Novel bidirectional liquid pipe drying and filtering device for heat pump and manufacturing method of novel bidirectional liquid pipe drying and filtering device

A filter and drying technology, which is applied in the field of liquid tube drying filter for a new type of bidirectional heat pump, can solve the problems of poor drying and filtration effect, limited use range and reduced practicability, and achieves improved filtration and drying effect. effect, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

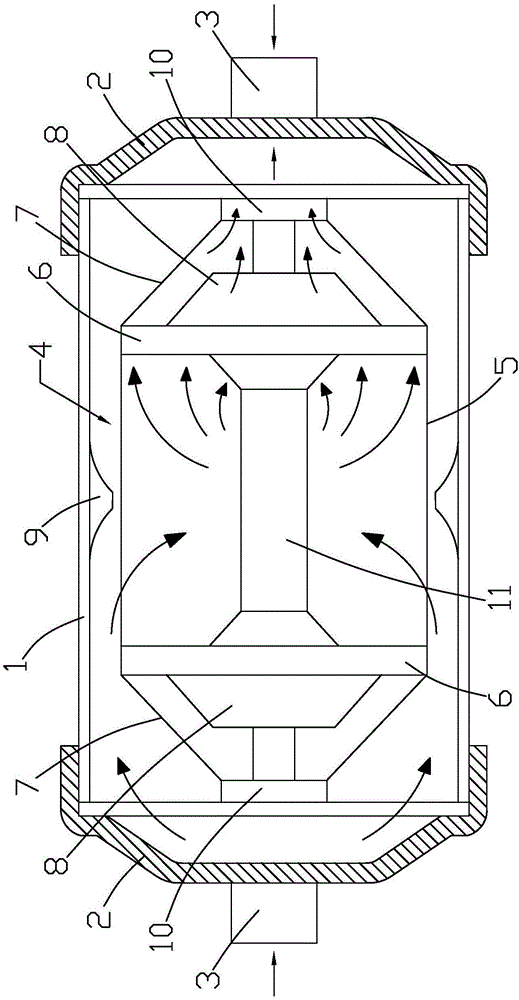

[0041] like Figure 1 to Figure 4 As shown, it is a novel bidirectional heat pump liquid pipe drying filter of the present invention. The liquid pipe drying filter includes a copper pipe 1 and an end cap 2, and the two end caps 2 are symmetrically arranged at both ends of the copper pipe 1. There are ports 3 on both of them, and a guide ring 9 is provided in the middle of the inner wall of the copper pipe 1. The guide ring 9 can effectively control the flow direction of the refrigerant, facilitate the refrigerant to form a rotating flow, and improve the filtration and cooling of the refrigerant. drying effect.

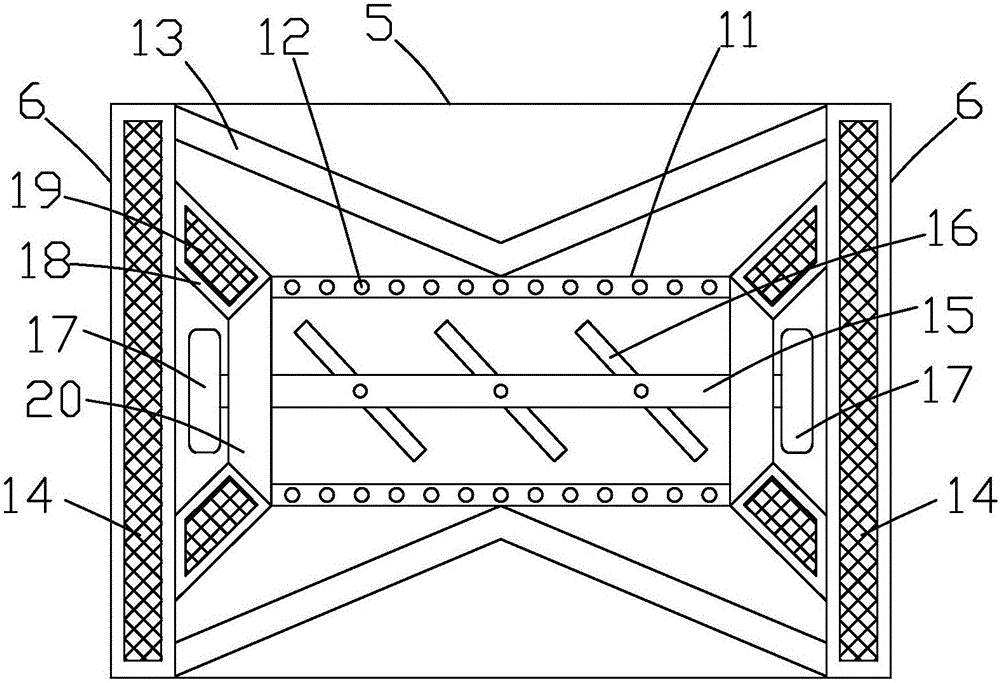

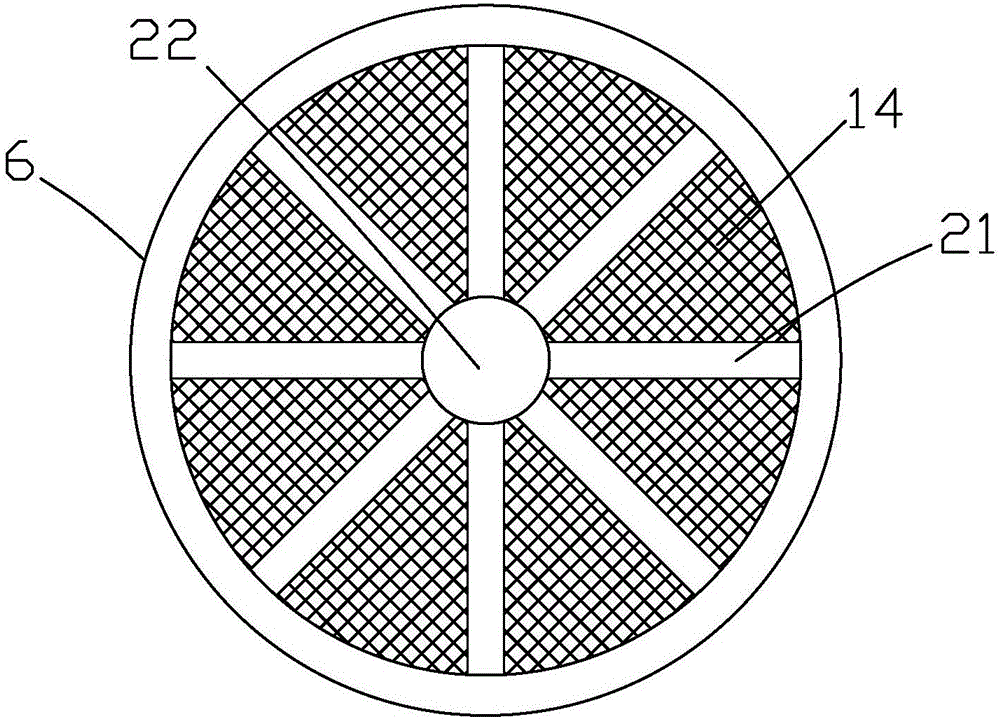

[0042] The copper pipe 1 is provided with a rotary filter core 4, the rotary filter core 4 includes a drying cylinder 5 and a positioning plate 6, the positioning plate 6 is located on both sides of the drying cylinder 5, a drying pipe 11 is arranged in the drying cylinder 5, and the drying The side of the pipe 11 is uniformly provided with inlet and outlet holes 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com