

Spraying waste gas purification method and device

InactiveCN107120666ASolution to short lifeImprove performanceIncinerator apparatusPurification methodsFiltration

A spraying waste gas purification method and device, the method includes the following steps: passing the spraying waste gas into a preheater for heating, drying the paint mist particles in the spraying waste to form paint mist powder; passing the spraying waste gas carrying the paint mist powder into the The dust collector is filtered, and the filtered spraying exhaust gas is passed into the catalytic burner. The above-mentioned device includes a preheater, a dust collector and a catalytic burner. A preheating chamber is arranged in the preheater, and there are many A preheating pipe, one end of the preheating pipe communicates with the inlet of the preheater, the other end communicates with the outlet of the preheater, the outlet of the preheater communicates with the inlet of the precipitator, and the outlet of the preheater communicates with the inlet of the catalytic burner The outlet of the catalytic burner is communicated with the inlet of the preheating chamber through the thermostat. This method skillfully heats the spraying exhaust gas through the preheater, thereby drying the paint mist particles in the spraying exhaust gas, and then filtering the paint mist through the dust collector. Powder, to achieve the filtration of paint mist particles in the spraying exhaust gas, so that the paint mist can be effectively treated, and the filtration is convenient, the filtration effect is stable, and the filtration cost is low.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

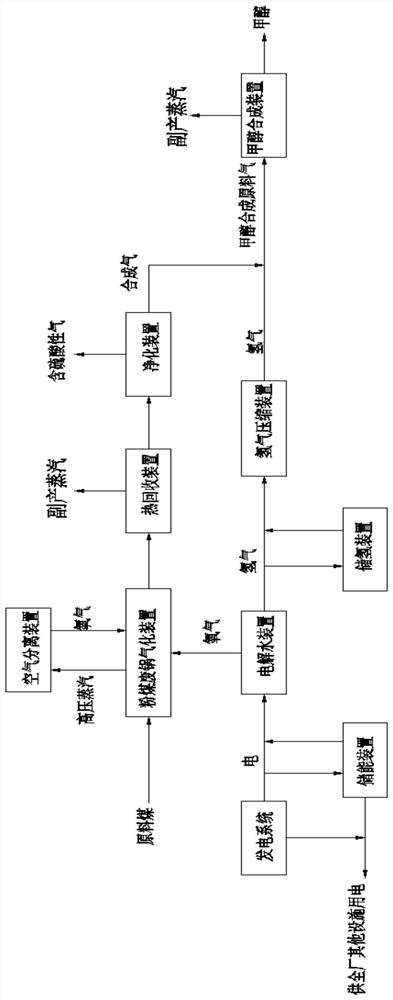

Method for preparing methanol by coupling gasification of pulverized coal waste boiler with green electricity and green hydrogen to realize near-zero carbon emission

PendingCN114394883AAchieving near-zero carbon productionEmission reductionOrganic compound preparationChemical industryNew energySuperheater

The invention relates to the field of methanol preparation with zero carbon emission, and particularly discloses a method for preparing methanol with near zero carbon emission by coupling gasification of a pulverized coal waste boiler with green electricity and green hydrogen, which comprises the following steps: oxygen generated by an air separation device and oxygen by-produced by a water electrolysis device react with coal in a gasification device of the pulverized coal waste boiler to obtain synthesis gas; the pulverized coal waste boiler gasification device recovers heat of high-temperature synthesis gas through a waste heat boiler and a steam superheater to produce high-pressure superheated steam, and the high-pressure superheated steam is sent to an air separation device to drive an air compressor turbine; the synthesis gas is conveyed to a heat recovery device for further heat recovery; the synthesis gas discharged from the heat recovery device is sent to a purification device, only sulfur-containing acid gas is removed, decarburization is not needed, and purified gas containing carbon monoxide, hydrogen and carbon dioxide is obtained; one part of electric energy generated by the new energy power generation system is transmitted to the water electrolysis hydrogen production device, one part is used by other electric facilities of the whole plant, and the rest part is transmitted to the energy storage device to be stored.

