Sintering method utilizing dust removal ash

A process and conventional technology, applied in the field of sintering and utilizing dust removal, can solve the problems of fine particle size of sintered dust removal dust, affecting sintering production, strong hydrophobicity, etc., and achieve the effects of good quality, improved granulation effect, and strong hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

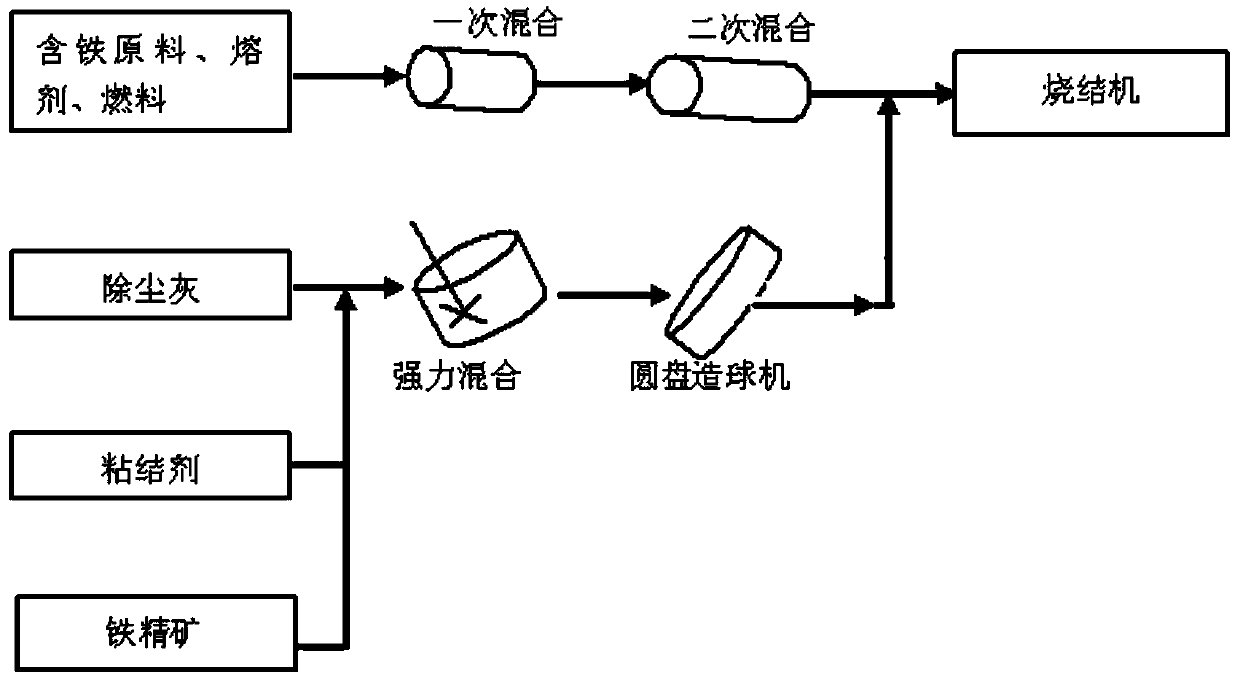

[0021] The sintering method of the present invention using dedusting ash is based on the principle of pre-pelleting the dedusting ash, fine-grained iron concentrate with good hydrophilicity and a binder, and utilizing the good hydrophilicity and bonding of the iron concentrate The bonding effect of the agent wraps the dust and iron concentrate together and granulates them into balls, and then mixes the granulated balls with other sintered mixtures granulated according to conventional processes for cloth ignition and sintering, thus It solves the problem that the dedusted ash is directly returned to the sintering compound and it is difficult to granulate, which affects the sintering production. The inventive method speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com