Single-phase AC permanent-magnet synchronous motor

A permanent magnet synchronous, single-phase AC technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of motor efficiency and output power reduction , small torque, proportional increase, etc., to improve efficiency and power factor, reduce copper loss and iron loss, and reduce the effect of induced current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

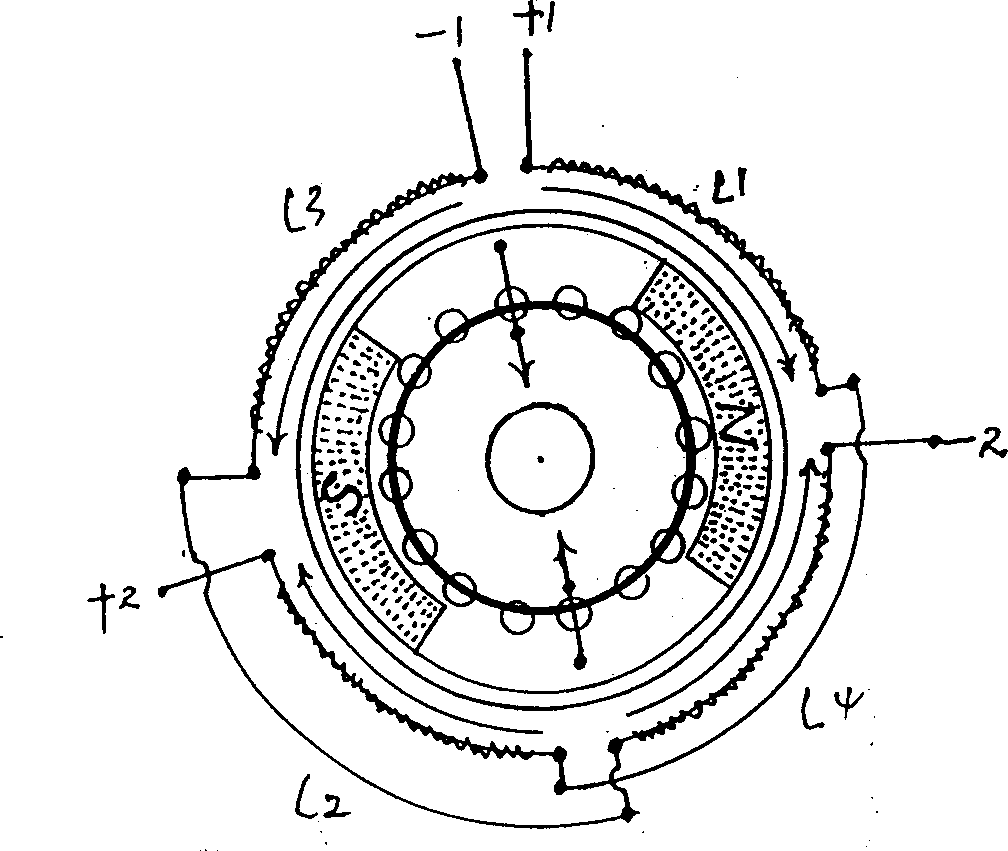

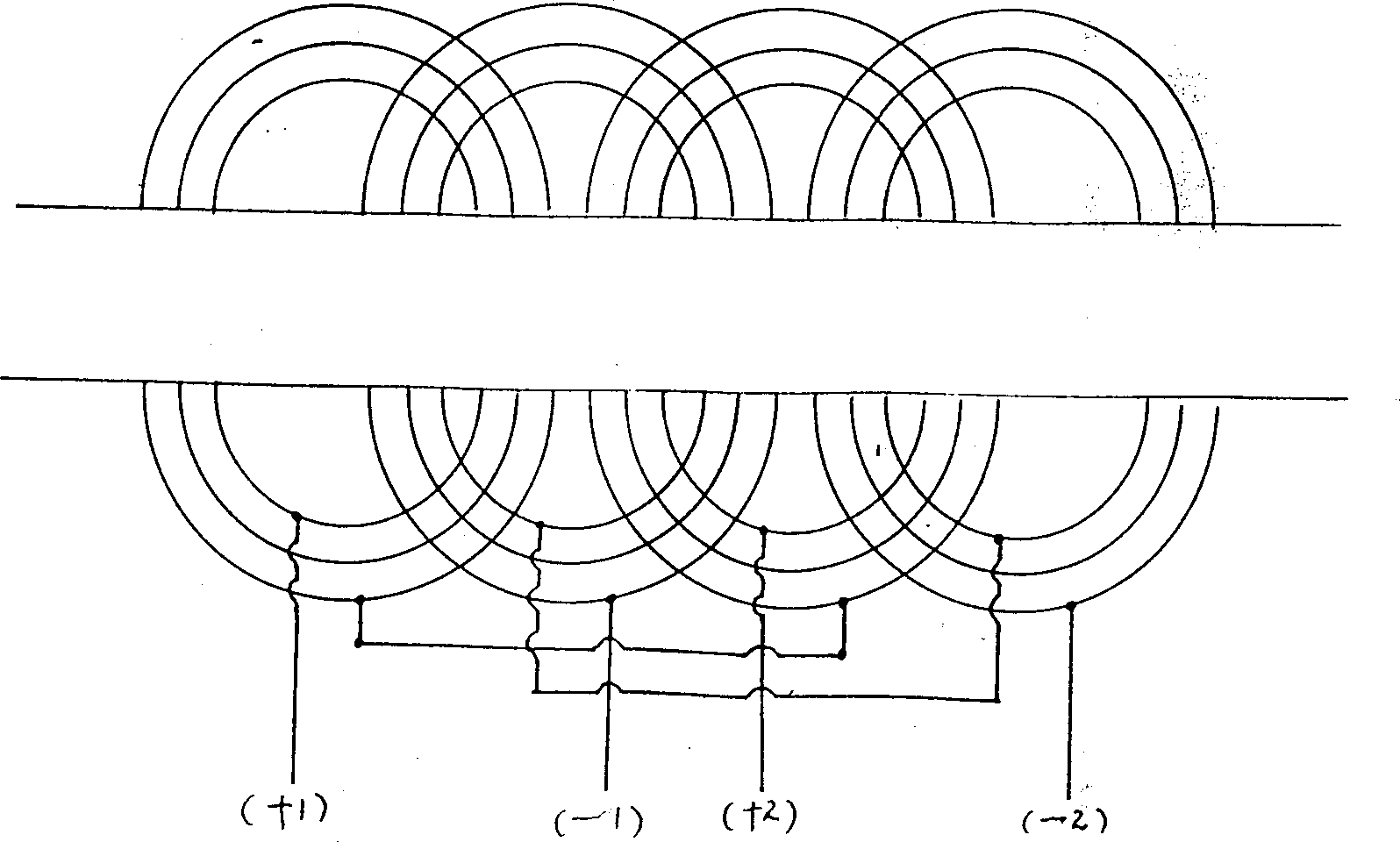

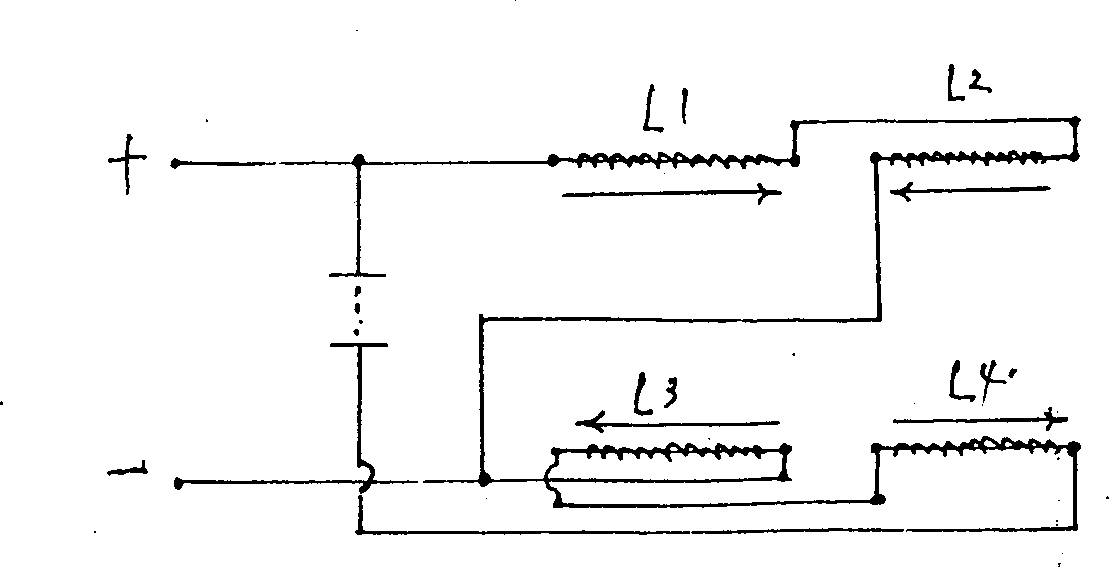

[0020] The single-phase permanent magnet synchronous motor of the present invention is composed of a housing, a front bearing, a rear bearing, a front end cover, a rear end cover, a stator, a stator winding, a rotor squirrel cage, a rotor core and a permanent magnet. There are fan blades and fan blade covers at both ends of the core. On the surface of the rotor, permanent magnets arranged in a symmetrical form of N-S poles are inlaid, and the number of pole pairs is set according to the number of poles of the motor. The thickness and magnetic field strength of the permanent magnet depend on the magnetic density of the motor stator. Each permanent magnet is separated by a magnetically permeable metal. A magnetic field loop is formed between every adjacent N-S two permanent magnets through a magnetically permeable metal material. When single-phase alternating current passes through the stator coil, the current alternating rotating magnetic field in the stator winding acts on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com