Owner:HUALU ENG & TECH

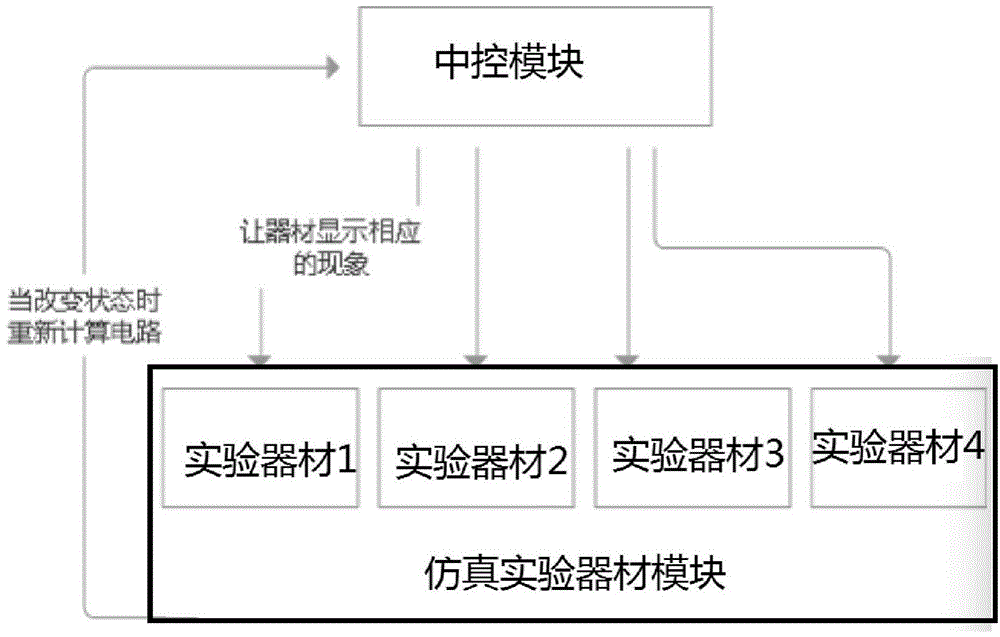

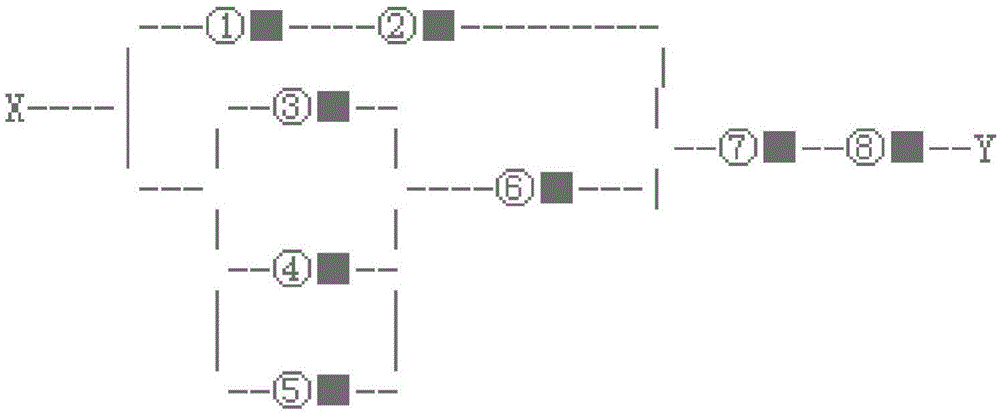

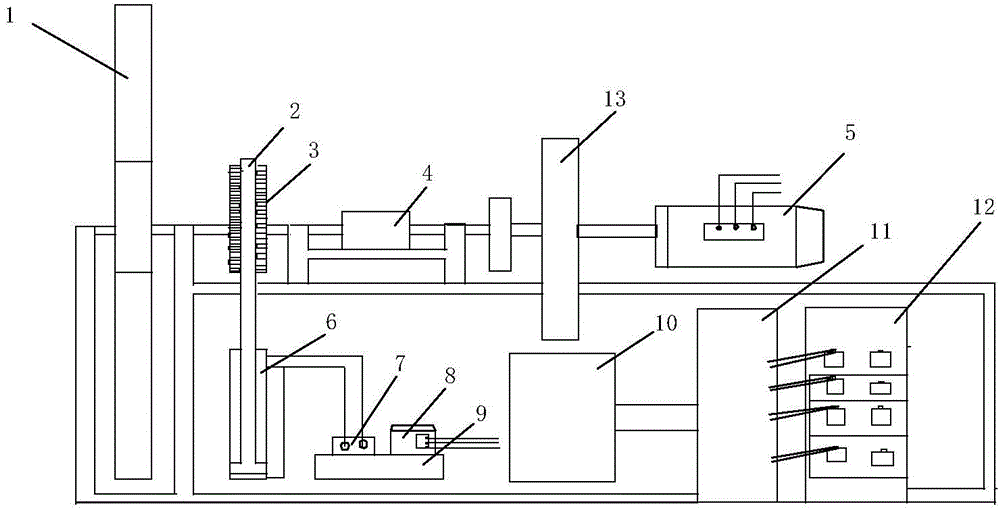

Simulation experiment system having dynamic response

InactiveCN104064088AAvoid missingWith follow-up maintenanceEducational modelsSimulationPhysical change

The invention discloses a simulation experiment system having a dynamic response. The simulation experiment system comprises a center control module and a simulation experiment equipment module which are in communication connection, wherein the center control module is used for detecting the connection state of the simulation experiment equipment module in real time, and providing physical parameter values and physical state for the simulation experiment equipment module according to the connection state of the simulation experiment equipment module; and the simulation experiment equipment module is used for displaying physical phenomenon and responding to the operation of users. The simulation experiment system in the invention can generate corresponding physical phenomenon and physical parameter attributes in real time when the user operates simulation experiment equipment in a simulation experiment, thereby enabling the experimenter to carry out the physical experiment in a low-cost and zero-consumption manner and to know the corresponding physical changes generated in the experiment.

Owner:YATAISHENGSHI TECH DEV CO LTD

Energy gathering pumping device and pumping method thereof

InactiveCN105133698AZero consumptionReduce expensesService pipe systemsWater mainsWater sourceEngineering

The invention provides an energy gathering pumping device which comprises multiple groups of n-shaped pipelines, a water injection cabin, a water injection pipeline, a negative pressure pipeline, a pumping pipeline and a sealing water tank, wherein the water injection cabin is communicated with a water injection pump in an upstream water source by a water pump pipeline; the tops of the multiple groups of n-shaped pipelines are respectively communicated with a water source cabin by the water injection pipeline provided with a water injection pipeline valve; the tops of the multiple groups of n-shaped pipelines are communicated with the sealing water tank by the negative pressure pipeline provided with a negative pressure pipeline valve; the side part of the sealing water tank is communicated with a downstream water source by the pumping pipeline provided with a pumping pipeline valve; a ventilating valve is arranged at the upper part of the sealing water tank, and a water discharge pipeline provided with a water discharge valve is arranged at the lower part of the sealing water tank. The device has the advantages of achieving the effect that energy consumption approaches to zero, realizing unattended operation in pumping, being safe in operation, greatly reducing relative charge against revenue for pump station managers, and truly achieving unattended management for the pump station.

