Spraying waste gas purification method and device

An exhaust gas purification device and exhaust gas purification technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of reducing the adsorption amount of activated carbon to VOCs, aggravating the difficulty of treatment process, shortening the life of filter materials, etc., so as to facilitate cleaning and Reuse, avoid secondary pollution, improve the effect of feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

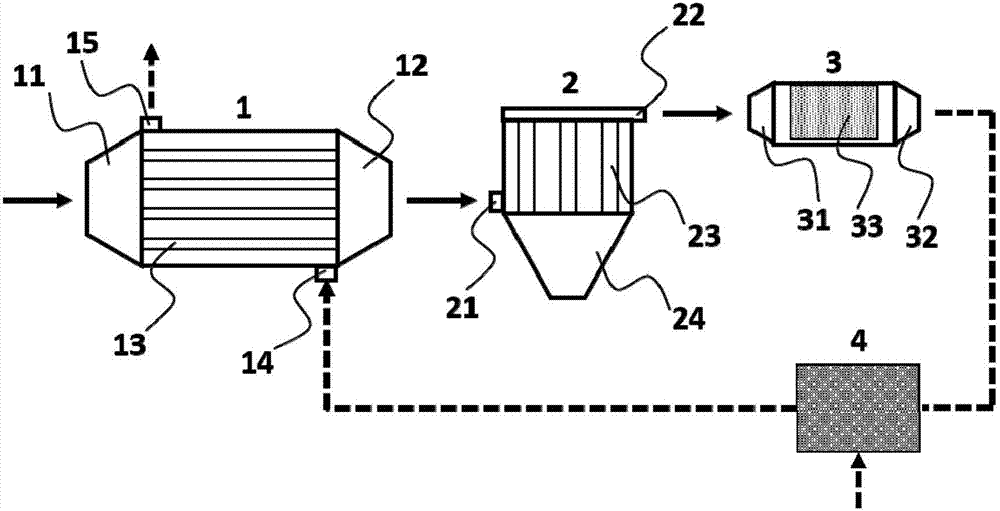

[0022] Such as figure 1 As shown, the spraying exhaust gas enters the preheater 1 through the preheater inlet 11 , and the exhaust gas flows through the preheater pipe 13 and then enters the dust collector 2 through the preheater outlet 12 . Among them, the preheater 1 adopts the heat exchange method of tube and shell to dry the paint mist in the spraying exhaust gas. The spraying waste gas communicates with the preheater outlet 12 through the preheater pipe 13, and the spraying waste gas is evenly dispersed into the preheater pipe 13 under the action of the deflector at the preheater inlet 11. The length of the preheater pipe 13 can be adjusted according to the paint ratio To set, as long as the paint mist discharged from the outlet 12 of the preheater is completely dry. The hot air in the preheater 1 is provided by the outlet 32 of the catalytic burner, and the hot air coming out of the outlet 32 of the catalytic burner enters from the inlet 14 of the preheating chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com