Owner:WUHAN UNIV

Process technology and equipment for granulating blast-furnace slag and utilizing waste heat

ActiveCN102268495BSmall and uniformSmall sizeProcess efficiency improvementSteam generation using hot heat carriersMolten slagBlast furnace

The invention provides a process technology for granulating blast-furnace slag and utilizing waste heat. The process technology is characterized by comprising the following steps of: performing primary cooling and triple granulation on high-temperature molten slag from a blast furnace in a slag primary cooling device to form fine granules with diameter of less than 3mm and temperature of about 800-1,000 DEG C; discharging the fine granules through a high-temperature slag discharge valve; entering a slag basket and conveying to the upper part of a slag secondary cooling device; falling to the lower part of the slag secondary cooling device along a plurality of layers of baffle heat exchange components which are arranged in the slag secondary cooling device; and cooling to about 200 DEG C and discharging through a low-temperature slag discharging valve, wherein waste heat of normal pressure steam of 200 DEG C can be recovered by the slag primary cooling device; and waste heat of hot circulating air of over 600 DEG C can be recovered by the slag secondary cooling device. The invention provides equipment for granulating blast-furnace slag and utilizing waste heat. The equipment mainlycomprises the slag primary cooling device, the slag secondary cooling device, a waste heat boiler and the like. The process technology and the equipment have the advantages of good granulation effectof the molten slag, small and uniform size of slag granules, almost zero new water consumption and low environmental pollution.

Owner:北京中冶设备研究设计总院有限公司

Cyclic utilization method of ammonia gas in production process of ammonium paratungstate

InactiveCN107089685AEasy to handleGuaranteed recyclingTungsten compounds preparationProcess efficiency improvementAmmonium paratungstateDesorption

The invention discloses a cyclic utilization method of ammonia gas in a production process of ammonium paratungstate. The method comprises the specific steps: firstly, connecting a crystallization boiler in the production process of the ammonium paratungstate with a discharging hole of a rotary furnace in a yellow and blue tungsten manufacturing process in parallel; conveying the ammonia gas generated in two devices into a rectifying tower and a condensation system by utilizing an induced draught fan and carrying out gas-liquid separation to obtain the ammonia gas; spraying and adsorbing most of the ammonia gas with hydrochloric acid, so as to obtain an ammonium chloride solution; pumping the ammonium chloride solution into a venturi device; meanwhile, transmitting the residual ammonia gas into the venturi device to obtain a mixed solution of ammonia water and ammonium chloride; cooling the mixed solution and preparing according to desorption agent concentration requirements needed by ion exchange, so as to realize the cyclic utilization of the ammonia gas in the production process of the ammonium paratungstate. The method disclosed by the invention is safe and environmentally friendly and has less investment and rapid effect; the ammonia gas discharged in the production process of the ammonium paratungstate can be completely recycled, so that zero storage and zero consumption of liquid nitrogen are realized.

Owner:江西省修水赣北钨业有限公司

Hydraulic inertia driving generator

InactiveCN105763023AReduce maintenance and repair costsSmall footprintDynamo-electric machinesFlywheelDynamo

The present invention discloses a hydraulic inertia driving generator which comprises a power supply component and a hydraulic system. The hydraulic system comprises a hydraulic motor, a hydraulic cylinder, an oil pump and a hydraulic rod. The hydraulic motor is connected with the power supply component which is a storage battery component which is divided into two groups to supply power to the hydraulic system. The power supply component is connected to the hydraulic motor through an inverter. The hydraulic motor is connected to the oil pump. The hydraulic cylinder is connected to the hydraulic rod. A transmission shaft is arranged above the hydraulic rod. The parallel teeth in the hydraulic rod is engaged with a reverse gear arranged on the transmission shaft. Two sides of the reverse gear in the transmission shaft are provided with two inertia flywheels. The transmission shaft is connected to an AC generator through a speed increaser. According to the embodiment of the invention, the switch is automatically switched through control, storage batteries are alternatively switched to supply power to an AC motor, e potential energy is converted into kinetic energy and then is converted into alternating current, the hydraulic inertia driving generator has the functions of self power generation and self charging, the energy consumption and maintenance cost are reduced at the same time, and the hydraulic inertia driving generator is a low-carbon, energy-saving, environmental-friendly power generation device.

Owner:韦福华

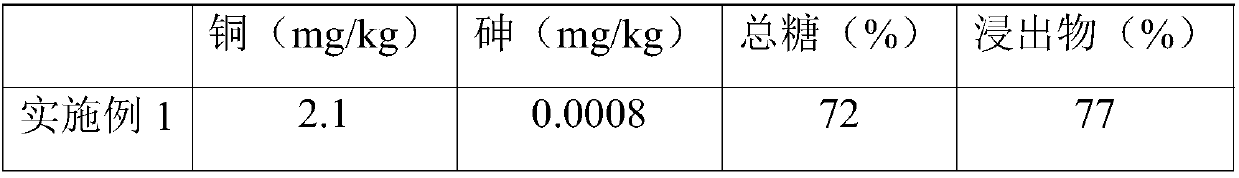

Ophiopogon japonicas drying method

InactiveCN109620910AImprove elutriation efficiencyReduce labor intensityDrying gas arrangementsHeating arrangementNutrientOphiopogon

The invention discloses an ophiopogon japonicas drying method which comprises the following steps: (1) washing ophiopogon japonicas; (2) pre-drying; (3) drying and rooting; (4) repeating the step (3)for 4 times, then utilizing a graded sieve to filter the ophiopogon japonicas, and separately collecting the filtered ophiopogon japonicas and the unfiltered ophiopogon japonicas; (5) conducting the drying and rooting operation in the step (3) on the unfiltered ophiopogon japonicas continuously, then mixing with the filtered ophiopogon japonicas in the step (4), cooling to the room temperature, and spreading the mixture indoors at the thickness of 8-12 cm for 3-5 hours. According to the method, not only the ophiopogon japonicas drying efficiency is improved, but also the loss of nutrients is reduced.

Owner:SICHUAN DAIDAIWEIBEN AGRI TECH

Novel bidirectional liquid pipe drying and filtering device for heat pump and manufacturing method of novel bidirectional liquid pipe drying and filtering device

ActiveCN106288551AImprove stabilityControl flow directionRefrigeration componentsFilter effectMechanical engineering

The invention discloses a novel bidirectional liquid pipe drying and filtering device for a heat pump and a manufacturing method of the novel bidirectional liquid pipe drying and filtering device. The liquid pipe drying and filtering device comprises a copper pipe and end covers; a rotary filter element body comprising a drying cylinder and locating plates is arranged in the copper pipe; the locating plates are located at two sides of the drying cylinder; a drying pipe is arranged inside the drying cylinder; negative-pressure plates are uniformly arranged at the outer side of the drying pipe; two ends of the rotary filter element body are connected with limited posts through sealing covers; and the limited posts are fixedly connected with the copper pipe through cross beams. The manufacturing method comprises the steps of 1) manufacturing the copper pipe and the end covers; 2) manufacturing and assembling the rotary filter element body; 3) assembling the rotary filter element body and the copper pipe; 4) sealing the end covers; and 5) testing the liquid pipe drying and filtering device. The manufacturing method disclosed by the invention is simple in step and convenient to mount and dismount; and not only are the sealing, drying and filtering effects of the drying and filtering device improved, but also the working stability of the whole drying and filtering device is improved, and the manufacturing process is shortened.

Owner:新昌县行峰制冷配件厂

PV-LED solar photovoltaic cell road warning indicator

InactiveCN107761591AAvoid short circuitAvoid enteringTraffic signalsRoad signsEngineeringMicrocomputer

A kind of PV-LED solar photovoltaic cell road warning device of the present invention, it comprises PV-LED solar photovoltaic cell assembly, LED display screen, indicator light, siren, frame body and microcomputer controller, it combines advanced solar photovoltaic cell assembly and The warning device is concentrated in a frame, and a transparent protective cover is installed on the solar photovoltaic cell module Shanghai. Low-voltage direct current can avoid the danger of electric shock; this invention fully demonstrates its high safety, strong energy saving and zero consumption characteristics.

Owner:南通市金马包装材料有限公司

Powder coating equipment

PendingCN108084765ANo pollutionComply with environmental standardsCombination devicesChemical industryEngineeringWind power

The invention relates to the technical field of powder coating, in particular to powder coating equipment. The powder coating equipment comprises a sorting machine and equipment integrating wind powersuction, cyclone separation and dust removing. The sorting machine is fixedly connected with a feeding pipe, the end, away from the sorting machine, of the feeding pipe is fixedly connected with a grinding head, a pipeline connector is fixedly arranged on the base surface of the grinding head, and the end, away from the grinding head, of the pipeline connector is connected with a pipeline in a sleeved mode. A port at the top of the equipment integrating wind power suction, cyclone separation and dust removing is fixedly connected with an upper end cover plate, the end, away from the equipmentintegrating wind power suction, cyclone separation and dust removing, of the upper end cover plate is fixedly connected with an impulse air pocket, a pipeline is fixedly connected with the equipmentintegrating wind power suction, cyclone separation and dust removing, and the end, away from the equipment integrating wind power suction, cyclone separation and dust removing, of the pipeline is fixedly connected with an induced draft fan. A flange cover is arranged between the cyclone separation and dust removing integrated equipment and a tapered collection barrel, the flange cover is detachable, and thus the space in the barrel can be cleaned conveniently.

Owner:谢小祥

Method and equipment for recycling ammonia gas in production of ammonium paratungstate

InactiveCN111672152AEasy to handleFully recoveredDispersed particle separationVapor condensationTungstic acidAmmonium chloride mixture

The invention relates to the technical field of tungsten smelting processing, in particular to a method for recycling ammonia gas in production of ammonium paratungstate. Ammonia gas is completely separated out mainly through two times of gas-liquid separation of different degrees, pure ammonia gas is obtained, and therefore follow-up ammonia gas treatment is simpler and more convenient, and recovery is more complete. Most of ammonia gas is conveyed into a spray adsorption tower, ammonia gas is sprayed and adsorbed through hydrochloric acid to obtain an ammonium chloride solution, the ammoniumchloride solution is collected in a container, then the ammonium chloride solution is used for dissolving the remaining ammonia gas through a Venturi device with a certain height, the remaining ammonia gas is also collected in the container, and therefore cyclic and continuous absorption of the ammonia gas is achieved, and it is guaranteed that the ammonia gas is completely absorbed.

Owner:江西智府科技有限公司

Lossless power machine

The invention discloses a lossless power machine, comprising a shell, wherein the shell is internally provided with a commutator, a generator and a super-energy electric motor; the commutator, the generator and the super-energy electric motor are arranged in the same spindle; two ends of the spindle are arranged on the shell; energy output by the super-energy electric motor is more than input energy; and the generator is a special generator which is matched with the technical requirements of the super-energy electric motor. When the lossless power machine starts to operate, the generator outputs electric energy; at the same time, the super-energy electric motor can acquire energy to generate power to drive the generator to generate electricity and outputs certain rest energy. Compared with the prior art, the lossless power machine has the advantages of zero consumption, zero emission and considerable practical value and can exert powerful driving forces and supereminent advantages.

Owner:赵进杰

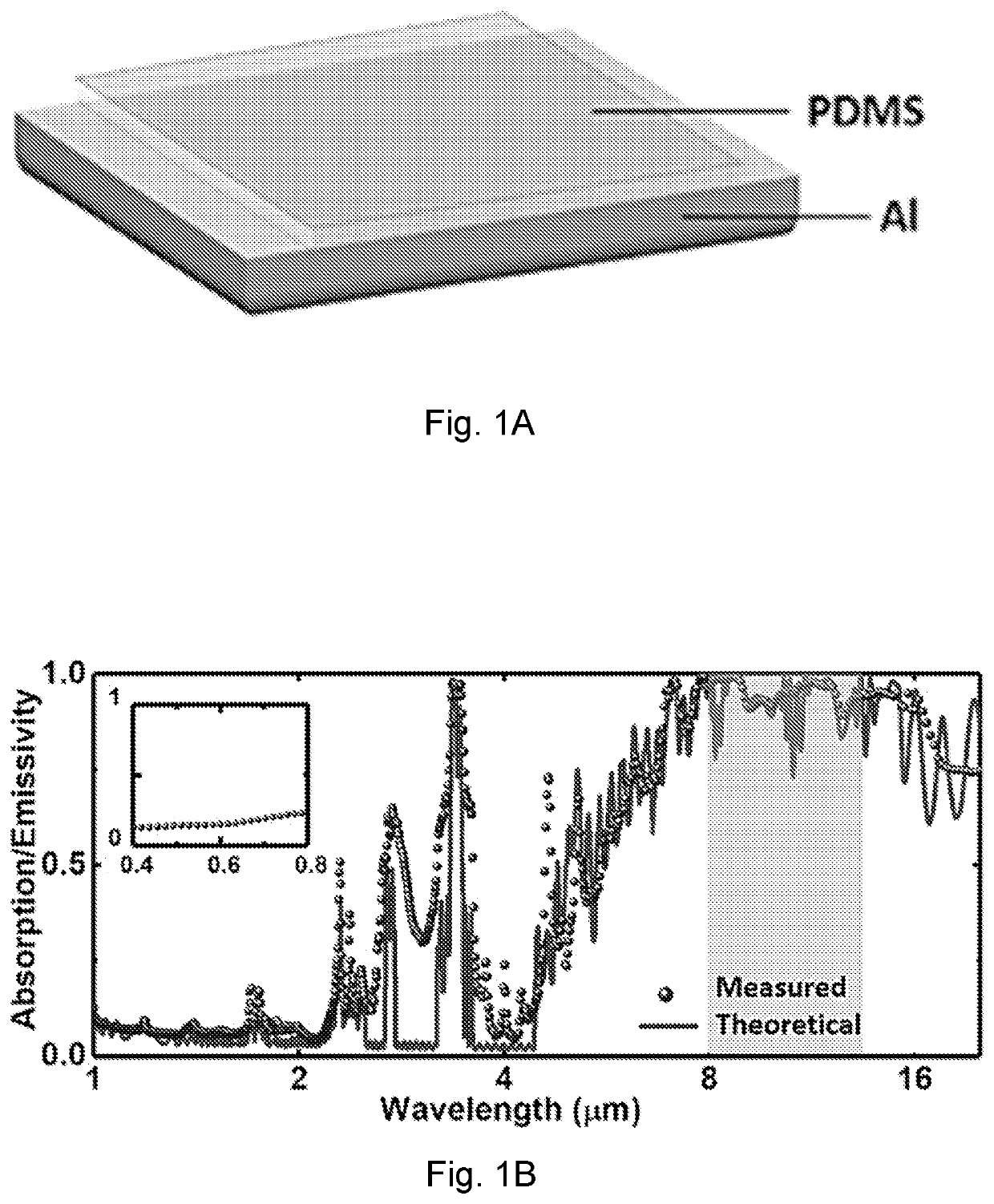

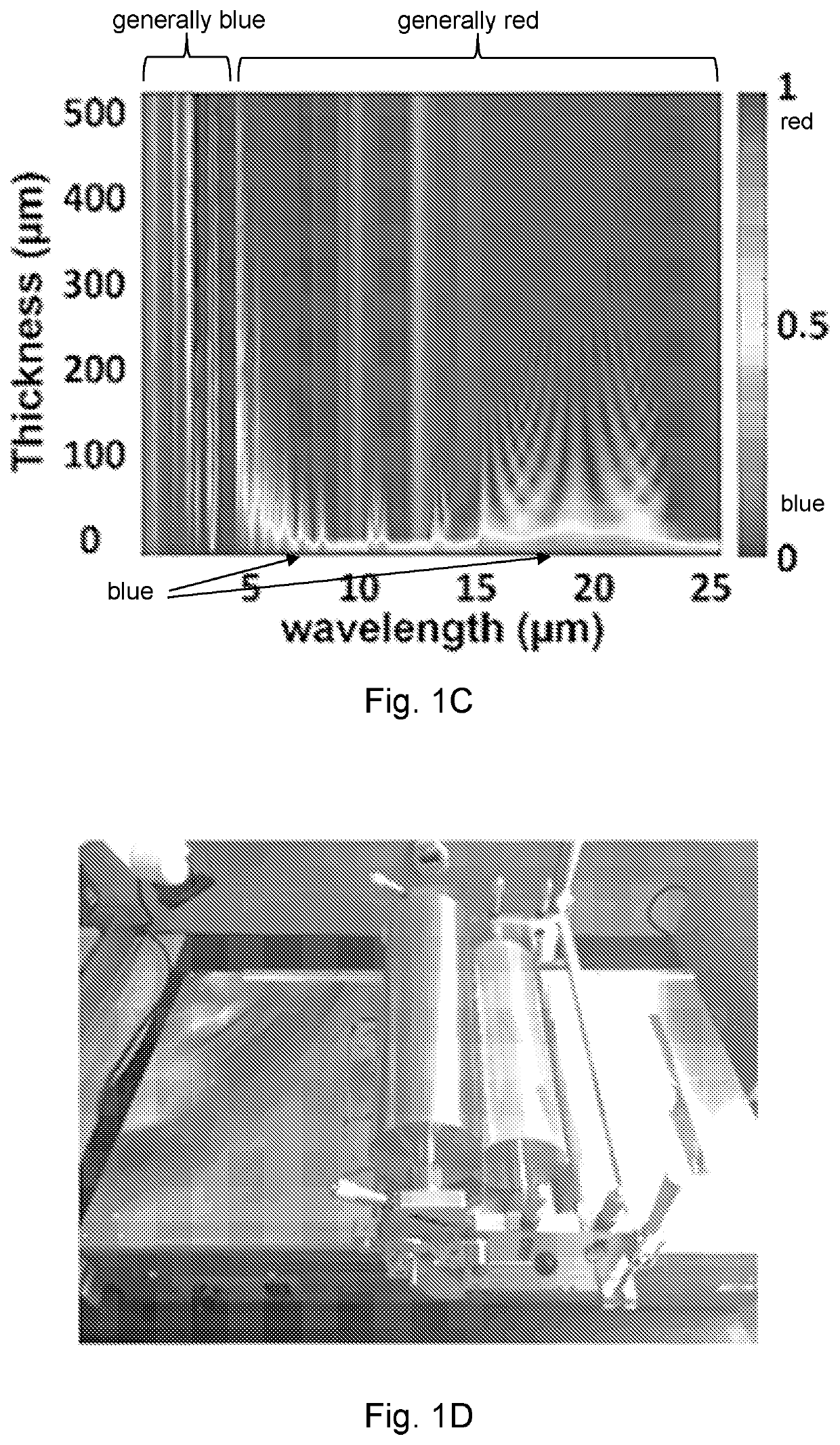

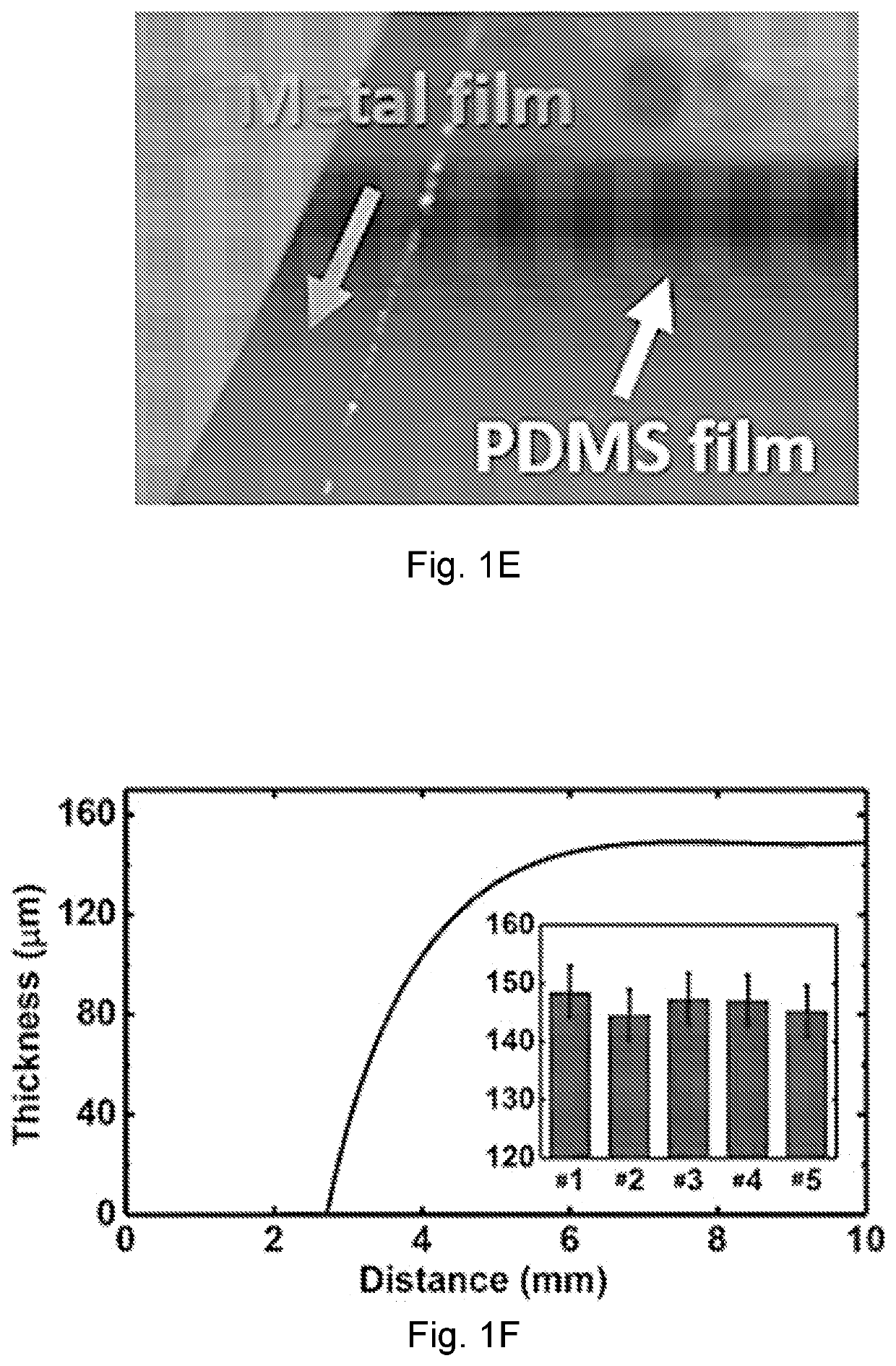

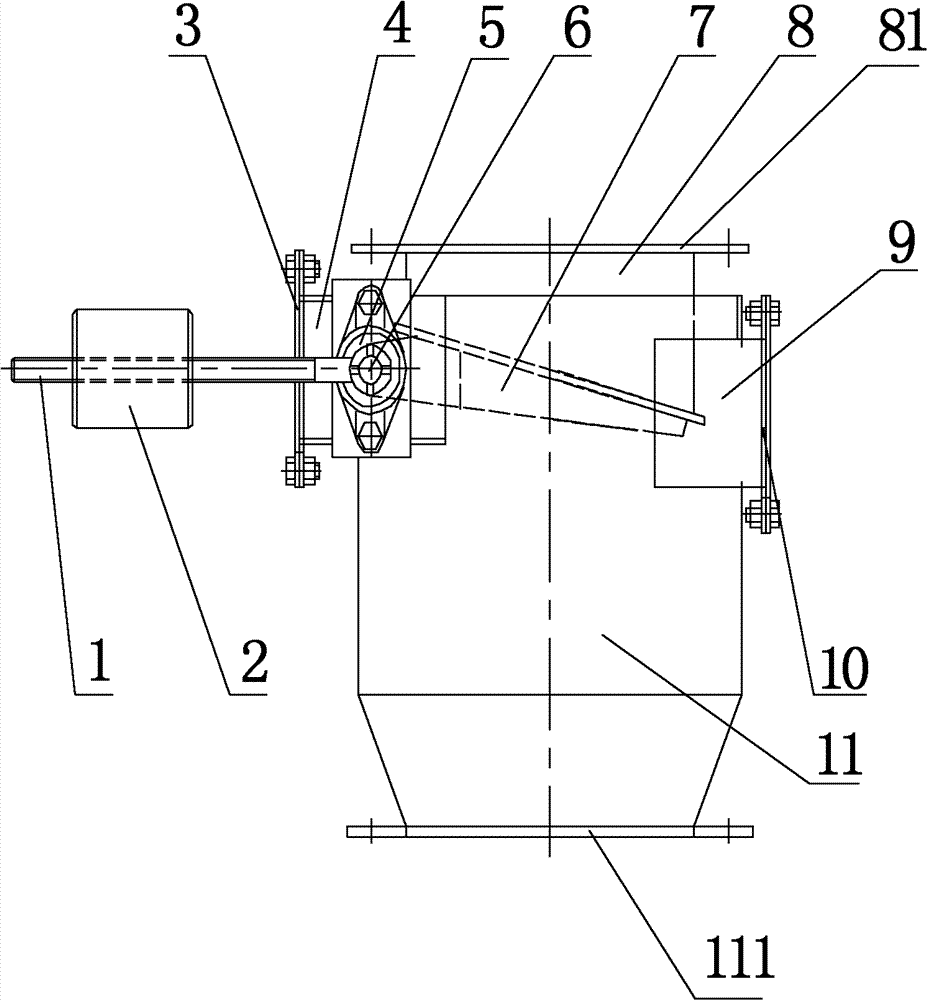

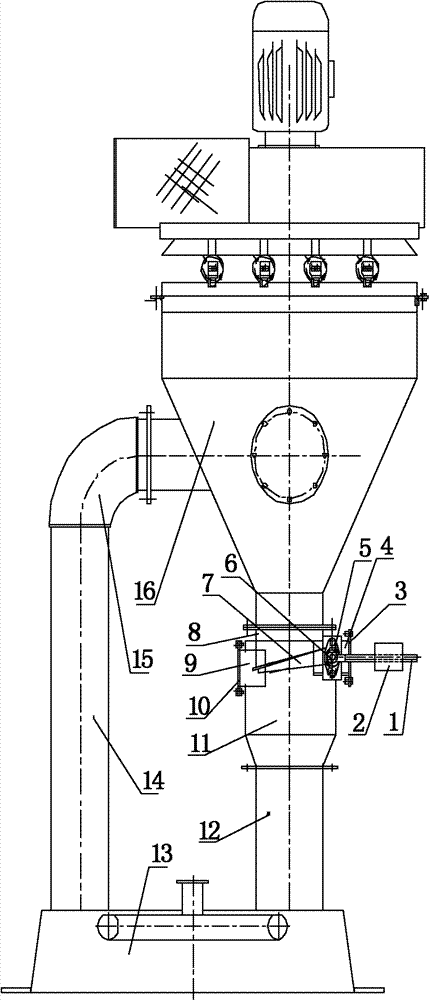

Beam-controlled spectral-selective architecture for a radiative cooler

PendingUS20210254869A1Zero consumptionImprove directionalityThermometer detailsSolar heating energyAbsorptanceEngineering

A passive cooler of the disclosure includes a thermal emitter having a substrate and a coating disposed on at least a portion of a first side of the substrate. The cooler has a beam guide made from a material having a high absorption to solar wavelengths and high reflectance at mid-infrared wavelengths. The beam guide is configured such that at least a portion of incident light is acted on by the beam guide before reaching the thermal emitter. In some embodiments, the beam guide has a graded optical index.

Owner:WISCONSIN ALUMNI RES FOUND

A method for recovering lead from lead-containing waste

ActiveCN110857454BConforming to the characteristics of an economic responseEliminate secondary pollutionPhotography auxillary processesProcess efficiency improvementElectrolytic agentDissolution reaction

The invention discloses a method for recovering lead from lead-containing waste, comprising the following steps: 1) reacting the lead-containing waste with a complexing agent aqueous solution, so that the lead oxide and / or lead sulfate in the lead-containing waste are completely dissolved, and the reaction After finishing, separate the supernatant containing lead ion and do not contain lead salt precipitate; 2) react the supernatant with precipitant, make the lead ion in the supernatant completely precipitate, and separate the lead salt precipitate and after the reaction finishes. Regenerating the complexing agent aqueous solution; 3) dissolving the lead-containing salt precipitation with the electrolyte A aqueous solution, so that the lead-containing salt precipitation is completely dissolved, and after the reaction finishes, the lead-containing electrolyte B and the precipitation agent are produced; Reclaim the precipitation agent; and Lead-containing electrolyte B is subjected to electrolytic reaction to obtain metal lead, oxygen and regenerated electrolyte A. The complexing agent, the precipitating agent and the electrolyte A used in the recovery process of the method of the present invention can be recycled and used repeatedly, which conforms to the characteristics of atomic economic reaction, thereby realizing zero consumption and zero discharge, and saving production costs.

Owner:BEIJING UNIV OF CHEM TECH

Method for converting electric furnace into converter

PendingCN114657321ARealize conversionGuaranteed zero power consumption smeltingElectric furnaceSmelting processMolten steel

The invention relates to the field of smelting process control, in particular to a method for converting an electric furnace into a converter. Comprising the following steps: (1) after the last furnace is smelted, the steel remaining amount in the furnace is 10-20% of the steel tapping amount, lifting an electrode to the highest position, screwing out a furnace cover, firstly adding waste steel, and adding molten iron accounting for 75-90% of the total steel material; (2) oxygen blowing is started after molten iron is added, in the first 2-5 minutes, a low-oxygen mode is started, the flow is 3000-3200 Nm < 3 > / h, then a medium-high-oxygen mode is started, the flow is about 4000-6000 Nm < 3 > / h, waste steel is melted down, the temperature is larger than or equal to 1540 DEG C, and sampling and total analysis are conducted; and after the tapping requirement is met, tapping is prepared. The proportion of the molten iron is high, the content of five harmful elements in the molten steel is effectively reduced, the cleanliness of the molten steel is improved, and the quality of steel is effectively improved.

Owner:SHANDONG IRON & STEEL CO LTD

Discharging device, dust remover and stirring equipment

ActiveCN102229202BRealize automatic collectionZero consumptionDischarging apparatusDirt cleaningEngineeringDust collector

The invention relates to a discharging device, a dust remover and stirring equipment. The discharging device comprises a through discharging cylinder, a rotating shaft, a discharging plate and a resetting piece; at the balanced initial position of the discharging plate and the resetting piece, the discharging plate and the discharging cylinder are closed; and at the imbalance discharging positionof the discharging plate and the resetting piece, the discharging plate and the discharging cylinder are separated. In the dust remover, the discharging device is arranged between a dust collector and a dust discharging pipe. In the discharging device, the volume of a feeding cylinder is reasonably determined according to the dust collecting volume of the dust collector; and adjustment and control of the weight of the dust collected by the dust collector and automatic discharge of the dust can be realized by screwing in or out a counterweight block arranged on a counterweight pull rod and using the lever balance principle. According to the dust remover provided with the discharging device, the discharging plate is opened and closed to play a role in blocking the communication among the dust collecting pipe, the dust collector, the dust discharging pipe and a stirring main machine, so that the dust collector can continuously extract the dust-containing gas in the main machine, and the dust removing efficiency of the main machine is greatly improved.

Owner:SANY HEAVY IND CO LTD (CN)

Optimization process of vacuum potassium carbonate method coke oven gas desulfurization and equipment thereof

InactiveCN103113928BReduce total outputReduce consumptionGas purification by liquid washingLiquid wasteProcess engineering

The invention discloses an optimization process of vacuum potassium carbonate method coke oven gas desulfurization. The process comprises the following steps: shunting regenerated potassium carbonate barren liquor, conveying a part of potassium carbonate barren liquor to the lower segment of a desulfurizing tower to come into reverse contact with coke oven gas flow to be recycled; and conveying the other part of the regenerated potassium carbonate barren liquor to the upper segment of the desulfurizing tower to come into reverse contact with coke oven gas to be washed for the second time so as to be recycled. A washing liquid waste outlet at the bottom part of the upper segment of the desulfurizing tower in the equipment is communicated with the liquid return opening of an alkaline tank, and the input end of the alkaline tank is communicated with a barren liquor outlet at the bottom part of a regenerating tower. In the invention, the potassium carbonate barren liquor is used for replacing the alkaline washing segment NaOH to reduce the NaOH consumption to zero on the condition that the H2S content in the coal gas reaches the standard, so that the production cost is greatly reduced; and meanwhile, the dosage of the desulfurization liquid waste generated by the original alkaline washing segment is reduced to zero, and the total yield of the desulfurization liquid waste is reduced by more than 80%, so that the environmental pollution is reduced.

Owner:武汉钢铁有限公司

Renewable Energy Preparation System

InactiveCN103952292BZero pollutionZero emissionGas production bioreactorsEnergy based wastewater treatmentSlagCombustible gas

The invention discloses a preparation system of renewable energy sources. The system comprises a biomass energy generator, a solar heat collector, a photovoltaic power generation device and a slag material treatment system, wherein the biomass energy generator comprises a tank body with a charging opening and a gas collecting bag at the top part, a heat exchange tube arranged at the lower part of the inner cavity of the tank body, a slag slurry lifting pump arranged at the bottom of the inner cavity of the tank body, and a bubbler arranged at the upper part of the inner cavity of the tank body; the outlet of the slag slurry lifting pump is communicated with a slag liquid separator by virtue of a pipeline; the inlet of the bubbler is communicated with the upper part of the slag liquid separator by virtue of a bubbling booster pump; the gas collecting bag of the tank body is communicated with a purification chamber of a biomass energy purifier; a slag hole of the slag liquid separator is engaged with the feeding end of a kong water conveying belt; the discharging end of the kong water conveying belt is engaged with the feeding port of a slag slurry dryer; the bottom of the purification chamber of the biomass energy purifier is communicated with an alkaline solution tank by virtue of the pipeline, and a combustible gas outlet pipe is arranged at the top of the purification chamber of the biomass energy purifier. The preparation system disclosed by the invention has the advantages of integrating solar energy and biomass energy and realizing zero pollution, zero emission and zero consumption.

Owner:杨合长

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com